PRESSURE SWITCH HEDE10-3X/250/2/-GA-K35-V

Manufacturer: Bosch Rexroth

Material #: R901433087

Model : HEDE10-3X/250/2/-GA-K35-V

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

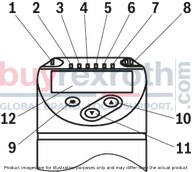

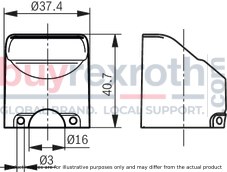

The Bosch Rexroth HEDE10-3X/250/2/-GA-K35-V (R901433087) is an advanced electronic pressure switch designed for precise monitoring and control of pressure levels in hydraulic systems. It features a robust stainless steel construction, ensuring durability and resistance to harsh media. The switch comes with a high-resolution display that allows for easy reading of pressure values and parameters, as well as configuration directly via the device's buttons or remotely through IOLink communication.

This model offers exceptional overload protection and bursting behavior thanks to its thin-film measuring cell technology. It provides two switching outputs that can be configured either for one switching output plus one analog output or for two switching outputs, based on application requirements. The pressure range capability of this device spans several ratings including 250 bar, making it versatile for various hydraulic applications.

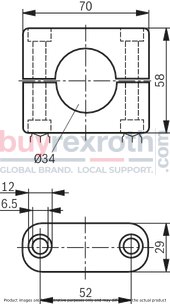

The HEDE10-3X/250/2/-GA-K35-V features a G-threaded hydraulic connection with an integrated throttle element in the pressure tube and channel, which aids in stabilizing the flow of hydraulic fluid. Its electrical connection is facilitated by a connector pole Mx Acoded according to EN standards, ensuring secure and reliable connectivity.

Suitable hydraulic fluids include HL, HLP, HFC, HETG, HEES, and HFD types. The unit is compliant with multiple industry standards including CE, UL, UKCA, EAC, and RoHS directives. Its compact design is complemented by an accuracy class of 0.5%, making it highly precise for critical applications. Additionally, the unit operates on a supply voltage of 24 VDC and includes FKM seals to maintain integrity under various operating conditions.

With its capability to transmit both pressure and diagnostic values via IOLink along with its straightforward interface for configuration and monitoring, the Bosch Rexroth HEDE10-3X/250/2/-GA-K35-V stands out as a reliable component for modern hydraulic systems requiring accurate pressure measurement and signal conversion.

$933.00 USD

More are expected on September 15, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $909.67 USD | $23.33 USD |

| 25+ | $886.35 USD | $46.65 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as September 15, 2026 when ordered in