***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

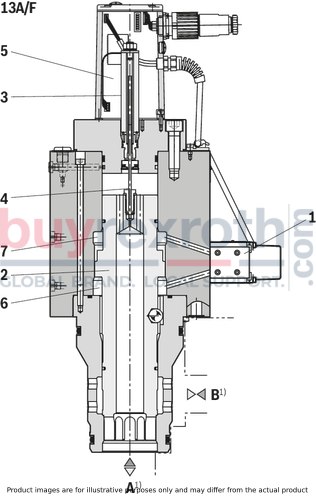

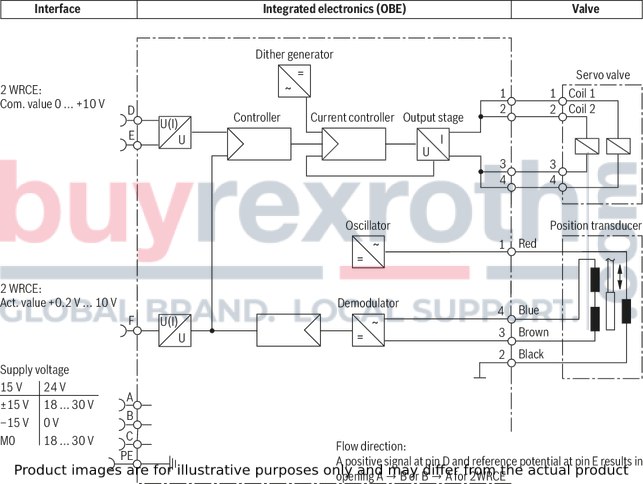

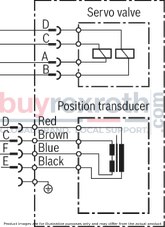

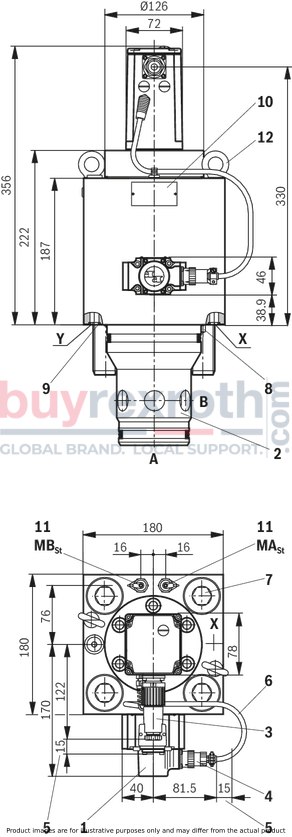

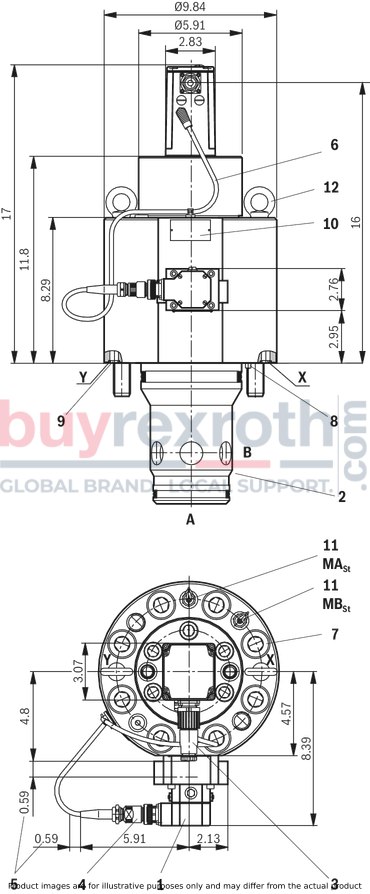

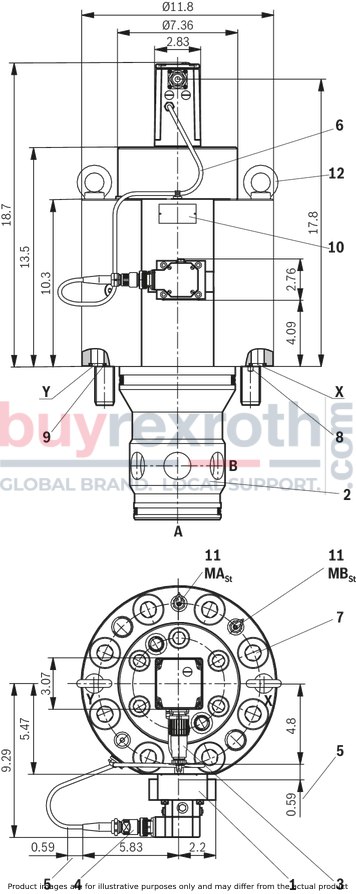

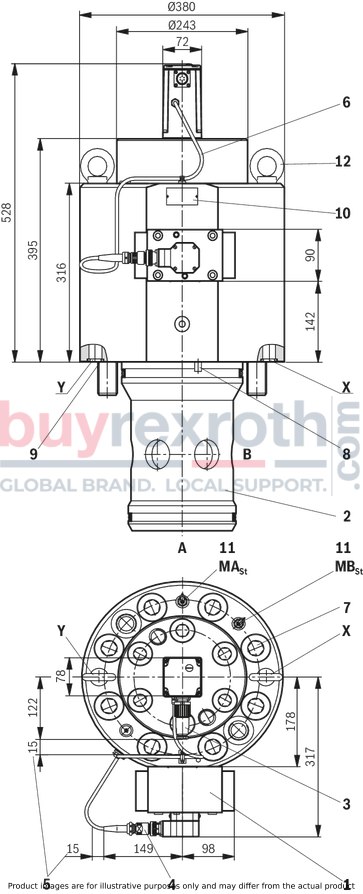

The Bosch Rexroth 2WRC125K001-1X/E/V (R901420262) is a high-response stage valve designed for precise control of flow rate and direction in closed-loop control circuits. This valve features a robust design that includes a pilot control valve with a servo directional valve pilot, a dry torque motor, and a low friction jet flapper amplifier. It also incorporates mechanical feedback of the spool position to ensure accuracy and reliability. The main control spool is responsible for the flow control, while an inductive position transducer, attached to the spool of the third stage, provides precise position sensing.

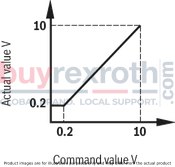

The integrated control electronics within the WRCE model allow for real-time comparison of command and actual values, adjusting the pilot control valve solenoids accordingly to minimize system deviation. The main spool's stroke is controlled proportionally to the command value, though it's important to note that flow also depends on the valve pressure drop.

Valve features include bidirectional flow capability from A to B or B to A and a leak-free closure with smaller command values due to the closed loop control circuit's correction of spool position. The opening point is factory preset at 0.5 V but can be calibrated after replacing parts using an AF nut.

In terms of maintenance, only the filter element on the pilot control valve can be replaced without further adjustments needed except for zero calibration at the position controller. The spools are not pressure balanced; hence they require a recommended minimum control pressure derived from system pressure and additional reserves.

This Bosch Rexroth valve is particularly suited for applications requiring closed-loop or open-loop control of large flows such as forging manipulators, pressing cylinders, and die casting machines. It offers high response performance in block installation design and can be equipped with either external or integrated electronics depending on the specific device type. The 2WRC series operates under maximum pressures as defined by its component series designation.

$147,604.00 USD

More are expected on September 17, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.Status: This product is temporarily out of stock.

Qty: Delivered as early as September 17, 2026 when ordered in