PROPORTIONAL PRESSURE RELIEF VALVE DBE6-2X/200G24K4M

Manufacturer: Bosch Rexroth

Material #: R901304383

Model : DBE6-2X/200G24K4M

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

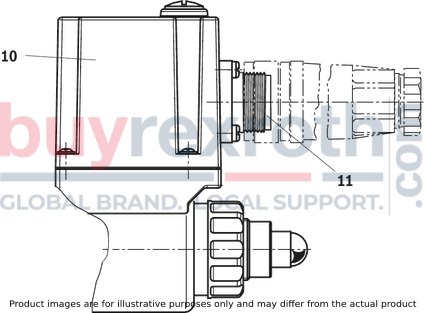

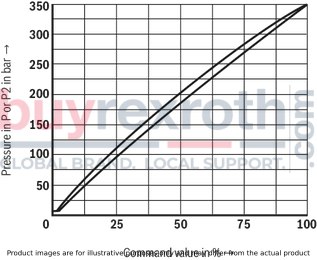

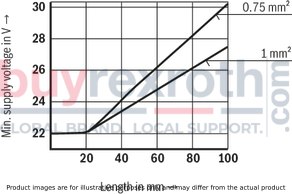

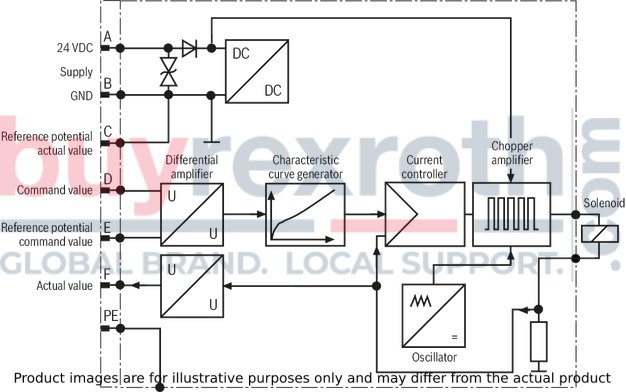

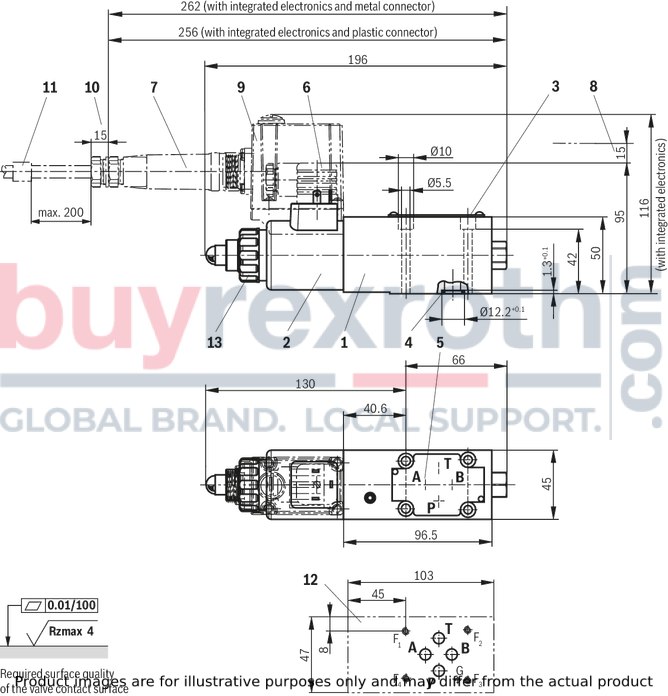

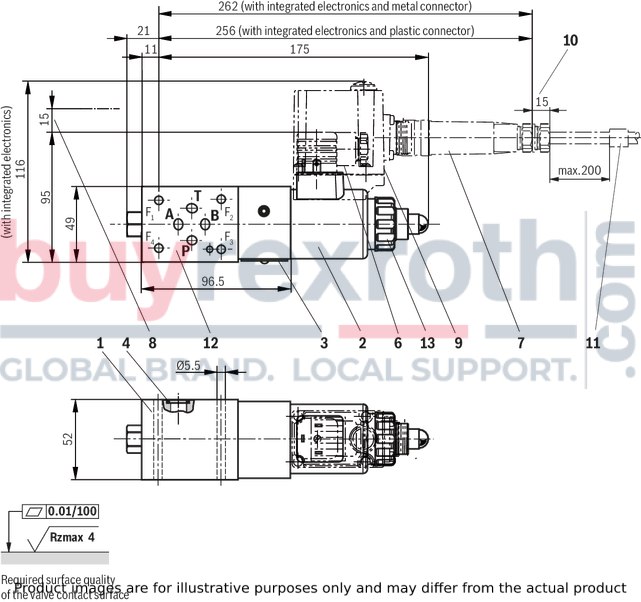

The Bosch Rexroth DBE6-2X/200G24K4M (R901304383) is a high-performance industrial hydraulic valve designed for reliable pressure limitation based on command value signals. It features a size 6 CETOP D subplate mounting connection and a maximum pressure rating of 350 bar, with a maximum flow rate of 200 l/min. The valve operates via electrical actuation with external electronics and is equipped with a 4-pole PE electrical connector according to EN 175301-803 standards.

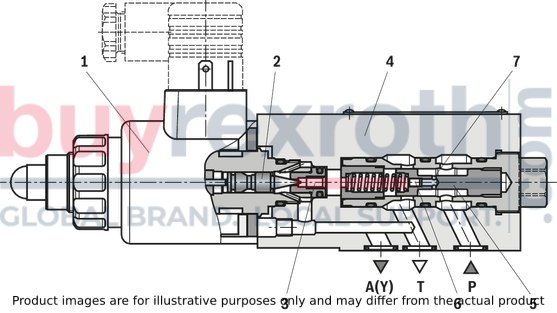

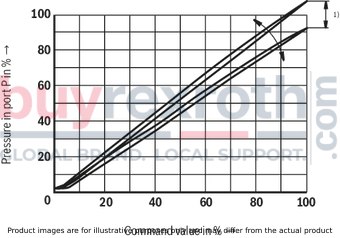

This product incorporates pilot-operated proportional pressure relief valves, which are actuated by a proportional solenoid to maintain system pressure within set parameters. The device consists of two key stages: the pilot control stage—including the solenoid, poppet, and seat—and the main stage comprising the housing and main spool insert assembly. As current increases, so does the mechanical force generated by the solenoid, allowing for precise control over system pressure.

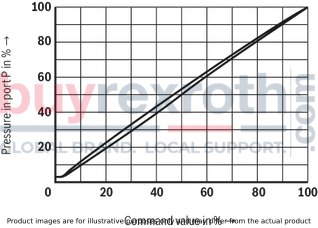

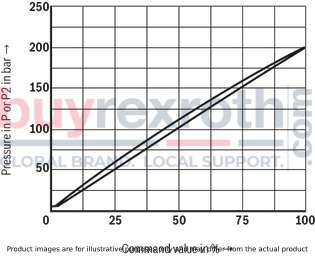

The DBE6-2X/200G24K4M is designed for ease of use with its rotatable and detachable coil, making it suitable for subplate or sandwich plate mounting configurations. The porting pattern aligns with ISO and DIN standards. This model also features a linear pressure-command value characteristic curve for straightforward operation.

Sealed with NBR (nitrile rubber), it can handle various hydraulic fluids including HL, HLP, HLPD, HVLP, HVLPD, and HFC types. The supply voltage required is 24 VDC.

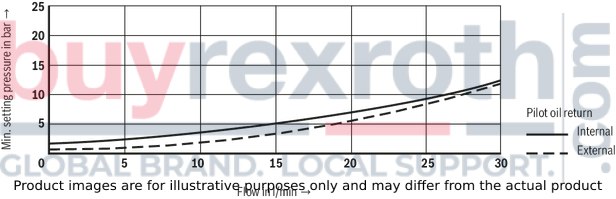

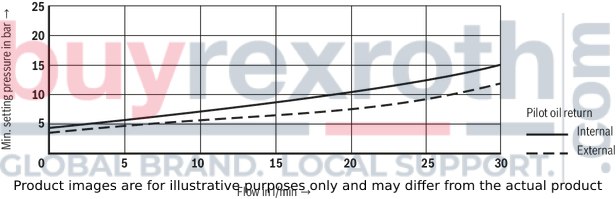

A critical notice for users includes ensuring that tank lines do not run empty during operation; installation conditions may necessitate a preload valve (preload pressure approximately 5 bar) to prevent this issue.

Overall, the Bosch Rexroth DBE6-2X/200G24K4M offers robust construction and advanced engineering for effective pressure regulation in hydraulic systems.

$2,446.00 USD

More are expected on September 15, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $2,384.85 USD | $61.15 USD |

| 25+ | $2,323.70 USD | $122.30 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as September 15, 2026 when ordered in