***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

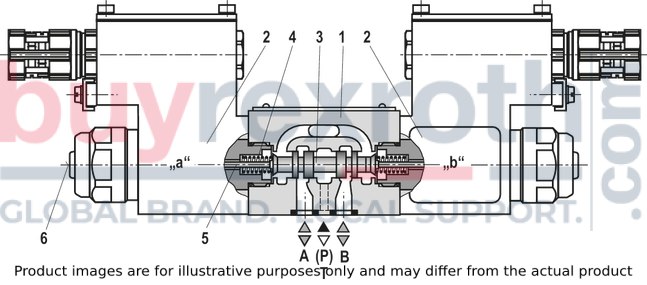

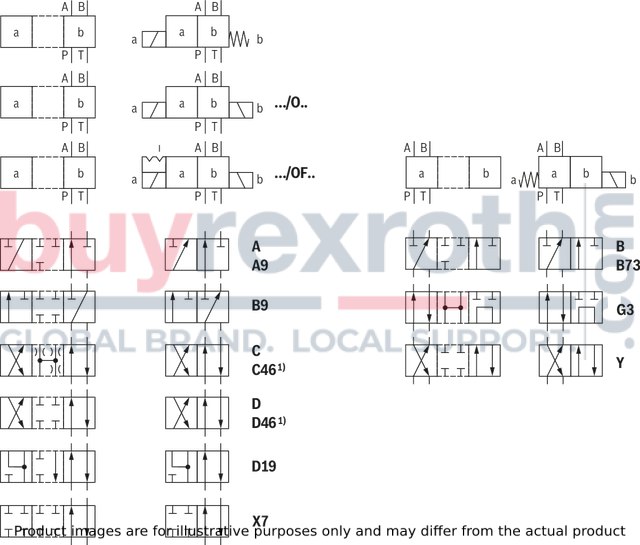

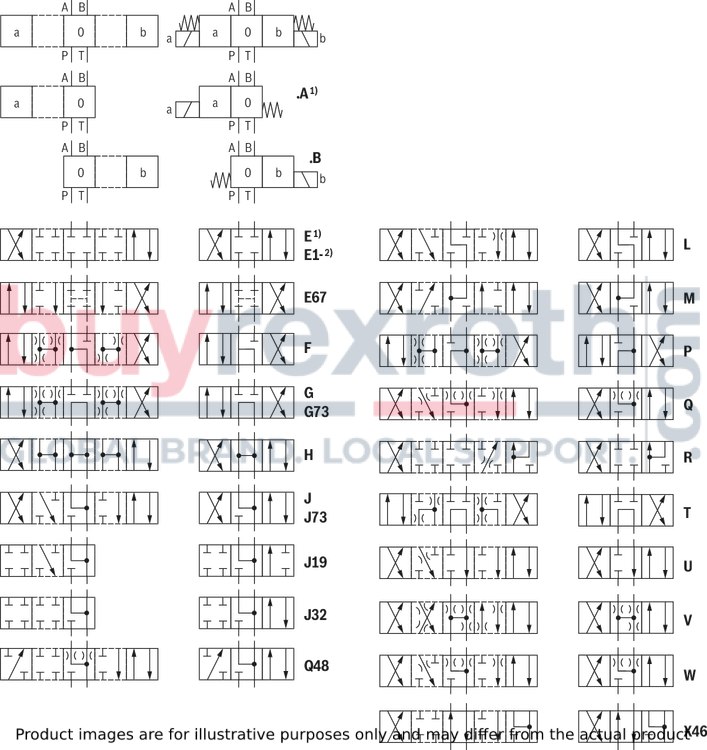

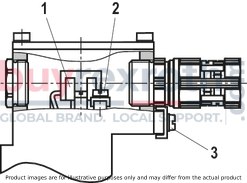

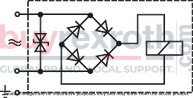

The Bosch Rexroth 4WE6Y6X/EW110RNXEZ2/V (R901077021) is a high-performance directional spool valve designed for controlling the start, stop, and direction of fluid flow within a hydraulic system. This model features two solenoid-actuated spool positions without detent, meaning the spool does not maintain a fixed position when de-energized. The valve operates with wet-pin DC or AC solenoids that actuate the control spool, which is held in its initial position by return springs when not energized.

This particular valve is equipped with manual override capabilities as an optional feature, allowing users to manually adjust the spool position in the absence of solenoid power. The robust design includes a throttle insert (designated by "...B") to manage flow during switching processes that exceed the valve's performance limit.

The 4WE6Y6X/EW110RNXEZ2/V valve is explicitly constructed for use in potentially explosive atmospheres and complies with the Explosion Protection Directive EU: II G. It offers Ex eb mb IIC T Gb type protection according to EN standards for its solenoids. Additionally, it adheres to ISO porting patterns for seamless integration into various hydraulic systems.

With a maximum operating pressure of up to bar and a maximum flow rate of l/min, this Bosch Rexroth directional valve ensures reliable performance across a range of applications while maintaining safety in hazardous environments. The electrical connection is facilitated through an individual connection with cable gland, enhancing installation convenience and security.

Note that internal leakage may occur inherently due to design reasons and can increase over the lifespan of the valve. To prevent unintended movements of the control spool caused by pressure peaks in tank lines when using valves with detent, separate return lines or check valves are recommended.

$3,099.00 USD

More are expected on September 22, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $3,021.52 USD | $77.48 USD |

| 25+ | $2,944.05 USD | $154.95 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as September 22, 2026 when ordered in