***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

The Bosch Rexroth 4WREQ10Q5-75-2X/VBF-24CA60 (R901057547) is a direct operated proportional directional valve with state-of-the-art integrated digital control electronics tailored for precise pressure, force, and flow control applications. This innovative valve is designed to operate via proportional solenoids featuring a central thread and detachable coil, ensuring ease of maintenance and high responsiveness. The model includes a valve control spool that is position-controlled for accurate operation.

The 4WREQ10Q5-75-2X/VBF-24CA60 valve can be equipped with an optional integrated pressure sensor plate or configured for an external pressure sensor, providing flexibility in monitoring and control based on specific application requirements. It supports subplate mounting with porting patterns according to ISO standards, ensuring compatibility with a wide range of systems.

The valve's digital integrated control electronics (IACP) facilitate advanced functionalities such as error detection for cable breaks in the pressure sensor or position transducer, undervoltage issues, communication errors, and watchdog timer faults. Additional features include a ramp generator, internal command value profile, enable function for analog/digital inputs, and an error output of 24 V.

Designed to communicate via field bus interfaces like CANopen protocol DS 301 or Profibus-DP, the unit allows for quick commissioning through the WINPED commissioning software. Despite its advanced capabilities, users should be aware that internal leakage is inherent to the design of these valves and may increase over their lifecycle; therefore, it's crucial to ensure that the tank line does not run empty.

This Bosch Rexroth valve boasts impressive specifications with a size of 10 and a component series X. It can handle a maximum operating pressure of up to 315 bar and facilitates maximum flow rates up to 75 l/min. Its robust construction and versatile design make it suitable for various demanding hydraulic applications where precision control is critical.

$9,987.00 USD

More are expected on September 22, 2026

| Qty | Price | Savings |

|---|---|---|

| 5-24 | $9,737.32 USD | $249.68 USD |

| 25+ | $9,487.65 USD | $499.35 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as September 22, 2026 when ordered in

This product is eligible for factory repair.

Direct operated proportional directional valve with integrated digital control electronics for the pressure, force and flow control (Integrated Axis Controller IAC-P) Completely adjusted unit consisting of valve, pressure sensor(s) (optional), digital control electronics and field bus connection Operation by means of proportional solenoids with central thread and detachable coil Valve control spool, position-controlled Integrated pressure sensor plate (optional) For subplate mounting: Porting pattern according to ISO 4401 Analog interface for command and actual value Design for CAN bus with CANopen protocol DS 408 or Profibus-DP Quick commissioning via PC and WIN-PED 6 commissioning software

Set-up:

Valve with integrated sensors:

The valve basically consists of:

Housing (1) and pressure sensor plate (12) with connection surface Control spool (2) with compression springs (3 and 4) and spring plates (8 and 9) Coils (5 and 6) and pole tubes (14 and 15) with central thread Position transducer (7) Integrated pressure sensors (10) Integrated digital control electronics IAC-P (11)Functional description

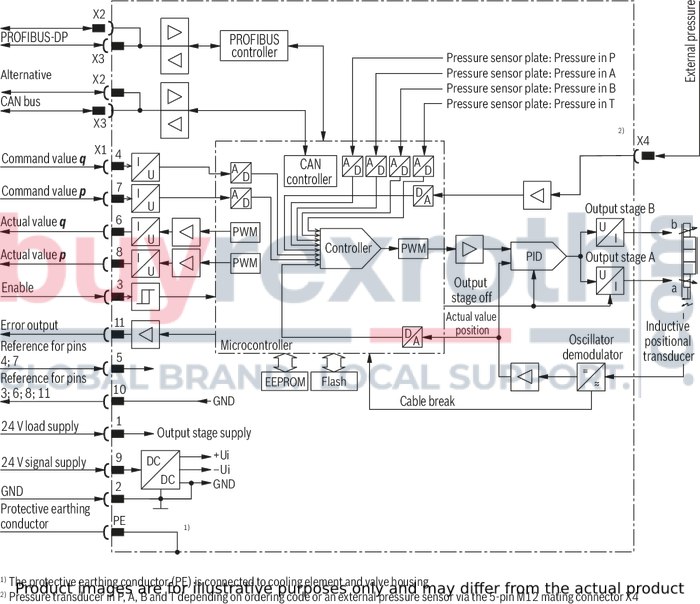

With de-energized solenoids (5 and 6), the control spool (2) is brought into the central position by compression springs (3 and 4) between the spring plates (8 and 9) (with V spool valve without spring plate). With V spool valves, the mechanical zero position does not correspond to the hydraulic one. Depending on the valve type, the following functions result (some of them can be combined): Flow control (Q) Flow control (Q) Pressure control in A and/or B (p) Force control (p) Substitutional control p/Q The command value presetting can alternatively be specified via an analog interface (X1) or via the field bus interface (X2, X3). The actual value signals are provided via an analog interface (X1) and can additionally be read out via the field bus (X2, X3). The controller parameters are set via the field bus Separate supply voltage for bus/controller and power part (output stage) for safety reasonsThe digital integrated control electronics enables the following error detection:

Cable break pressure sensor (10) Undervoltage Cable break position transducer (7) Communication error Watchdog Cable break command value inputs (only with current interface)The following additional functions are available:

Ramp generator Internal command value profile Enable function analog / digital Error output 24 VPC program WIN-PED 6

To implement the project planning task and to parameterize the IFB-P valves, the user may use the WIN-PED commissioning software.

Parameterization Diagnosis Comfortable data management on a PCSystem requirements

IBM PC or compatible system Windows 2000 or Windows XP RAM (recommendation: 256 MB) 150 MB of available hard disk capacityNotice

The "WIN-PED 6" PC program is not included in the scope of delivery. It is available for free download!4WREQ 6 with integrated pressure sensors

Set-up:

Valve for external sensor:

The valve basically consists of:

Housing (1) with connection surface Control spool (2) with compression springs (3 and 4) and spring plates (8 and 9) Coils (5 and 6) and pole tubes (14 and 15) with central thread Position transducer (7) Integrated digital control electronics IAC-P (11) Port (X4) for an external pressure sensor (12)Functional description

With de-energized solenoids (5 and 6), the control spool (2) is brought into the central position by compression springs (3 and 4) between the spring plates (8 and 9) (with V spool valve without spring plate). With V spool valves, the mechanical zero position does not correspond to the hydraulic one. Functions: Flow control (Q) Pressure control (p) Substitutional control p/Q The command value presetting can alternatively be specified via an analog interface (X1) or via the field bus interface (X2, X3). The actual value signals are provided via an analog interface (X1) and can additionally be read out via the field bus (X2, X3). The controller parameters are set via the field bus Separate supply voltage for bus/controller and power part (output stage) for safety reasonsThe digital integrated control electronics enables the following error detection:

Cable break pressure sensor (depending on sensor interface) Undervoltage Cable break position transducer (7) Communication error Watchdog Cable break command value inputs (only with current interface)The following additional functions are available:

Ramp generator Internal command value profile Enable function analog / digital Error output 24 VPC program WIN-PED 6

To implement the project planning task and to parameterize the IFB-P valves, the user may use the WIN-PED commissioning software.

Parameterization Diagnosis Comfortable data management on a PCSystem requirements

IBM PC or compatible system Windows 2000 or Windows XP RAM (recommendation: 256 MB) 150 MB of available hard disk capacityNotice

The "WIN-PED 6" PC program is not included in the scope of delivery. It is available for free download!4WREQ 6 for external pressure sensor

Important notice:

The PG fitting (13) must not be opened. Mechanical adjustment of the adjustment nut located below is prohibited and damages the valve!

Notice!

Due to the design principle, internal leakage is inherent to the valves, which may increase over the life cycle. The tank line must not be allowed to run empty. With corresponding installation conditions, a preload valve must be installed.

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

10 |

11 |

12 |

13 |

14 |

15 |

|||

|

4 |

WRE |

Q |

‒ |

2X |

/ |

V |

‒ |

24 |

* |

|

01 |

4 main ports |

4 |

|

02 |

Proportional directional valve with electrical position feedback |

WRE |

|

03 |

With integrated digital electronics and pQ functionality |

Q |

|

04 |

Size 6 |

6 |

|

Size 10 |

10 |

|

|

05 |

Symbols; for the possible version, see "Symbols/Circuit diagrams" |

Q5-; V |

|

Rated flow NG6 |

||

|

06 |

8 l/min |

8 |

|

16 l/min |

16 |

|

|

32 l/min |

32 |

|

|

Rated flow NG10 |

||

|

06 |

25 l/min |

25 |

|

50 l/min |

50 |

|

|

75 l/min |

75 |

|

|

07 |

Component series 20 ... 29 (20 ... 29: unchanged installation and connection dimensions) |

2X |

|

Seal material |

||

|

08 |

FKM seals |

V |

|

Pressure rating with internal sensors |

||

|

09 |

100 bar |

4 1) |

|

160 bar |

5 1) |

|

|

250 bar |

8 1) |

|

|

400 bar |

B 2) |

|

|

external sensor |

0 |

|

|

Position of the pressure sensors |

||

|

10 |

external sensor |

0 |

|

Internal sensor in the channel |

||

|

A (p closed-loop control only in A) |

A |

|

|

B (p closed-loop control only in B) |

B |

|

|

A + B (p closed-loop control in A+B or Δp closed-loop control) |

C |

|

|

P + A + B (Q closed-loop control) |

F |

|

|

11 |

Supply voltage 24 V |

24 |

|

Bus interface |

||

|

12 |

CANBus DS 408 |

C |

|

Profibus DP V0/V1 |

P |

|

|

Electrical interface |

||

|

13 |

Command value ±10 V |

A6 3) |

|

Command value 4 to 20 mA |

F6 3) |

|

|

Sensor interface with external pressure sensor 4) |

||

|

14 |

4 ... 20 mA |

2 |

|

0 ... 10 V |

3 |

|

|

0 ... 5 V |

4 |

|

|

0,5 ... 5 V |

9 |

|

|

Without external sensor interface |

0 |

|

|

15 |

Further details in the plain text |

* |

|

1) |

The selected pressure rating limits the maximum valve pressure |

|

|

2) |

Please note: Maximum valve pressure is 315 bar |

|

|

3) |

If internal pressure sensors are used, no external pressure sensor can be connected |

|

|

4) |

With command value input "A6", only the sensor interfaces "3", "4" or "9" are possible With command value input "F6", only the sensor interface "2" is possible |

|

For applications outside these parameters, please consult us!

general

|

Type |

4WREQ | |||

|

Size |

6 | 10 | ||

|

Installation position |

any, preferably horizontal | |||

|

Ambient temperature range |

°C |

-20 … +50 | ||

|

Storage temperature range |

°C |

-20 … +80 | ||

|

Weight |

withsandwich plate (3 sensors) |

kg |

3.6 | 8.5 |

|

without sandwich plate |

kg |

2.4 | 6.5 | |

hydraulic

|

Size |

6 | 10 | ||

|

Maximum operating pressure |

bar |

315 | ||

|

Maximum operating pressure |

Port P (sensor 100 bar) |

bar |

100 | |

|

Port P (sensor 160 bar) |

bar |

160 | ||

|

Port P (sensor 250 bar) |

bar |

250 | ||

|

Port P (sensor 400 bar) |

bar |

315 | ||

|

Port T (sensor 100 bar) |

bar |

100 | ||

|

Port T (sensor 160 bar) |

bar |

160 | ||

|

Port T (sensor 250 bar) |

bar |

210 | ||

|

Port T (sensor 400 bar) |

bar |

210 | ||

|

Port A (sensor 100 bar) |

bar |

100 | ||

|

Port A (sensor 160 bar) |

bar |

160 | ||

|

Port A (sensor 250 bar) |

bar |

250 | ||

|

Port A (sensor 400 bar) |

bar |

315 | ||

|

Port B (sensor 100 bar) |

bar |

100 | ||

|

Port B (sensor 160 bar) |

bar |

160 | ||

|

Port B (sensor 250 bar) |

bar |

250 | ||

|

Port B (sensor 400 bar) |

bar |

315 | ||

|

Maximum flow |

l/min |

80 | 180 | |

|

Nominal flow |

l/min |

8 16 32 |

25 50 75 |

|

|

Hydraulic fluid |

see table | |||

|

Hydraulic fluid temperature range |

°C |

-20 … +70 | ||

|

preferably |

°C |

+40 … +50 | ||

|

Viscosity range |

mm²/s |

20 … 380 | ||

|

preferably |

mm²/s |

30 … 46 | ||

|

Maximum admissible degree of contamination of the hydraulic fluid, cleanliness class according to ISO 4406 (c) 1) |

Class 20/18/15 according to ISO 4406 (c) | |||

|

Hysteresis |

% |

≤ 0.1 | ||

|

Range of inversion |

% |

≤ 0.05 | ||

|

Response sensitivity |

% |

≤ 0.05 | ||

|

Zero shift upon change of |

Hydraulic fluid temperature |

%/10 K |

< 0.15 | |

|

Operating pressure |

%/100 bar |

< 0.1 | ||

| 1) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

|

Hydraulic fluid |

Classification |

Suitable sealing materials |

Standards |

|

Mineral oils and related hydrocarbons |

HL, HLP |

NBR / FKM |

DIN 51524 |

|

Flame-resistant - containing water |

HFC (Fuchs HYDROTHERM 46M, Petrofer Ultra Safe 620) |

NBR |

ISO 12922 |

|

Important information on hydraulic fluids: For more information and data on the use of other hydraulic fluids please contact us. There may be limitations regarding the technical valve data (temperature, pressure range, life cycle, maintenance intervals, etc.). The flash point of the process and operating medium used must be 40 K over the maximum solenoid surface temperature.

Flame-resistant - containing water: |

|||

electrical

|

Size |

6 | 10 | ||

|

Voltage type |

Direct voltage | |||

|

Maximum current consumption |

of the amplifier |

A |

2 | |

|

of the amplifier (impulse current) |

A |

3 | ||

|

Maximum current |

Output stage |

A |

1.7 | |

|

Signal part |

A |

0.3 | ||

|

Actuated time 1) |

% |

100 | ||

|

Maximum coil temperature 2) |

°C |

150 | ||

|

Protection class according to DIN EN 60529 |

IP65 (with mating connector mounted and locked) | |||

|

Converter resolution (command/actual value signals) |

bits |

10 | ||

|

Power supply |

V |

24 | ||

|

Supply voltage range |

V |

19.4 … 35 | ||

|

Earthing (GND) |

V |

0 | ||

|

Enable input range |

"A6" |

V |

9 … 35 | |

|

"F6" |

V |

9 … 35 | ||

|

Command value input |

UQ "A6" |

mA |

10 | |

|

Command value input range |

UP "A6" |

mA |

0 … 10 | |

|

IQ and IP "F6" |

mA |

4 … 20 | ||

|

Actual value output |

UQ "A6" |

V |

± 10 | |

|

Actual value output range |

UP "A6" |

mA |

0 … 10 | |

|

IQ and IP "F6" |

mA |

4 … 10 | ||

|

Control voltage |

Level as for pin 1 | |||

|

0 V reference potential |

For pins 3, 6, 8 and 11 (connected to pin 2 in valve) | |||

|

Error output |

24 V (19.4 V to 35 V), 200 mA maximum load | |||

| 1) | Connect the valve to the supply voltage only when this is required for the functional sequence of the machine. |

| 2) | Due to the surface temperatures occurring at solenoid coils, the European standards ISO 13732-1 and ISO 4413 need to be adhered to. |

Sensor technology

|

Overload protection |

Sensor 100 bar |

bar |

200 |

|

Sensor 160 bar |

bar |

320 | |

|

Sensor 250 bar |

bar |

500 | |

|

Sensor 400 bar |

bar |

800 | |

|

Bursting pressure |

Sensor 100 bar |

bar |

400 |

|

Sensor 160 bar |

bar |

640 | |

|

Sensor 250 bar |

bar |

1000 | |

|

Sensor 400 bar |

bar |

1600 | |

|

Characteristic curve deviation |

% |

< 0.2 | |

|

Hysteresis |

% |

< 0.1 | |

|

Repetition accuracy |

% |

< 0.05 | |

|

Long-term drift (1 year) under reference conditions |

% |

< 0.2 | |

(measured with HLP46, ϑÖl = 40 ±5 °C)

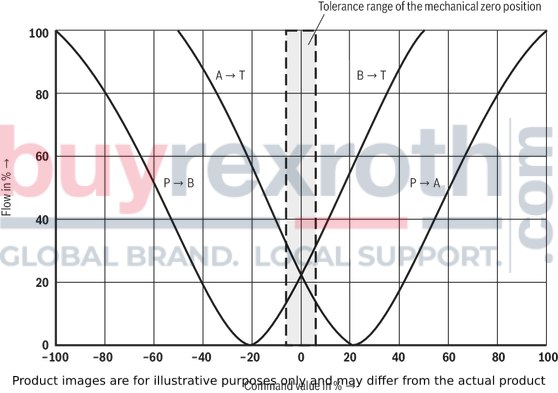

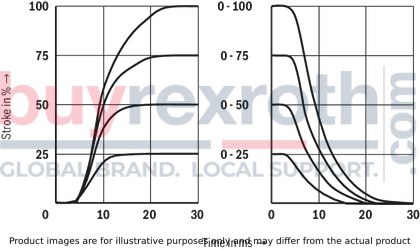

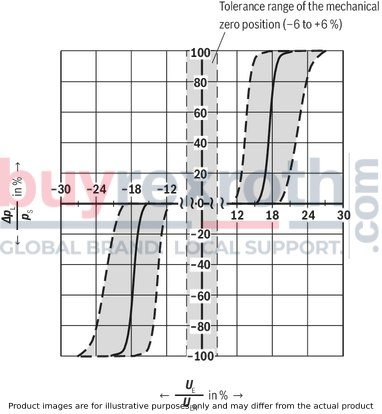

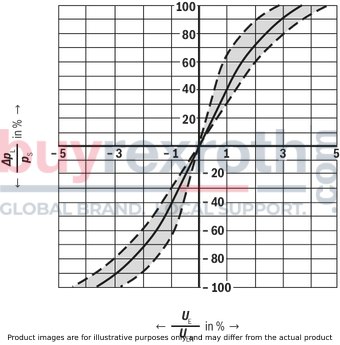

Pressure-signal characteristic curve (control spool Q5), ps = 100 bar

NG6

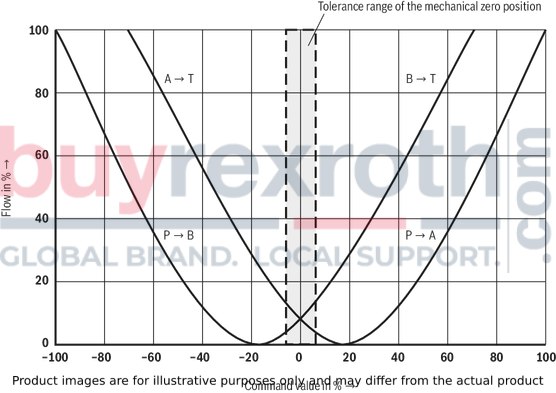

Pressure-signal characteristic curve (symbol V; measured with ps = 100 bar)

NG6

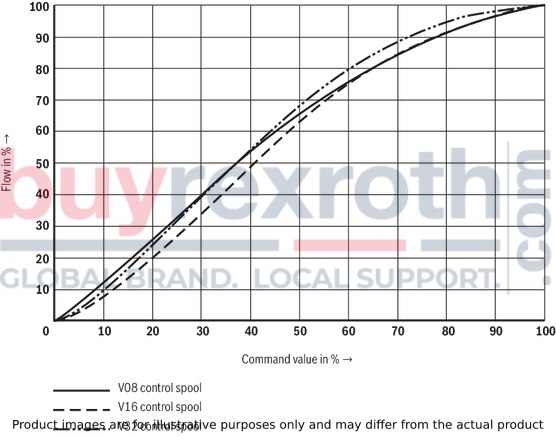

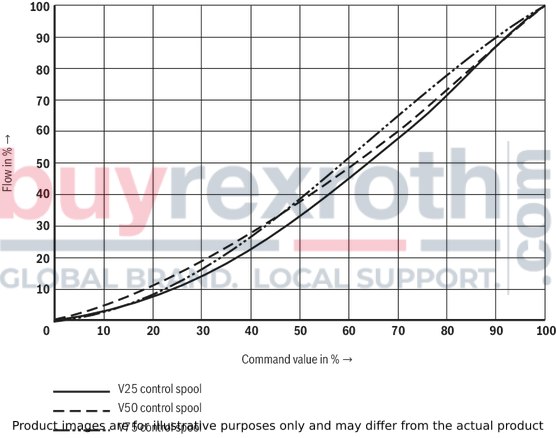

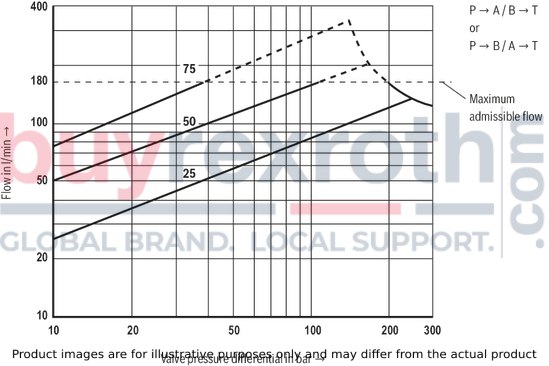

Flow; control spool Q5

NG6

Flow; control spool V

NG6

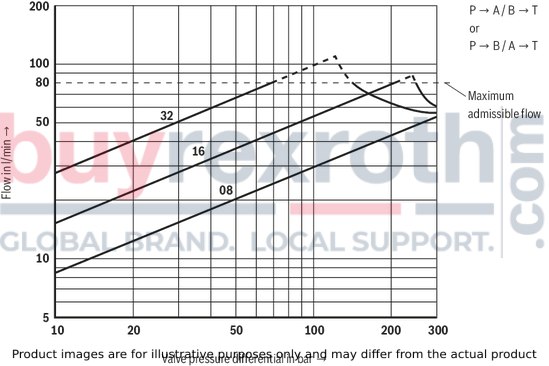

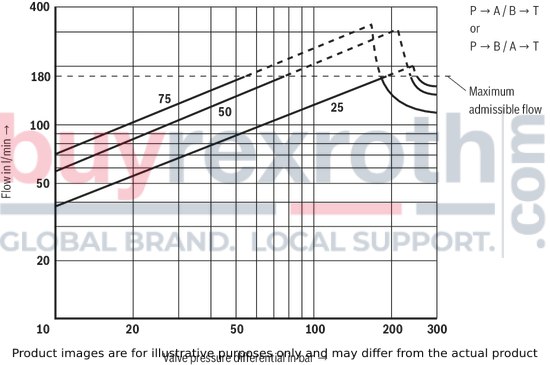

Load function with maximum valve opening; control spool Q5

NG6

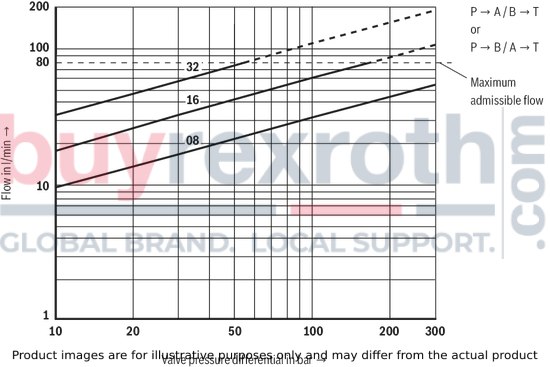

Load function with maximum valve opening; control spool V

NG6

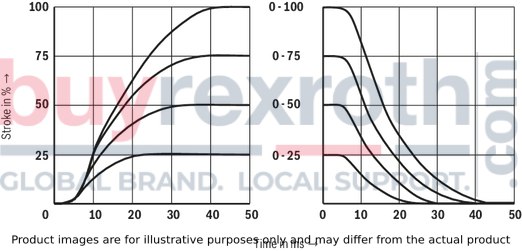

Transition function with stepped electric input signals

NG6

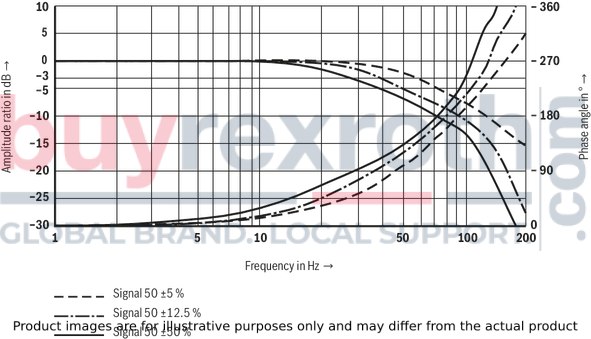

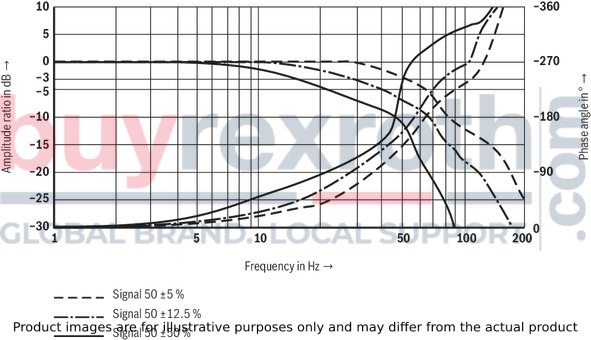

Frequency response (control spool Q5), ps = 10 bar)

NG6

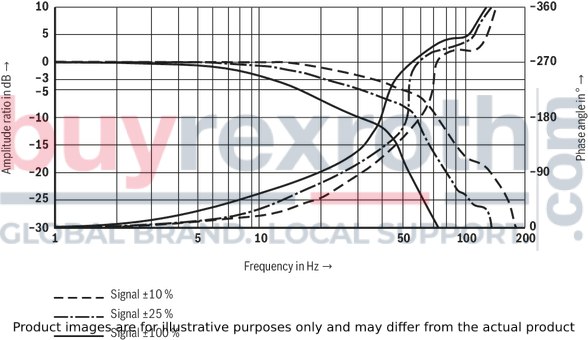

Frequency response (control spool V), ps = 10 bar)

NG6

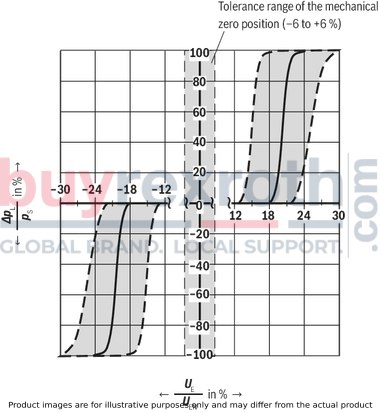

Pressure-signal characteristic curve (control spool Q5), ps = 100 bar

NG10

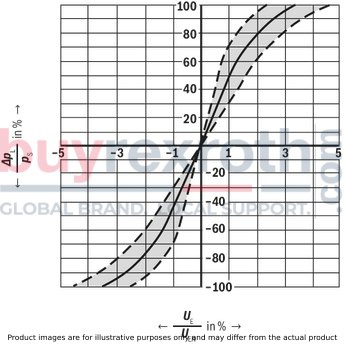

Pressure-signal characteristic curve (symbol V; measured with ps = 100 bar)

NG10

Flow; control spool Q5

NG10

Flow; control spool V

NG10

Load function with maximum valve opening; control spool Q5

NG10

Load function with maximum valve opening; control spool V

NG10

Transition function with stepped electric input signals

NG10

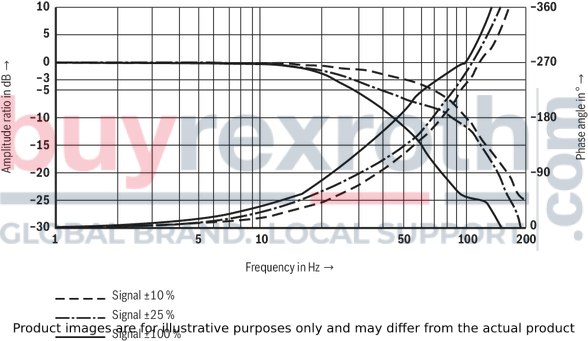

Frequency response (control spool Q5), ps = 10 bar)

NG10

Frequency response (control spool V), ps = 10 bar)

NG10

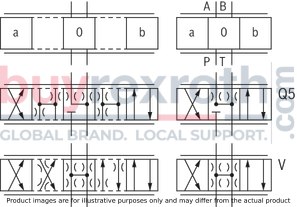

Symbols

Type 4WREQ.Q5-...

Type 4WREQ.V-...

|

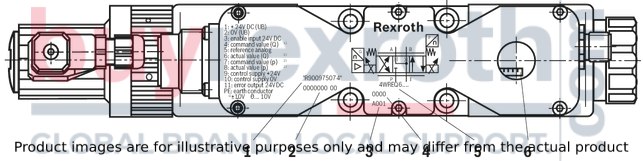

1 |

Material number |

|

2 |

Production order number |

|

3 |

Date of production |

|

4 |

Serial number |

|

5 |

Type designation |

|

6 |

DIL switch for address and baud rate setting (position B0 on the right) |

Connector pin assignment X1, 11-pole + PE according to EN 175201-804

|

Pin |

Assignment of interface A6 |

Assignment of interface F6 |

|

1 |

24 VDC (u(t) = 19.4 V ... 35 V), Imax = 1.7 A (for output stage) |

|

|

2 |

0 V ≙ load zero, reference for pins 1 and 9 |

|

|

3 |

enable input 9 ... 35 V ≙ enable on |

|

|

4 |

± 10 V command value Q; Re > 50 kΩ |

4 ... 20 mA command value Q; Re = 100 Ω |

|

5 |

Reference for command values Q and p |

|

|

6 |

± 10 V actual value Q (limit load 5 mA) |

4 ... 20 mA actual value Q, (maximum load resistance 300 Ω) |

|

7 |

0 ... 10 V command value p; Re > 50 kΩ |

4 ... 20 mA command value p; Re = 100 Ω |

|

8 |

0 ... 10 V actual value p (limit load 5 mA) |

4 ... 20 mA actual value p, (maximum load resistance 300 Ω) |

|

9 |

Control voltage, level as pin 1, Imax = 0.3 A (for signal part and bus) |

|

|

10 |

0V reference potential for pins 3, 6, 8 and 11 (connected with pin 2 in valve) |

|

|

11 |

Error output 24 V (19.4 V ... 35 V), 200 mA maximum load |

|

|

PE |

connected to cooling element and valve housing |

|

Connector pin assignment for CAN bus X2/X3 (coding A), M12, 5-pole, pins/socket

|

Contact |

Pin assignment |

|

1 |

n.c. |

|

2 |

n.c. |

|

3 |

CAN_GND |

|

4 |

CAN_H |

|

5 |

CAN_L |

|

Transmission rate kbit/s |

20 ... 1000 |

|

Bus address |

1 ... 127 |

|

CAN-specific settings: |

|

Connector pin assignment for Profibus DP, X2/X3 (coding B), M12, 5-pole, socket/pins

|

Contact |

Pin assignment |

|

1 |

+ 5 V |

|

2 |

RxD/TxD-N (A line) |

|

3 |

D_GND |

|

4 |

RxD/TxD-P (B line) |

|

5 |

Shield |

|

Transmission rate up to 12 MBaud |

|

|

Bus address |

1 ... 126 |

|

Setting via DIL switch. The + 5 V voltage of the IFB-P serves to supply an external bus connection (as required) |

|

External pressure sensor port X4 (coding A), M12, 5-pole, socket

|

Contact |

Assignment of voltage interface |

Assignment of current interface |

|

1 |

Supply 24 VDC |

Supply 24 VDC |

|

2 |

Signal (0 ... + 5 V) |

Signal (2 ... 20 mA) |

|

3 |

Zero 0 V (GND) |

Zero 0 V (GND) |

|

4 |

n.c. |

n.c. |

|

5 |

n.c. |

n.c. |

CANopen

|

B7 |

B6 |

B5 |

B4 |

B3 |

B2 |

B1 |

B0 |

HEX |

Baudrate: B7, B6

|

Address range: B5 to B0 |

|

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

00 1) |

Standard 20 kBaud or re-programmed |

1 = Standard or re-programmed |

|

0 |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

01 |

20 kBaud |

1 to 63 |

|

to |

to |

|||||||||

|

0 |

0 |

1 |

1 |

1 |

1 |

1 |

1 |

3F |

||

|

0 |

1 |

0 |

0 |

0 |

0 |

0 |

0 |

40 |

125 kBaud |

1 = Standard or re-programmed |

|

0 |

1 |

0 |

0 |

0 |

0 |

0 |

1 |

41 |

125 kBaud |

1 to 63 |

|

to |

to |

|||||||||

|

0 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

7F |

||

|

1 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

80 |

250 kBaud |

1 = Standard or re-programmed |

|

1 |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

81 |

250 kBaud |

1 to 63 |

|

to |

to |

|||||||||

|

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

BF |

||

|

1 |

1 |

0 |

0 |

0 |

0 |

0 |

0 |

C0 |

500 kBaud |

1 = Standard or re-programmed |

|

1 |

1 |

0 |

0 |

0 |

0 |

0 |

1 |

C1 |

500 kBaud |

1 to 62 |

|

to |

to |

|||||||||

|

1 |

1 |

1 |

1 |

1 |

1 |

1 |

0 |

FE |

||

|

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

FF |

250 kBaud |

Monitor mode/programming mode 1 = fixed |

|

1) Factory setting |

||||||||||

PROFIBUS DP

|

B7 |

B6 |

B5 |

B4 |

B3 |

B2 |

B1 |

B0 |

HEX |

Address range |

|

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

00 1) |

125 = Standard or re-programmed |

|

0 |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

01 |

1 to 126 with parameter channel |

|

to |

to |

||||||||

|

0 |

1 |

1 |

1 |

1 |

1 |

1 |

0 |

7E |

|

|

0 |

1 |

0 |

0 |

0 |

0 |

0 |

0 |

80 |

1 to 126 without parameter channel |

|

to |

to |

||||||||

|

1 |

1 |

1 |

1 |

1 |

1 |

1 |

0 |

FE |

|

|

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

FF |

Monitor operation address 125 |

|

1) Factory setting |

|||||||||

Command value:

Positive command value 0 ... +10 V (or 12 ... 20 mA) at pin 4 and reference potential at pin 5 result in flow from P → A and B → T.

Negative command value 0 ... –10 V (or 12 ... 4 mA) at pin 4 and reference potential at pin 5 result in flow from P → B and A → T.

Actual value:

Positive actual value 0 ... +10 V (or 12 ... 20 mA) at pin 6 and reference potential at pin 10 result in flow from P → A and B → T.

Negative actual value 0 ... –10 V (or 12 ... 4 mA) at pin 6 and reference potential at pin 10 result in flow from P → B and A → T.

Connection cable: Recommendation:

up to 25 m cable length type LiYCY 7 x 0.75 mm²

up to 50 m cable length type LiYCY 7 x 1.0 mm²

4WREQ 6 with integrated pressure sensors

Dimensions in mm

|

1 |

Valve housing |

|

2 |

Proportional solenoid "a" with inductive position transducer |

|

3 |

Proportional solenoid "b" |

|

4 |

R-ring 9.81 x 1.5 x 1.78 (ports P, A, B, T) |

|

5 |

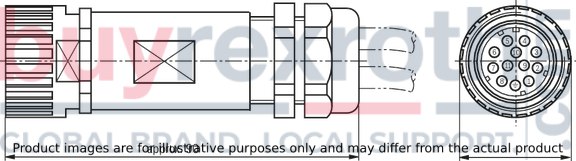

Space required to remove the mating connector |

|

6 |

Integrated digital control electronics |

|

7 |

Mating connector according to DIN EN 175201-804, separate order |

|

8 |

Name plate |

|

9 |

Integrated pressure transducer |

|

10 |

Machined valve contact surface; Porting pattern according to ISO 4401-03-02-0-05 (with locating hole) |

4WREQ 6 for external pressure sensor

Dimensions in mm

|

1 |

Valve housing |

|

2 |

Proportional solenoid "a" with inductive position transducer |

|

3 |

Proportional solenoid "b" |

|

4 |

R-ring 9.81 x 1.5 x 1.78 (ports P, A, B, T) |

|

5 |

Space required to remove the mating connector |

|

6 |

Integrated digital control electronics |

|

7 |

Mating connector according to DIN EN 175201-804, separate order |

|

8 |

Name plate |

|

9 |

Machined valve contact surface; Porting pattern according to ISO 4401-03-02-0-05 (with locating hole) |

Recommended valve mounting screws (separate order):

for valves with integrated pressure sensors:

4 hexagon socket head cap screws ISO 4762 - M5 x 90 - 10.9-flZn-240h-L

Tightening torque MA = 7 Nm ± 10 %, material no. R913000222

for valves with external pressure sensor:

4 hexagon socket head cap screws ISO 4762 - M5 x 50 - 10.9-flZn-240h-L

Tightening torque MA = 7 Nm ± 10 %, material no. R913000064 or

4 hexagon socket head cap screws ISO 4762 - M5 x 50 - 10.9

Tightening torque MA = 8.9 Nm ± 10 %

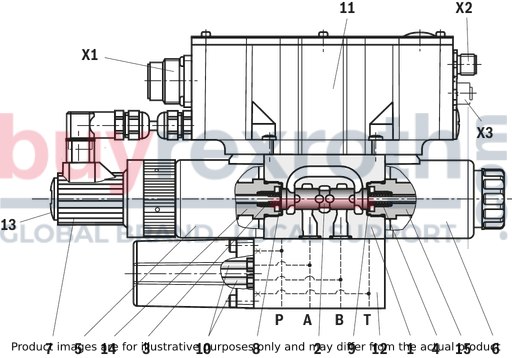

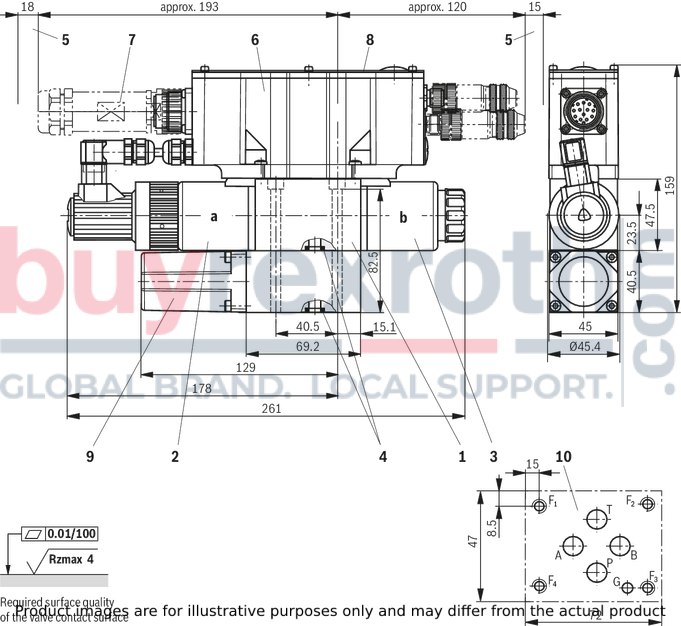

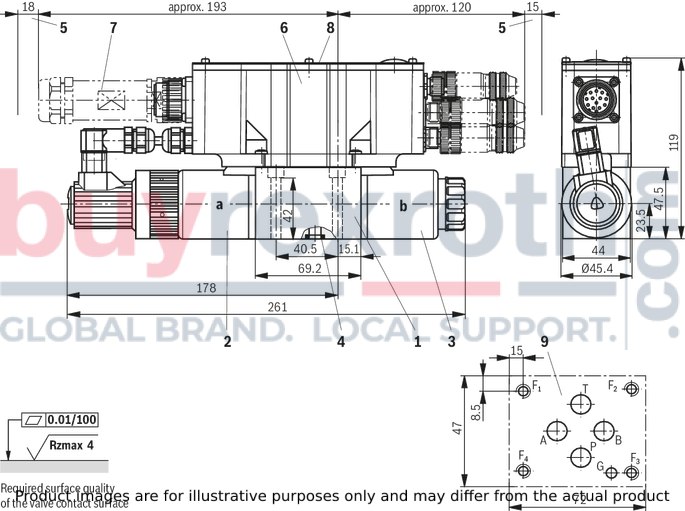

4WREQ 10 with integrated pressure sensors

Dimensions in mm

|

1 |

Valve housing |

|

2 |

Proportional solenoid "a" with inductive position transducer |

|

3 |

Proportional solenoid "b" |

|

4 |

R-ring 13.0 x 1.6 x 2.0 (ports P, A, B, T, T1) |

|

5 |

Space required to remove the mating connector |

|

6 |

Integrated digital control electronics |

|

7 |

Mating connector according to DIN EN 175201-804, separate order |

|

8 |

Name plate |

|

9 |

Integrated pressure transducer |

|

10 |

Machined valve contact surface; Porting pattern according to ISO 4401-05-04-0-05 |

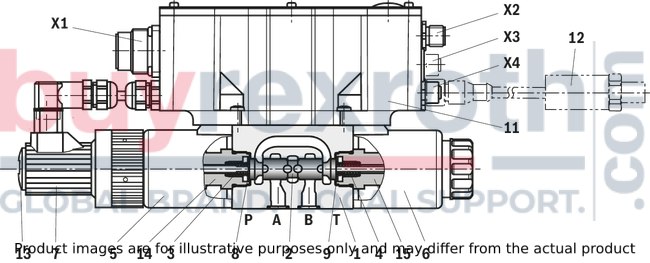

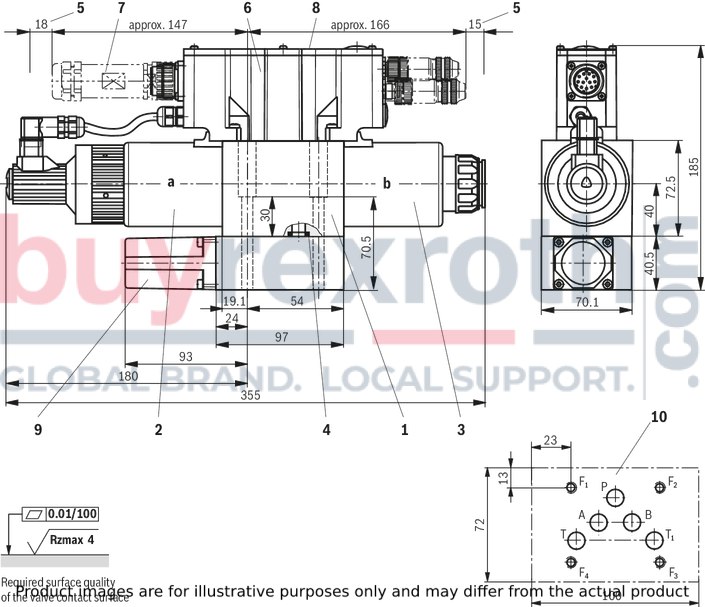

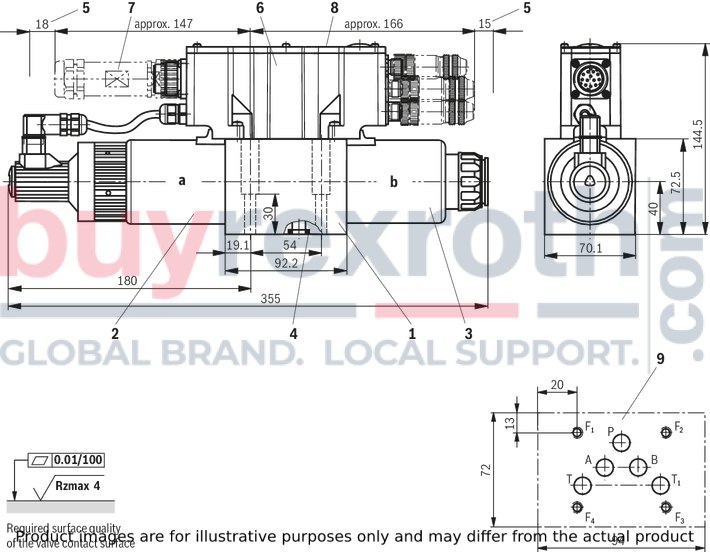

4WREQ 10 for external pressure sensor

Dimensions in mm

|

1 |

Valve housing |

|

2 |

Proportional solenoid "a" with inductive position transducer |

|

3 |

Proportional solenoid "b" |

|

4 |

R-ring 13.0 x 1.6 x 2.0 (ports P, A, B, T, T1) |

|

5 |

Space required to remove the mating connector |

|

6 |

Integrated digital control electronics |

|

7 |

Mating connector according to DIN EN 175201-804, separate order |

|

8 |

Name plate |

|

9 |

Machined valve contact surface; Porting pattern according to ISO 4401-05-04-0-05 |

Recommended valve mounting screws (separate order):

for valves with integrated pressure sensors:

4 hexagon socket head cap screws ISO 4762 - M6 x 80 - 10.9-flZn-240h-L

Tightening torque MA = 12.5 Nm ± 10 %, material no. R913000512 or

4 hexagon socket head cap screws ISO 4762 - M6 x 80 - 10.9

Tightening torque MA = 15.5 Nm ± 10 %

for valves with external pressure sensor:

4 hexagon socket head cap screws ISO 4762 - M6 x 40 - 10.9-flZn-240h-L

Tightening torque MA = 12.5 Nm ± 10 %, material no. R913000058 or

4 hexagon socket head cap screws ISO 4762 - M6 x 40 - 10.9

Tightening torque MA = 15.5 Nm ± 10 %

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

Project planning and maintenance instructions

Connect the valve to the supply voltage only when this is required for the functional sequence of the machine. Do not use electrical signals provided via control electronics (e. g. "No error" signal) for switching safety-relevant machine functions (see also EN ISO 13849 "Safety of machinery – safety-related parts of control systems"). If electro-magnetic interference is to be expected, take appropriate measures ensuring the function (depending on the application, e. g. shielding, filtration). The devices have been tested in the plant and are supplied with default settings. Only complete devices can be repaired. Repaired devices are returned with default settings. User-specific settings will not be applied. The machine end-user will have to re-transfer the corresponding user parameters.|

The following is required for the parameterization via PC: |

CANopen |

PROFIBUS DP |

||

|

1 |

Interface converter |

(USB) |

VT‑ZKO‑USB/CA‑1‑1X/V0/0 |

VT‑ZKO‑USB/P‑1‑1X/V0/0 |

|

2 |

Commissioning software |

WinPed |

||

|

3 |

Connection cable |

3 m |

D-Sub / M12, coding A |

D-Sub / M12, coding B |

|

||||

Port X1

|

Mating connector for X1 |

Dimensions |

Material number |

|

Mating connector according to DIN EN 175201-804 11-pole + PE, plastic version |

Without cable (assembly kit) |

R900884671 |

|

With cable set 2 x 5 m 12-pole |

R900032356 |

|

|

With cable set 2 x 20 m 12-pole |

R900860399 |

|

|

two cable ducts Ø 6 ... 8 mm

|

||

Sensor connection

|

X4 |

Dimensions |

Material number |

|

Analog sensor Plug-in connector, 5-pin, M12, pin, A coding Straight mating connector, metal design |

(Line diameter 4 ... 6 mm) |

R901075542 |

CAN bus (A coding)

|

Plug-in connector for X2 and X3 |

Dimensions |

Material number |

|

X2 Round connector, processable, 5-pole, M12 x 1 Straight mating connector, metal design |

(Line diameter 6 ... 8 mm) |

R901076910 |

|

X3 Round connector, processable, 5-pole, M12 x 1 Straight mating connector, metal design |

(Line diameter 6 ... 8 mm) |

R901076906 |

Profibus (B coding)

|

Plug-in connector for X2 and X3 |

Dimensions |

Material number |

|

X2 Round connector, processable, 5-pole, M12 x 1 Straight mating connector, metal design |

(Line diameter 6 ... 8 mm) |

R901075545 |

|

X3 Round connector, processable, 5-pole, M12 x 1 Straight mating connector, metal design |

(Line diameter 6 ... 8 mm) |

R901075550 |

Protective caps

|

Protective cap M12 |

Version |

Material number |

|

M12 protective cap |

|

R901075563 |

|

M12 protective cap |

|

R901075564 |

Related Products

R901000842

$1,677.00 USD

R900942767

$8,587.00 USD

R901406230

$12,353.00 USD

R900962455

$3,990.00 USD

R900955862

$3,076.00 USD