4WE10D3X/CG24N9K4=CSA

Manufacturer: Bosch Rexroth

Material #: R900958087

Model : 4WE10D3X/CG24N9K4=CSA

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

The Bosch Rexroth 4WE10D3X/CG24N9K4=CSA (R900958087) is a high-performance directional spool valve designed for controlling the start, stop, and direction of fluid flow in hydraulic systems. This valve is characterized by its robust housing, electronic solenoids, control spool, and return springs which ensure reliable operation. The control spool can be actuated by wet-pin electronic solenoids that move it from a rest position to an active end position, allowing for precise direction of flow between ports.

This model features manual override capabilities that permit manual actuation of the valve without the need for solenoid power. It's essential to maintain an oil-filled pressure chamber in the solenoid to guarantee proper functionality. The throttle insert option allows for increased flow resistance in various channels (P, A, B, or T), enhancing performance under certain operating conditions.

The 4WE10D3X/CG24N9K4=CSA valve operates without spring return in its default state when de-energized; however, it can also be configured with a detent (OF version) to maintain the control spool in a selected position without continuous current application—offering energy-efficient operation.

It's important to note that pressure peaks in tank lines connected to multiple valves might cause unintentional control spool movements. Separate return lines or check valves are recommended solutions for this issue.

This specific model offers versatility with its 3 or 4-way versions and high-power solenoid design. It adheres to ISO porting patterns and features wet-pin AC solenoids with detachable coils that are rotatable by 90 degrees and replaceable without opening the sealed chamber. The electrical connections are customizable as either individual or central connections, with an optional auxiliary operating device available.

The valve supports a maximum operating pressure of up to 350 bar and can accommodate maximum flow rates of up to 120 l/min. It belongs to component series X and X2—indicating its modern engineering standards and compatibility with contemporary hydraulic systems.

This product is not available. CLICK HERE to create a support ticket for us to locate your part or a suitable replacement

This product is eligible for factory repair.

4/3-, 4/2- or 3/2-way version High-power solenoid Porting pattern according to ISO 4401-05-04-0-05 Wet-pin AC solenoids with detachable coil Solenoid coil is rotatable by 90° The coil can be changed without having to open the pressure-tight chamber Electrical connection as individual connection or central connection Optional auxiliary operating device

The directional valve type WE is a solenoid-actuated directional spool valve. It controls the start, stop and direction of a flow.

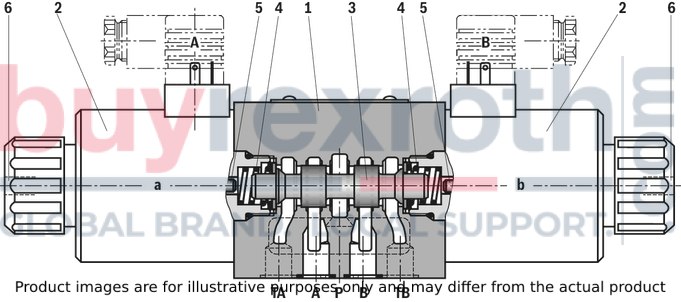

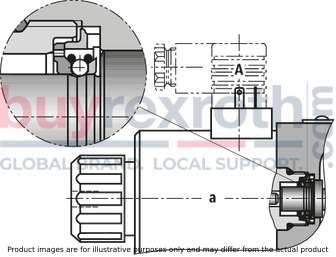

The directional valve basically consists of housing (1), one or two electronic solenoids (2), control spool (3), and the return springs (4). When de-energized, the control spool (3) is held in the central position or in the initial position by the return springs (4) (except for version "O"). The control spool (3) is actuated by wet-pin electronic solenoids (2).

The force of electronic solenoid (2) acts via the plunger (5) on the control spool (3) and pushes the latter from its rest position to the required end position. This enables the necessary direction of flow from P to A and B to T or P to B and A to T.

When the electronic solenoid (2) is switched off, the return spring (4) pushes the control spool (3) back to its rest position.

A manual override (6) allows for the manual switching of the valve without solenoid energization.

To ensure proper functioning, make sure that the pressure chamber of the solenoid is filled with oil.

Type .WE 10 E…

Throttle insert "B.."

Using a throttle insert (7) in channels P, A, B or T, the flow resistance at the valve can be increased. Its use is required when, due to prevailing operating conditions, flows occur during the switching processes, which exceed the performance limit of the valve.

Without spring return “O” (only possible with symbols A, C and D)

This version is a directional valve with 2 spool positions and 2 electronic solenoids without detent.

The valve without spring return at the control spool (3) does not have a defined basic position in the de-energized condition.

Without spring return with detent “OF” (only possible with symbols A, C and D)

This version is a directional valve with 2 spool positions and 2 electronic solenoids with detent.

The detents are used to lock the control spool (3) in the relevant spool position. During operation,

continuous application of current to the electronic solenoid can thus be omitted which contributes to energy-efficient operation.

Notice!

Pressure peaks in the tank line to two or several valves can result in unintended

movements of the control spool if valves are equipped with a detent! We therefore recommend providing separate return lines or

installing a check valve in the tank line.

Type .WE 10 ../OF…

|

01 |

3 main ports |

3 |

|

4 main ports |

4 |

|

|

02 |

Directional valve |

WE |

|

03 |

Size 10 |

10 |

|

04 |

Symbols e. g. C, E, EA, EB, etc.; for the possible version, see Symbols |

|

|

05 |

Component series 30 ... 39 (30 ... 39: unchanged installation and connection dimensions) |

3X |

|

Component series 40 … 49 (40 … 49: unchanged installation and mounting dimensions) |

4X |

|

|

06 |

With spring return |

no code |

|

Without spring return |

O |

|

|

Without spring return with detent |

OF |

|

|

07 |

High-power solenoid, wet-pin, with detachable coil |

C |

|

08 |

AC voltage 42 V 50/60 Hz |

W42 |

|

AC voltage 110 V 50/60 Hz / 120 V 60 Hz |

W110 |

|

|

AC voltage 230 V 50/60 Hz |

W230 |

|

|

DC voltage see data sheet 23340 |

||

|

09 |

With concealed manual override (standard) |

N9 |

|

With manual override |

N |

|

|

Without manual override |

no code |

|

|

Electrical connection |

||

|

10 |

Individual connection |

|

|

Without mating connector; connector DIN EN 175301-803 |

K41) |

|

|

With M12x1 plug-in connection, high-performance version 5-pole, integrated interference protection circuit, operating display with LED |

K72L2) |

|

|

Central connection |

||

|

Cable entry at the cover, with indicator light |

DL |

|

|

Central plug-in connection at the cover, with indicator light (without mating connector) |

DK6L |

|

|

With M12x1 plug-in connection, high-performance version: 4-pole |

DK24L2) |

|

|

With M12x1 plug-in connection, high-performance version: 4-pole, integrated interference protection circuit, operating display with LED |

DK35L2) |

|

|

Spool position monitoring |

||

|

11 |

Without position switch |

no code |

|

Inductive position switch type QM |

||

|

Monitored spool position "a" |

QMAG24 |

|

|

Monitored spool position "b" |

QMBG24 |

|

|

Monitored rest position |

QM0G24 |

|

|

12 |

Without throttle insert |

no code |

|

Throttle Ø 0.8 mm |

B08 |

|

|

Throttle Ø 1.0 mm |

B10 |

|

|

Throttle Ø 1.2 mm |

B12 |

|

|

Use with flows which exceed the performance limit of the valve (see Product description) |

||

|

Seal material |

||

|

13 |

NBR seals |

no code |

|

FKM seals |

V |

|

|

Observe compatibility of seals with hydraulic fluid used. (Other seals upon request) |

||

|

14 |

Further details in the plain text |

* |

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

10 |

11 |

12 |

13 |

14 |

||

|

WE |

10 |

/ |

C |

/ |

* |

Notice!

For valves with 3 spool positions and valves with detent (version "O" and "OF"), position switches type QM are not possible!

Notice! Preferred types and standard units are contained in the EPS (standard price list).

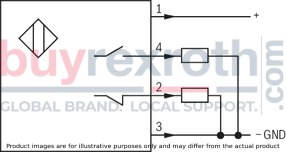

Inductive position switch type QM: electrical connection

general

|

Type |

Einzelanschluss | Zentralanschluss | ||

|

Weight |

Valve with one solenoid |

kg |

3.6 | 3.5 |

|

Valve with two solenoids |

kg |

4.4 | 4.3 | |

|

Installation position |

any | |||

|

Ambient temperature range |

NBR seals |

°C |

-30 … +50 | |

|

FKM seals |

°C |

-20 … +50 | ||

|

MTTFD values according to EN ISO 13849 1) |

Years |

150 | ||

| 1) | For further details, see data sheet 08012 |

hydraulic

|

Size |

10 | ||

|

Maximum operating pressure |

Port P |

bar |

315 |

|

Port A |

bar |

315 | |

|

Port B |

bar |

315 | |

|

Port T 1) |

bar |

160 | |

|

Maximum flow |

l/min |

120 | |

|

Flow cross-section |

Symbol Q (A/B → T) |

mm² |

5.5 |

|

Symbol V (A/B → T) |

mm² |

11 | |

|

Symbol V (P → A/B) |

mm² |

10.3 | |

|

Symbol W (A/B → T) |

mm² |

2.5 | |

|

Hydraulic fluid |

see table | ||

|

Hydraulic fluid temperature range 2) |

NBR seals |

°C |

-30 … +80 |

|

FKM seals |

°C |

-20 … +80 | |

|

Viscosity range |

mm²/s |

2.8 … 500 | |

|

Maximum admissible degree of contamination of the hydraulic fluid 3) |

Class 20/18/15 according to ISO 4406 (c) | ||

| 1) | With symbols A and B, port T must be used as leakage oil connection if the operating pressure exceeds the admissible tank pressure. |

| 2) | at the valve working ports of the valve |

| 3) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

|

Hydraulic fluid |

Classification |

Suitable sealing materials |

Standards |

|

|

Mineral oils |

HL, HLP, HLPD, HVLP, HVLPD |

NBR, FKM |

DIN 51524 |

|

|

Bio-degradable |

Insoluble in water |

HETG |

NBR, FKM |

VDMA 24568 |

|

HEES |

FKM |

|||

|

Soluble in water |

HEPG |

FKM |

VDMA 24568 |

|

|

Containing water |

Water-free |

HFDU, HFDR |

FKM |

ISO 12922 |

|

Containing water |

HFC (Fuchs Hydrotherm 46M, Petrofer Ultra Safe 620 ) |

NBR, HNBR |

ISO 12922 |

|

|

Important information on hydraulic fluids! For further information and data on the use of other hydraulic fluids, please refer to data sheet 90220 or contact us! There may be limitations regarding the technical valve data (temperature, pressure range, life cycle, maintenance intervals, etc.)! The flash point of the hydraulic fluid used must be 40 K higher than the maximum solenoid surface temperature. Flame-resistant – containing water: Maximum pressure differential per control edge 50 bar. Pressure pre-loading at the tank port >20% of the pressure differential; otherwise, increased cavitation Life cycle compared to operation with mineral oil HL, HLP 50 to 100 % Bio-degradable: When using bio-degradable hydraulic fluids that are zinc-solving, zinc may accumulate in the fluid (700 mg zinc per pole tube) |

||||

electrical

|

Voltage type |

AC voltage 50/60 Hz | ||

|

Available voltages 1) |

42 / 110 / 230 | ||

|

Voltage tolerance (nominal voltage) |

% |

± 10 | |

|

Holding power |

VA |

90 | |

|

Switch-on power |

VA |

550 | |

|

Duty cycle |

% |

100 | |

|

Switching time according to ISO 6403 |

ON |

ms |

15 … 25 |

|

OFF |

ms |

20 … 60 | |

|

Maximum switching frequency |

1/h |

7200 | |

|

Protection class according to DIN EN 60529 |

IP65 (with mating connector mounted and locked) | ||

|

Insulation class VDE 0580 |

H | ||

|

Electrical fuse protection |

Every solenoid must be protected individually using a suitable fuse with tripping characteristics K (inductive loads). | ||

|

Behavior in error cases |

Solenoid does not switch through: The solenoid surface temperature may be exceeded. | ||

| 1) | Special voltage upon request; mains for AC solenoids, see notice and ordering code. |

electrical

|

Connection voltage (DC voltage) |

24 V | |||

|

Voltage tolerance (connection voltage) |

+30 %/-15 % | |||

|

Admissible residual ripple |

% |

≤ 10 | ||

|

Max. load capacity |

mA |

400 | ||

|

Switching outputs

|

PNP transistor outputs, load between switching outputs and GND | |||

|

Pinout

|

1 |

V |

24 | |

|

2, 4 |

Switching output |

mA |

400 | |

|

3 |

Earthing (GND) |

V |

0 | |

M12x1 plug-in connection

The electric connection is realized via a 4-pole mating connector (separate order) with connection thread M12 x 1.

electrical

|

M12x1 plug-in connections 1) |

K72L, DK24L, DK35L | ||

|

Available voltages 2) |

V |

24 | |

|

Limited switch-off voltage peak |

K72L, DK35L |

V |

-44 … -55 |

|

DK24L |

without limitation | ||

|

Voltage tolerance (nominal voltage) |

% |

± 10 | |

|

Power consumption |

W |

35 | |

|

Duty cycle |

% |

100 | |

|

Switching time according to ISO 6403 |

ON |

ms |

45 … 60 |

|

Smoothly switching ON |

3 to 4 times longer than standard | ||

|

OFF |

ms |

20 … 30 | |

|

Smoothly switching OFF |

3 to 4 times longer than standard | ||

|

Maximum switching frequency |

Standard |

1/h |

15000 |

|

Smoothly switching |

1/h |

7200 | |

|

Protection class according to DIN EN 60529 3) |

IP65 | ||

|

Protection class according to DIN EN 61140 |

III | ||

|

Maximum coil temperature 4) |

°C |

150 | |

| 1) | Mating connectors according to IEC 60947-5-2, separate order, see data sheet 08006 |

| 2) | Connection to functional low voltage with secure separation only = PELV/SELV |

| 3) | Only with the use of the mating connectors indicated by us and with correct installation. |

| 4) | Due to the surface temperatures of the solenoid coils, the standards ISO 13732-1 and EN 982 need to be adhered to! |

Notice!

Valve versions with electrical individual connection “K…” or central connection “DK…”, see Ordering code.

Notices!

The solenoid coils must not be painted. Actuation of the manual override is only possible up to a tank pressure of approx. 50 bar. Avoid damage to the bore of the manual override!(Special tool for actuation, separate order, material no. R900024943). When the manual override is blocked, actuation of the opposite solenoid must be ruled out!

The simultaneous actuation of 2 solenoids of one valve must be ruled out! Use cables that are approved for a working temperature above 105° C. When solenoid coils are switched off, voltage peaks result which may cause faults or damage in the connected control electronics. The user has to provide for a suitable circuit for limiting the voltage peaks. It must be noted that a diode switched in an antiparallel form extends the switching off time. Valves with individual connection and a supply voltage of 12 V or 24 V can be operated with twice the voltage to reduce the switching time. For this purpose, the voltage has to be reduced to the nominal valve voltage after 100 ms by means of pulse width modulation. The maximum admissible switching frequency is 5 1/s. Due to possible overload of the board, valves with central connection must not be operated with twice the voltage.

Notice!

AC solenoids can be used for 2 or 3 mains; e. g. solenoid type W110 for: 110V, 50Hz; 110 V, 60Hz; 120V, 60Hz

In the electrical connection, the protective earthing conductor (PE, grounded) is to be connected in accordance with the stipulations.

For applications outside these parameters, please consult us!

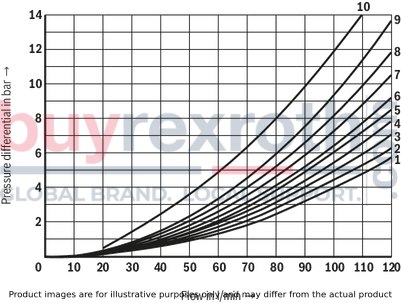

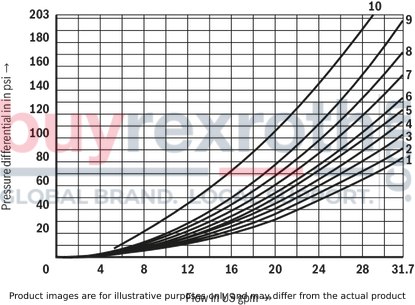

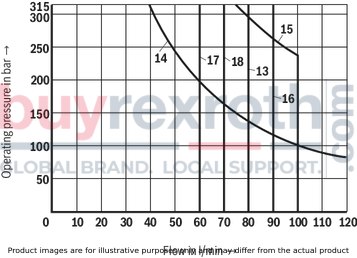

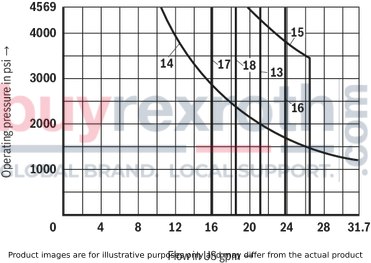

(measured with HLP46, ϑOil = 40 ±5 °C)

Δp-qV characteristic curves

|

Symbol |

Direction of flow |

|||

|

P-A |

P-B |

A-T |

B-T |

|

|

A; B |

3 |

3 |

- |

- |

|

C |

3 |

3 |

4 |

5 |

|

D; Y |

5 |

5 |

6 |

6 |

|

E |

1 |

1 |

4 |

4 |

|

F |

2 |

3 |

7 |

4 |

|

G |

3 |

3 |

6 |

7 |

|

H |

1 |

1 |

6 |

7 |

|

J |

1 |

1 |

3 |

3 |

|

L |

2 |

2 |

3 |

5 |

|

M |

1 |

1 |

4 |

5 |

|

P |

4 |

2 |

5 |

7 |

|

Q |

1 |

2 |

1 |

3 |

|

R |

3 |

6 |

4 |

- |

|

T |

3 |

3 |

6 |

7 |

|

U; V |

2 |

2 |

3 |

3 |

|

W |

2 |

2 |

4 |

5 |

|

Central position: |

|||||

|

Symbol |

Direction of flow |

||||

|

P-A |

P-B |

B-T |

A-T |

P-T |

|

|

F |

4 |

- |

- |

9 |

9 |

|

P |

- |

5 |

8 |

- |

10 |

|

G, T |

- |

- |

- |

- |

9 |

|

H |

- |

- |

- |

- |

3 |

|

Switching position: |

||||

|

Symbol |

Direction of flow |

|||

|

P - A |

B - A |

A - T |

P - T |

|

|

R |

- |

9 |

- |

- |

Notice!

The specified performance limits are valid for use with two directions of flow (e. g. from P to A and simultaneous return flow from B to T).

Due to the flow forces acting within the valves, the admissible performance limit may be considerably lower with only one direction of flow (e. g. from P to A while port B is blocked)!

In such use cases, please consult us!

The performance limit was determined when the solenoids were at operating temperature, at 10% undervoltage and without tank preloading.

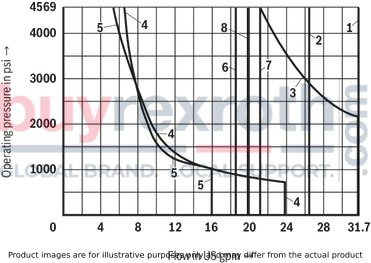

Performance limits

(measured with HLP46, ϑOil = 40 ±5 °C)

|

Characteristic curve |

Symbol |

|

1 |

C; C/O; C/OF; D; D/O; D/OF; Y |

|

2 |

E; L; U; Q; W |

|

3 |

A/O; A/OF; J |

|

4 |

F; P |

|

5 |

T |

|

6 |

H |

|

7 |

R |

|

8 2) |

L; U |

42 V, 50 Hz; 110 V, 50 Hz; 120 V, 60 Hz;

127 V, 50 Hz; 220 V, 50 Hz; 240 V, 60 Hz

|

Characteristic curve |

Symbol |

|

9 |

M |

|

10 |

A, B |

|

11 |

G |

|

12 |

V |

42 V, 50 Hz; 110 V, 50 Hz; 120 V, 60 Hz;

127 V, 50 Hz; 220 V, 50 Hz; 240 V, 60 Hz

Notice!

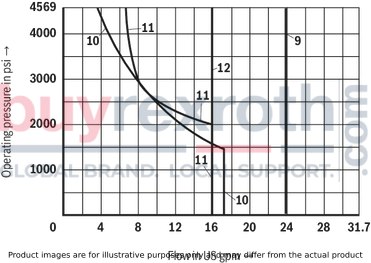

The specified performance limits are valid for use with two directions of flow (e. g. from P to A and simultaneous return flow from B to T). Due to the flow forces acting within the valves, the admissible performance limit may be considerably lower with only one direction of flow (e. g. from P to A while port B is blocked)!

In such use cases, please consult us!

The performance limit was determined when the solenoids were at operating temperature, at 10% undervoltage and without tank preloading.

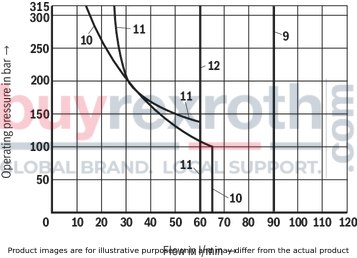

Performance limits

(measured with HLP46, ϑOil = 40 ±5 °C)

Performance limits (measured with HLP46, ϑOil = 40 ±5 °C)

|

Characteristic curve |

Symbol |

|

13 |

C; C/O; C/OF;D; D/O; D/OF; Y |

|

14 |

A/O; A/OF |

|

15 |

E |

|

16 |

M |

|

17 |

V |

|

18 |

H |

42 V, 60 Hz; 110 V, 60 Hz;

127 V, 60 Hz; 220 V, 60 Hz

Please consult us regarding the performance limits for other symbols.

| 1) |

Example: Symbol E with spool position "a" ordering code ..EA.. |

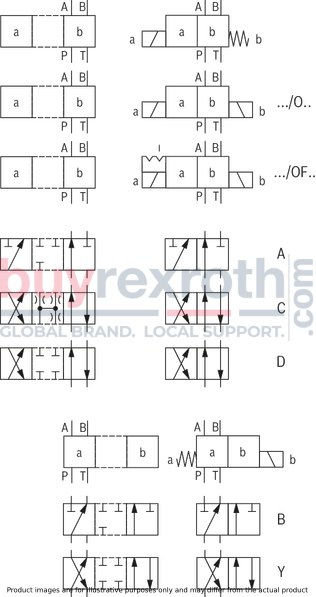

Notices!

Representation according to DIN ISO 1219-1.

Hydraulic interim positions are shown by dashes.

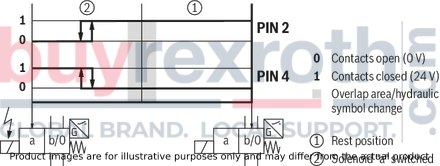

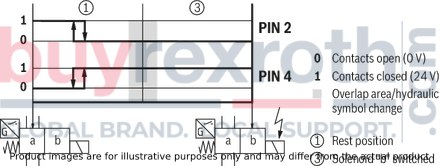

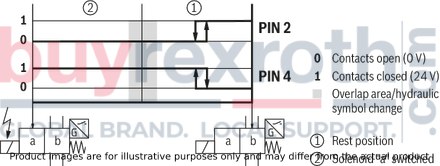

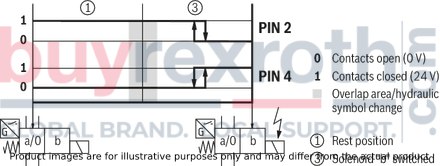

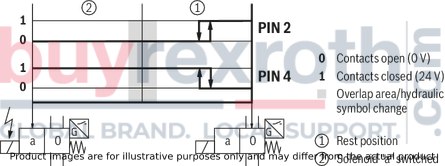

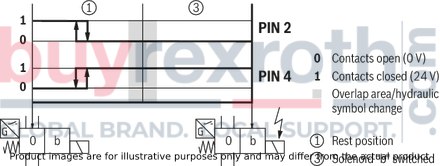

Inductive position switch type QM Switching logics

Version QMA

(Position switch on side B, monitored spool position "a")

Version QMA

(Position switch on side A, monitored spool position "a")

Version QMB

(Position switch on side B, monitored spool position "b")

Version QMB

(Position switch on side A, monitored spool position "b")

Version QM0

(Position switch on side B, monitored rest position)

Version QM0

(Position switch on side A, monitored rest position)

M12x1 plug-in connection ‒ Individual connection – “K72L”

Pin 5 without function

M12x1 plug-in connection ‒ Central connection – “DK35L”

M12x1 plug-in connection ‒ Central connection – “DK24L”

Individual connection

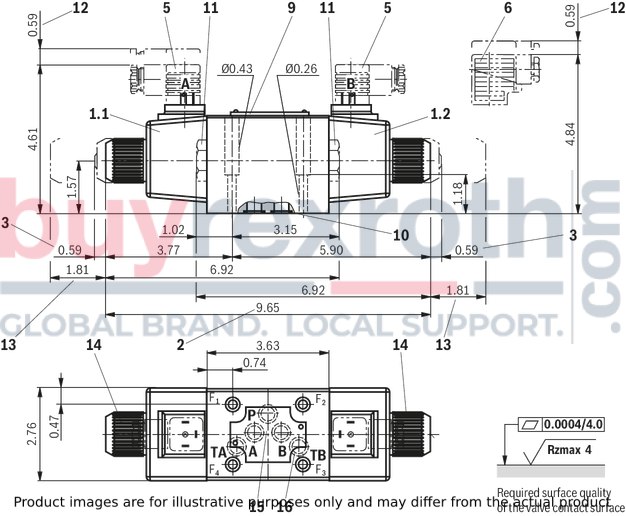

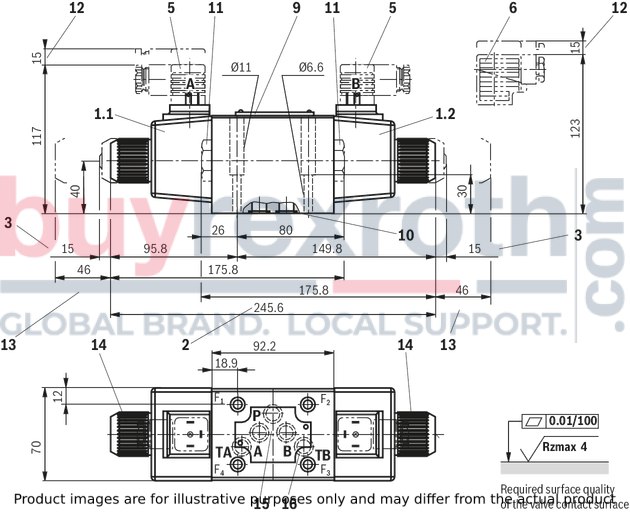

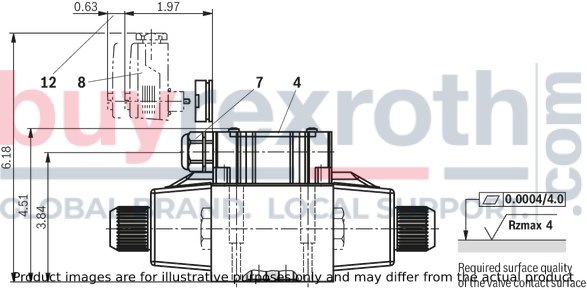

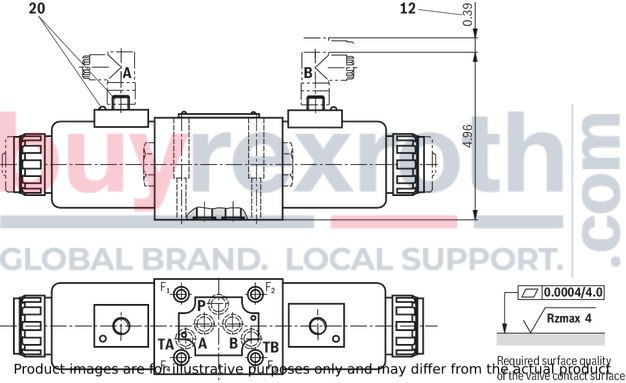

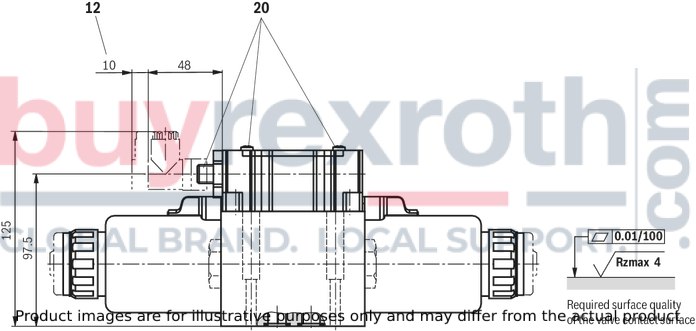

Dimensions in mm

Dimensions in mm

Notice!

Deviating from ISO 4401, port T is referred to as TA and port T1 is referred to as TB in this data sheet. The dimensions are nominal dimensions which are subject to tolerances.Central connection

Dimensions in mm

Dimensions in mm

|

4 |

Cover |

|

7 |

Cable gland Pg 16 [1/2“ NPT] "DL" |

|

8 |

Angled socket (color red, separate order) material no. R900005538) |

|

12 |

Space required to remove the mating connector/angled socket |

Terminal assignment with central connection:

1 solenoid:Always connect the solenoid to terminals 1 and 2,

the protective earthing conductor to terminal PE, grounded

2 solenoids:Always connect solenoid "a" to terminals 1 and 2,

solenoid "b" to terminals 3 and 4,

the protective earthing conductor to terminal PE, grounded

Notice!

Deviating from ISO 4401, port T is referred to as TA and port T1 is referred to as TB in this data sheet. The dimensions are nominal dimensions which are subject to tolerances.Subplates according to data sheet 45054 (separate order)

G 66/01 (G3/8)

G 67/01 (G1/2)

G 534/01 (G3/4)

G 66/12 (SAE-6; 9/16-18)1)

G 67/12 (SAE-8; 3/4-16)1)

G 534/12 (SAE-12; 1-1/16-12)1)

1) Upon request

Valve mounting screws (separate order)

4 hexagon socket head cap screws, metric

ISO 4762 - M6 x 40 - 10.9-flZn-240h-L

(friction coefficient µtotal = 0.09 … 0.14);

tightening torque MA = 12.5 Nm±10 %,

material no. R913000058

or

4 hexagon socket head cap screws

ISO 4762 - M6 x 40 - 10.9 (self procurement)

(friction coefficient µtotal = 0.12 … 0.17);

tightening torque MA = 15.5 Nm±10 %

4 hexagon socket head cap screws UNC

1/4-20 UNC x 1-1/2” ASTM-A574

(friction coefficient µtotal = 0.19 … 0.24);

tightening torque MA = 20 Nm ±15 %,

(friction coefficient µtotal = 0.12 … 0.17);

tightening torque MA = 14 Nm ±10 %,

material no. R978800710

With different friction coefficients, the tightening torques are to be adjusted accordingly!

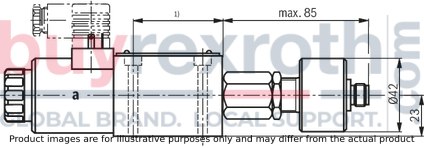

Spool position monitoring

Inductive position switch type QM

Dimensions in mm

| 1) | For dimensions, see valve dimensions |

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

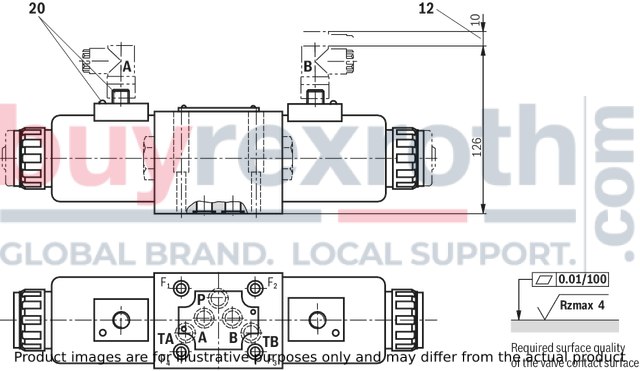

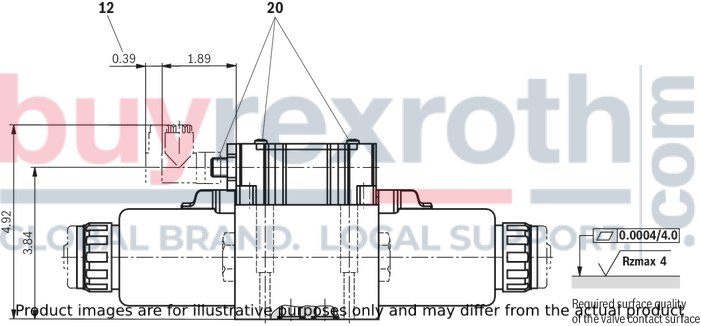

M12x1 plug-in connection ‒ Individual connection

Type .WE 10 .3X/.CG24.K72L…

Dimensions in mm

Dimensions in mm

M12x1 plug-in connection ‒ Central connection

Type .WE 10 .4X/.CG24.DK…

Dimensions in mm

Dimensions in mm

|

12 |

Space required to remove the mating connector |

|

20 |

M12x1 plug-in connection with status LED (mating connectors according to IEC 60947-5-2, separate order, see data sheet 08006); electrical connections “DK35L” and “DK24L” see Electrical connections |

|

12 |

Space required to remove the mating connector |

|

20 |

M12x1 plug-in connection with status LED (mating connector according to IEC 60947-5-2, separate order, see data sheet 08006); electrical connections “K72L”: see Electrical connections |

Mating connectors for valves with connector “K4”, without circuitry, standard

3P Z4

Mating connectors for valves with connector “K4”, without circuitry, standard

3P Z4

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Mating connectors for valves with connector “K4”, without circuitry, standard

3P Z45

Mating connectors for valves with connector “K4”, without circuitry, standard

3P Z45

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Mating connectors for valves with connector “K4”, with indicator light

3P Z5L

Mating connectors for valves with connector “K4”, with indicator light

3P Z5L

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Mating connectors for valves with connector “K4”, with indicator light

3P Z55L

Mating connectors for valves with connector “K4”, with indicator light

3P Z55L

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Mating connectors for valves with connector “K4”, with indicator light and Zener diode suppression circuit

3P Z5L1

Mating connectors for valves with connector “K4”, with indicator light and Zener diode suppression circuit

3P Z5L1

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Related Products

R900595477

$737.00 USD

R978025719

$508.00 USD

R900029511

$1,254.00 USD

R978907174

$1,565.00 USD

R900921755

$1,168.00 USD