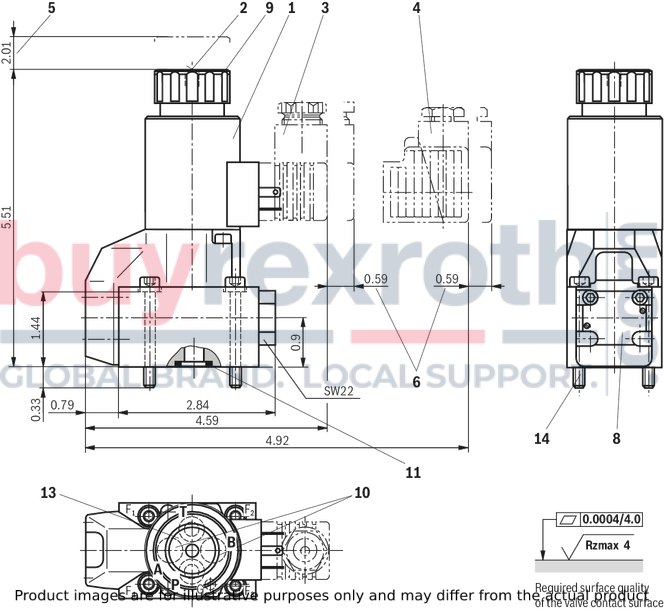

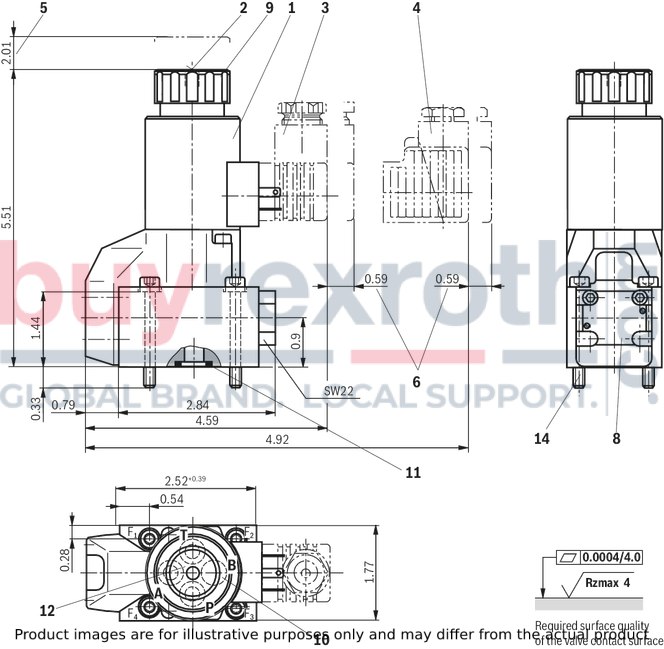

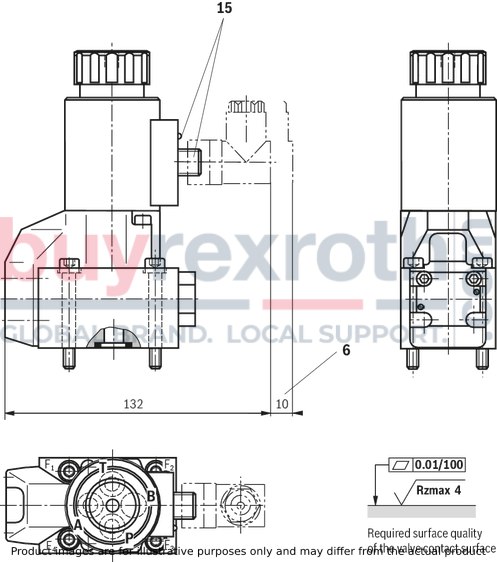

2/2 directional seat valve

Dimensions in mm

2/2 directional seat valve

Dimensions in mm

|

1

|

Solenoid “a”

|

|

2

|

Concealed manual override “N9”

|

|

3

|

Mating connector without circuitry (separate order)

|

|

4

|

Mating connector without circuitry (separate order)

|

|

5

|

Space required to remove the coil

|

|

6

|

Space required to remove the mating connector

|

|

8

|

Name plate

|

|

9

|

Mounting nut, tightening torque MA = 4 Nm

|

|

10

|

With 3/2 directional seat valves version "420", port B is designed as blind counterbore, in version "630", it is not available. With 2/2 directional seat valves version "420", ports A and B are available as blind counterbores.

|

|

11

|

Identical seal rings for ports A, B, and T; seal ring for port P

|

|

13

|

Porting pattern according to ISO 4401-03-02-0-05 (with locating hole for locking pin ISO 8752-3x8-St, material no. R900005694, included in the scope of delivery)

|

|

14

|

Valve mounting screws

|

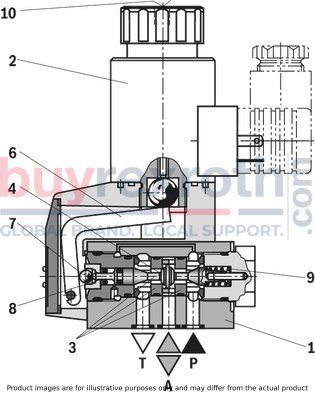

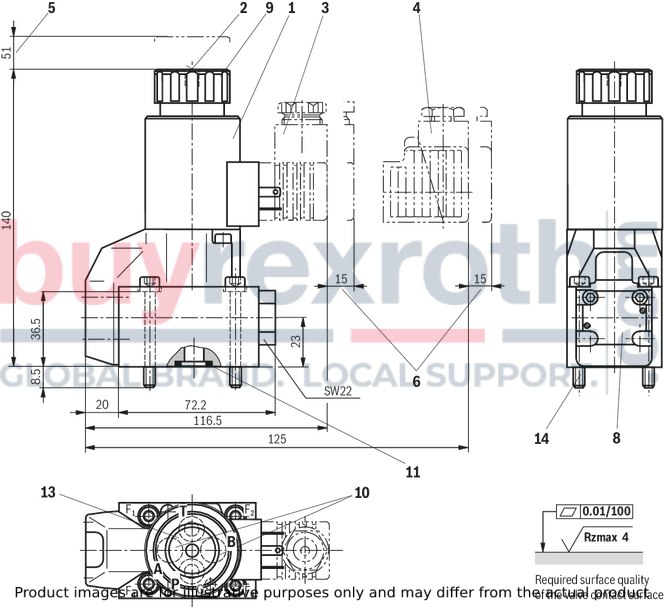

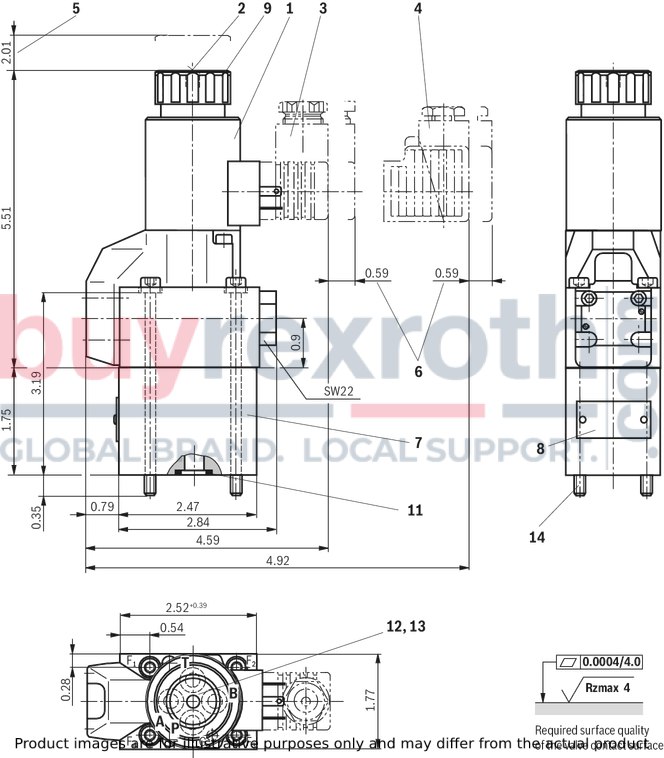

3/2 directional seat valve

Dimensions in mm

3/2 directional seat valve

Dimensions in mm

|

1

|

Solenoid “a”

|

|

2

|

Concealed manual override “N9”

|

|

3

|

Mating connector without circuitry (separate order)

|

|

4

|

Mating connector without circuitry (separate order)

|

|

5

|

Space required to remove the coil

|

|

6

|

Space required to remove the mating connector

|

|

8

|

Name plate

|

|

9

|

Mounting nut, tightening torque MA = 4 Nm

|

|

10

|

With 3/2 directional seat valves version "420", port B is designed as blind counterbore, in version "630", it is not available. With 2/2 directional seat valves version "420", ports A and B are available as blind counterbores.

|

|

11

|

Identical seal rings for ports A, B, and T; seal ring for port P

|

|

12

|

Porting pattern according to DIN 24340, form A

|

|

14

|

Valve mounting screws

|

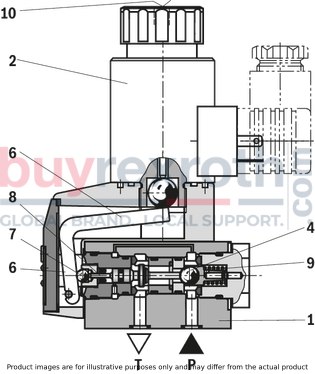

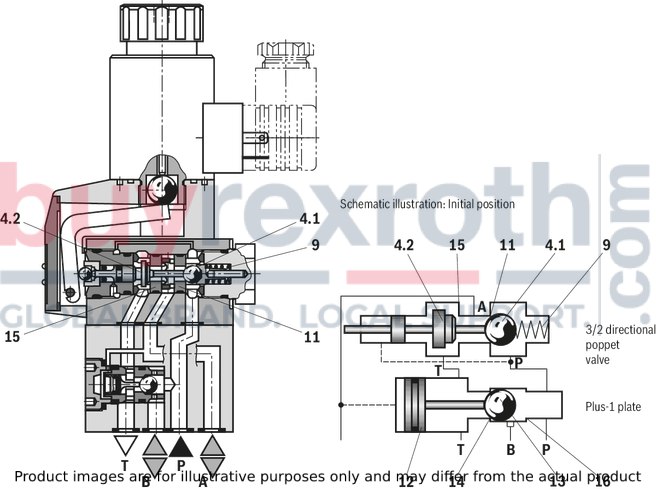

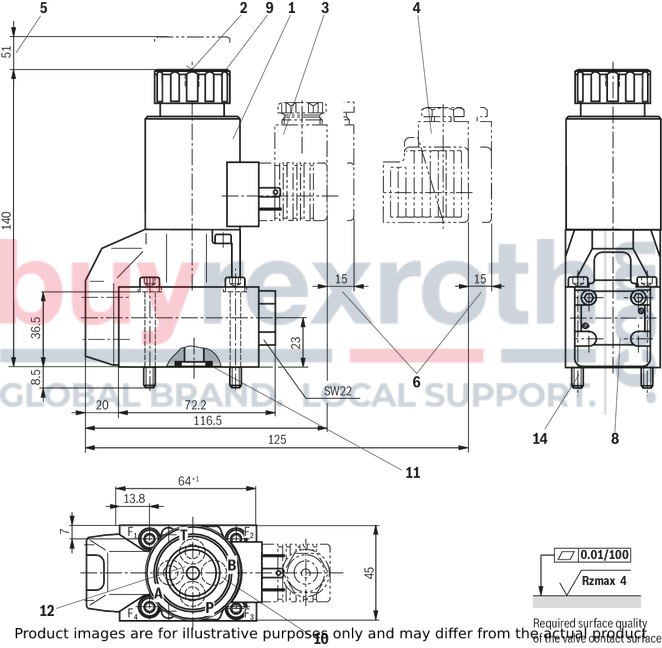

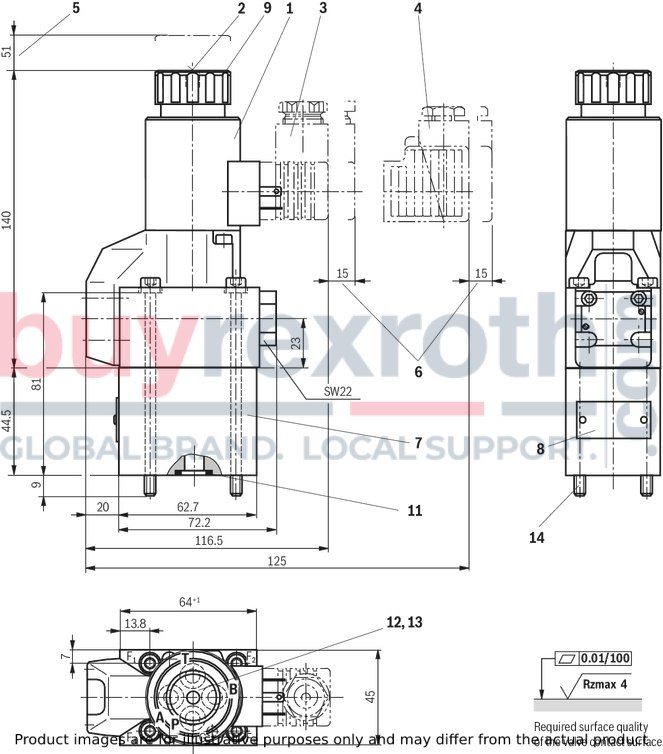

4/2 directional seat valve

Dimensions in mm

4/2 directional seat valve

Dimensions in mm

|

1

|

Solenoid “a”

|

|

2

|

Concealed manual override “N9”

|

|

3

|

Mating connector without circuitry (separate order)

|

|

4

|

Mating connector with circuitry (separate order, see page data separate order, see data sheet 08006)

|

|

5

|

Space required to remove the coil

|

|

6

|

Space required to remove the mating connector

|

|

7

|

Plus-1 plate

|

|

8

|

Name plate

|

|

9

|

Mounting nut, tightening torque MA = 4 Nm

|

|

11

|

Identical seal rings for ports A, B, and T; seal ring for port P

|

|

12

|

Porting pattern according to DIN 24340, form A

|

|

13

|

Porting pattern according to ISO 4401-03-02-0-05 (with locating hole for locking pin ISO 8752-3x8-St, material no. R900005694, included in the scope of delivery)

|

|

14

|

Valve mounting screws

|

Valve mounting screws (separate order)

2/2 and 3/2 directional seat valve

Version “420”:

4 hexagon socket head cap screws metric

ISO 4762 - M5 x 45 - 10.9-flZn-240h-L

(friction coefficient μtotal = 0.09 to 0.14);

tightening torque MA = 7 Nm ± 10 %,

material no. R913000140

or

4 hexagon socket head cap screws

ISO 4762 - M5 x 45 - 10.9 1)

(friction coefficient μges = 0.12 to 0.17);

tightening torque MA = 8,1 Nm ± 10 %

4 hexagon socket head cap screws UNC

10-24 UNC x 1 3/4” ASTM-574 1)

(friction coefficient μtotal = 0.19 to 0.24 according to ASTM-574);

tightening torque MA = 11 Nm ± 15 %,

(friction coefficient μtotal = 0.12 to 0.17 according to ISO 4762);

tightening torque MA = 8 Nm ± 10 %,

material no. R978802649

version “630”:

4 hexagon socket head cap screws metric

ISO 4762 - M6 x 45 - 10.9-flZn-240h-L

(friction coefficient μtotal = 0.09 to 0.14);

tightening torque MA = 12,5 Nm ± 10 %,

material no. metric R913000258

or

4 hexagon socket head cap screws

ISO 4762 - M6 x 45 - 10.9 1)

(friction coefficient μtotal = 0.12 to 0.17);

tightening torque MA = 15,5 Nm ± 10 %

4 hexagon socket head cap screws UNC

1/4-20 UNC x 1 3/4” ASTM-574 1)

(friction coefficient μtotal = 0.19 to 0.24 according to ASTM-574);

tightening torque MA = 20 Nm ± 15 %,

(friction coefficient μtotal = 0.12 to 0.17 according to ISO 4762);

tightening torque MA = 14 Nm ± 10 %,

material no. R978800711

4/2 directional seat valve

version “420”:

4 hexagon socket head cap screws metric

ISO 4762 - M5 x 90 - 10.9-flZn-240h-L

(friction coefficient μtotal = 0.09 to 0.14);

tightening torque MA = 7 Nm ± 10 %,

material no. R913000222

oder

4 hexagon socket head cap screws

ISO 4762 - M5 x 90 - 10.9 1)

(friction coefficient μtotal = 0.12 to 0.17);

tightening torque MA = 8,1 Nm ± 10 %

4 hexagon socket head cap screws UNC

10-24 UNC x 3 1/2” 1)

(friction coefficient μtotal = 0.19 to 0.24 according to ASTM-574);

tightening torque MA = 11 Nmv± 15 %,

(friction coefficient μtotal = 0.12 to 0.17 according to ISO 4762);

tightening torque MA = 8 Nm ± 10 %,

material no. R978800696

version “630”:

4 hexagon socket head cap screws metric

ISO 4762 - M6 x 90 - 10.9-flZn-240h-L

(friction coefficient μtotal = 0.09 to 0.14);

tightening torque MA = 12,5 Nm ± 10 %,

material no. R913000259

or

4 hexagon socket head cap screws

ISO 4762 - M6 x 90 - 10.9 1)

(friction coefficient μtotal = 0.12 to 0.17);

tightening torque MA = 15,5 Nm ± 10 %

4 hexagon socket head cap screws UNC

1/4-20 UNC x 3 1/2” 1)

(friction coefficient μtotal = 0.19 to 0.24);

tightening torque MA = 20 Nm ± 15 %,

(friction coefficient μtotal = 0.12 to 0.17);

tightening torque MA = 14 Nm ± 10 %,

material no. R978800717

1) Not included in the Rexroth delivery range

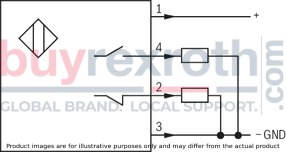

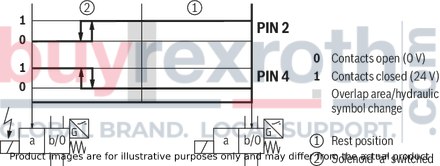

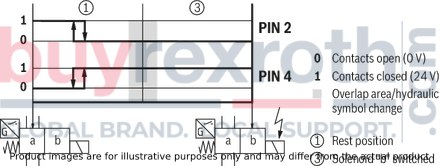

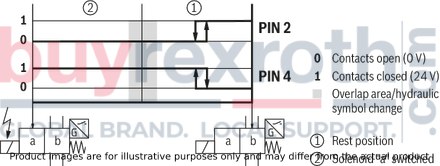

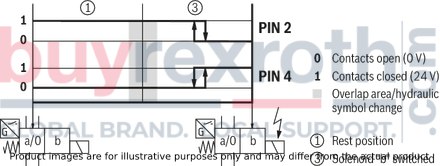

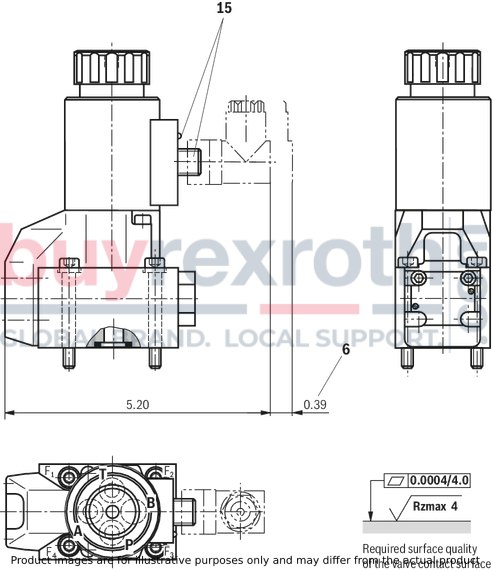

Spool position monitoring

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

M12x1 plug-in connection

Dimensions in mm

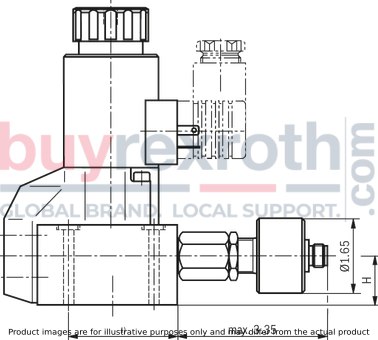

Type M-.SEW 6 .-3X/420MG24.K72L…

Dimensions in mm

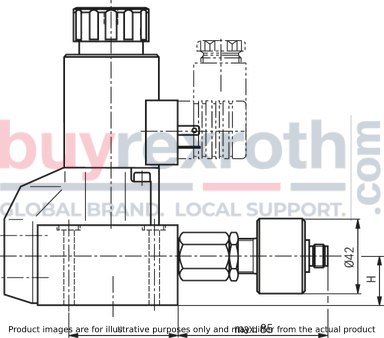

Dimensions in mm

Inductive position switch type QM

Dimensions in mm

|

1)

|

For dimensions, see valve dimensions

|