$45,532.00 USD

More are expected on September 10, 2026

| Qty | Price | Savings |

|---|---|---|

| 5-24 | $44,393.70 USD | $1,138.30 USD |

| 25+ | $43,255.40 USD | $2,276.60 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as September 10, 2026 when ordered in

This product is eligible for factory repair.

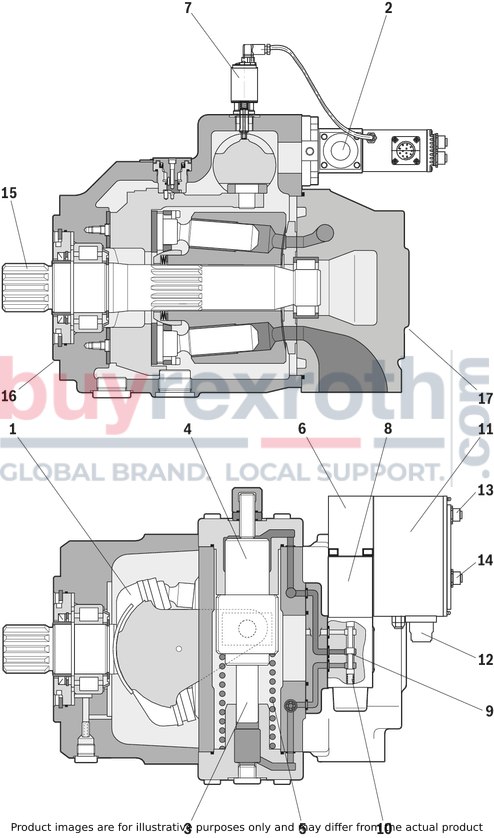

A SYHDFEE-1X control system is used for the electro-hydraulic control of swivel angle, pressure and power (partially optional, see ordering code) of an axial piston variable displacement pump.

The control system consists of the following components: A4VSO axial piston variable displacement pump optimized for the operation in the control system VT-DFPE-2X or VT-DFPD-1X proportional valve as pilot valve including inductive position transducer for valve position sensing. Position transducer for sensing the swivel angle Pressure transducer with suitable signal level and dynamics (optionally HM 20, separate order)

|

1 |

Swash plate |

|

2 |

Pilot control valve |

|

3 |

Counter piston |

|

4 |

Actuating piston |

|

5 |

Spring |

|

6 |

Inductive position transducer for valve position |

|

7 |

Swivel angle position sensor |

|

8 |

Proportional solenoid |

|

9 |

Valve spool |

|

10 |

Spring |

|

11 |

Integral electronics |

|

12 |

Connector X1 |

|

13 |

Connector X2 for connection of the pressure transducer HM 20, cable version (for SYHDFEE only with actual pressurevalue input F, for SYHDFEC/SYHDFEn always available) |

|

14 |

Mating connector X3 for connection of the CAN bus (only available with SYDFEC/SYDFEn) |

|

15 |

Drive shaft |

|

16 |

Connection flange |

|

17 |

Subplate, optionally with through-drive |

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

10 |

11 |

12 |

13 |

14 |

15 |

||||

|

SYHDFEE-1X/ |

125 |

– |

25 |

U99 |

– |

– |

0 |

– |

* |

|

Pump of the SYHDFE.-1X control system |

||||||||

|

Series |

||||||||

|

01 |

Control system with integrated analog electronics |

SYHDFEE‑1X |

||||||

|

Size |

040 |

071 |

125 |

180 |

250 |

355 |

||

|

02 |

Displacement cm³ |

40 |

71 |

125 |

180 |

250 |

355 |

|

|

Direction of rotation looking at the drive shaft |

||||||||

|

03 |

Right |

● |

● |

● |

● |

● |

● |

R |

|

Left |

● |

● |

● |

● |

● |

● |

L |

|

|

Hydraulic fluid |

||||||||

|

04 |

Mineral oil according to DIN 51524 (HL/HLP) |

● |

● |

● |

● |

● |

● |

V |

|

HFC |

– |

● |

● |

● |

● |

● |

F |

|

|

Drive shaft variant |

||||||||

|

05 |

Cylindrical with fitting key DIN 6885 (not in connection with through-drive) |

● |

● |

● |

● |

● |

● |

P |

|

Splined shaft profile DIN 5480 |

● |

● |

● |

● |

● |

● |

Z |

|

|

Connection flange |

||||||||

|

06 |

ISO 4-hole |

● |

● |

● |

● |

● |

● |

B |

|

Port for working lines pressure port B and suction port S |

||||||||

|

07 |

Port B and S: SAE, laterally displaced by 90°, metric mounting thread, 2nd pressure port B1 vis-à-vis B – upon delivery closed by means of flange plate |

● |

● |

● |

● |

● |

● |

25 |

|

Through-drive (All through-drives with single pumps come without a hub and are operationally safe, provided with an end cover) |

||||||||

|

08 |

Universal through-drive U99 closed operationally safe with end cover at the factory; for components for the adaptation of more pump stages, see table Accessories for through-drives |

– |

– |

● |

● |

● |

● |

U99 |

|

Through-drive K99 closed operationally safe with end cover at the factory; for components for the adaptation of more pump stages, see the table in accessories for through-drives |

● |

● |

– |

– |

– |

– |

K99 |

|

|

Without through-drive |

● |

● |

– |

– |

– |

– |

N00 |

|

|

Centering: ISO ⌀100 mm |

– |

● |

– |

– |

– |

– |

KD3 |

|

|

Centering: SAE ⌀82,55 mm |

● |

● |

– |

– |

– |

– |

KC1 |

|

|

Base pump variant |

||||||||

|

09 |

Standard (internal pilot oil) |

● |

● |

● |

● |

● |

● |

0000 |

|

External supply |

● |

● |

● |

● |

● |

● |

0576 |

|

|

Pilot and preload valve of the SYHDFEE control system |

||||||||

|

Spool design |

||||||||

|

10 |

Standard |

A |

||||||

|

4-groove spool (e.g. for HFC fluids) |

C |

|||||||

|

Integrated electronics, installation orientation |

||||||||

|

11 |

Integrated electronics parallel to the pump axis direction subplate |

0 |

||||||

|

Control, additional function |

A |

B |

C |

D |

|

|||

|

12 |

Switchable pressure controller (high signal) |

● |

A |

|||||

|

Power limitation adjustable at the OBE valve |

● |

B |

||||||

|

Power limitation adjustable via analog input |

● |

C |

||||||

|

Pressure controller that can be switched off (high signal) |

● |

D |

||||||

|

Electronics assembly, option |

||||||||

|

13 |

Standard electronics with leakage oil compensation |

● |

● |

● |

● |

0 |

||

|

Standard electronics without leakage oil compensation |

● |

● |

● |

● |

1 |

|||

|

Actual pressure value input |

Plug-in connector |

|||||||

|

14 |

Current input 4...20 mA |

X1 |

C |

|||||

|

Voltage input 0...10 V |

X1 |

V |

||||||

|

Voltage input 1...10 V |

X1 |

E |

||||||

|

Voltage input 0.5...5 V |

X2 |

F |

||||||

|

15 |

Further details in the plain text e. g. SO variant |

* |

||||||

|

● |

available |

|

- |

not available |

Ordering code pump combination SYHDFEE-1X

|

01 |

02 |

03 |

04 |

05 |

||||

|

SY2HDFEE-1X |

/ |

– |

/ |

+ |

|

01 |

2-fold pump |

SY2HDFEE-1X |

|

02 |

Size of the main pump 1) |

|

|

03 |

Size of the attachment pump or pump abbreviation if the attachment pump is not SYHDFE (e.g. PGF) 1) |

|

|

04 |

Material number without "R9" for the main pump or type designation if material number is not known |

|

|

05 |

Material number without "R9" for the attachment pump or type designation if material number is not known |

| 1) | Detailed information see type key |

|

01 |

02 |

03 |

04 |

|||

|

SY3HDFEE-1X |

/ |

+ |

+ |

|

01 |

3-fold pump |

SY3HDFEE-1X |

|

02 |

Material number without "R9" for the main pump or type designation if material number is not known |

|

|

03 |

Material number without "R9" for the attachment pump or type designation if material number is not known |

|

|

04 |

Material number without "R9" for the attachment pump or type designation if material number is not known |

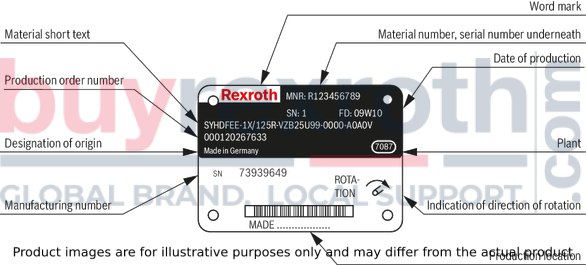

Example of a name plate

Notice:

For enquiries regarding the control system, material number, production order number, serial number, and date of production are necessary.

For applications outside these parameters, please consult us!

mechanic and hydraulic

|

Size |

40 | 71 | 125 | 180 | 250 | 355 | ||||

|

Displacement |

Vg max |

cm³ |

40 | 71 | 125 | 180 | 250 | 355 | ||

|

Speed 1) |

maximum at Vg max |

no |

rpm |

2600 | 2200 | 1800 | 1900 | 1700 | ||

|

maximum at Vg max and HFC fluids |

no |

rpm |

2200 | 1800 | 1500 | |||||

|

Minimum speed 2) |

nmin |

rpm |

200 | |||||||

|

Min. Speed at HFC-fluids |

with ν = 25 mm2/s |

nmin |

rpm |

750 | 850 | 600 | 550 | 450 | ||

|

Max. flow (displacement) |

at n0 and Vg max |

qv0 max |

l/min |

104 | 156 | 225 | 324 | 450 | 533 | |

|

with nE = 1500 min-1 and Vg max |

qvE max |

l/min |

60 | 107 | 186 | 270 | 375 | 533 | ||

|

Max. power (Δp = 350 bar) |

at n0 and Vg max |

P0 max |

kW |

61 | 91 | 131 | 189 | 263 | 311 | |

|

with nE = 1500 min-1 and Vg max |

PE max |

kW |

35 | 62 | 109 | 158 | 219 | 311 | ||

|

Max. torque (Δp = 350 bar) |

Tmax |

Nm |

223 | 395 | 696 | 1002 | 1391 | 1976 | ||

|

Maximum permissible drive torque |

Fitting key |

Ttotal |

Nm |

380 | 700 | 1392 | 1400 | 2300 | 3557 | |

|

Splined shaft S overall torque |

Ttotal |

Nm |

446 | 790 | 1392 | 2004 | 2782 | 3952 | ||

|

Max. admissible through-drive torque |

TD |

Nm |

223 | 395 | 696 | 1002 | 1391 | 1976 | ||

|

Drive shaft load |

|

max. admissible axial force |

Fax max |

N |

600 | 800 | 1000 | 1400 | 1800 | 2000 |

|

max. admissible radial force 3) |

Fq |

N |

1000 | 1200 | 1600 | 2000 | 2200 | |||

|

Weight without filling quantity |

m |

kg |

39 | 53 | 88 | 102 | 184 | 207 | ||

|

Moment of inertia around drive axis |

kg·m² |

0.0049 | 0.0121 | 0.03 | 0.055 | 0.0959 | 0.19 | |||

|

Filling quantity of the housing |

l |

2 | 2.5 | 5 | 4 | 10 | 8 | |||

|

Maximum admissible operating pressure 4) |

pmax |

bar |

350 | |||||||

|

Operating pressure, min. (without load) |

pmin |

bar |

≥ 20 | |||||||

|

Admissible inlet pressure |

p |

bar |

0.8 ... 30 | |||||||

|

Hydraulic fluid |

Mineral oil (HL, HLP) according to DIN 51524; HFC optional | |||||||||

|

Hydraulic fluid temperature range |

ϑ |

°C |

-20 … +70 | |||||||

|

Maximum admissible degree of contamination of the hydraulic fluid according to ISO 4406 |

Class 18/16/13 (for particle size ≤ 4/6/14 μm) | |||||||||

| 1) | The values are applicable at an absolute pressure of 1 bar at the suction opening S. With a reduction of the displacement or an increase in the inlet pressure, the speed can be increased according to the following characteristic curve. With a reduced inlet pressure, the speed is to be reduced. |

| 2) | Does not apply to HFC fluid, formula for determination of the minimum speed see below |

| 3) | In case of higher radial forces, please consult us. Not applicable for use of HFC fluids. |

| 4) | When using HFC fluids, also see data sheet 92053. |

Admissible load ‒ determination of nominal load and minimum speed

| 1) | At SYHDFEN, the minimum speed can be determined by means of the derating function. |

Example 1:

A4VSO125 may be operated at ν = 16 mm2/s

as of n = 1328 rpm with nominal load

Example 2:

the admissible load for A4VSO250

is n = 500 rpm and 10 mm2/s

x = 10/25*500/550 = 0.364 (= 127 bar at Vgmax)

electrical

|

Size |

40 | 71 | 125 | 180 | 250 | 355 | |||

|

Operating voltage |

UB |

24 VDC +40 % –5 % | |||||||

|

Operating range (short-time operation) |

Upper limit value |

UB(t)max |

V |

35 | |||||

|

Lower limit value |

UB(t)min |

V |

21 | ||||||

|

Current consumption (in static control operation) |

Rated current |

Inom |

A |

0.6 | |||||

|

Maximum current |

Imax |

A |

1.25 | ||||||

|

Inputs |

Actual pressure value input X1; |

U or I |

Determination by means of ordering code | ||||||

|

Analog current inputs, load |

RB |

100 Ω | |||||||

|

Analog voltage inputs |

RE |

≥ 50 kΩ | |||||||

|

Digital inputs |

Logic 0 |

≤ 0,6 V | |||||||

|

Logic 1 |

≥ 21 V | ||||||||

|

Outputs |

pactual / UOUT1 |

UO 1) |

0 ... 10 V | ||||||

|

Imax 1) |

1,5 mA | ||||||||

|

αactual / UOUT2 |

UO 1) |

± 10 V | |||||||

|

Imax 1) |

1,5 mA | ||||||||

|

Digital outputs |

Logic 0 |

Ua < 1 V | |||||||

|

Logic 1 |

Ua ≥ UB – 5 V; 10 mA (short-circuit-proof) | ||||||||

|

Ambient temperature range at the pump |

ϑ |

°C |

0 … 60 | ||||||

|

Storage temperature range (pump + electronics) |

ϑ |

°C |

0 … 70 | ||||||

|

Electronics design |

Integrated in the pilot valve (OBE) | ||||||||

|

Type of protection according to EN 60529 |

Pump incl. pilot valve |

IP65 with mounted and locked plug-in connectors | |||||||

|

Power limitation |

optional | ||||||||

| 1) | With SYDFEC, the outputs are parameterizable, for the condition as supplied, see electrical connection |

Notice:

For information on the environment simulation testing for the areas of EMC (electro-magnetic compatibility), climate and mechanical load, see data sheet 30030-U.

Bearing flushing

With the following operating conditions, bearing flushing is necessary for safe continuous operation:

Applications with special fluids (not mineral fluids) due to limited lubricity and tight operating temperature range Operation with boundary conditions of temperature and viscosity with mineral oil operationWith vertical installation (drive shaft upwards), bearing flushing is recommended for lubrication of the front bearing and the shaft seal ring.

The bearing is flushed using port "U" in the area of the front flange of the variable displacement pump. The flushing fluid flows through the front bearing and exits with the pump leakage at the leakage connection.

For the individual sizes, the following flushing quantities are recommended:

|

Size |

40 | 71 | 125 | 180 | 250 | 355 | ||

|

recommended flushing quantity |

qSp |

l/min |

3 | 4 | 5 | 7 | 10 | 15 |

The specified flushing quantities result in a pressure differential between port "U” (including fitting) and the leakage chamber of approx. 2 bar (series 1) and approx. 3 bar (series 3).

When using the external bearing flushing, the throttle screw in port U has to be screwed-in to the stop.

Leakage pressure

The admissible leakage pressure (housing pressure) depends on the speed (see diagram).

Max. leakage pressure (housing pressure)

pL abs max = 4 bar absolute

These specifications are guidelines; under special operating conditions, a limitation may become necessary.

Flow direction

S → B

Control loop quality

Notes:

The specified values are only valid when using the system-related components specified in this data sheet. At pressures < 20 bar, higher tolerances have to be anticipated due to lower actuating forces.|

Swivel angle control |

Pressure control 1) |

|

|

Linearity tolerance |

≤ 1.0 % |

≤ 1.5 % |

|

Temperature error |

≤ 0.5 % / 10 K |

≤ 0.5 % / 10 K |

|

Hysteresis |

≤ 0.2 % |

≤ 0.2 % |

|

Repetition accuracy |

≤ 0.2 % |

≤ 0.2 % |

| 1) | Without considering the pump pulsation. |

Through-drives: Torques

|

Admissible drive and through-drive torques |

||||||||

|

Size |

40 |

71 |

125 |

180 |

250 |

355 |

||

|

Splined shaft |

||||||||

|

Maximally admissible total drive torque at the shaft of pump 1 (pump 1 + pump 2) |

TGes max |

[Nm] |

446 |

790 |

1392 |

2004 |

2782 |

3952 |

|

A Admissible through-drive torque |

TD1 max |

[Nm] |

223 |

395 |

696 |

1002 |

1391 |

1976 |

|

TD2 max |

[Nm] |

223 |

395 |

696 |

1002 |

1391 |

1976 |

|

|

B Admissible through-drive torque |

TD1 max |

[Nm] |

223 |

395 |

696 |

1002 |

1391 |

1976 |

|

TD2 max |

[Nm] |

223 |

395 |

696 |

1002 |

1391 |

1976 |

|

|

Fitting key |

||||||||

|

Maximally admissible total drive torque at the shaft of pump 1 (pump 1 + pump 2) |

TGes max |

[Nm] |

380 |

700 |

1392 |

1400 |

2300 |

3557 |

|

A Admissible through-drive torque |

TD1 max |

[Nm] |

223 |

395 |

696 |

1002 |

1391 |

1976 |

|

TD2 max |

[Nm] |

157 |

305 |

696 |

398 |

909 |

1581 |

|

|

B Admissible through-drive torque |

TD1 max |

[Nm] |

157 |

305 |

696 |

398 |

909 |

1581 |

|

TD2 max |

[Nm] |

223 |

395 |

696 |

1002 |

1391 |

1976 |

|

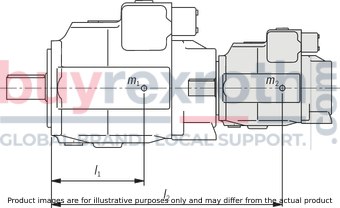

Distribution of the torques

Admissible mass torque

related to mounting flange of the main pump

|

Tm [Nm] |

Admissible mass torque |

|

m1, m2 [kg] |

Weight of the pump |

|

l1, l2 [mm] |

Distance of the center of gravity |

|

Size |

40 |

71 |

125 |

180 |

250 |

355 |

||

|

Admissible mass torque |

Tm zul. |

Nm |

1800 |

2000 |

4200 |

4200 |

9300 |

9300 |

|

Admissible mass torque with dynamic mass acceleration of 10 g = 98.1 m/sec2 |

Tm zul. |

Nm |

180 |

200 |

420 |

420 |

930 |

930 |

|

Weight (SYHDFE or A4VSO...DR) |

m |

kg |

39 |

53 |

88 |

102 |

184 |

207 |

|

Distance of the center of gravity |

l1 |

mm |

120 |

140 |

170 |

180 |

210 |

220 |

Tightening torques:

The tightening torques specified in this data sheet are maximum values and must not be exceeded (maximum values for screw-in threads).Manufacturer's specifications on the max. admissible tightening torques of the fittings used are to be observed! For mounting screws according to DIN 13, we recommend checking the tightening torque case by case according to VDI 2230, version 2003.

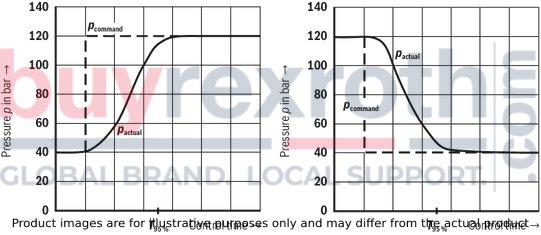

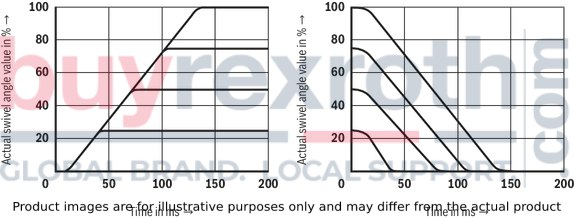

Transition function with pressure command value step with spool design "A"

The specified curve shapes and control times refer to a drive speed of 1500 rpm and are only reached with an optimization of the pressure controller.

T95% in ms with a connected hydraulic fluid volume (lines and actuators)

|

Hydraulic fluid volume |

T95% |

|

5 – 10 l |

200 ms |

|

15 – 25 l |

250 ms |

| For pressures up to 40 bar, the values of the response times are greater. |

Transition function with swivel angle command value step with spool design "A"

Size 40, 71 p = 100 bar

Size 125 p = 100 bar

Size 180 p = 100 bar

Size 250 p = 100 bar

Size 355 p = 100 bar

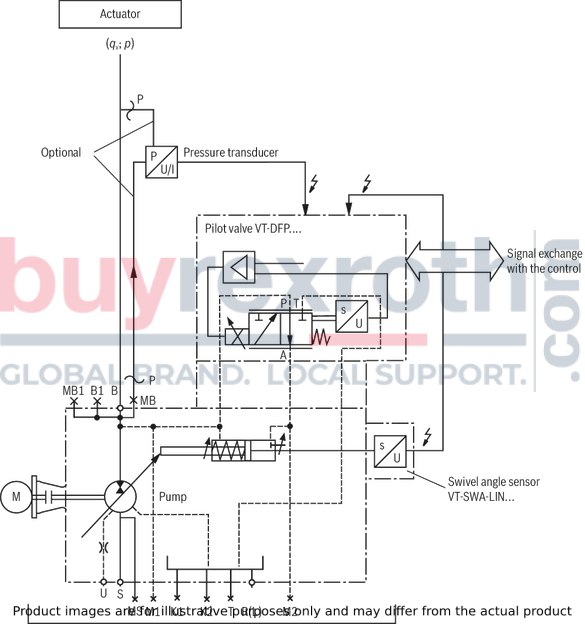

Schematic diagram: Actuating system supplied internally

|

S |

Suction port |

|

K1, K2 |

Flushing port |

|

T |

Fluid drain |

|

MB |

Measuring port operating pressure (M14x1,5) |

|

MS |

Measuring port suction pressure |

|

M1, M2 |

Measuring port control chamber pressure |

|

R(L) |

Fluid filling + bleeding (leakage connection) |

|

U |

Flushing port |

|

B |

Pressure port |

|

B1 |

2nd Pressure port/additional port |

|

MB1 |

Measuring port operating pressure |

When using the HM20-2X/...C13 pressure transducer:

Installation in MB or MB1 (pump) in connection with electronic version "actual pressure value input F" For attaching an HM20-2X/315-F-C13-0,5 in MB attachment, an adapter from M14x1.5 to G1/4 (mat. no. R900695665) is necessary. Due to the installation position, the HM20 cable version cannot be used for all sizes without restrictions (use with M12 extension cable).When using an external pressure transducer:

Installation in the B line (preferably close to the actuator) and electrical connection via the central connection X1. Explanation in the operating instructions.

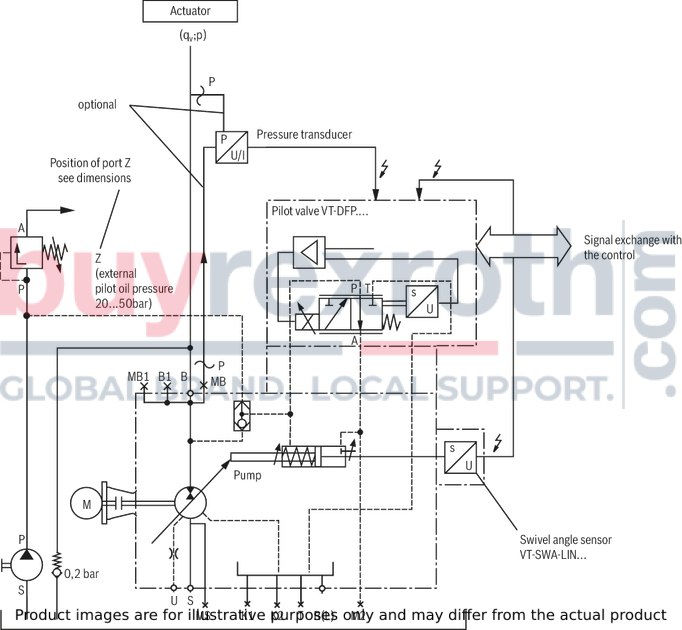

Schematic diagram: Actuating system supplied externally

|

S |

Suction port |

|

K1, K2 |

Flushing port |

|

T |

Fluid drain |

|

MB |

Measuring port operating pressure (M14x1,5) |

|

MS |

Measuring port suction pressure |

|

M1, M2 |

Measuring port control chamber pressure |

|

R(L) |

Fluid filling + bleeding (leakage connection) |

|

U |

Flushing port |

|

B |

Pressure port |

|

B1 |

2nd Pressure port/additional port |

|

MB1 |

Measuring port operating pressure |

|

Z |

external pilot oil pressure |

Important notes on external supply:

In the case of an actuating system with external supply, the pump adjustment will - in case of voltage failure - not switch to zero stroke but to the negative stop (displacement of 100 % flow from the system to the tank). With an active fault message, it is imperative that the machine control reacts (e. g. switching off the drive motor of the pump, interrupting the external supply of the actuating system). The command values for pressure and flow must always be greater than zero (pcommand ≥ 3 bar, αcommand ≥ 5 %) as due to drift or tolerances, there is no exact "zero" pressure or "zero" swivel angle. Under unfavorable conditions, smaller command value presettings can lead to cavitation. The actual pressure value must not be less than 10 bar for more than 10 minutes (lubrication).

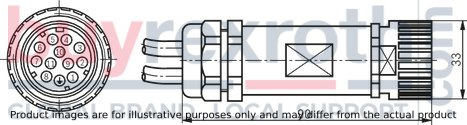

Allocation of connector or mating connector and cable set

X1: Central connection

Mating connector according to EN 175201-804 (12-pole), for the ordering code, see Accessories.

|

Pin |

Signal |

Description |

Signal direction |

Type of signal |

Allocation in the cable set (accessories) |

|

|

1 |

+ UB |

Voltage supply |

IN |

24 V DC |

1 |

Supply line 3 x 1.0 mm2 |

|

2 |

0 V = L0 |

Reference potential for the voltage supply |

– |

2 |

||

|

PE |

Earth |

Earthing connection for the electronics |

– |

green/yellow |

||

|

3 |

Fault |

Signals faults, e.g. cable break command / actual values, controller monitoring (logic 0 = error) |

OUT |

logic 24 V |

white |

Supply line 10 x 0.14 mm2 shielded (one end of the shield must be connected to the control!) |

|

4 |

M0 |

Reference potential for analog signals |

– |

yellow |

||

|

5 |

αCommand |

Swivel angle command value |

IN |

analog ±10 V |

green |

|

|

6 |

αActual |

Actual swivel angle value, normalized |

OUT |

analog ±10 V |

Violet |

|

|

7 |

pCommand |

Pressure command value |

IN |

analog 0...10 V 1) |

pink |

|

|

8 |

pActual |

Actual pressure value, normalized |

OUT |

analog 0...10 V |

red |

|

|

9 |

Function dependent on electronic type and additional function, see table Functions at pin 9 |

brown |

||||

|

10 |

Actual pressure value H |

Actual pressure value input: Signal level dependent on feature 14 of the ordering codes Reserved with type "F" (0.5...5 V) |

IN |

analog |

black |

|

|

11 |

Actual pressure value L |

– |

analog |

blue |

||

|

n.c. |

gray |

|||||

| 1) | When using a pressure transducer with raised zero point (e. g. 4 ... 20 mA), a voltage of –1 ... –2.5 V will be output in case of a cable break. |

Functions at pin 9

|

Pin |

Additional function |

Function dependent on feature 12 of the ordering codes (see page type key pilot and preload valve) |

Signal direction |

Type of signal |

|

9 |

-..A… |

Selecting a different oil volume adjustment (switch TD) |

IN |

logic 24 V |

|

-..B… |

Power limitation active |

OUT |

logic 24 V |

|

|

-..C… |

Command value of power limitation |

IN |

analog 0...10 V |

|

|

-..D… |

Switch off pressure controller |

IN |

logic 24 V |

X2: Connection of pressure transducer HM 20 HM 20-2X/315-F-C13-0,5 (cable version) (mating connector M12)

Top view mating connector

|

Pin |

Signal HM 20 |

Pin |

|

|

1 |

OUT, +UB |

2 |

n.c. |

|

3 |

Reference L0 |

||

|

4 |

IN, analog, 0.5 to 5 V DC |

5 |

n.c. |

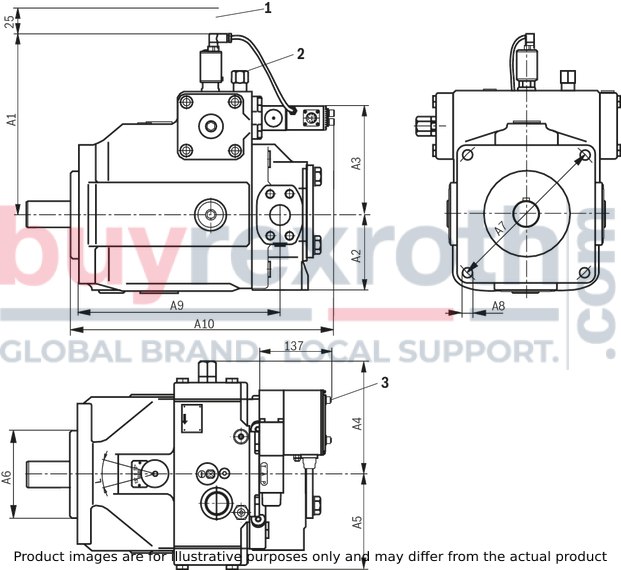

The unit dimensions of the base pump (axial piston variable displacement pump A4VSO) are contained in data sheet 92050.

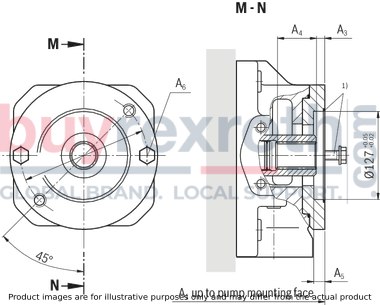

Dimensions in mm

|

1 |

Space required to remove the mating connector |

|

2 |

Port Z (for version SYHDFE.-1X...0576) |

|

3 |

Connection X2 (pressure transducer HM 16) is available with actual pressure value input F |

|

Size |

A1 |

A2 |

A3 |

A4 |

A5 |

A6 |

A7 |

A8 |

A9 |

A10 |

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

|

| 40 | 239 | 80 | 127 | 130 | 104 | 125 | 160 | 15 | 227 | 325 |

| 71 | 256 | 92.5 | 141 | 149 | 127 | 140 | 180 | 15 | 254 | 352 |

| 125 | 291 | 112.5 | 171 | 177 | 147 | 160 | 200 | 20 | 310 | 421 |

| 180 | 291 | 116 | 171 | 177 | 147 | 160 | 200 | 20 | 318 | 421 |

| 250 | 339 | 144 | 207 | 212 | 179 | 224 | 280 | 24 | 380 | 483 |

| 355 | 339 | 144 | 207 | 212 | 179 | 224 | 280 | 24 | 393 | 575 |

Shaft ends:

|

Size |

Shaft Ø |

= P 1) |

= Z 2) |

|

mm |

|||

| 40 | 32 | AS 10x8x56 | W 32x2x14x9g |

| 71 | 40 | AS 12x8x68 | W 40x2x18x9g |

| 125 | 50 | AS 14x9x80 | W 50x2x24x9g |

| 180 | 50 | AS 14x9x80 | W 50x2x24x9g |

| 250 | 60 | AS 18x11x100 | W 60x2x28x9g |

| 355 | 70 | AS 20x12x100 | W 70x3x22x9g |

| 1) | Cylindrical with fitting key DIN 6885 |

| 2) | Splined shaft profile DIN 5480 |

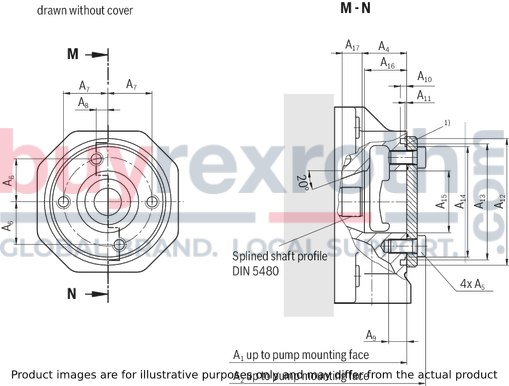

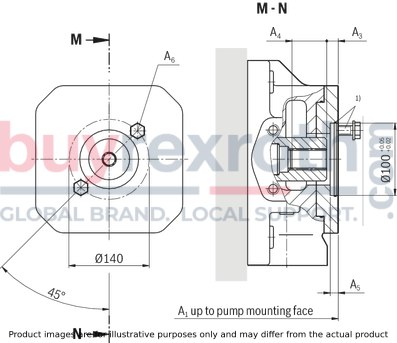

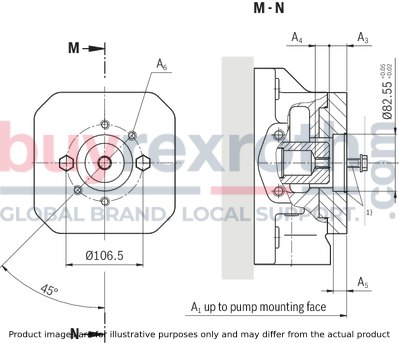

Through-drive "K99"

The control systems of size 40 to 71 are partly supplied with through-drive K99.

Their advantage is that the through-drive can be subsequently modified. By simply exchanging the intermediate flange and the hub, the through-drive can be adjusted to the on-site requirements.

The assemblies as exchange kits can be ordered separately, see "Accessories for through-drives" as well as data sheet 95581.

Small centering diameters are directly worked into the pump subplate. Subsequent modification is not possible. Please note the type key under ordering code and the overview under "Accessories for through-drives". Hubs for through-drives can be ordered separately.

Size 40 to 71

with through-drive shaft, without hub, without intermediate flange, closed by means of a pressure-resistant cover in a fluid-tight way

Dimensions in mm

|

Size |

A1 |

A2 |

A4 |

A5 |

A6 |

A7 |

A8 |

A9 |

A10 |

A11 |

⌀A12 |

⌀A13 |

⌀A14 |

⌀A15 |

A16 |

A17 |

Splined shaft profile DIN 5480 |

1)O-ring for subsequent attachment |

||||||||

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

|||||

| 40 | 263 | 280 | 51.3 | ± 1 | M12; 25 mm deep | 37 | + 0.2 | 37 | + 0.2 | 0 |

- - |

18 | 9 | 2.3 | + 0.1 | 118 | H7 | 105 | g6 | 97.6 | - 0.4 | 52 | 44 | 14 | W25 x 1,25 x 18 x 9 g | 99 x 3 |

| 71 | 291 | 310 | 48 | ± 1 | M12; 25 mm deep | 42.3 | + 0.15 | 45 | + 0.15 | 15.4 |

- ± 15 |

18 | 9 | 2.7 | + 0.1 | 130 | H7 | 116 | g6 | 106.4 | - 0.4 | 63 | 38 | 16 | W30 x 1,25 x 22 x 9 g | 110,72 x 3,53 |

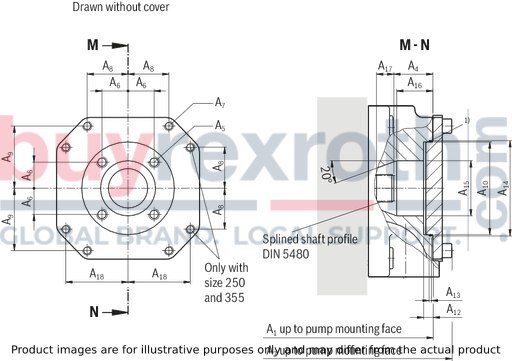

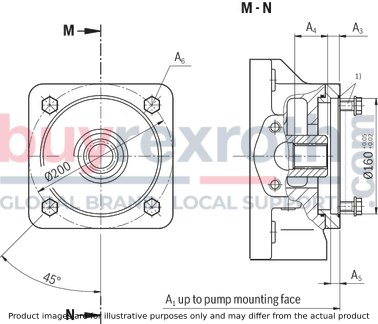

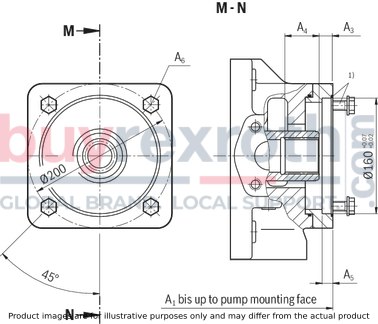

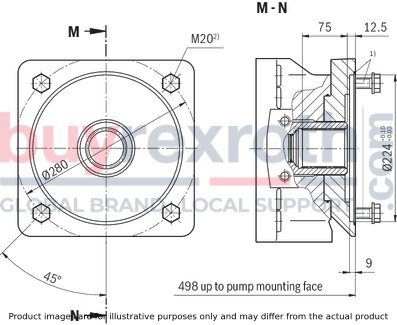

Through-drive "U99"

The control systems of size 125 to 355 are supplied with universal through-drives U99.

Their advantage is that the through-drive can be subsequently modified. By simply exchanging the intermediate flange and the hub, the through-drive can be adjusted to the on-site requirements.

The assemblies as exchange kits can be ordered separately, see "Accessories for through-drives" as well as data sheet 95581.

Size 125 to 355

with through-drive shaft, without hub, without intermediate flange, closed by means of a pressure-resistant cover in a fluid-tight way

|

Size |

A1 |

A2 |

A4 |

A5 |

A6 |

A7 |

A8 |

A9 |

ØA10 |

A12 |

A13 |

ØA14 |

ØA15 |

A16 |

A17 |

A18 |

Splined shaft profile DIN 5480 |

1)O-ring for subsequent attachment |

||||||||

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

|||||

| 125 | 347 | 368 | 49.7 | ± 1 | M14; 15 deep | 33.2 |

+ 0.15 0 |

M12; 18 deep | - |

- - |

79.2 |

+ 0.15 0 |

118 |

H7 |

9 | 2.8 |

+ 0.2 0 |

121 |

+ 0.1 + 0 |

70 | 46 | 22 | - |

- - |

W35 x 1.25 x 26 x 9 g | 118 x 2 |

| 180 | 371 | 392 | 49.7 | ± 1 | M14; 15 deep | 33.2 |

+ 0.15 0 |

M12; 18 deep | - |

- - |

79.2 |

+ 0.15 0 |

118 |

H7 |

9 | 2.8 |

+ 0.2 0 |

121 |

+ 0.1 + 0 |

70 | 46 | 25 | - |

- - |

W35 x 1.25 x 26 x 9 g | 118 x 2 |

| 250 | 431 | 455 | 61.4 | ± 1 | M20; 22 deep | 44.5 |

+ 0.15 0 |

M10; 15 deep | 58.15 |

+ 0.15 0 |

86.2 |

+ 0.15 0 |

160 |

H7 |

9 | 2.8 |

+ 0.2 0 |

163 |

+ 0.1 + 0 |

87 | 64 | 30.5 | 86.2 |

+ 0.15 0 |

W42 x 1.25 x 32 x 9 g | 160 x 2 |

| 355 | 460 | 487 | 61.4 | ± 1 | M20; 22 deep | 44.5 |

+ 0.15 0 |

M10; 15 deep | 58.15 |

+ 0.15 0 |

86.2 |

+ 0.15 0 |

160 |

H7 |

9 | 2.8 |

+ 0.2 0 |

163 |

+ 0.1 + 0 |

87 | 64 | 34 | 86.2 |

+ 0.15 0 |

W42 x 1.25 x 32 x 9 g | 160 x 2 |

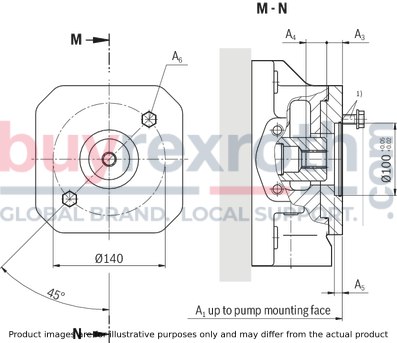

UB3

Flange ISO 3019-2 100, 2-hole

Hub for splined shaft, 22-4 SAE B, 7/8 ″, 16/32 DP; 13T 2)

for attaching an A10VSO 28/31 splined shaft S (see data sheet 92711)

Dimensions in mm

| 1) | Mounting screws and O-ring seal are included in the scope of delivery |

| 2) | according to ANSI B92.1a-1976, 30° pressure angle, flat root, side fit, tolerance class 5 |

|

Size |

A1 |

A3 |

A4 |

A5 |

A6 1) |

||||

|

mm |

mm |

mm |

mm |

||||||

| 125 | 369 | - | 20.5 | - | 24.9 | - | 10 | - | M12 |

| 180 | 393 | - | 20.5 | - | 24.9 | - | 10 | - | M12 |

| 250 | - | in preparation | - | in preparation | - | in preparation | - | in preparation | in preparation |

| 355 | - | in preparation | - | in preparation | - | in preparation | - | in preparation | in preparation |

| 1) | Thread according to DIN 13, for the max. tightening torques, the installation information is to be observed |

| Before determining your design, please request a binding installation drawing. |

UB4

Flange ISO 3019-2 100, 2-hole

Hub for splined shaft, 25-4 SAE B-B, 1 ″, 16/32 DP; 15T 2)

for attaching an A10VSO 45/31 splined shaft S (see data sheet 92711)

Dimensions in mm

| 1) | Mounting screws and O-ring seal are included in the scope of delivery |

| 2) | according to ANSI B92.1a-1976, 30° pressure angle, flat root, side fit, tolerance class 5 |

|

Size |

A1 |

A3 |

A4 |

A5 |

A6 1) |

|

mm |

mm |

mm |

mm |

||

| 125 | 369 | 18.9 | 29.5 | 10 | M12 |

| 180 | 393 | 18.9 | 29.5 | 10 | M12 |

| 250 | 453 | 20.9 | 29.5 | 10 | M12 |

| 355 | 482 | 20.9 | 29.5 | 10 | M12 |

| 1) | Thread according to DIN 13, for the max. tightening torques, the installation information is to be observed |

| Before determining your design, please request a binding installation drawing. |

UB8

Flange ISO 3019-2 160, 4-hole

Hub for splined shaft, 32-4 SAE C, 1 1/4 ″, 12/24 DP; 14T 2)

for attaching an A10VSO 71/32 splined shaft S (see data sheet 92714)

Dimensions in mm

| 1) | Mounting screws and O-ring seal are included in the scope of delivery |

| 2) | according to ANSI B92.1a-1976, 30° pressure angle, flat root, side fit, tolerance class 5 |

|

Size |

A1 |

A3 |

A4 |

A5 |

A6 1) |

||||

|

mm |

mm |

mm |

mm |

||||||

| 125 | - | in preparation | - | in preparation | - | in preparation | - | in preparation | in preparation |

| 180 | - | in preparation | - | in preparation | - | in preparation | - | in preparation | in preparation |

| 250 | 453 | - | 20.9 | - | 38 | - | 9 | - | M16 |

| 355 | - | in preparation | - | in preparation | - | in preparation | - | in preparation | in preparation |

| 1) | Thread according to DIN 13, for the max. tightening torques, the installation information is to be observed |

| Before determining your design, please request a binding installation drawing. |

UB7

Flange ISO 3019-2 180, 4-hole

Hub for splined shaft, 44-4 SAE D, 1 3/4 ″, 8/16 DP; 13T 2)

for attaching an A10VSO 140/31(32) splined shaft S (see data sheet 92711 (RE 92714))

Dimensions in mm

| 1) | Mounting screws and O-ring seal are included in the scope of delivery |

| 2) | according to ANSI B92.1a-1976, 30° pressure angle, flat root, side fit, tolerance class 5 |

1) Mounting screws and O-ring seal are included in the scope of delivery

2) according to ANSI B92.1a-1976, 30° pressure angle, flat root, side fit, tolerance class 5

|

Size |

A1 |

A3 |

A4 |

A5 |

A6 1) |

|

mm |

mm |

mm |

mm |

||

| 180 | 406 | 10.6 | 62 | 9 | M16 |

| 250 | 453 | 10.6 | 64 | 9 | M16 |

| 355 | 482 | 10.6 | 4 | 9 | M16 |

| 1) | Thread according to DIN 13, for the max. tightening torques, the installation information is to be observed |

| Before determining your design, please request a binding installation drawing. |

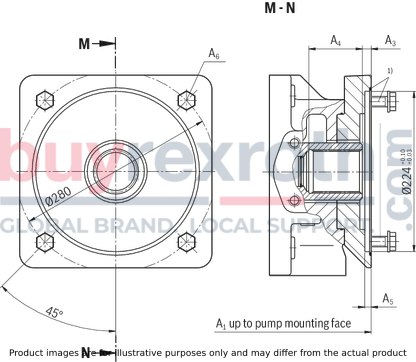

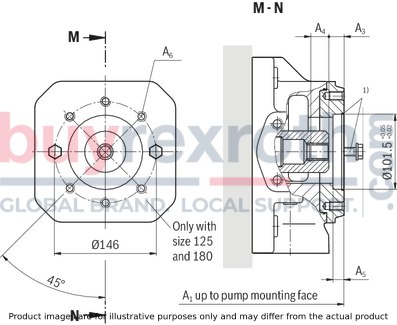

U34

Flange ISO 3019-2 160, 4-hole

Hub according to DIN 5480 N50x2x24x8H

for attaching an A4VSO/G 125 or 180 splined shaft

Dimensions in mm

| 1) | Mounting screws and O-ring seal are included in the scope of delivery |

|

Size |

A1 |

A3 |

A4 |

A5 |

A6 1) |

|

mm |

mm |

mm |

mm |

||

| 125 | 369 | 12.5 | 51.6 | 9 | M16 |

| 180 | 393 | 12.5 | 51.6 | 9 | M16 |

| 250 | 453 | 12.5 | 54 | 9 | M16 |

| 355 | 482 | 12.5 | 54 | 9 | M16 |

| 1) | Thread according to DIN 13, for the max. tightening torques, the installation information is to be observed |

| Before determining your design, please request a binding installation drawing. |

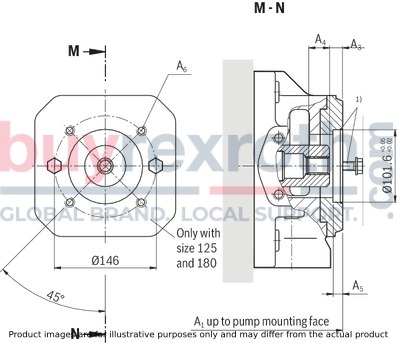

U35

Flange ISO 3019-2 224, 4-hole

Hub according to DIN 5480 N60x2x28x8H

for attaching an A4VSO/G or A4CSG 250 splined shaft

Dimensions in mm

| 1) | Mounting screws and O-ring seal are included in the scope of delivery |

|

Size |

A1 |

A3 |

A4 |

A5 |

A6 1) |

|

mm |

mm |

mm |

mm |

||

| 250 | 469 | 12.6 | 75 | 9 | M20 |

| 355 | 498 | 12.6 | 75 | 9 | M20 |

| 1) | Thread according to DIN 13, for the max. tightening torques, the installation information is to be observed |

| Before determining your design, please request a binding installation drawing. |

U77

Flange ISO 3019-2 224, 4-hole

Hub according to DIN 5480 N70x3x22x8H

for attaching an A4VSO/G or A4CSG 355 splined shaft

Dimensions in mm

| 1) | Mounting screws and O-ring seal are included in the scope of delivery |

| 2) | Thread according to DIN 13, for the max. tightening torques, the installation information is to be observed |

Size 355

Before determining your design, please request a binding installation drawing.

U01

Flange ISO 3019-1 82-2 (SAE A)

Hub for splined shaft, 16-4 SAE A, 5/8 ″, 16/32 DP; 9T 2)

for attaching an external gear pump AZ-PF-1X-004 ... 022 (see data sheet 10089)

Rexroth recommends a special version of the gear pumps, please contact us

Dimensions in mm

| 1) | Mounting screws and O-ring seal are included in the scope of delivery |

| 2) | according to ANSI B92.1a-1976, 30° pressure angle, flat root, side fit, tolerance class 5 |

|

Size |

A1 |

A3 |

A4 |

A5 |

A6 1) |

|

mm |

mm |

mm |

mm |

||

| 125 | 369 | 16 | 19.4 | 13 | M10 |

| 180 | 393 | 16 | 19.4 | 13 | M10 |

| 250 | 453 | 16 | 19.4 | 13 | M10 |

| 355 | 482 | 16 | 19.4 | 13 | M10 |

| 1) | Thread according to DIN 13, for the max. tightening torques, the installation information is to be observed |

| Before determining your design, please request a binding installation drawing. |

U68

Flange ISO 3019-1 101-2 (SAE B)

Hub for splined shaft, 22-4 SAE B, 7/8 ″, 16/32 DP; 13T 2)

for attaching an external gear pump AZ-PN-1x020...032 (see data sheet 10091) or an A10VO 28/31 and 52(53) splined shaft S (see data sheet 92701 and 92703)

Rexroth recommends special versions of the gear pumps, please contact us

Dimensions in mm

| 1) | Mounting screws and O-ring seal are included in the scope of delivery |

| 2) | according to ANSI B92.1a-1976, 30° pressure angle, flat root, side fit, tolerance class 5 |

|

Size |

A1 |

A3 |

A4 |

A5 |

A6 1) |

|

mm |

mm |

mm |

mm |

||

| 125 | 369 | 28 | 25 | 13 | M12 |

| 180 | 393 | 28 | 25 | 13 | M12 |

| 250 | 453 | 19.5 | 23.1 | 13 | M12 |

| 355 | 482 | 19.5 | 23.1 | 13 | M12 |

| 1) | Thread according to DIN 13, for the max. tightening torques, the installation information is to be observed |

| Before determining your design, please request a binding installation drawing. |

U04

Flange ISO 3019-1 101-2 (SAE B)

Hub for splined shaft, 25-4 SAE B-B, 1 ″, 16/32 DP; 15T 2)

for attaching an A10VO 45/31 and 52 (53) splined shaft S (see data sheet 92701 and 92703) or an internal gear pump PGH4 (see data sheet 10223)

Dimensions in mm

| 1) | Mounting screws and O-ring seal are included in the scope of delivery |

| 2) | according to ANSI B92.1a-1976, 30° pressure angle, flat root, side fit, tolerance class 5 |

|

Size |

A1 |

A3 |

A4 |

A5 |

A6 1) |

|

mm |

mm |

mm |

mm |

||

| 125 | 369 | 18.9 | 29.4 | 13 | M12 |

| 180 | 393 | 18.9 | 29.4 | 13 | M12 |

| 250 | 453 | 18.9 | 29.4 | 13 | M12 |

| 355 | 482 | 18.9 | 29.4 | 13 | M12 |

| 1) | Thread according to DIN 13, for the max. tightening torques, the installation information is to be observed |

| Before determining your design, please request a binding installation drawing. |

U24

Flange ISO 3019-1 127-2 (SAE C)

Hub for splined shaft 38-4 SAE C-C, 1 1/2 ″, 12/24 DP; 17T 2)

for attaching an A10VSO 100/31 splined shaft S (see data sheet 92701) or an A10VO 85/52(53) splined shaft S (see data sheet 92703) or an internal gear pump PGH5 (see data sheet 10223)

Dimensions in mm

| 1) | Mounting screws and O-ring seal are included in the scope of delivery |

| 2) | according to ANSI B92.1a-1976, 30° pressure angle, flat root, side fit, tolerance class 5 |

|

Size |

A1 |

A3 |

A4 |

A5 |

A6 1) |

|

mm |

mm |

mm |

mm |

||

| 125 | 369 | 10.4 | 50 | 13 | M16 |

| 180 | 393 | 10.4 | 50 | 13 | M16 |

| 250 | 453 | 12.4 | 55 | 13 | M16 |

| 355 | 482 | 12.4 | 55 | 13 | M16 |

| 1) | Thread according to DIN 13, for the max. tightening torques, the installation information is to be observed |

Command values may only be switched via relays with gold-plated contacts (low voltage, low currents) Always shield command and actual value cables. The distance to aerial lines or radios must be at least 1 m. Do not lay signal lines close to power lines. Amending notes on the SYHDFE control system can be found in the operating instructions (See section “Further information about this control system”).

Accessories for through-drives

Mounting kits for axial piston variable displacement pumps and SYHDFE control systems

The order numbers for the combination of pumps are contained in the table shown below and in the data sheet 95581.

|

Components universal through-drive U99 |

Main pump SYHDFE.-1X |

Attachment pump |

||||

|

NG125 |

NG250 |

Size and type |

Through-drive Centering Hub |

Flange designation |

||

|

Mounting kit |

R902447035 |

R902447037 |

NG18 |

SYDFE.-2X Shaft S or R |

U52 |

SAE |

|

Flange kit |

R902446836 |

R902446850 |

||||

|

Hub |

R902446823 |

R902446843 |

||||

|

Mounting kit |

R902446996 |

R902446998 |

NG28 |

UB3 |

ISO 3019-2 |

|

|

Flange kit |

R902446808 |

R902446809 |

||||

|

Hub |

R902446824 |

R902446844 |

||||

|

Mounting kit |

R902447001 |

R902447003 |

NG45 |

UB4 |

ISO 3019-2 |

|

|

Flange kit |

R902446808 |

R902446809 |

||||

|

Hub |

R902446825 |

R902446845 |

||||

|

Mounting kit |

Upon request |

Upon request |

NG40 |

SYDFE.-3X Shaft S or R |

UE1 |

ISO 3019-2 |

|

Flange kit |

Upon request |

R902446813 |

||||

|

Hub |

R902446825 |

R902446845 |

||||

|

Mounting kit |

R902447014 |

R902447016 |

NG71 |

UB8 |

ISO 3019-2 |

|

|

Flange kit |

R902446816 |

R902446817 |

||||

|

Hub |

R902446826 |

R902443227 |

||||

|

Mounting kit |

R902447021 |

R902447022 |

NG100 |

UB9 |

ISO 3019-2 |

|

|

Flange kit |

R902446818 |

R902446820 |

||||

|

Hub |

R910943555 |

R910921237 |

||||

|

Mounting kit |

R902447025 |

R902447026 |

NG140 |

UB7 |

ISO 3019-2 |

|

|

Flange kit |

R902446818 |

R902446820 |

||||

|

Hub |

R910904588 |

R902446849 |

||||

|

Mounting kit |

R902447010 |

R902447011 |

NG40 |

SYHDFE-1X Shaft Z |

U31 |

ISO 3019-2 |

|

Flange kit |

R902446812 |

R902446813 |

||||

|

Hub |

R902446828 |

R902446846 |

||||

|

Mounting kit |

R902447012 |

R902447013 |

NG71 |

U33 |

ISO 3019-2 |

|

|

Flange kit |

R902446814 |

R902446815 |

||||

|

Hub |

R902491155 |

R902446847 |

||||

|

Mounting kit |

R902447019 |

R902447020 |

NG125 |

U34 |

ISO 3019-2 |

|

|

Flange kit |

R902446816 |

R902446817 |

||||

|

Hub |

R902446848 |

R902446830 |

||||

|

Mounting kit |

R902447028 |

NG250 |

U35 |

ISO 3019-2 |

||

|

Flange kit |

R902446822 |

|||||

|

Hub |

R910902972 |

|||||

|

Mounting kit |

R902447029 |

NG355 |

U77 |

ISO 3019-2 |

||

|

Flange kit |

R902446822 |

|||||

|

Hub |

R910941327 |

|||||

|

Components universal through-drive K99 |

Main pump SYHDFE.-1X |

Attachment pump |

||||

|

NG40 |

NG71 |

Size and type |

Through-drive Centering Hub |

Flange designation |

||

|

Mounting kit |

R902546965 |

NG18 |

SYDFE.-2X Shaft S or R |

K52 |

ISO 3019-1 |

|

|

Hub |

R910944344 Tooth hub for KC1 |

|||||

|

Mounting kit |

R902488855 |

NG28 |

KB3 |

ISO 3019-2 |

||

|

Hub |

R910987983 Tooth hub for KD3 |

|||||

|

Mounting kit |

Upon request |

Upon request |

NG45 |

KB4 |

ISO 3019-2 |

|

|

Mounting kit |

R902543215 |

NG45 |

SYDFE.-3X Shaft S or R |

KE1 |

ISO 3019-2 |

|

|

Mounting kit |

R902543416 |

NG71 |

KB8 |

ISO 3019-2 |

||

|

Mounting kit |

R902425118 |

R910904879 |

NG40 |

SYHDFE-1X Shaft Z |

K31 |

ISO 3019-2 |

|

Mounting kit |

R902403972 |

NG71 |

K33 |

ISO 3019-2 |

||

The following conditions apply to the attachment pumps listed in the table:

PGH with shaft R, flange U2, see data sheet 10223 PGF3 with shaft J, flange U2, see data sheet 10213 AZPF with shaft R, front cover R, see data sheet 10089Also note that the flange and the through-drive (see ordering code) are identical. Check in the current data sheet of the gear pump whether the shaft ends have the specified dimensions.

|

Components universal through-drive |

Main pump SYHDFE.-1X |

Attachment pump |

|||

|

NG125 |

NG250 |

Size and type |

Through-drive Centering Hub |

Flange designation |

|

|

Mounting kit |

R902447030 |

R902447032 |

PGF2, PGH2, PGH3, AZPF |

U01 |

SAE J744 |

|

Flange kit |

R902446836 |

R902446850 |

|||

|

Hub |

R902446831 |

R902497505 |

|||

|

Mounting kit |

R902447040 |

R902447042 |

PGF 3 |

U68 |

SAE J744 |

|

Flange kit |

R902446837 |

R902446851 |

|||

|

Hub |

R902446824 |

R902446844 |

|||

|

Mounting kit |

R902447045 |

R902447047 |

PGH 4 |

U04 |

SAE J744 |

|

Flange kit |

R902446837 |

R902446851 |

|||

|

Hub |

R902446825 |

R902446845 |

|||

|

Mounting kit |

R902447052 |

R902447053 |

PGH 5 |

U24 |

SAE J744 |

|

Flange kit |

R902446838 |

R902446852 |

|||

|

Hub |

R910943555 |

R910921237 |

|||

|

Components universal through-drive |

Main pump SYHDFE.-1X |

Attachment pump |

|||

|

NG40 |

NG71 |

Size and type |

Through-drive Centering Hub |

Flange designation |

|

|

Hub |

R910944342 Tooth hub for KC1 |

R910944356 Tooth hub for KC1 |

PGF2, PGH2, PGH3, AZPF |

K01 |

ISO 3019-1- |

Hubs for standard electric motor coupling

Coupling with gear rim for ambient temperatures up to 80 °C, e.g. for motor assemblies with IM V1 motor.

|

Motor |

SYHDFE.-1X |

Z-Wave |

|||

|

Frame size/characteristic |

Shaft diameter |

NG71 Shaft 40 mm W40x2x18x9g |

NG125/180 Shaft 50 mm W50x2x24x9g |

NG250 Shaft 60 mm W60x2x28x9g |

NG355 Shaft 70 mm W70x3x22x9g |

|

225/0 |

60 |

R900026054 |

R900026055 |

||

|

250/0 |

65 |

R900026058 |

R900026059 |

||

|

280/0 |

75 |

R900026062 |

R900026063 |

R900714636 |

|

|

315/0 |

80 |

R901037250 |

R901076760 |

R900088584 1) |

R900210961 1) |

|

315/1 |

80 |

R900026068 |

R900783295 |

R900210960 |

|

| 1) | Up to 40 °C |

Accessories

Version 12/2014, enquire availability

|

Accessories |

Material number |

Data sheet |

|

Mating connector 12-pole for central connection X1 without cable (assembly kit) |

R900884671 |

08006 |

|

Mating connector 12-pole for central connection X1 with cable set 2 x 5 m |

R900032356 |

|

|

Mating connector 12-pole for central connection X1 with cable set 2 x 20 m |

R900860399 |

|

|

Pressure transducer HM 20-2X, measurement range 315 bar (4 ... 20 mA) |

R901342029 |

30272 |

|

Pressure transducer HM 20-2X, measurement range 315 bar (0.1 ... 10 V) |

R901342030 |

30272 |

|

Test device VT-PDFE-1-1X/V0/0 |

R900757051 |

29689-B |

|

Compact power supply unit VT-NE32-1X |

R900080049 |

29929 |

|

More accessories |

|

|

|

Accessories for through-drives |

see Accessories, section "Accessories for through-drives" |

|

|

Torsionally flexible couplings for attachment to a standard electric motor |

see Accessories, section "Hubs for standard electric motor coupling" |

|

Mating connectors for valves with round connector, 11-pole + PE

12P N11

Mating connectors for valves with round connector, 11-pole + PE

12P N11

For valves with round connector according to EN 175201-804, 11-pole + PEData sheet

Spare parts & repair

Mating connectors for valves with round connector, 11-pole + PE, shielded, with assembled connection line

12P N11 +

Mating connectors for valves with round connector, 11-pole + PE, shielded, with assembled connection line

12P N11 +

For valves with round connector according to EN 175201-804, 11-pole + PEData sheet

Spare parts & repair

Related Products

R901123736

$608.00 USD

R901439038

$756.00 USD

R978031855

$13,269.00 USD

R901107094

$506.00 USD

R978051818

$11,928.00 USD