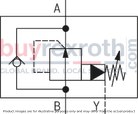

The pressure valve type DR is a pilot-operated pressure reducing valve. It is used to reduce the system pressure.

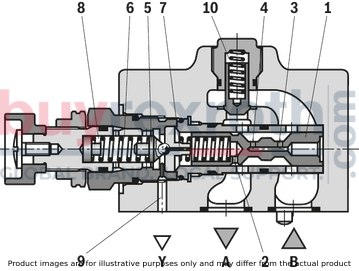

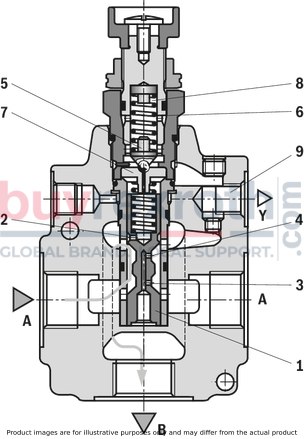

It mainly consists of screw-in cartridge valve (cartridge) and housing, optionally with or without check valve (subplate mounting only).

In the rest position the valve is open. The hydraulic fluid is able to flow freely from the inlet channel via the main control spool (1) to the outlet channel. The pressure in the outlet channel is applied to the spring-loaded side of the main control spool (1) via the bore (2). At the same time, the pressure acts upon the side of the main control spool (1) that is opposite to the spring via the bores (3) and (4).

If the pressure in the outlet channel exceeds the value set at the spring (6), the pilot poppet (5) opens.

Hydraulic fluid flows from the spring-loaded side of the main control spool (1) via the nozzle (7) and the pilot poppet (5) into the spring chamber (8).

The main control spool (1) assumes its control position and keeps the value in the outlet channel set at the spring (6) constant. The pilot oil return from the spring chamber (8) is always realized externally via the Y port (9).

In subplate mounting version "P", a check valve (10) can be optionally installed for free return flow from channel A to B.

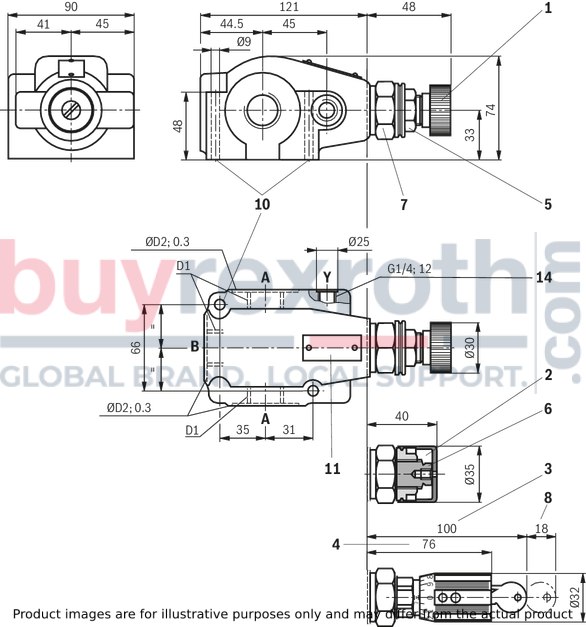

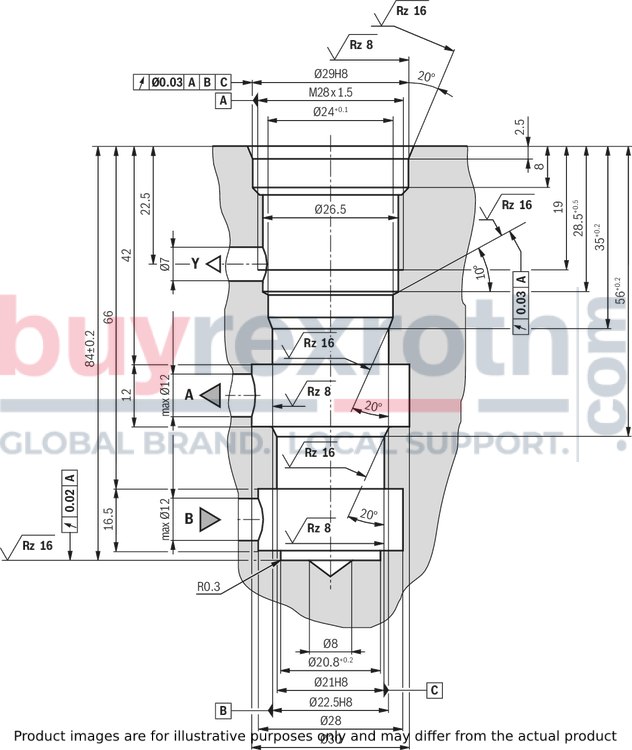

Type DR 10 -4-4X/…

Type DR 20 G-4-4X/…

Notice!

The pressure in port Y is added 1:1 to the set reduced pressure.