***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

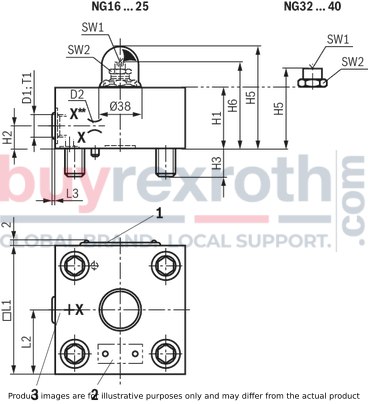

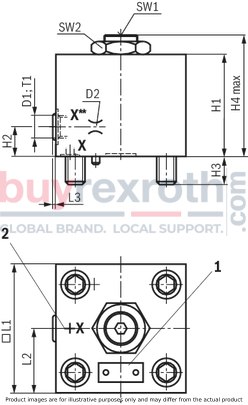

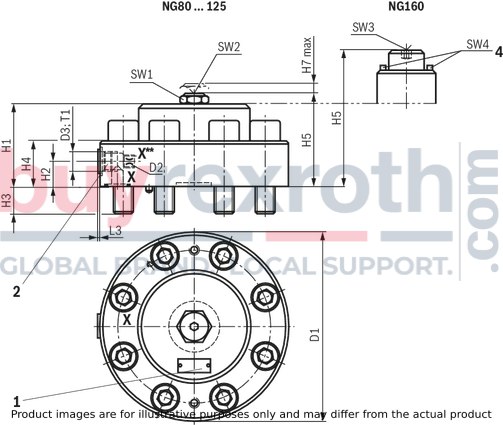

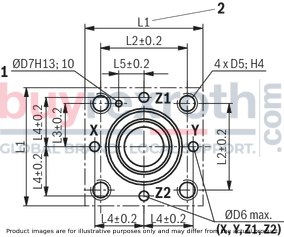

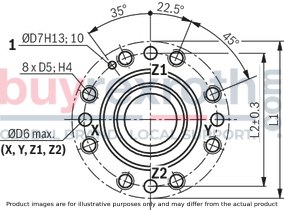

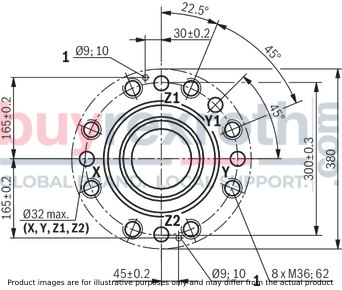

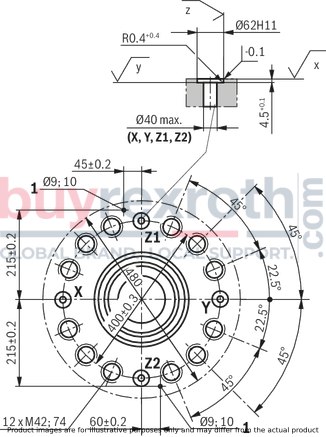

The Bosch Rexroth LFA 40 H2-7X/FX15/12 (R978912979) is a high-performance way cartridge valve designed for integration into a compact block design. This valve is tailored to provide efficient control for pressure, directional, and throttle functions or combinations thereof, making it an adaptable solution for various hydraulic applications. The power section of this model is installed into a standardized receiving hole in the control block and sealed with a cover that also serves as the connection point to the pilot control valves.

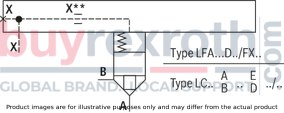

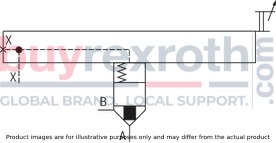

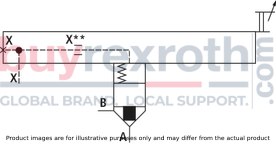

The model LFA 40 H2-7X/FX15/12 features a control cover equipped with control bores and can optionally include a stroke limitation function, a hydraulically controlled directional seat valve, or a shuttle valve depending on the required functionality. It also allows for the installation of electrically operated directional spool or seat valves on the control cover. The installation kit includes essential components such as a bushing, ring (up to NG), valve poppet (with or without damping nose), and closing spring.

This way cartridge valve operates based on pressure-dependency, creating three distinct pressurized areas (A1, A2, A3) that are crucial for its function. The area ratios between these zones determine the spool position by balancing opening and closing forces. The LFA 40 H2-7X/FX15/12 ensures non-leakage blocking from channel A when area A3 is pressurized either through pilot oil discharge from channel B or an external pilot supply.

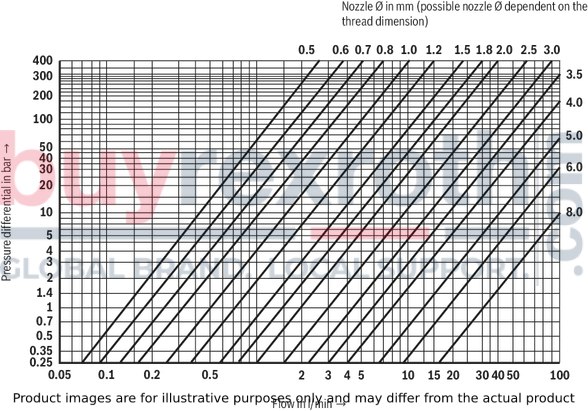

Equipped with remote control port capabilities and stroke limitation options, this standard series way cartridge valve can handle maximum operating pressures up to bar and maximum flow rates measured in liters per minute. Its component series includes X variants that denote its size and specifications which are critical for ensuring compatibility and performance within hydraulic systems.

$654.00 USD

More are expected on August 6, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $637.65 USD | $16.35 USD |

| 25+ | $621.30 USD | $32.70 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as August 6, 2026 when ordered in