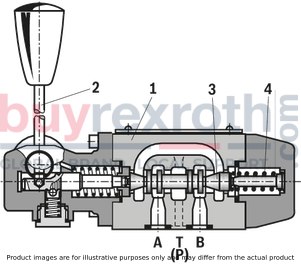

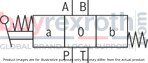

4/2 directional seat valve – with detent

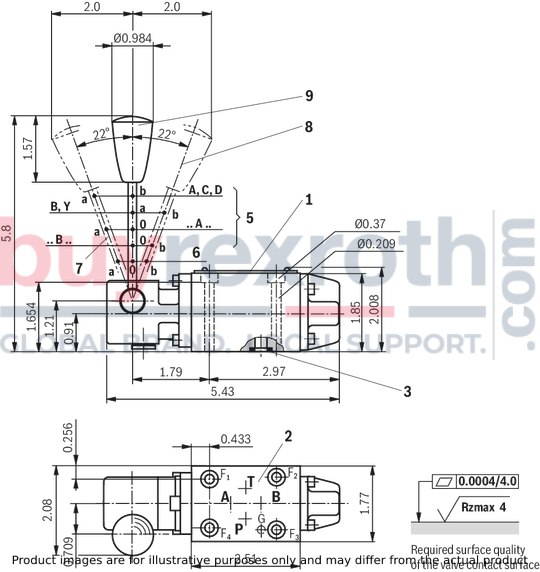

Dimensions in mm

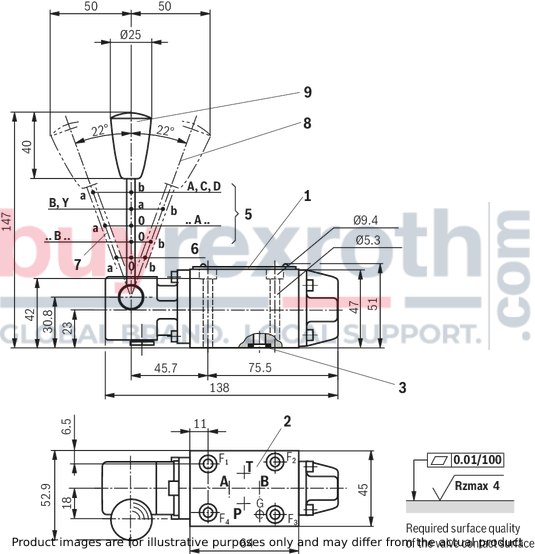

Dimensions in mm

|

1

|

Name plate

|

|

2

|

Porting pattern according toISO 4401-03-02-0-05 (with locating hole for locking pin ISO 8752-3x8-St, material no. R900005694, separate order)

|

|

3

|

Identical seal rings for ports A, B, P, and T

|

|

5

|

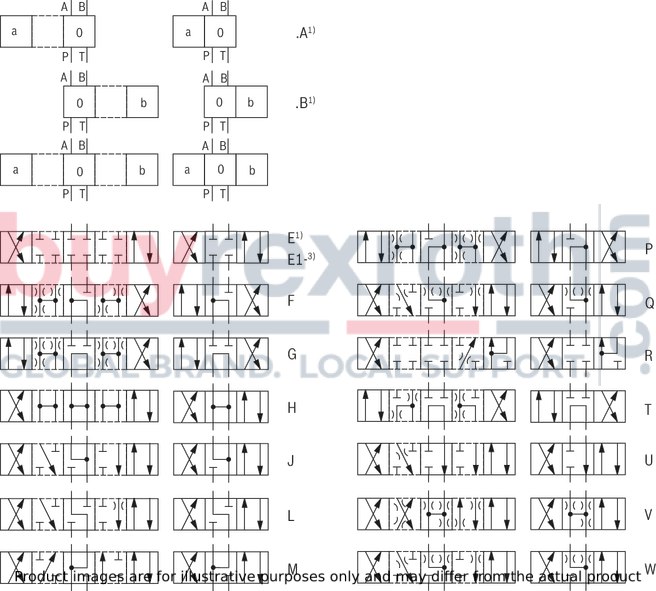

Valve with 2 spool positions

|

|

6

|

Valve with 3 spool positions

|

|

7

|

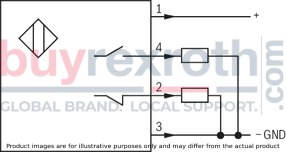

Spool position “a”

|

|

8

|

Spool position “b”

|

|

9

|

Spool position “0”, “a” and “b” (a and b for valves with 2 spool positions)

|

Subplates according to data sheet 45052 (separate order)

(without locating hole)

G 341/01 (G1/4)

G 342/01 (G3/8)

G 502/01 (G1/2)

(with locating hole)

G 341/60 (G1/4)

G 342/60 (G3/8)

G 502/60 (G1/2)

G 341/12 (SAE-6)1)

G 342/12 (SAE-8)1)

G 502/12 (SAE-10)1)

1) On request

Valve mounting screws (separate order)

Clamping length 42 mm:

4 hexagon socket head cap screws, metric

ISO 4762 - M5 x 50 - 10.9-flZn-240h-L

(friction coefficient μtotal = 0.09 to 0.14);

tightening torque MA = 7 Nm ± 10 %,

Material no. R913000064

or

4 hexagon socket head cap screws

ISO 4762 - M5 x 50 - 10.9 (self procurement)

(friction coefficient μtotal = 0.12 to 0.17);

tightening torque MA = 8.1 Nm ± 10 %

4 hexagon socket head cap screws UNC

10-24 UNC x 2″ ASTM-A574

(friction coefficient μtotal = 0.19 to 0.24);

tightening torque MA = 11 Nm ± 15 %,

(friction coefficient μtotal = 0.12 to 0.17);

tightening torque MA = 8 Nm ± 10 %,

material no. R978800693

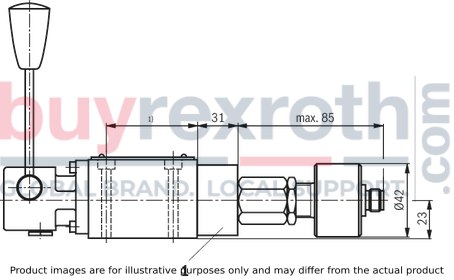

Spool position monitoring

Inductive position switch type QM, 4WMM

Dimensions in mm

|

1)

|

For dimensions, see valve dimensions

|

3/2 directional seat valve – with detent

Dimensions in mm

|

1

|

Cover not available for type WMRZ

|

Notice:

The dimensions are nominal dimensions which are subject to tolerances.