***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

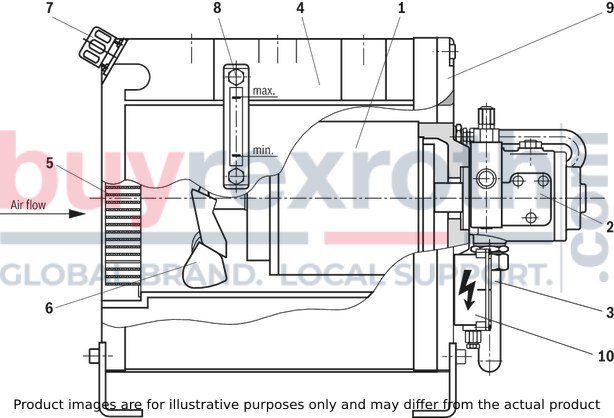

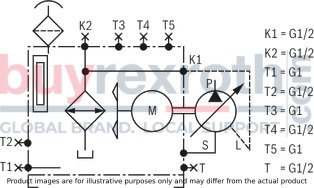

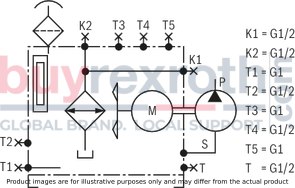

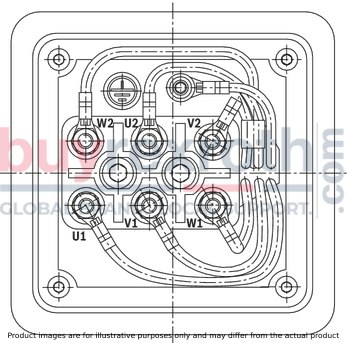

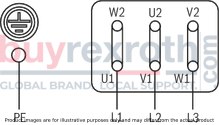

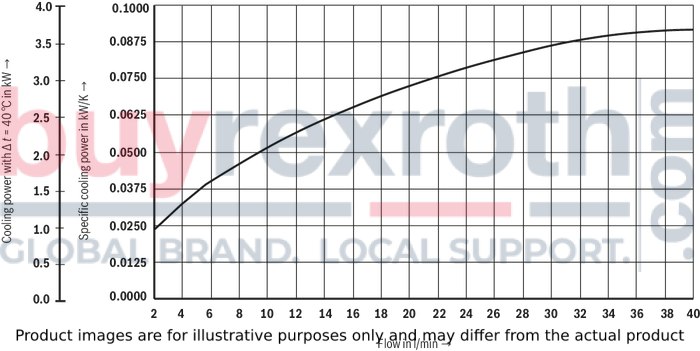

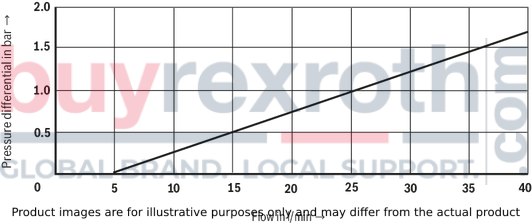

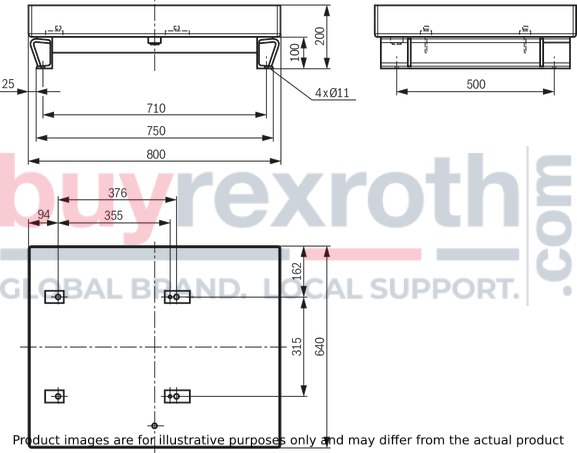

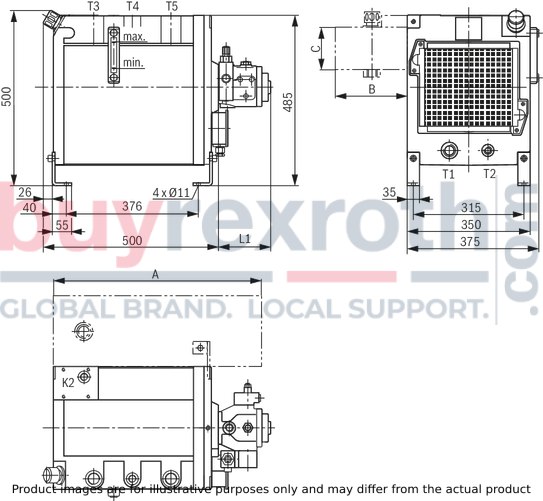

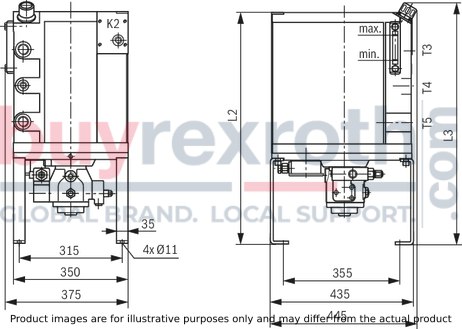

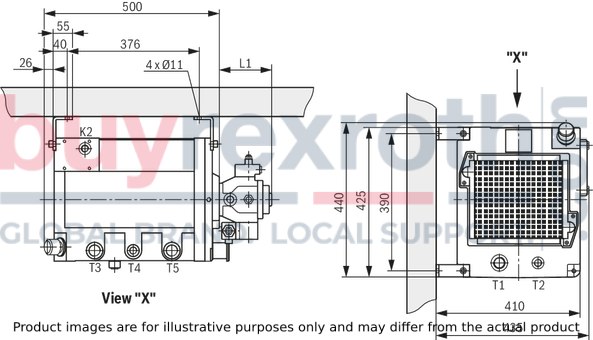

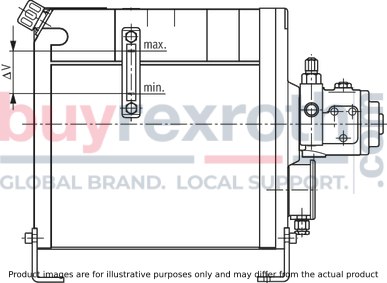

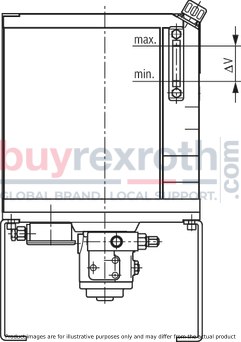

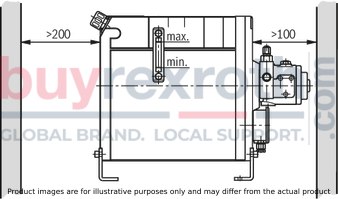

The Bosch Rexroth UPE5-1X/400V7/20-25AN-H-1+04100643 (R904100644) is a highly efficient and compact drive module designed for hydraulic systems. This unit integrates an electric motor with a hydraulic pump, eliminating the need for coupling by directly plugging the pump shaft into the electric motor's hollow drilled shaft end. This design significantly reduces the overall length of the pump-motor group, making it ideal for applications where space is at a premium. The module operates by drawing in hydraulic fluid from a tank through a suction tube, delivering it to the hydraulic control, and then returning it via connections K and K through an oil-air cooler. The axial fan wheel attached to the electric motor ensures both the hydraulic fluid and motor remain cool during operation.

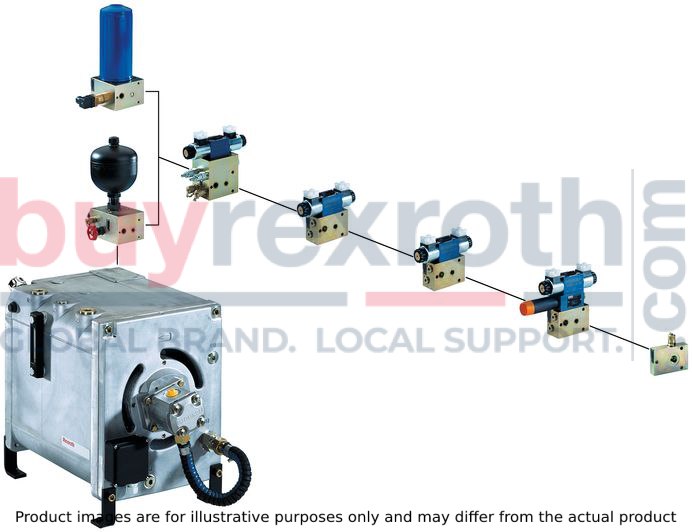

The tank of this drive module can be filled easily through a filling plug, and its oil level can be consistently monitored with an oil level display. It comes with a tank cover to which the pump-motor group and terminal box are secured, providing a ready-for-connection solution upon delivery. For enhanced functionality, options include electric oil level and temperature monitoring systems, as well as complete hydraulic controls featuring elements like filters, accumulators, and valves.

Additional customization possibilities include oil-water cooling systems, an oil pan compliant with Water Resources Act WHG standards, double pumps, or extra tanks based on user requirements. Safety is paramount with this unit; during operation, it can generate heat that poses an injury risk if not handled properly.

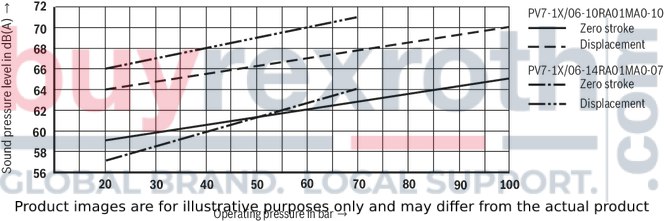

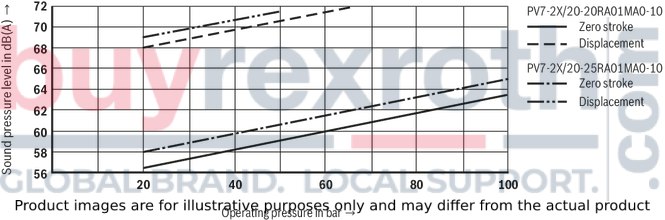

With its compact design, low noise output, high cooling capacity, wide application field, large number of variants available for different needs, various mounting options provided for ease of installation, and capability of realizing complete hydraulic controls using IHB control modules—the Bosch Rexroth UPE5-1X/400V7/20-25AN-H-1+04100643 (R904100644) is designed to meet diverse industrial hydraulic requirements while delivering reliable performance.

$9,354.00 USD

More are expected on August 13, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $9,120.15 USD | $233.85 USD |

| 25+ | $8,886.30 USD | $467.70 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as August 13, 2026 when ordered in