***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

The Bosch Rexroth H-4WEH25C6X/6EG24NXEETZ2/B10D3 (R901427470) is a high-performance directional spool valve with electrohydraulic actuation designed to control the start, stop, and direction of fluid flow in hydraulic systems. The model features a robust main valve with housing, a main control spool, return springs, and a pilot control valve equipped with solenoids for precise operation. The main control spool is maintained in its initial position by the springs or pressurization and can be actuated via the pilot control valve to alter flow paths within the system.

The H-4WEH25C6X/6EG24NXEETZ2/B10D3 offers various methods for pilot oil supply and return, including external supply via port X or internal from channel P of the main valve. Depending on the specific type within the HWEH series (such as HWEHE, HWEHET, or HWEHT), these configurations can vary to suit different application needs. A throttle insert is available for scenarios where it's necessary to limit pilot oil supply in channel P.

This model also comes with several advanced features like spring centering, an optional manual override without solenoid energization, wet-pin DC or AC solenoids with rotatable coils, and an electrical connection that includes a cable gland. Additional optional characteristics include switching time adjustment and a preload valve in channel P of the main valve.

Engineered for use in potentially explosive atmospheres, it adheres to EU Explosion Protection Directive standards with Type of protection Ex eb mb IIC T4 Gb according to EN standards. This makes it suitable for hazardous environments requiring reliable and safe hydraulic controls. The Bosch Rexroth H-4WEH25C6X/6EG24NXEETZ2/B10D3 is built for subplate mounting with porting patterns according to ISO standards and can handle maximum operating pressures up to bar with maximum flow rates of l/min. Its versatility ensures optimal performance across various hydraulic applications while maintaining safety in explosive conditions.

$10,376.00 USD

More are expected on September 29, 2026

| Qty | Price | Savings |

|---|---|---|

| 5-24 | $10,116.60 USD | $259.40 USD |

| 25+ | $9,857.20 USD | $518.80 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as September 29, 2026 when ordered in

This product is eligible for factory repair.

For intended use in potentially explosive atmosphere For subplate mounting Porting pattern according to ISO 4401 Spring centering, spring end position or hydraulic end position wet-pin DC or AC solenoids Solenoid coil is rotatable by 90° Optional auxiliary operating device Electrical connection as individual connection with cable gland Switching time adjustment, optional Preload valve in channel P of the main valve, optional

Type H-4WEH 16…XE...

Directional valves type H-4WEH…

The valve type H-4WEH is a directional spool valve with electro-hydraulic actuation. It controls the start, stop and direction of a flow.

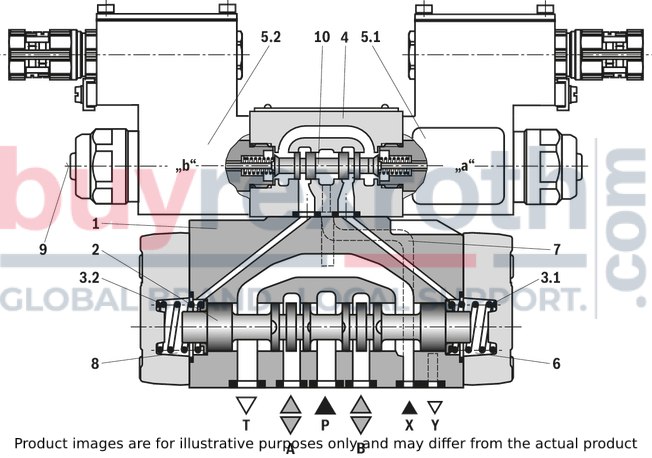

The directional valves basically consist of the main valve with housing (1), the main control spool (2), one or two return springs (3.1) and (3.2), as well as the pilot control valve (4) with one or two solenoids "a" (5.1) and/or "b" (5.2).

The main control spool (2) in the main valve is held in the zero or initial position by the springs or by means of pressurization. In the initial position, the two spring chambers (6) and (8) are connected with the tank in a depressurized form via the pilot control valve (4). Via the control line (7), the pilot control valve is supplied with pilot oil. Supply can be implemented internally or externally (externally via port X).

Upon actuation of the pilot control valve, e.g. solenoid "a", the pilot control spool (10) is moved to the left and thus, the spring chamber (8) is pressurized with pilot pressure. The spring chamber (6) remains depressurized.

The pilot pressure acts on the left side of the main control spool (2) and moves it against the spring (3.1). This connects port P with B and A with T in the main valve.

When the solenoid is switched off, the pilot control spool returns into the initial position (except for impulse spool). The spring chamber (8) is unloaded to the tank.

The pilot oil from the spring chamber is displaced into channel Y via the pilot control valve.

The pilot oil supply and return can be effected internally or externally.

The manual override (9) allows control spool (10) to be moved without solenoid energization.

Notes:

The return springs (3.1) and (3.2) in the spring chambers (6) and (8) hold the main control spool (2) in central position without pilot pressure even with, for example, vertical valve positioning.

Due to the design principle, internal leakage is inherent to the valves, which may increase over the life cycle.

Pilot oil supply

Type H-4WEH…

The pilot oil supply is effected externally via channel X from a separate circuit.

The pilot oil return is effected externally via channel Y into the tank.

Type H-4WEH…E…

The pilot oil supply is effected internally from channel P of the main valve.

The pilot oil return is effected externally via channel Y into the tank. In the subplate, port X is closed.

Type H-4WEH…ET…

The pilot oil supply is effected internally from channel P of the main valve.

The pilot oil return is effected internally via channel T into the tank. In the subplate, ports X and Y are closed.

Type H-4WEH…T…

The pilot oil supply is effected externally via channel X from a separate circuit.

The pilot oil return is effected internally via channel T into the tank. In the subplate, port Y is closed.

Throttle insert

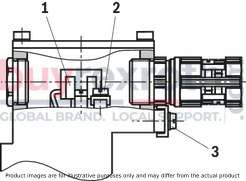

Use of the throttle insert (2) is necessary if the pilot oil supply in channel P of the pilot control valve (1) is to be limited.

The throttle insert (2) is inserted in channel P of the pilot control valve (1).

|

1 |

Pilot control valve |

|

2 |

Throttle insert |

|

3 |

Seal ring |

|

4 |

Main valve |

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

||

|

H |

– |

4 |

WEH |

/ |

6E |

XE |

Z2 |

|

01 |

Up to 350 bar |

H |

|

02 |

4-way version |

4 |

|

03 |

Directional valve, electro-hydraulically actuated |

WEH |

|

Size |

||

|

04 |

NG10 |

10 |

|

NG16 |

16 |

|

|

NG25 |

25 |

|

|

NG32 |

32 |

|

|

Control spool return main valve |

||

|

05 |

by means of springs |

no code |

|

hydraulic 1) |

H |

|

|

06 |

For control spool symbols, see symbols |

|

|

07 |

Component series 40 ... 49 – NG10 (40 ... 49: unchanged installation and connection dimensions) |

4X |

|

Component series 60 ... 69 – NG25 (4W.H 25.) and NG32 (60 ... 69: unchanged installation and connection dimensions) |

6X |

|

|

Component series 70 ... 79 – NG16 (70 ... 79: unchanged installation and connection dimensions) |

7X |

|

|

Control spool return in the pilot control valve with 2 spool positions and 2 solenoids only possible with control spool C, D, K, Z and hydraulic control spool return in the main valve |

||

|

08 |

Without spring return |

O |

|

Without spring return with detent |

OF |

|

|

09 |

Pilot control valve with wet-pin solenoids, high-power valve (data sheet 23178-XE) |

6E |

|

10 |

Direct voltage 24 V |

G24 |

|

Alternating voltage 230 V, 50/60 Hz |

W230R |

|

|

Further ordering codes for other voltages are provided under "Electrical connection" |

||

|

11 |

Without manual override |

no code |

|

with manual override (standard) |

N |

|

|

12 |

“Increased safety” explosion protection; for details, please refer to the explosion protection information |

XE |

|

13 |

External pilot oil supply, external pilot oil return 2) |

no code |

|

Internal pilot oil supply, external pilot oil return 3) |

E |

|

|

Pilot oil supply internal, pilot oil return internal 3) |

ET |

|

|

External pilot oil supply, internal pilot oil return 2) |

T |

|

|

14 |

without switching time adjustment |

no code |

|

Switching time adjustment as supply control |

S |

|

|

Switching time adjustment as discharge control |

S2 |

|

|

Electrical connection |

||

|

15 |

Solenoid with terminal box and cable gland; for details please refer to "Electrical connection" |

Z2 |

|

Throttle insert |

||

|

16 |

Without throttle insert |

no code |

|

Throttle Ø 0.8 mm |

B08 |

|

|

Throttle Ø 1.0 mm |

B10 |

|

|

Throttle Ø 1.2 mm |

B12 |

|

|

Throttle Ø 1.5 mm |

B15 |

|

|

preload valve (not for NG10) |

||

|

17 |

without preload valve |

no code |

|

with preload valve (pö = 4.5 bar) |

P4,5 |

|

|

18 |

without pressure reducing valve |

no code |

|

with pressure reducing valve 4) |

D3 |

|

|

19 |

NBR seals |

no code |

|

FKM seals (other seals upon request) |

V |

|

|

Observe compatibility of seals with hydraulic fluid used. |

||

| 1) | 2 spool positions (hydraulic end position): only symbols C, D, K, Z, Y |

| 2) | External pilot oil supply X or pilot oil return Y: |

| – Observe the maximum pilot pressure according to Technical data! | |

| 3) | Internal pilot oil supply (version “ET” and “E”): |

| – Observe the minimum pilot pressure according to Technical data! | |

| – In order to prevent inadmissibly high pressure peaks, a throttle insert "B10" has to be provided in port P of the pilot control valve (see Product description, Pilot oil supply). | |

| – You must moreover provide the pressure reducing valve "D3". | |

| 4) | Only in connection with throttle insert "B10" |

Notice:

The manual override cannot be allocated a safety function and may only be used up to a tank pressure of 50 bar.

general

|

Size |

10 | 16 | 25 | 32 | |||

|

Installation position |

any; horizontal with valves with hydraulic control spool return “H” and control spool C, D, K, Z or Y | ||||||

|

Ambient temperature range 1) |

°C |

-20 … +70 | |||||

|

Storage temperature range |

°C |

+5 … +40 | |||||

|

Maximum storage time |

Years |

1 | |||||

|

Weight |

Valve with one solenoid |

kg |

8.5 | 11 | 19 | 36.5 | |

|

Valve with two solenoids, spring-centered |

kg |

10.2 | 12.5 | 20.5 | 39 | ||

|

Switching time adjustment |

kg |

0.8 | |||||

|

Pressure reducing valve |

kg |

0.4 | |||||

|

Surface protection |

Valve body |

Pilot control valve |

Galvanized | ||||

|

Main valve |

Galvanized | ||||||

|

Solenoid |

Galvanized | ||||||

|

MTTFD values according to EN ISO 13849 |

Years |

100 | |||||

| 1) | Observe the "Special application conditions for safe application" |

hydraulic

|

Size |

10 | 16 | 25 | 32 | |||

|

Maximum operating pressure |

Port P |

bar |

350 | ||||

|

Anschluss A |

bar |

350 | |||||

|

Port B |

bar |

350 | |||||

|

Port T |

with external pilot oil return Y |

bar |

250 | ||||

|

with internal pilot oil return Y |

bar |

210 | |||||

|

Port Y |

with pilot oil return external |

bar |

210 | ||||

|

Maximum flow of the main valve |

l/min |

160 | 300 | 700 | 1100 | ||

|

Maximum pilot pressure 1) |

bar |

250 | |||||

|

Minimum pilot pressure |

External or internal pilot oil supply X (with control spool D, K, E, J, L, M, Q, R, U, W) |

3-spool position valve, spring-centered |

bar |

10 | 14 | 13 | 8.5 |

|

2-spool position valve, spring end position |

bar |

10 | 14 | 13 | 10 | ||

|

2-spool position valve, hydraulic end position |

bar |

7 | 14 | 8 | 5 | ||

|

Internal pilot oil supply X (with control spool C, F, H, P, T, V, Z, S) 2) |

bar |

6.5 3) | 4.5 4) | ||||

|

Pilot volume for switching process |

3-spool position valve, spring-centered |

cm³ |

2.04 | 5.72 | 14.2 | 29.4 | |

|

2-spool position valve |

cm³ |

4.08 | 11.45 | 28.4 | 58.8 | ||

|

Pilot volume for shortest switching time, approx. |

l/min |

35 | 45 | ||||

|

Hydraulic fluid |

see table "Hydraulic fluid" | ||||||

|

Hydraulic fluid temperature range |

NBR seals |

°C |

-20 … +80 | ||||

|

FKM seals |

°C |

-15 … +80 | |||||

|

Viscosity range |

mm²/s |

2.8 … 500 | |||||

|

Maximum admissible degree of contamination of the hydraulic fluid 5) |

Class 20/18/15 according to ISO 4406 (c) | ||||||

|

Maximum surface temperature |

see Information on explosion protection | ||||||

| 1) | With a higher pilot pressure, use of a pressure reducing valve is required. |

| 2) | Symbol S only for NG16 |

| 3) | For symbols C, F, G, H, P, T, V, Z, an internal pilot oil supply is only possible if the flow from P → T in the central position (for 3-spool position valve) or while crossing the central position (for 2-spool position valve) is so large that the pressure differential of P → T reaches a value of at least 6.5 bar. |

| 4) | For symbols C, F, G, H, P, T, V, Z, S (Symbol S only for Size 16) – by meansof a preload valve (not Size 10) or a correspondinglyhigh flow. |

| 5) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

|

Hydraulic fluid |

Classification |

Suitable sealing materials |

Standards |

Data sheet |

|

|

Mineral oil |

HL, HLP, HLPD |

NBR, FKM |

DIN 51524 |

90220 |

|

|

Bio-degradable |

Insoluble in water |

HETG |

NBR, FKM |

ISO 15380 |

90221 |

|

HEES |

FKM |

||||

|

Soluble in water |

HEPG |

FKM |

ISO 15380 |

||

|

Flame-resistant |

Containing water |

HFC (Fuchs Hydrotherm 46M, Petrofer Ultra Safe 620) |

NBR |

ISO 12922 |

90223 |

Important notice on hydraulic fluids:

For more information and data on the use of other hydraulic fluids, please refer to the data sheets above or contact us. There may be limitations regarding the technical valve data (temperature, pressure range, life cycle, maintenance intervals, etc.). Ignition temperature > 180 °C

• Flame-resistant - containing water:

- Maximum pressure differential per control edge 50 bar

- Pressure pre-loading at the tank port >20% of the pressure differential, otherwise increased cavitation

- Life cycle as compared to operation with mineral oil HL, HLP 50 to 100%

electrical

|

Voltage type |

Direct voltage | AC voltage | |

|

Available voltages |

V |

24 / 48 / 96 / 110 | 110 / 230 |

|

Voltage tolerance (nominal voltage) |

% |

± 10 | |

|

Admissible residual ripple |

% |

< 5 | - |

|

Duty cycle/operating mode according to VDE 0580 |

S1 (continuous operation) | ||

|

Switching time according to ISO 6403 1) |

See switching times table | ||

|

Maximum switching frequency |

1/h |

15000 | 7200 |

|

Nominal power with ambient temperature 20 °C |

W |

17 | |

|

Maximum power with 1.1 x nominal voltage and an ambient temperature of 20 °C |

W |

20.6 | |

|

Type of protection according to EN 60529 2) |

IP66 | ||

| 1) | The switching times were determined at a hydraulic fluid temperature of 40 °C and a viscosity of 46 mm2/s. Deviating hydraulic fluid temperatures can result in different switching times. Switching times change dependent on operating time and application conditions. |

| 2) | With correctly installed electrical connection |

Notice:

Solenoids for AC voltage are DC solenoids with integrated rectifier

Information on explosion protection

|

Application according to Explosion Protection Directive 2014/34/EU |

II 2G | |

|

Type of protection valve |

c (EN 13463-5) | |

|

Maximum surface temperature 1) |

°C |

135 |

|

Temperature class |

T4 | |

|

Valve solenoid type of protection according to EN 60079-7 / EN 60079-18 |

Ex eb mb IIC T4 Gb | |

|

Baumusterprüfbescheinigung Magnet |

KEMA 02ATEX2240 X | |

|

“IECEx Certificate of Conformity” for solenoid |

IECEx DEK 12.0068X | |

|

Ambient temperature range 2) |

°C |

-20 … +70 |

| 1) | Surface temperature > 50 °C, provide contact protection. |

| 2) | Observe the "Special application conditions for safe application" |

Special application conditions for a safe application

In case of valves with two solenoids, maximally one of the solenoids may be energized at a time. Simultaneously power supply to several valves in bank assembly is possible if the ambient temperature does not exceed 60°C. In case of bank assembly, if only one of the solenoids is energized at a time, and during individual operation, the maximum ambient temperature must not exceed 70°C. The maximum temperature of the surface of the valve jacket is 120°C. This has to be considered when selecting the connection cable and/or a contact of the connection cable with the surface of the jacket is to be prevented.Switching times (= Contacting at the pilot control valve until start of opening of the control edge in the main valve and change in the control spool stroke by 95%)

|

Pilot pressure |

bar |

70 |

250 |

Spring |

|

|

ON |

OFF |

||||

|

NG10 |

Without throttle insert |

ms |

50 … 70 |

50 … 70 |

30 … 40 |

|

With throttle insert |

ms |

70 … 100 |

60 … 80 |

30 … 40 |

|

|

NG16 |

Without throttle insert |

ms |

60 … 90 |

50 … 70 |

60 … 90 |

|

With throttle insert |

ms |

120 … 140 |

90 … 110 |

60 … 90 |

|

|

NG25 |

Without throttle insert |

ms |

80 … 110 |

60 ... 80 |

110 ... 140 |

|

With throttle insert |

ms |

210 …260 |

130 … 160 |

110 ... 140 |

|

|

NG32 |

Without throttle insert |

ms |

90 … 140 |

80 … 110 |

150 … 170 |

|

With throttle insert |

ms |

430 … 570 |

240 … 360 |

150 … 170 |

|

Notices:

The switching times are measured according to ISO 6403 with HLP46, ϑOil = 40 ° C ± 5 ° C). With different oil temperatures, variations are possible. The switching times increase by approx. 30 ms if the pressure reducing valve "D3" is used. The switching times have been determined under ideal conditions and may differ in the system, depending on the application conditions.Free flow cross-sections in zero position with control spools Q, V and W

|

Size |

10 | 16 | 25 | 32 | ||

|

Control spool Q |

A – T; B – T |

mm² |

13 | 32 | 83 | 78 |

|

Control spool V |

A – T; B – T |

mm² |

13 | 32 | 83 | 73 |

|

P – A |

mm² |

13 | 32 | 83 | 84 | |

|

Control spool W |

A – T; B – T |

mm² |

2.4 | 6 | 14 | 20 |

(measured with HLP46, ϑOil = 40 °C ±5 °C)

Type H-4WEH 10…

Δp-qV characteristic curves

|

Characteristic curve selection |

||||||||

|

Symbol |

Spool position |

Symbol |

Zero position |

|||||

|

P – A |

P – B |

A – T |

B – T |

A – T |

B – T |

P – T |

||

|

E, Y, D |

2 |

2 |

4 |

5 |

||||

|

F |

1 |

4 |

1 |

4 |

F |

3 |

– |

6 |

|

G, T |

4 |

2 |

2 |

6 |

G, T |

– |

– |

7 |

|

H, C |

4 |

4 |

1 |

4 |

H |

1 |

3 |

5 |

|

J, K |

1 |

2 |

1 |

3 |

||||

|

L |

2 |

3 |

1 |

4 |

L |

3 |

– |

– |

|

M |

4 |

4 |

3 |

4 |

||||

|

P |

4 |

1 |

3 |

4 |

P |

– |

7 |

5 |

|

Q, V, W, Z |

2 |

2 |

3 |

5 |

||||

|

R |

2 |

2 |

3 |

– |

||||

|

U |

3 |

3 |

3 |

4 |

U |

– |

4 |

– |

Performance limits: (measured with HLP46, ϑOil = 40 °C ±5 °C)

NG10

|

2- and 3-spool position valve – qV maxin l/min |

|||

|

Symbol |

Operating pressure pmax in bar |

||

|

200 |

250 |

315 |

|

|

E, J, L, M, Q, R, U, V, W, C, D, K, Z, Y |

160 |

160 |

160 |

|

H |

160 |

150 |

120 |

|

G, T |

160 |

160 |

140 |

|

F, P |

160 |

140 |

120 |

(measured with HLP46, ϑOil = 40 °C ±5 °C)

Type H-4WEH 16…

Δp-qV characteristic curves

|

Characteristic curve selection |

|||||

|

Symbol |

Switching positions |

||||

|

P – A |

P – B |

A – T |

B – T |

P – T |

|

|

E, Y, D |

1 |

1 |

3 |

4 |

– |

|

E19 |

– |

6 |

8 |

7 |

– |

|

F |

1 |

1 |

5 |

4 |

– |

|

G, T |

4 |

1 |

5 |

5 |

9 |

|

H, C, Q, V, Z |

1 |

1 |

5 |

6 |

– |

|

J, K, L |

1 |

1 |

5 |

6 |

– |

|

Symbol |

Spool position |

||||

|

P – A |

P – B |

A – T |

B – T |

P – T |

|

|

M, W |

1 |

1 |

3 |

4 |

– |

|

R |

1 |

1 |

3 |

– |

– |

|

U |

2 |

2 |

3 |

5 |

– |

|

S |

3 |

3 |

3 |

– |

10 |

Performance limits: (measured with HLP46, ϑOil = 40 °C ±5 °C)

NG16

|

2-spool position valve – qV maxin l/min |

|||||

|

Symbol |

Operating pressure pmax in bar |

||||

|

70 |

140 |

210 |

280 |

350 |

|

|

X external – spring end position in the main valve (with ppilot min = 12 bar) |

|||||

|

C, D, K, Y, Z |

300 |

300 |

300 |

300 |

300 |

|

X external – spring end position in the main valve 1) |

|||||

|

C |

300 |

300 |

300 |

300 |

300 |

|

D, Y |

300 |

270 |

260 |

250 |

230 |

|

K |

300 |

250 |

240 |

230 |

210 |

|

Z |

300 |

260 |

190 |

180 |

160 |

|

X external – hydraulic end position in the main valve |

|||||

|

HC, HD, HK, HZ, HY |

300 |

300 |

300 |

300 |

300 |

| 1) | If the specified flow values are exceeded, the function of the return spring is no longer guaranteed if the pilot pressure fails! |

NG16

|

3-spool position valves – qV max in l/min |

|||||

|

Symbol |

Operating pressure pmax in bar |

||||

|

70 |

140 |

210 |

280 |

350 |

|

|

X external, spring centering in the main valve |

|||||

|

E, E19, H, J, L, M, Q, U, W, R |

300 |

300 |

300 |

300 |

300 |

|

F, P |

300 |

250 |

180 |

170 |

150 |

|

G, T |

300 |

300 |

240 |

210 |

190 |

|

S |

300 |

300 |

300 |

250 |

220 |

|

V |

300 |

250 |

210 |

200 |

180 |

| With control spools V, Z and HZ, the preload valve is not required for flows >180 l/min . |

(measured with HLP46, ϑOil = 40 °C ±5 °C)

Type H-4WEH 25…

Δp-qV characteristic curves

|

Characteristic curve selection |

||||

|

Symbol |

Spool position |

|||

|

P – A |

P – B |

A – T |

B – T |

|

|

E |

1 |

1 |

1 |

3 |

|

F |

1 |

4 |

3 |

3 |

|

G |

3 |

1 |

2 |

4 |

|

H |

4 |

4 |

3 |

4 |

|

J, Q |

2 |

2 |

3 |

5 |

|

Symbol |

Spool position |

|||

|

P – A |

P – B |

A – T |

B – T |

|

|

L |

2 |

2 |

3 |

3 |

|

M |

4 |

4 |

1 |

4 |

|

P |

4 |

1 |

1 |

5 |

|

R |

2 |

1 |

1 |

– |

|

Symbol |

Spool position |

|||

|

P – A |

P – B |

A – T |

B – T |

|

|

U |

4 |

1 |

1 |

6 |

|

V |

2 |

4 |

3 |

6 |

|

W |

1 |

1 |

1 |

3 |

|

T |

3 |

1 |

2 |

4 |

Performance limits: (measured with HLP46, ϑOil = 40 °C ±5 °C)

NG25

|

2-spool position valve – qV maxin l/min |

|||||

|

Symbol |

Operating pressure pmax in bar |

||||

|

70 |

140 |

210 |

280 |

350 |

|

|

X external – spring end position in the main valve (with ppilotmin = 13 bar) |

|||||

|

C, D, K, Y, Z |

700 |

700 |

700 |

700 |

650 |

|

X external – spring end position in the main valve 1) |

|||||

|

C |

700 |

700 |

700 |

700 |

650 |

|

D, Y |

700 |

650 |

400 |

350 |

300 |

|

K |

700 |

650 |

420 |

370 |

320 |

|

Z |

700 |

700 |

650 |

480 |

400 |

|

X external – hydraulic end position in the main valve |

|||||

|

HC, HD, HK, HZ, HY |

700 |

700 |

700 |

700 |

700 |

|

HC./O…, HD./O…, HK./O…, HZ./O… |

700 |

700 |

700 |

700 |

700 |

|

HC./OF…, HD./OF…, HK./OF…, HZ./OF… |

700 |

700 |

700 |

700 |

700 |

| 1) | If the specified flow values are exceeded, the function of the return spring is no longer guaranteed if the pilot pressure fails! |

NG25

|

3-spool position valves – qV max in l/min |

|||||

|

Symbol |

Operating pressure pmax in bar |

||||

|

70 |

140 |

210 |

280 |

350 |

|

|

X external, spring centering in the main valve |

|||||

|

E, L, M, Q, U, W |

700 |

700 |

700 |

700 |

650 |

|

G, T |

400 |

400 |

400 |

400 |

400 |

|

F |

650 |

550 |

430 |

330 |

300 |

|

H |

700 |

650 |

550 |

400 |

360 |

|

J |

700 |

700 |

650 |

600 |

520 |

|

P |

650 |

550 |

430 |

330 |

300 |

|

V |

650 |

550 |

400 |

350 |

310 |

|

R |

700 |

700 |

700 |

650 |

580 |

(measured with HLP46, ϑOil = 40 °C ±5 °C)

Type H-4WEH 32…

Δp - qV characteristic curves – Symbol E, R and W

Type H-4WEH 32…

∆p - qV characteristic curves – Symbol G and T

|

Characteristic curve selection |

|||||

|

Symbol |

Spool position |

||||

|

P – A |

P – B |

A – T |

B – T |

B – A |

|

|

E |

4 |

4 |

3 |

2 |

– |

|

R |

4 |

4 |

3 |

– |

1 |

|

W |

4 |

4 |

3 |

2 |

– |

|

Symbol |

Spool position |

||||

|

P – A |

P – B |

A – T |

B – T |

P – T |

|

|

G |

7 |

8 |

7 |

5 |

6 |

|

T |

7 |

8 |

7 |

5 |

6 |

Performance limits: (measured with HLP46, ϑOil = 40 °C ±5 °C)

Size 32

|

2-spool position valve – qV maxin l/min |

|||||

|

Symbol |

Operating pressure pmax in bar |

||||

|

70 |

140 |

210 |

280 |

350 |

|

|

X external – spring end position in the main valve (with ppilot min = 10 bar) |

|||||

|

C, D, K, Y, Z |

1100 |

1040 |

860 |

750 |

680 |

|

X external – spring end position in the main valve 1) |

|||||

|

C |

1100 |

1040 |

860 |

800 |

700 |

|

D, Y |

1100 |

1040 |

540 |

480 |

420 |

|

K |

1100 |

1040 |

860 |

500 |

450 |

|

Z |

1100 |

1040 |

860 |

700 |

650 |

|

X external – hydraulic end position in the main valve |

|||||

|

HC, HD, HK, HZ, HY |

1100 |

1040 |

860 |

750 |

680 |

| 1) | If the specified flow values are exceeded, the function of the return spring is no longer guaranteed if the pilot pressure fails! |

Size 32

|

3-spool position valves – qV max in l/min |

|||||

|

Symbol |

Operating pressure pmax in bar |

||||

|

70 |

140 |

210 |

280 |

350 |

|

|

X external, spring centering in the main valve |

|||||

|

E, J, L, M, Q, R, U, W |

1100 |

1040 |

860 |

750 |

680 |

|

G, T, H, F, P |

900 |

900 |

800 |

650 |

450 |

|

V |

1100 |

1000 |

680 |

500 |

450 |

Performance limits: important information

Notice (applies to all sizes):

The specified switching power limits are valid for use with two directions of flow (e. g. from P → A and simultaneous return flow from B → T) at the ratio 1:1.

Due to the flow forces acting within the valves, the admissible switching power limit may be considerably lower with only one direction of flow (e. g. from P → A while port B is blocked, with flow in the same or in different directions)!

In such cases, please consult us!

The switching power limit was established while the solenoids were at operating temperature, at 10 % undervoltage and without tank preloading.

|

NG16 |

With pilot oil supply X internal, a preload valve has to be used for flows < 160 l/min due to the negative overlap of symbols V, C, Z and HC, HZ. With pilot oil supply X internal, sufficient flow has to be ensured due to the negative overlap of symbols F, G, H, P, S and T (for the determination of the required flow, see "Preload valve" characteristic curves). If the required flow is not reached, a preload valve has to be used (see technical data). |

|

NG25 |

With pilot oil supply X internal, a preload valve has to be used for flows < 180 l/min due to the negative overlap of the symbols Z, HZ and V. With pilot oil supply X internal, sufficient flow has to be ensured due to the negative overlap of symbols C, HC, F, G, H, P, and T (for the determination of the required flow, see "Preload valve" characteristic curves). If the required flow is not reached, a preload valve has to be used (see technical data). |

|

NG32 |

With pilot oil supply X internal a preload valve has to be used for flows < 180 l/min due to the negative overlap of symbols Z, HZ and V. With pilot oil supply X internal sufficient flow needs to be ensured due to the negative overlap of symbols C, HC, F, G, H, P and T (for determination of the required flow, see “Preload valve” characteristic curves. If the required flow is not reached, a preload valve has to be used (see technical data). |

2 spool positions / 3 spool positions

| 1) | Example: Symbol E with spool position “a” order example: H-4WEH 16 EA7X/6EG24N9XEETSZ2B10..V.. |

| 2) | Only for NG16 |

Notes:

Representation of the symbols according to DIN ISO 1219-1. Hydraulic interim positions are shown by dashes. Other symbols upon requestControl spool symbols for valves with 2 spool positions

Control spool symbols for valves with 3 spool positions

The type-examination tested valve solenoid of the valve is equipped with a terminal box and a type-tested cable gland.

The connection is polarity-independent.

Solenoids to be connected to AC voltage are equipped with an integrated rectifier.

Notice

In the electrical connection, the protective earthing conductor (PE, grounded) is to be connected in accordance with the stipulations.

|

Properties of the connection terminals |

||

|

Position |

Function |

Connectable line cross-section |

|

1 |

Operating voltage connection |

Single-wire 0.75 … 2.5 mm2 Finely stranded,0.75 … 1.5 mm2 |

|

2 |

Connection for protective earthing conductor |

Single-wire 2.5 mm2 max. Finely stranded, 1.5 mm2 max. |

|

3 |

Connection for potential equalization conductor |

Single-wired, 4 … 6 mm2 Finely stranded, 4 mm2 |

|

Cable gland |

Type approval |

II 2G Ex e IIC Gb | |

|

Threaded connection |

M20 x 1.5 | ||

|

Type of protection according to EN 60529 |

IP66 (with correctly installed electrical connection) | ||

|

Line diameter |

mm |

7 ... 10.5 | |

|

Sealing |

Outer sheath sealing | ||

|

Connection line |

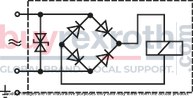

Line type |

Non-armored cables and lines (outer sheath sealing) | |

|

Temperature range |

°C |

-30 … +110 | |

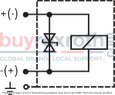

Circuit diagrams

Direct voltage, polarity-independent

AC voltage

Over-current fuse and switch-off voltage peak

Notice

A fuse which corresponds to the rated current according to DIN 41571 and EN / IEC 60127 has to be connected upstream of every valve solenoid (max. 3 x Irated).

The shut-off threshold of the fuse has to match the prospective short-circuit current of the supply source.

The prospective short-circuit current of the supply source may amount to a maximum of 1500 A.

This fuse may only be installed outside the potentially explosive atmosphere or must be of an explosion-proof design.

When inductivities are switched off, voltage peaks result which may cause faults in the connected control electronics.

The voltage peak must be damped by a suitable external circuitry. We recommend a circuitry with a suppressor diode with a limitation voltage of approx. 50 V.

|

Voltage data in the valve type code |

Nominal voltage valve solenoid |

Rated current valve solenoid |

Rated current for external miniature fuse: Medium time-lag (M) according to DIN 41571 and EN/IEC 60127 |

Rated voltage of external miniature fuse: Medium time-lag (M) according to DIN 41571 and EN/IEC 60127 |

Maximum voltage value when switching off |

Interference protection circuit |

|

G24 |

24 V DC |

0.708 A DC |

800 mA |

250 V |

–90 V |

Suppressor diode bi-directional |

|

G48 |

48 V DC |

0.354 A DC |

400 mA |

250 V |

–200 V |

|

|

G96 |

96 V DC |

0.177 A DC |

200 mA |

250 V |

–370 V |

|

|

G110 |

110 V DC |

0.155 A DC |

200 mA |

250 V |

–390 V |

|

|

W110R |

110 V AC |

0.163 A AC |

200 mA |

250 V |

–3 V |

Bridge rectifier and suppressor diode |

|

W230R |

230 V AC |

0.078 A AC |

80 mA |

250 V |

–3 V |

Type H-4WEH 10…

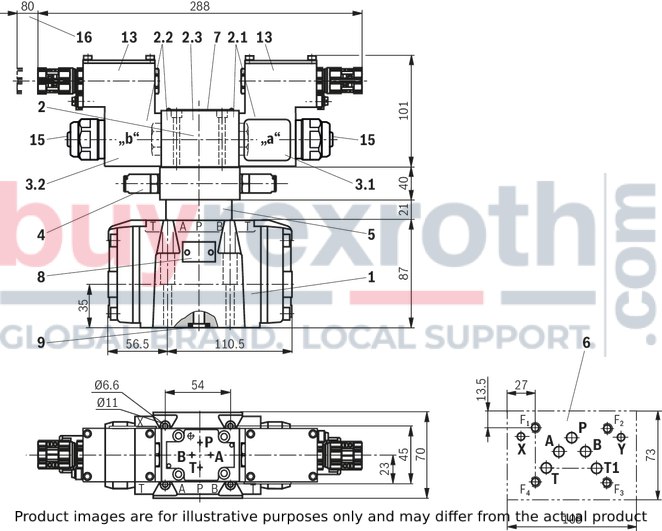

Dimensions in mm

|

|

Required surface quality of the valve contact surface |

|

1 |

Main valve |

|

2 |

Pilot control valve type 4WE 6…XE according to data sheet 23178-XE-B2 |

|

2.1 |

Pilot control valve type 4WE 6 D (1 solenoid “a”) for main valves with: Symbols C, D, K, Z Symbols HC, HD, HK, HZPilot control valve type 4WE 6 JA... (1 solenoid “a”) for main valves with: Symbols EA, FA, etc., spring return |

|

2.2 |

Pilot control valve type 4WE 6 Y... (1 solenoid "b") for main valves with symbol Y symbol HYPilot control valve type 4WE 6 JB... (1 solenoid "b") for main valves with symbols EB, FB, etc., spring return |

|

2.3 |

Pilot control valve type 4WE 6 J… (2 solenoids) for main valves with 3 spool positions, spring-centered |

|

3.1 |

Valve solenoid "a" |

|

3.2 |

Valve solenoid "b" |

|

4 |

Switching time adjustment, optional |

|

5 |

Pressure reducing valve, optional |

|

6 |

machined valve contact surface Porting pattern according to: ISO 4401-05-05-0-05 for NG10 ISO 4401-07-07-0-05 for NG16 ISO 4401-08-08-0-05 for NG25 ISO 4401-10-09-0-05 for NG32 |

|

7 |

Name plate for the pilot control valve |

|

8 |

Name plate for the complete valve |

|

9 |

R-rings/O-rings |

|

13 |

Terminal box |

|

15 |

Optional auxiliary operating device |

|

16 |

Space required to remove the solenoid coil |

Valve mounting screws (separate order)

For reasons of stability, exclusively use the following valve mounting screws:

4 hexagon socket head cap screws

ISO 4762-M6x45-10.9-flZn-240h-L

(friction coefficient μtotal = 0.09 - 0.14)

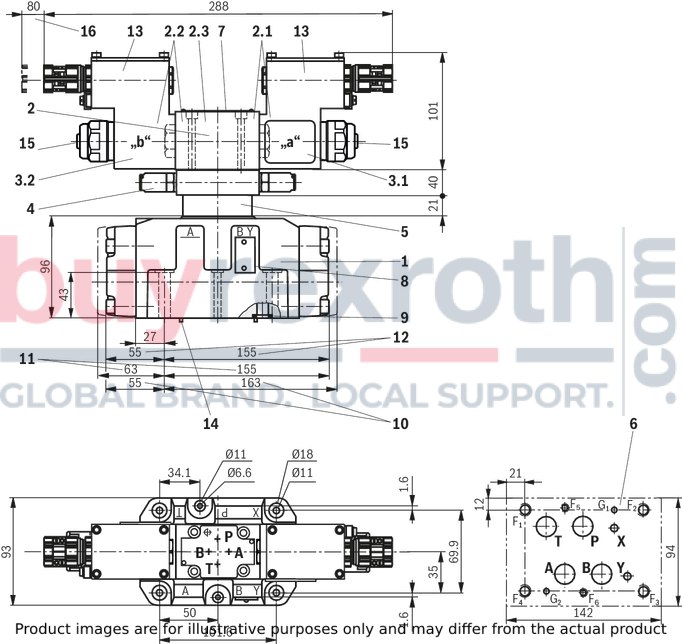

Type H-4WEH 16…

Dimensions in mm

|

|

Required surface quality of the valve contact surface |

|

1 |

Main valve |

|

2 |

Pilot control valve type 4WE 6…XE according to data sheet 23178-XE-B2 |

|

2.1 |

Pilot control valve type 4WE 6 D (1 solenoid “a”) for main valves with: Symbols C, D, K, Z Symbols HC, HD, HK, HZPilot control valve type 4WE 6 JA... (1 solenoid “a”) for main valves with: Symbols EA, FA, etc., spring return |

|

2.2 |

Pilot control valve type 4WE 6 Y... (1 solenoid "b") for main valves with symbol Y symbol HYPilot control valve type 4WE 6 JB... (1 solenoid "b") for main valves with symbols EB, FB, etc., spring return |

|

2.3 |

Pilot control valve type 4WE 6 J… (2 solenoids) for main valves with 3 spool positions, spring-centered |

|

3.1 |

Valve solenoid "a" |

|

3.2 |

Valve solenoid "b" |

|

4 |

Switching time adjustment, optional |

|

5 |

Pressure reducing valve, optional |

|

6 |

machined valve contact surface Porting pattern according to: ISO 4401-05-05-0-05 for NG10 ISO 4401-07-07-0-05 for NG16 ISO 4401-08-08-0-05 for NG25 ISO 4401-10-09-0-05 for NG32 |

|

7 |

Name plate for the pilot control valve |

|

8 |

Name plate for the complete valve |

|

9 |

R-rings/O-rings |

|

10 |

2-spool position valves with spring end position in the main valve (C, D, K, Z) |

|

11 |

2-spool position valves with spring end position in the main valve (Y) |

|

12 |

3-spool position valves, spring-centered, 2-spool position valves with hydraulic end position in the main valve |

|

13 |

Terminal box |

|

14 |

Locking pin |

|

15 |

Optional auxiliary operating device |

|

16 |

Space required to remove the solenoid coil |

Valve mounting screws (separate order)

For reasons of stability, exclusively the following valve mounting screws are to be used:

4 hexagon socket head cap screws

ISO 4762-M10x60-10.9-flZn-240h-L

(friction coefficient μtotal = 0.09 - 0.14 according to VDA 235-101)

2 hexagon socket head cap screws

ISO 4762-M6x60-10.9-flZn-240h-L

(friction coefficient µtotal = 0.09 - 0.14)

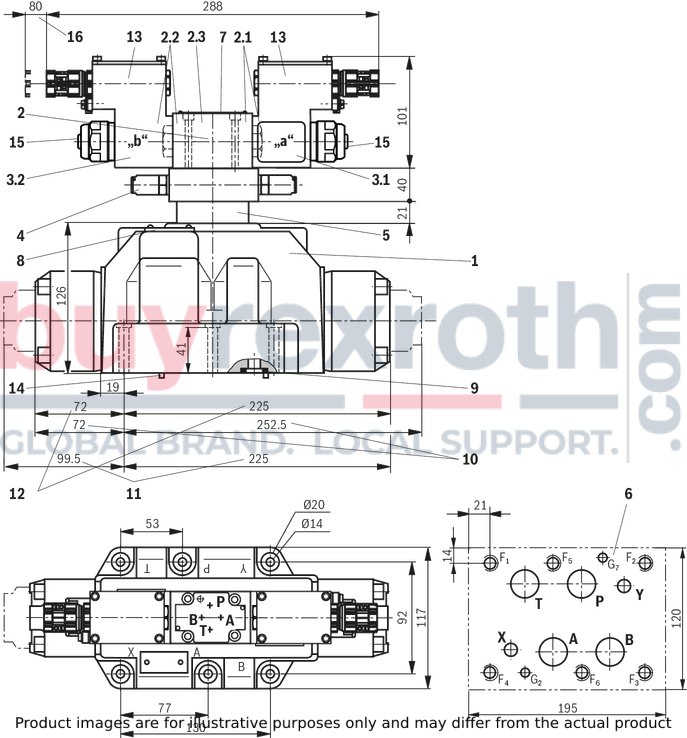

Type H-4WEH 25…

Dimensions in mm

|

|

Required surface quality of the valve contact surface |

|

1 |

Main valve |

|

2 |

Pilot control valve type 4WE 6…XE according to data sheet 23178-XE-B2 |

|

2.1 |

Pilot control valve type 4WE 6 D (1 solenoid “a”) for main valves with: Symbols C, D, K, Z Symbols HC, HD, HK, HZPilot control valve type 4WE 6 JA... (1 solenoid “a”) for main valves with: Symbols EA, FA, etc., spring return |

|

2.2 |

Pilot control valve type 4WE 6 Y... (1 solenoid "b") for main valves with symbol Y symbol HYPilot control valve type 4WE 6 JB... (1 solenoid "b") for main valves with symbols EB, FB, etc., spring return |

|

2.3 |

Pilot control valve type 4WE 6 J… (2 solenoids) for main valves with 3 spool positions, spring-centered |

|

3.1 |

Valve solenoid "a" |

|

3.2 |

Valve solenoid "b" |

|

4 |

Switching time adjustment, optional |

|

5 |

Pressure reducing valve, optional |

|

6 |

machined valve contact surface Porting pattern according to: ISO 4401-05-05-0-05 for NG10 ISO 4401-07-07-0-05 for NG16 ISO 4401-08-08-0-05 for NG25 ISO 4401-10-09-0-05 for NG32 |

|

7 |

Name plate for the pilot control valve |

|

8 |

Name plate for the complete valve |

|

9 |

R-rings/O-rings |

|

10 |

2-spool position valves with spring end position in the main valve (C, D, K, Z) |

|

11 |

2-spool position valves with spring end position in the main valve (Y) |

|

12 |

3-spool position valves, spring-centered, 2-spool position valves with hydraulic end position in the main valve |

|

13 |

Terminal box |

|

14 |

Locking pin |

|

15 |

Optional auxiliary operating device |

|

16 |

Space required to remove the solenoid coil |

Valve mounting screws (separate order)

For reasons of stability, exclusively use the following valve mounting screws:

6 hexagon socket head cap screws

ISO 4762-M12x60-10.9-flZn-240h-L

(friction coefficient μtotal = 0.09 - 0.14)

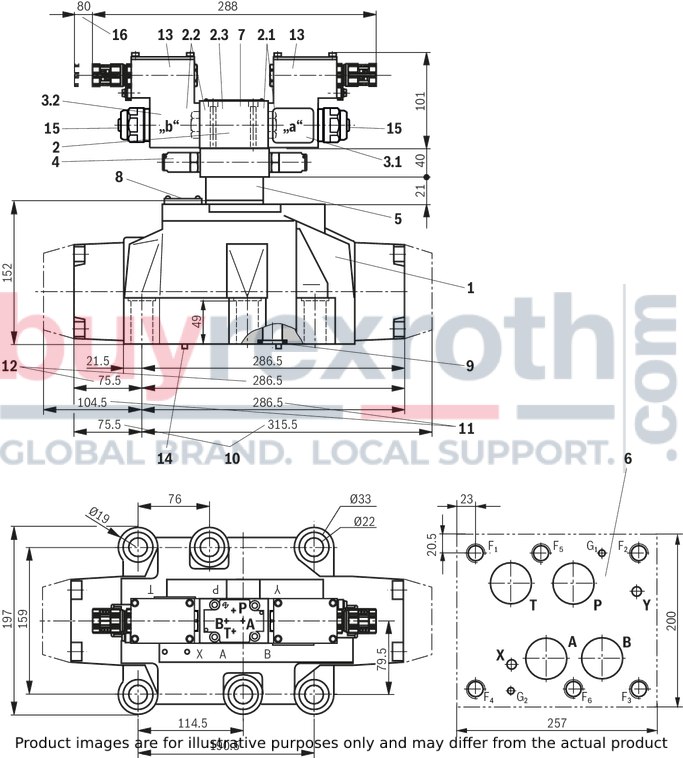

Type H-4WEH 32…

Dimensions in mm

|

|

Required surface quality of the valve contact surface |

|

1 |

Main valve |

|

2 |

Pilot control valve type 4WE 6…XE according to data sheet 23178-XE-B2 |

|

2.1 |

Pilot control valve type 4WE 6 D (1 solenoid “a”) for main valves with: Symbols C, D, K, Z Symbols HC, HD, HK, HZPilot control valve type 4WE 6 JA... (1 solenoid “a”) for main valves with: Symbols EA, FA, etc., spring return |

|

2.2 |

Pilot control valve type 4WE 6 Y... (1 solenoid "b") for main valves with symbol Y symbol HYPilot control valve type 4WE 6 JB... (1 solenoid "b") for main valves with symbols EB, FB, etc., spring return |

|

2.3 |

Pilot control valve type 4WE 6 J… (2 solenoids) for main valves with 3 spool positions, spring-centered |

|

3.1 |

Valve solenoid "a" |

|

3.2 |

Valve solenoid "b" |

|

4 |

Switching time adjustment, optional |

|

5 |

Pressure reducing valve, optional |

|

6 |

machined valve contact surface Porting pattern according to: ISO 4401-05-05-0-05 for NG10 ISO 4401-07-07-0-05 for NG16 ISO 4401-08-08-0-05 for NG25 ISO 4401-10-09-0-05 for NG32 |

|

7 |

Name plate for the pilot control valve |

|

8 |

Name plate for the complete valve |

|

9 |

R-rings/O-rings |

|

10 |

2-spool position valves with spring end position in the main valve (C, D, K, Z) |

|

11 |

2-spool position valves with spring end position in the main valve (Y) |

|

12 |

3-spool position valves, spring-centered, 2-spool position valves with hydraulic end position in the main valve |

|

13 |

Terminal box |

|

14 |

Locking pin |

|

15 |

Optional auxiliary operating device |

|

16 |

Space required to remove the solenoid coil |

Valve mounting screws (separate order)

For reasons of stability, exclusively use the following valve mounting screws:

6 hexagon socket head cap screws

ISO 4762-M20x80-10.9-flZn-240h-L

(friction coefficient μtotal = 0.09 - 0.14)

Switching time adjustment, pressure reducing valve, preload valve

“S/S2” switching time adjustment

The influence on the switching time of the main valve (1) is achieved by using a twin throttle check valve (2), type Z2FS 6.

Symbol (3) shows the switching time adjustment “S” (supply control), symbol (4) shows the switching time adjustment “S2” (discharge control)

Type H-4WEH 10 ..4X/…S oder S2

“D3” pressure reducing valve

With internal pilot oil supply (ET or E) or external pilot oil supply and a pilot pressure of more than 250 bar, the valve must be ordered with a pressure reducing valve (5), type ZDR6PO, and a throttle insert “B10”.

Ordering code: “B10..D3”

Type H-4WEH 10 ..4X/…/..D3

“P4,5” preload valve (not for NG10)

In case of valves with depressurized circulation and internal pilot oil supply, a preload valve is required in channel P of the main valve in order to build up the minimum pilot pressure.

Ordering code: “P4,5”

The pressure differential of the preload valve is to be added to the pressure differential of the main valve (see characteristic curves) to result in one total value.

The cracking pressure is approx. 4.5 bar.

Δp–qV characteristic curve

(measured with HLP46, ϑOil = 40 ±5 °C)

Related Products

R901031907

$437.00 USD

R900929184

$1,292.00 USD

R978027798

$684.00 USD

R901239019

$634.00 USD

R901392998

$569.00 USD