***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

The Bosch Rexroth 5-4WE10J5X/EG24K4QS0G24W/M=AN (R901415583) is a high-performance directional spool valve designed for controlling the start, stop, and direction of fluid flow within a hydraulic system. The valve features a housing, electronic solenoids, control spool, and return springs. In its default state, the control spool is held in position by the return springs; however, when the solenoid is energized, it moves to an end position to allow for the desired flow direction.

This model includes manual override capabilities for situations where manual actuation of the valve is necessary without solenoid power. It also has provisions for throttle inserts in various channels to adjust flow resistance when operational conditions exceed the valve's performance limit. The version offered here comes without spring return (type O), meaning that there isn't a defined rest position when de-energized unless it's a version with detent (type OF), which locks the control spool in place.

The 5-4WE10J5X/EG24K4QS0G24W/M=AN valve allows for switching time adjustments via a throttle screw or selected orifice to delay switching times up to milliseconds based on pressure, flow rate, and fluid viscosity specific to installation requirements. Additionally, this model ensures soft switching by separating the T channels from spring chambers.

This directional valve can be configured as 3 or 4-way and has porting patterns according to ISO standards. It features high-power solenoids that are optionally rotatable by 90 degrees and provides electrical connections as individual connections or with optional PWM connectors for fast switching amplifiers and energy reduction. Options include auxiliary operating devices, spool position monitoring, and compliance with CE conformity standards for electrical voltages above certain thresholds. Solenoid coils come with UR approval (UL recognized), and CSA approval is optional.

The unit operates effectively up to a maximum pressure of 350 bar and can handle maximum flow rates up to specified limits depending on size and component series. It's engineered for robust performance in various hydraulic applications requiring precise flow direction control.

$7,824.00 USD

More are expected on September 17, 2026

| Qty | Price | Savings |

|---|---|---|

| 5-24 | $7,628.40 USD | $195.60 USD |

| 25+ | $7,432.80 USD | $391.20 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as September 17, 2026 when ordered in

This product is eligible for factory repair.

4/3-, 4/2- or 3/2-way version Porting pattern according to ISO 4401-05-04-0-05 High-power solenoid, optionally rotatable by 90° Electrical connection as individual connection Use optionally with PWM connector (fast switching amplifier, energy reduction) Optional auxiliary operating device Spool position monitoring, optional CE conformity according to the Low-Voltage Directive 2006/95/EC for electrical voltages >50 VAC or > 75VDC Solenoid coil with UR approval UL 429 Approval according to CSA C22.2 no. 139-10, optional

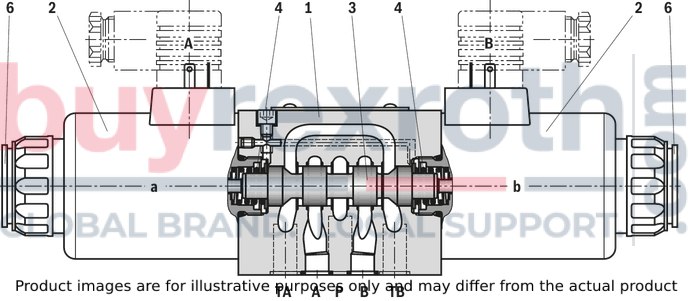

The 5-chamber directional valve type 5-.WE is a solenoid-actuated directional spool valve with switching time increase. It controls the start, stop and direction of a flow. The directional valve basically consists of housing (1), one or two electronic solenoids (2), control spool (3), and the return springs (4).

In de-energized condition, the control spool (3) is held in the central position or in the initial position by the return springs (4) (except for valves without spring "O").

If the wet-pin electronic solenoid (2) is energized, the control spool (3) moves out of its rest position into the required end position. In this way, the required direction of flow according to the selected symbol is released.

After the electronic solenoid (2) has been switched off, the control spool (3) is pushed back into the central position or in the initial position (except for valve with "OF" detent and valve without spring type "O").

A manual override (6) allows for the manual switching of the valve without solenoid energization.

To ensure proper functioning, make sure that the pressure chamber of the solenoid is filled with oil.

Type 5-4WE 10 …

Throttle insert

Using a throttle insert (9) in channels P, A, B or T, the flow resistance at the valve can be increased. Its use is required when, due to prevailing operating conditions, flows occur during the switching processes, which exceed the performance limit of the valve.

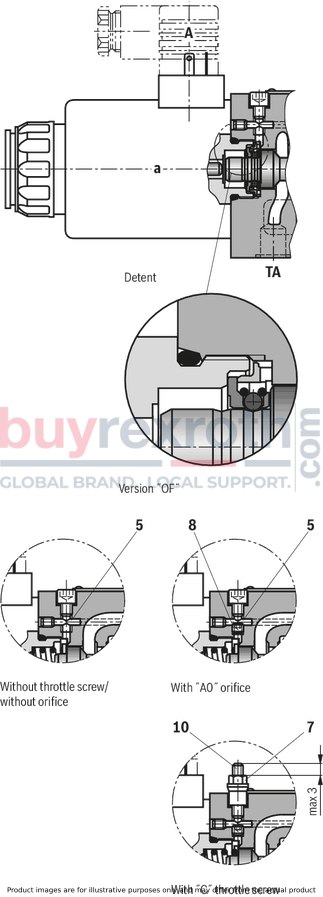

Without spring return “O” (only possible with symbols A, C and D)

This version is a directional valve with 2 spool positions and 2 electronic solenoids without detent. The valve without spring return at the control spool (3) does not have a defined basic position in the de-energized condition.

Without spring return with detent “OF” (only possible with symbols A, C and D)

This version is a directional valve with 2 spool positions and 2 electronic solenoids with detent. The detents are used to lock the control spool (3) in the relevant spool position. During operation, continuous application of current to the electronic solenoid can thus be omitted which contributes to energy-efficient operation.

Notice:

Pressure peaks in the tank line to two or several valves can result in unintended movements of the control spool in the case of valves with detent. We therefore recommend that separate return lines be provided or a check valve installed in the tank line.

Influencing the switching time

With the 5-chamber directional valve type 5-.WE, the switching time can be delayed to 100 ms and more by means of a throttle screw "C" (7) or a selected orifice "A0.” (8). In this connection, the switching time is pressure-, flow- and viscosity-dependent, specific to the installation. The switching time is influenced by means of a restriction (throttle or orifice) in the connection channel (5) between the two spring chambers in which the liquid volume is displaced from one spring chamber into the other in case of a switching process.

The T channels are separated from the spring chambers in order to achieve soft switching.

Notices!

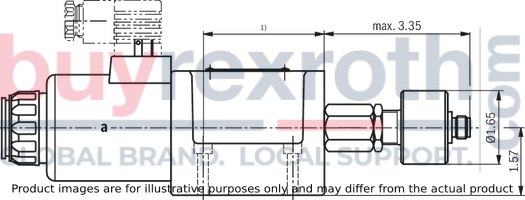

The adjustment spindle (10) may only be screwed out so that it protrudes from the nut by max. 3 mm.

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

|||||

|

5 |

- |

WE |

10 |

- |

5X |

/ |

E |

/ |

= |

* |

|

01 |

Standard version (maximum operating pressure 350 bar) |

no code |

||

|

High-pressure version (maximum operating pressure 420 bar) |

H |

|||

|

02 |

5-chamber version |

5 |

||

|

03 |

3 main ports |

3 |

||

|

4 main ports |

4 |

|||

|

04 |

Directional valve |

WE |

||

|

05 |

Size 10 |

10 |

||

|

06 |

Symbols e. g. C, E, EA, EB, etc.; for the possible version, see Symbols |

|||

|

07 |

Component series 50 … 59 (50 … 59: unchanged installation and connection dimensions) |

5X |

||

|

Spool return |

||||

|

08 |

With spring return |

no code |

||

|

With reinforced compression spring (for quick switching off) |

D |

|||

|

Without spring return |

O |

|||

|

Without spring return with detent |

OF |

|||

|

09 |

High-power solenoid, wet-pin, with detachable coil |

E |

||

|

10 |

Direct voltage 12 V |

G12 |

||

|

Direct voltage 24 V |

G24 |

|||

|

Direct voltage 26 V |

G26 |

|||

|

Direct voltage 48 V |

G48 |

|||

|

Nominal voltage 96 V at DC solenoid in operation with AC voltage mains (AC voltage mains 100/110 V - 50/60 Hz with an admissible voltage tolerance of +/- 10 %) |

G96 |

|||

|

Direct voltage 110 V |

G110 |

|||

|

Direct voltage 125 V |

G125 |

|||

|

Nominal voltage 180 V at DC solenoid in operation with AC voltage (AC voltage mains 200 V - 50/60 Hz with an admissible voltage tolerance of +/- 10 %) |

G180 |

|||

|

Nominal voltage 205 V at DC solenoid with operation with AC voltage mains (AC voltage mains 230 V – 50/60 Hz with an admissible voltage tolerance of +/- 10 %) |

G205 |

|||

|

Direct voltage 220 V |

G220 |

|||

|

Connection to AC voltage mains via control with rectifier (see table Mating connectors) |

||||

|

Electrical connections and available voltages see Technical data |

||||

|

11 |

Without manual override |

no code |

||

|

With concealed manual override (standard) |

N9 1) |

|||

|

With concealed manual override and protective cap 3) |

N8 1) |

|||

|

With lockable manual override "mushroom button" (large) |

N5 1;2) |

|||

|

With manual override "mushroom button" (large), not lockable |

N6 1) |

|||

|

Corrosion resistance (outside) |

||||

|

12 |

None (valve housing primed) |

no code |

||

|

Improved corrosion protection (240 h salt spray test according to EN ISO 9227); (only version "K4K") |

J3 |

|||

|

Electrical connection 5) |

||||

|

13 |

Individual connection |

|||

|

Without mating connector, with connector DIN EN 175301-803 |

K4 4) |

|||

|

Without mating connector, with connector DIN EN 175301-803 (coil with potted-in connector base and sealing element to valve housing (IP67); possible with version "J3") |

K4K 4) |

|||

|

Without mating connector, 4-pole with connector M12x1, integrated interference protection circuit, status LED according to IEC 60947-5-2 |

K72L 4;5) |

|||

|

Without mating connector; connector AMP Junior-Timer |

C4Z 4) |

|||

|

For further electrical connections and available voltages, see Technical data |

||||

|

Spool position monitoring |

||||

|

14 |

Without position switch |

no code |

||

|

Inductive position switch type QM |

||||

|

Monitored spool position "a" |

QMAG24 |

|||

|

Monitored spool position "b" |

QMBG24 |

|||

|

Monitored spool position "0" |

QM0G24 |

|||

|

Inductive position switch type QS |

||||

|

Monitored spool position "a" |

QSAG24W |

|||

|

Monitored spool position "b" |

QSBG24W |

|||

|

Monitored spool position "0" |

QS0G24W |

|||

|

Monitored spool position "0" and "a" |

QS0AG24W |

|||

|

Monitored spool position "0" and "b" |

QS0BG24W |

|||

|

Monitored spool position "a" and "b" |

QSABG24W |

|||

|

For further details, see data sheet 24830 |

||||

|

Switching time increase |

||||

|

15 |

Without switching time increase |

no code |

||

|

With throttle screw |

C |

|||

|

With orifice Ø 0.6 mm |

A06 |

|||

|

With orifice Ø 0.8 mm |

A08 |

|||

|

With orifice Ø 1.0 mm |

A10 |

|||

|

Throttle insert |

||||

|

16 |

Without throttle insert |

no code |

||

|

With throttle insert 6); 7) : |

||||

|

Port |

Throttle Ø in mm |

|||

|

0,8 mm |

1,0 mm |

1,2 mm |

||

|

P |

B08 |

B10 |

B12 |

|

|

A |

H08 |

H10 |

H12 |

|

|

B |

R08 |

R10 |

R12 |

|

|

A and B |

N08 |

N10 |

N12 |

|

|

T 8) |

X08 |

X10 |

X12 |

|

|

Further throttle insert diameters upon request |

||||

|

Control spool play |

||||

|

17 |

Standard |

no code |

||

|

Minimum (to be selected in case of reduced leakage → higher level of oil cleanliness recommended) |

T06 |

|||

|

Increased (to be selected in case of a hydraulic fluid/environment temperature difference >25 K → increased internal leakage) |

T12 |

|||

|

Seal material |

||||

|

18 |

NBR seals |

M |

||

|

FKM seals |

V |

|||

|

Seals for HFC hydraulic fluids |

MH |

|||

|

Low-temperature version |

MT |

|||

|

Observe compatibility of seals with hydraulic fluid used. (Other seals upon request) |

||||

|

19 |

Approval according to CSA C22.2 no. 139-10 |

CSA |

||

|

Porting pattern according to ANSI B93.9 (if solenoid "a" is energized, channel P is connected to A) |

AN |

|||

|

20 |

Further details in the plain text |

* |

||

| 1) The manual override cannot be allocated a safety function. The manual override units may only be used up to a tank pressure of 50 bar. | |

| 2) With tank pressures above 50 bar, it cannot be guaranteed that the valve remains in the position switched by the manual override "N5". | |

| 3) Protective cap must be removed prior to actuation. | |

| 4) Mating connectors, separate order, see table Mating connectors and data sheet 08006. | |

| 5) M12x1 plug-in connection see data sheet 08010. | |

| 6) When the admissible valve performance limits are exceeded, installation of throttle inserts is to be intended (performance limits see 2 spool positions). | |

| 7) Not with low-temperature version "MT". | |

| 8) When throttle inserts are used in channel T, the pressure in the working ports and in case of connection to the tank chambers must not exceed 210 bar. |

|

AC voltage mains (admissible voltage tolerance ± 10%) |

Nominal voltage of the DC solenoid in case of operation with alternating voltage |

Ordering code |

|

100 V - 50/60 Hz |

96 V |

G96 |

|

100 V - 50/60 Hz |

96 V |

G96 |

|

200 V - 50/60 Hz |

180 V |

G180 |

|

230 V - 50/60 Hz |

205 V |

G205 |

Notice:

Conversion from AC voltage to DC voltage requires a mating connector with rectifier (separate order, material no. R901017025).

general

|

Size |

10 | ||

|

Installation position |

any | ||

|

Ambient temperature range |

NBR seals |

°C |

-20 … +70 |

|

FKM seals |

°C |

-15 … +70 | |

|

Version for HFC hydraulic fluid |

°C |

-20 … +50 | |

|

Low-temperature version |

°C |

-40 … +50 | |

|

Storage temperature range |

°C |

-20 … +50 | |

|

Weight |

Valve with one solenoid |

kg |

3.9 |

|

Valve with two solenoids |

kg |

5.5 | |

|

MTTFD values according to EN ISO 13849 1) |

Years |

300 | |

| 1) | For further details, see data sheet 08012 |

hydraulic

|

Size |

10 | ||

|

Maximum operating pressure (pP > pA; pB > pT) |

Port P |

bar |

350 420 |

|

Port A |

bar |

350 420 |

|

|

Port B |

bar |

350 420 |

|

|

Port T 1) |

bar |

210 | |

|

Maximum flow |

l/min |

150 | |

|

Flow cross-section (spool position 0) |

Symbol Q |

approx. 6 % of nominal cross-section | |

|

Symbol W |

approx. 3 % of nominal cross-section | ||

|

Hydraulic fluid |

see table | ||

|

Hydraulic fluid temperature range |

NBR seals |

°C |

-20 … +80 |

|

FKM seals |

°C |

-15 … +80 | |

|

HFC hydraulic fluid |

°C |

-20 … +50 | |

|

Low-temperature version |

°C |

-40 … +50 | |

|

Viscosity range |

mm²/s |

2.8 … 500 | |

|

Maximum admissible degree of contamination of the hydraulic fluid 2) |

Class 20/18/15 according to ISO 4406 (c) | ||

| 1) | With symbols A and B, port T must be used as leakage oil connection if the operating pressure exceeds the admissible tank pressure. |

| 2) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

|

Hydraulic fluid |

Classification |

Suitable sealing materials |

Standards |

Data sheet |

|

|

Mineral oils |

HL, HLP, HLPD, HVLP, HVLPD |

NBR, FKM |

DIN 51524 |

90220 |

|

|

Bio-degradable |

Insoluble in water |

HETG |

NBR, FKM |

ISO 15380 |

90221 |

|

HEES |

FKM |

||||

|

Soluble in water |

HEPG |

FKM |

ISO 15380 |

||

|

Containing water |

Water-free |

HFDU, HFDR |

FKM |

ISO 12922 |

90222 |

|

Containing water |

HFC (Fuchs Hydrotherm 46M, Petrofer Ultra Safe 620 ) |

NBR |

ISO 12922 |

90223 |

|

|

Important information on hydraulic fluids: For further information and data on the use of other hydraulic fluids, please refer to the data sheets above or contact us. There may be limitations regarding the technical valve data (temperature, pressure range, life cycle, maintenance intervals, etc.). The ignition temperature of the hydraulic fluid used must be 40 K higher than the maximum solenoid surface temperature.Flame-resistant – containing water: Maximum pressure differential per control edge 50 bar. Pressure pre-loading at the tank port >20% of the pressure differential; otherwise, increased cavitation Life cycle compared to operation with mineral oil HL, HLP 50 to 100 %Bio-degradable and flame-resistant: When using hydraulic fluids that are simultaneously zinc-solving, zinc may accumulate (700 mg zinc per pole tube). |

|||||

electrical

|

Voltage type |

Direct voltage | AC voltage | ||

|

Nominal voltage according to VDE 0580 |

V |

12 24 26 48 96 110 125 180 205 220 |

100 1) 110 1) 200 1) 230 1) |

|

|

Voltage tolerance (nominal voltage) |

% |

± 10 | ||

|

Nominal power according to VDE 0580 2) |

W |

40 | ||

|

Duty cycle 3) |

% |

100 | ||

|

Switching time |

ON (pressure change 5 %) 4) |

ms |

60 … 104 | |

|

ON (pressure change 95 %) 4) |

ms |

90 … 165 | ||

|

OFF (pressure change 5 %) 5) |

ms |

12 … 50 | 230 … 330 | |

|

OFF (pressure change 95 %) 5) |

ms |

48 … 104 | 250 … 360 | |

|

Switching time according to ISO 6403 6) |

ON |

ms |

45 … 60 | |

|

OFF |

ms |

20 … 30 | 250 … 360 | |

|

Maximum switching frequency |

1/h |

15000 | 7200 | |

|

Maximum surface temperature of the coil 7) |

°C |

140 | ||

|

Insulation class VDE 0580 |

F | |||

|

Electrical fuse protection |

Every solenoid must be protected individually using a suitable fuse with tripping characteristics K (inductive loads). The valve must be installed on a surface that is included in the equipotential bonding. | |||

|

Protective earthing conductor and screening |

see connector pin assignment (CE-compliant installation) | |||

|

Conformity |

CE according to Low-Voltage Directive 2006/95/EC tested according to DIN EN 60204-1 (VDE0113-1): 2010-05 and DIN VDE 0580: 2000-07 | |||

| 1) | Only possible with rectifier. Mating connectors with rectifier (separate order). For possible voltages, see ordering code. Rectifiers must comply with the relevant standards as well as the coil performance data! |

| 2) | Reduction of the nominal power by approx. 40 % when using a 24 V coil with connector switching amplifier type VT-SSBA1-PWM-1X/V002/5 (separate order, material no. R901265633, see data sheet 30362) |

| 3) | Operating mode according to VDE 0580 |

| 4) | Measured with flow, 80 % performance limit and horizontal installation position. Not with symbols A and B. Reduction of the switching time by approx. 50 % when using a 12 V coil with connector switching amplifier type VT-SSBA1-PWM-1X/V001/5 (separate order, material no. R901265633, see data sheet 30362) |

| 5) | Measured with flow, 80% performance limit and horizontal installation position. |

| 6) | Measured without flow |

| 7) | Surface temperature > 50 °C, provide contact protection. |

Notes!

The solenoid coils must not be painted. Actuation of the manual override is only possible up to a tank pressure of approx. 50 bar. Avoid damage to the bore of the manual override! (Special tool for actuation, separate order, material no. R900024943). When the manual override is blocked, actuation of the opposite solenoid must be ruled out! The simultaneous actuation of 2 solenoids of one valve must be ruled out! Use cables that are approved for a working temperature above 105 °C. When solenoid coils are switched off, voltage peaks result which may cause faults or damage in the connected control electronics. The user has to provide for a suitable circuit for limiting the voltage peaks. It must be noted that a diode switched in an antiparallel form extends the switching off time. Valves with single connection and supply voltage 12 V or 24 V can be operated with twice the voltage for reducing the switching time. For this purpose, the voltage has to be reduced to the nominal valve voltage after 100 ms by means of pulse width modulation. The maximum admissible switching frequency is 5 1 /s. If the standard environmental conditions according to VDE 0580 cannot be provided, the valve must be especially protected!|

Electrical connections and coil connection combinations |

||||||||||||||

|

Ordering code connector |

Ordering code Direct voltage |

Protection class according to DIN EN 60529 1) |

Protection class according to VDE 0580 |

|||||||||||

|

G12 |

G24 |

G26 |

G48 |

G96 |

G110 |

G125 |

G180 |

G205 |

G220 |

|||||

|

Individual connection |

Without mating connector Connector according to DIN EN 175301-803 |

K4 |

✔ |

✔ |

– |

✔ |

✔ |

– |

✔ |

✔ |

✔ |

✔ 2) |

IP65 |

I |

|

K4K 3) |

✔ 2) |

✔ 2) |

✔ 2) |

– |

– |

– |

– |

‒ |

– |

– |

IP67 |

I |

||

|

Without mating connector |

K72L |

‒ |

✔ 2) |

‒ |

– |

‒ |

– |

– |

‒ |

‒ |

‒ |

IP65 |

II 4) |

|

|

Without mating connector; connector AMP Junior-Timer |

C4Z |

‒ |

‒ |

✔ 2) |

– |

‒ |

– |

– |

‒ |

‒ |

‒ |

IP66 |

II 4) |

|

1) Only with correctly mounted valve with a mating connector suitable for the protection class.

2) Solenoid coils without "Recognized component" according to UL 429

3) Possible with version “J3”.

4) With protection class III, a protective extra-low voltage with isolation transformer (PELV, SELV) is to be provided.

In the electrical connection, the protective earthing conductor (PE, grounded) is to be connected in accordance with the stipulations.

Notes:

Connector pin assignment see Electrical connections and data sheet 08006. The plug-in connectors used are not intended to be plugged in or disconnected during normal operation under load. Operation of the valves only admissible with appropriate and locked mating connector.Inductive position switch type QM: electrical connection

The electric connection is realized via a 4-pole mating connector (separate order) with connection thread M12 x 1.

electrical

|

Connection voltage (DC voltage) |

24 V | |||

|

Voltage tolerance (connection voltage) |

+30 %/-15 % | |||

|

Admissible residual ripple |

% |

≤ 10 | ||

|

Max. load capacity |

mA |

400 | ||

|

Switching outputs

|

PNP transistor outputs, load between switching outputs and GND | |||

|

Pinout

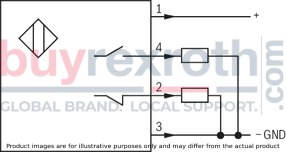

|

1 |

V |

24 | |

|

2, 4 |

Switching output |

mA |

400 | |

|

3 |

Earthing (GND) |

V |

0 | |

Inductive position switch type QL: electrical connection

The electrical connection is realized via a 4-pole mating connector (separate order) with connection thread M12 x 1.

electrical

|

Connection voltage (DC voltage) |

24 V | |||

|

Voltage tolerance (connection voltage) |

+56/-31 % | |||

|

Admissible residual ripple |

% |

≤ 10 | ||

|

Max. load capacity |

mA |

25 | ||

|

Switching outputs

|

PNP transistor outputs, load between switching outputs and GND | |||

|

Pinout

|

1 |

V |

24 | |

|

2, 4 |

Switching output |

mA |

25 | |

|

3 |

Earthing (GND) |

V |

0 | |

Inductive proximity sensor type QS: electrical connection

The electrical connection is realized via a 4-pole mating connector (separate order) with connection thread M12 x 1.

electrical

|

Connection voltage (DC voltage) |

24 V | |||

|

Voltage tolerance (connection voltage) |

±25 % | |||

|

Admissible residual ripple |

% |

≤ 15 | ||

|

Max. load capacity |

mA |

200 | ||

|

Switching outputs

|

PNP transistor outputs, load between switching outputs and GND | |||

|

Pinout

|

1 |

V |

24 | |

|

2, 4 |

Switching output |

mA |

200 | |

|

3 |

Earthing (GND) |

V |

0 | |

M12x1 plug-in connection

electrical

|

M12x1 plug-in connections 1) |

K72L | ||

|

Available voltages 2) |

V |

24 | |

|

Limited switch-off voltage peak |

K72L, DK35L |

V |

-44 … -55 |

|

Voltage tolerance (nominal voltage) |

% |

± 10 | |

|

Power consumption |

W |

35 | |

|

Duty cycle |

% |

100 | |

|

Switching time according to ISO 6403 |

ON |

ms |

45 … 75 |

|

OFF |

ms |

35 … 45 | |

|

Maximum switching frequency |

Standard |

1/h |

15000 |

|

Protection class according to DIN EN 60529 3) |

IP65 | ||

|

Protection class according to DIN EN 61140 |

III | ||

|

Maximum coil temperature 4) |

°C |

110 | |

| 1) | Mating connectors according to IEC 60947-5-2, separate order, see data sheet 08006 |

| 2) | Connection to functional low voltage with secure separation only = PELV/SELV |

| 3) | Only with the use of the mating connectors indicated by us and with correct installation. |

| 4) | Due to the surface temperatures of the solenoid coils, the standards ISO 13732-1 and EN 982 need to be adhered to! |

Notice!

Valve versions with electrical individual connection “K…”, see Ordering code.

For applications outside these parameters, please consult us!

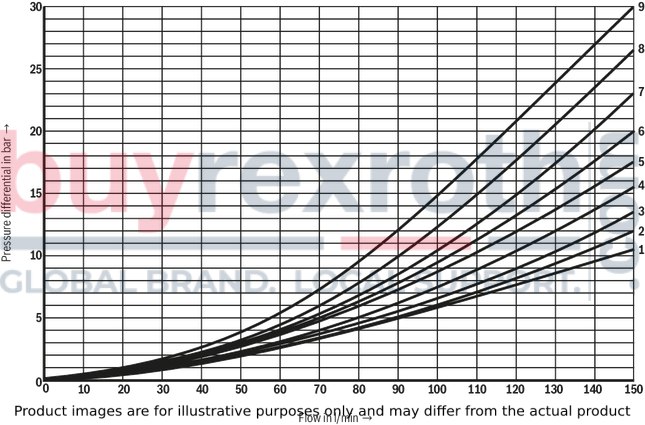

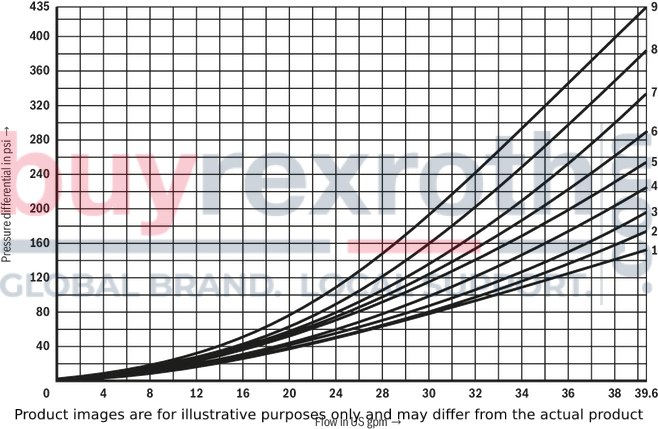

(measured with HLP46, ϑOil = 40 °C ± 5 °C)

Δp-qV characteristic curves

|

Symbol |

Direction of flow |

Symbol |

Direction of flow |

||||||||

|

P - A |

P - B |

A - T |

B - T |

P - A |

P - B |

A - T |

B - T |

P - T |

|||

|

A |

4 |

4 |

‒ |

‒ |

F |

1 |

3 |

3 |

8 |

4 |

|

|

B |

4 |

5 |

‒ |

‒ |

G |

4 |

5 |

6 |

8 |

7 |

|

|

C, J, Q, Y |

2 |

3 |

5 |

7 |

H |

1 |

1 |

6 |

8 |

7 |

|

|

D |

2 |

2 |

5 |

7 |

P |

3 |

1 |

5 |

6 |

5 |

|

|

E |

3 |

3 |

6 |

7 |

|||||||

|

E - „QS“ |

3 |

2 |

6 |

7 |

|||||||

|

E34 |

5 |

‒ |

5 |

8 |

|||||||

|

E67 |

3 |

4 |

4 |

7 |

|||||||

|

H |

1 |

1 |

6 |

8 |

|||||||

|

J19 |

7 |

‒ |

9 |

9 |

|||||||

|

L, Y11 |

3 |

3 |

5 |

7 |

|||||||

|

R |

3 |

4 |

5 |

6 |

|||||||

|

U |

2 |

2 |

5 |

7 |

|||||||

|

W |

2 |

2 |

5 |

6 |

|||||||

|

X7 |

3 |

‒ |

‒ |

6 |

|||||||

Characteristic curve for symbol G41 upon request.

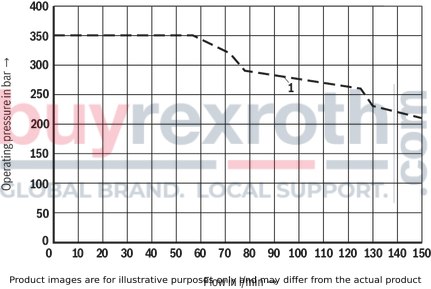

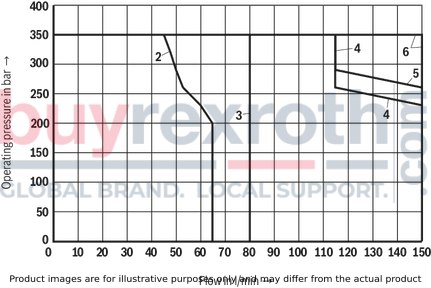

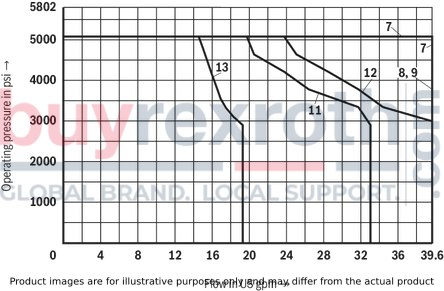

Performance limits: 2 spool positions (measured with HLP46, ϑOil = 40 ±5 °C)

Notice!

The specified switching power limits are valid for use with two directions of flow (e. g. from P to A and simultaneous return flow from B to T).

Due to the flow forces acting within the valves, the admissible switching power limits may be considerably lower with only one direction of flow (e. g. from P to A while port B is blocked)!

In such use cases, please consult us!

The switching power limit was established while the solenoids were at operating temperature, at 10 % undervoltage and without tank preloading.

Spring side

|

Characteristic curve |

Symbol |

|

1 |

B |

Solenoid side

|

Characteristic curve |

Symbol |

|

2 |

A, B |

|

3 |

C; Y11 |

|

4 |

D |

|

5 |

Y |

|

6 |

X7 |

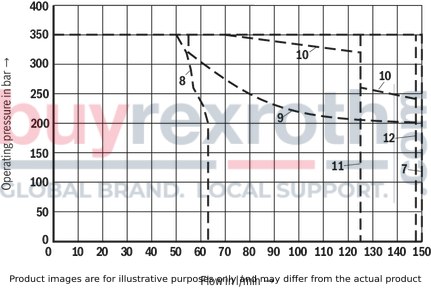

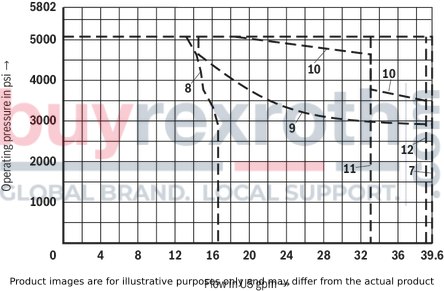

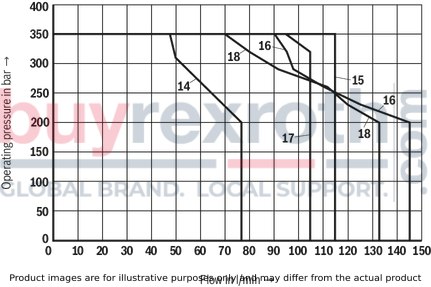

Performance limits: 3 spool positions (measured with HLP46, ϑOil = 40 ±5 °C)

Notice!

The specified switching power limits are valid for use with two directions of flow (e. g. from P to A and simultaneous return flow from B to T).

Due to the flow forces acting within the valves, the admissible switching power limits may be considerably lower with only one direction of flow (e. g. from P to A while port B is blocked)!

In such use cases, please consult us!

The switching power limit was established while the solenoids were at operating temperature, at 10 % undervoltage and without tank preloading.

Spring side

|

Characteristic curve |

Symbol |

|

7 |

E |

|

8 |

F |

|

9 |

G |

|

10 |

H |

|

11 |

J; J19 |

|

12 |

L |

Solenoid side

|

Characteristic curve |

Symbol |

|

7 |

E |

|

8 |

F |

|

9 |

G |

|

11 |

J, J19 |

|

12 |

L |

|

13 |

E34 |

Characteristic curves for symbols G41 and P upon request.

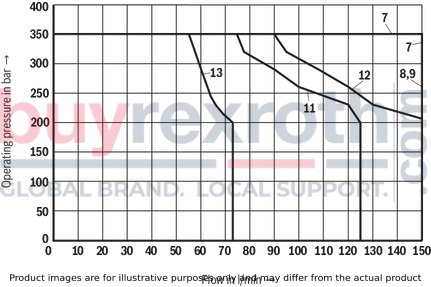

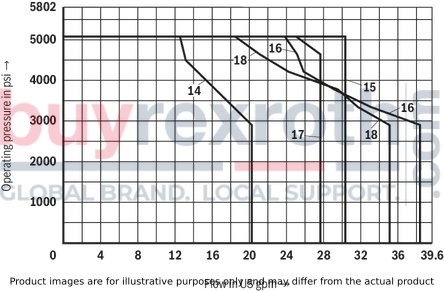

Notice!

The specified switching power limits are valid for use with two directions of flow (e. g. from P to A and simultaneous return flow from B to T).

Due to the flow forces acting within the valves, the admissible switching power limits may be considerably lower with only one direction of flow (e. g. from P to A while port B is blocked)!

In such use cases, please consult us!

The switching power limit was established while the solenoids were at operating temperature, at 10 % undervoltage and without tank preloading.

Solenoid side

|

Characteristic curve |

Symbol |

|

14 |

E67 |

|

15 |

E ‒ „QS“ |

|

16 |

U |

|

17 |

R |

|

18 |

W |

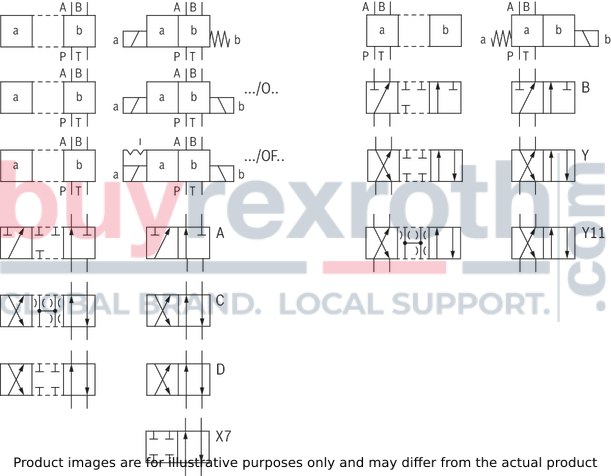

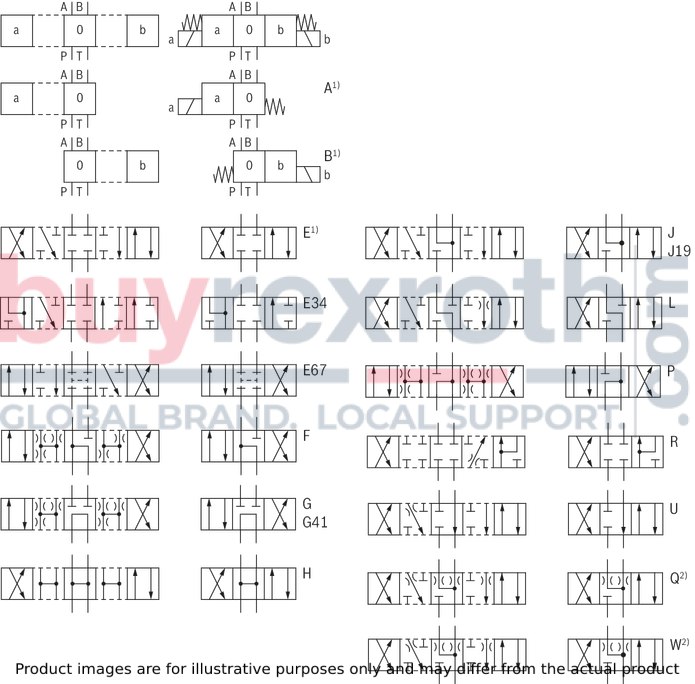

2 spool positions

Notices!

Representation according to DIN ISO 1219-1. Hydraulic interim positions are shown by dashes. Other symbols upon request

3 spool positions

| 1) |

Example: ● Symbol E with spool position “a” ordering code ..EA.. ● Symbol E with spool position “b” ordering code ..EB.. |

| 2) | For symbol Q and W, see “Flow cross-section" in the technical data |

Notices!

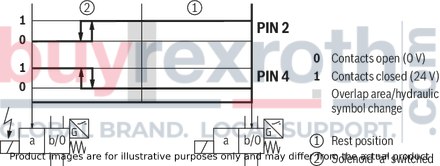

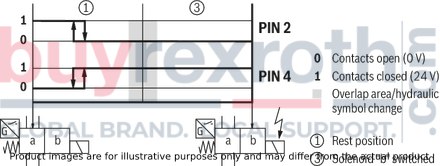

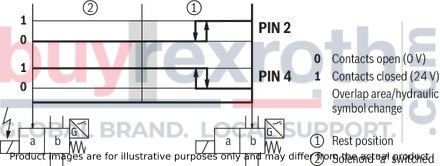

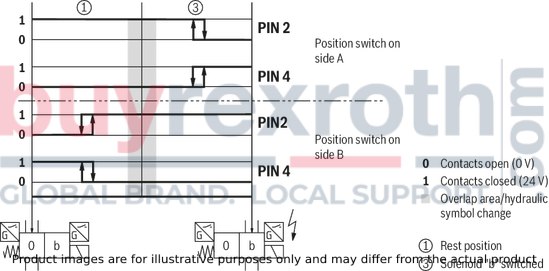

Representation according to DIN ISO 1219-1. Hydraulic interim positions are shown by dashes. Other symbols upon request.Inductive position switch type QM Switching logics

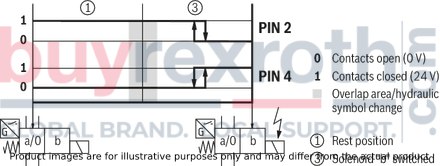

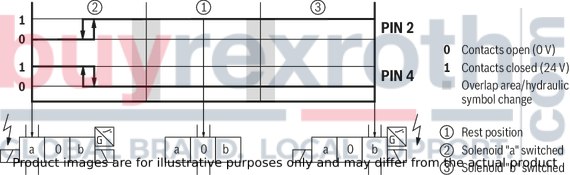

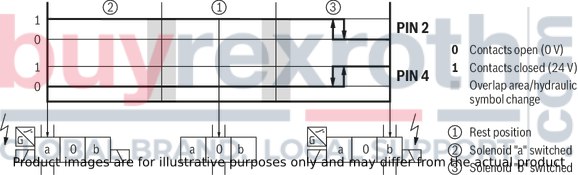

Version QMA

(Position switch on side B, monitored spool position "a")

Version QMA

(Position switch on side A, monitored spool position "a")

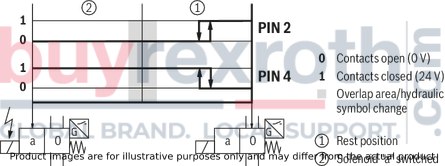

Version QMB

(Position switch on side B, monitored spool position "b")

Version QMB

(Position switch on side A, monitored spool position "b")

Version QM0

(Position switch on side B, monitored rest position)

Version QM0

(Position switch on side A, monitored rest position)

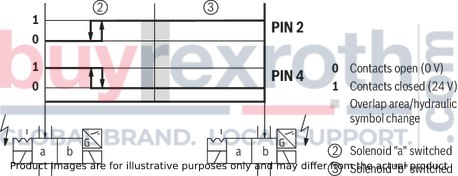

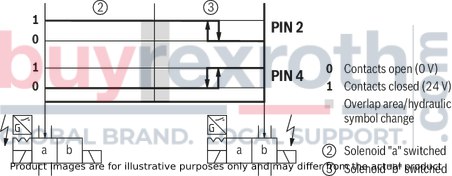

Inductive position switch type QL: switching logics

Version QLA

(Position switch on side B, monitored spool position "a")

Version QLA

(Position switch on side A, monitored spool position "a")

Version QLB

(Position switch on side B, monitored spool position "b")

Version QLB

(Position switch on side A, monitored spool position "b")

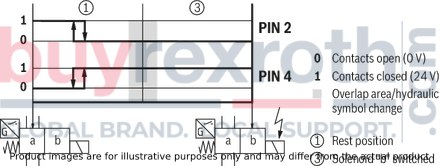

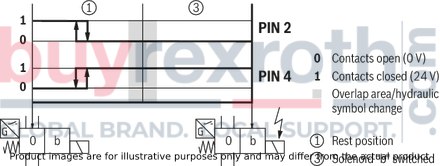

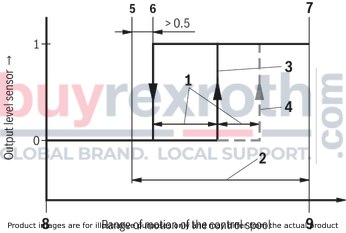

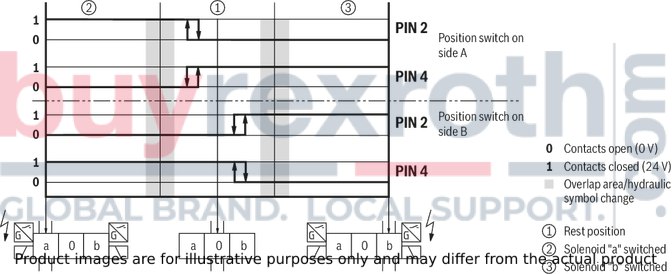

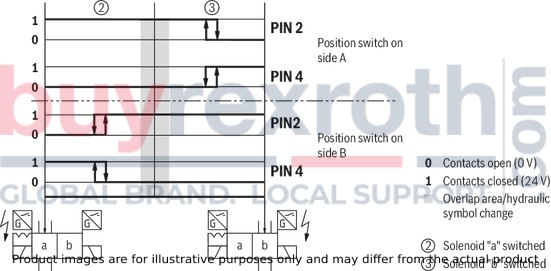

Inductive proximity sensor type QS: electrical connection

|

1 |

Width depending on hysteresis and temperature drift |

|

2 |

Overlap in the monitored spool position |

|

3 |

Signal flow (in the switching position to be monitored) |

|

4 |

Signal flow (leaving the monitored switching position) |

|

5 |

Beginning of the overlap |

|

6 |

Switching point |

|

7 |

Stroke end |

|

8 |

Not monitored spool position |

|

9 |

Monitored spool position |

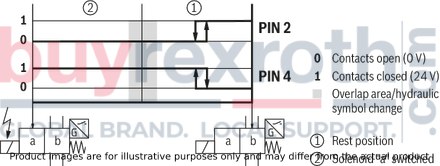

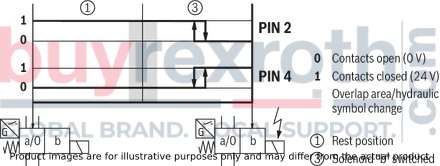

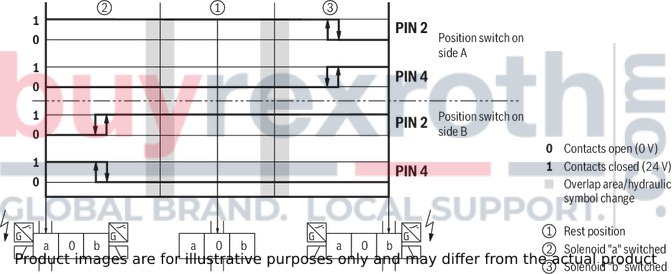

Inductive proximity sensor type QS: Switching logics

Version QSAG24W (valves with 3 spool positions, e.g. symbols E, J, G, …)

(Proximity sensor on side B, monitored spool position "a")

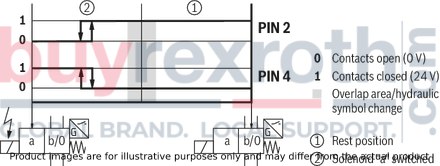

Version QSBG24W (valves with 3 spool positions, z. B. symbols E, J, G, …)

(Proximity sensor on side A, monitored spool position “b”)

Version QS0G24W (valves with 3 spool positions, z. B. symbols E, J, G, …)

(Proximity sensor on side A and B, monitored rest position)

Version QSABG24W (valves with 3 spool positions, e.g. symbols E, J, G, …)

(Proximity sensor on side A and B, monitored spool position "a" and "b")

Version QSABG24W (valves with 2 spool positions, e. g. symbols A, B, D, Y, …)

(Proximity sensor on side A and B, monitored spool position "a" and "b")

Version QS0BG24W (valves with 2 spool positions, e.g. symbols EB, …)

(Proximity sensor on side A and B, monitored spool position “0” and "b")

Version OF…QSAG24W

(Proximity sensor on side B, monitored spool position "a")

Version OF…QSBG24W

(Proximity sensor on side A, monitored spool position “b”)

Version OF…QSABG24W

(Proximity sensor on side A and B, monitored spool position "a" and "b")

M12x1 plug-in connection ‒ Individual connection – “K72L”

Pin 5 without function

Over-current fuse and switch-off voltage peaks

|

Maximum admissible overvoltages according to DIN EN 60664-1:2008-01 (VDE 0110-1) (overvoltage category II): |

|||

|

Electrical connection 1) |

Nominal voltage in V |

Rated current in A |

Maximum admissible Switch-off overvoltage in V 2) |

|

K4, K4K |

12 |

3,72 |

500 |

|

K4, K4K, K72L |

24 |

1,74 |

500 |

|

K4, C4Z |

26 |

1,70 |

500 |

|

K4 |

48 |

0,57 |

500 |

|

K4 |

96 |

0,47 |

500 |

|

K4 |

125 |

0,22 |

500 |

|

K4, C4Z |

180 |

0,28 |

500 |

|

K4 |

205 |

0,22 |

500 |

|

K4 |

220 |

0,21 |

500 |

| 1) | Interference protection circuit integrated |

| 2) | To be ensured by user circuitry |

Notice:

When solenoid coils are switched off, voltage peaks result which may cause faults or damage in the connected control electronics. We therefore recommend limiting them to 2 x nominal voltage by means of an interference protection circuit. It must be noted that a diode switched in an antiparallel form extends the switching off time.

Electrical connections, assignment

|

Electrical connections and coil connection combinations |

|||||

|

Ordering code connector |

Top view |

Circuit diagram |

Pin |

Connections, assignment |

|

|

3-pole connector (2+PE) according to DIN EN 175301-803 |

K4, K4K 1) |

|

|

1 |

Solenoid coil, polarity-independent |

|

2 |

|||||

|

Earthed |

Earthing |

||||

|

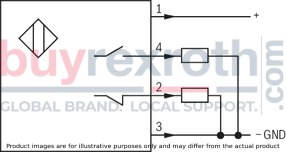

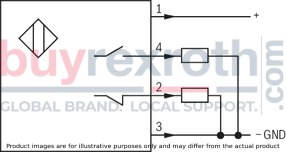

4-pole connector according to IEC 60947-5-2, M12x1 with suppressor diode, only 24 V DC, integrated interference protection circuit and status LED |

K72L |

|

|

1 |

Internal bridge |

|

2 |

|||||

|

3 |

Solenoid coil GND |

||||

|

4 |

Solenoid coil 24 VDC supply voltage |

||||

|

5 |

Without function |

||||

|

2-pole connector, type AMP Junior-Timer, rotated by 90° relative to valve axis |

C4Z |

|

|

1 |

Solenoid coil, polarity-independent |

|

2 |

|||||

| 1) | M3, tightening torque maximum MA max = 0.5 Nm |

| 2) | Coil with potted-in connector base and sealing element to valve housing (IP67) |

Mating connectors according to DIN EN 175301-803

|

For details and more mating connectors see data sheet 08006 |

||||||

|

Connection |

Valve side |

Color |

Part number |

|||

|

Without circuitry |

With indicator light 12 ... 240 V |

With rectifier 12 ... 240 V |

With indicator light and Zener diode suppression circuit 24 V |

|||

|

M16 x 1,5 |

a |

gray |

R901017010 |

– |

– |

– |

|

a/b |

black |

R901017011 |

R901017022 |

R901017025 |

R901017026 |

|

|

1/2″ NPT |

a |

red/brown |

R900004823 |

– |

– |

– |

|

a/b |

black |

R900011039 |

R900057453 |

R900842566 |

– |

|

|

Energy savings and fast switching 1) |

|||

|

Details see data sheet 30362 |

|||

|

Part number |

|||

|

Type VT-SSBA1-PWM-1X/V001/5 as fast switching amplifier (switching time reduction by approx. 50 %) 2) |

Type VT-SSBA1-PWM-1X/V002/5 for energy reduction (energy saving by approx. 40 %) 3) |

||

|

a/b |

black |

R901265633 |

R901290194 |

| 1) | Only with J2 and X84; not for version “D” |

| 2) | Only for version “G12” and “K4/K4K” |

| 3) | Only for version “G24” and “K4/K4K” |

Cartridge with PWM connector according to data sheet 30362:

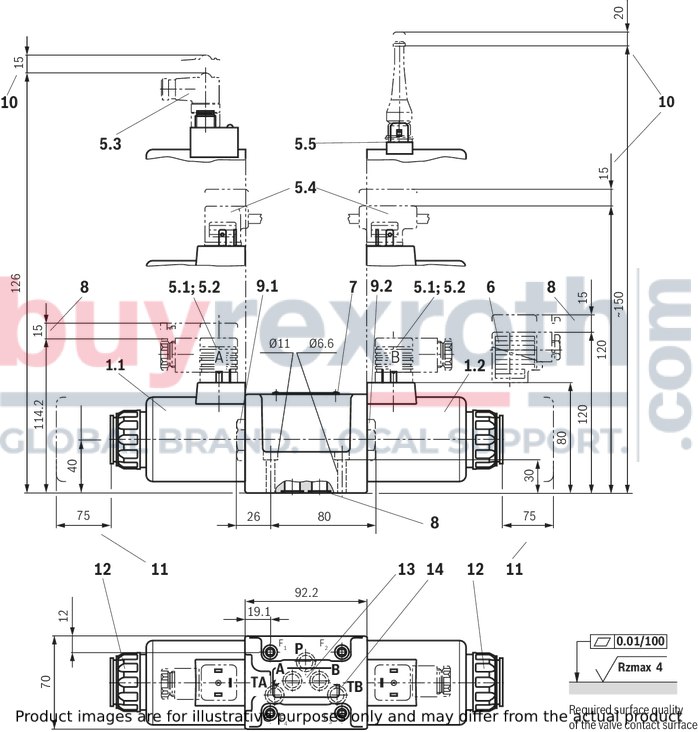

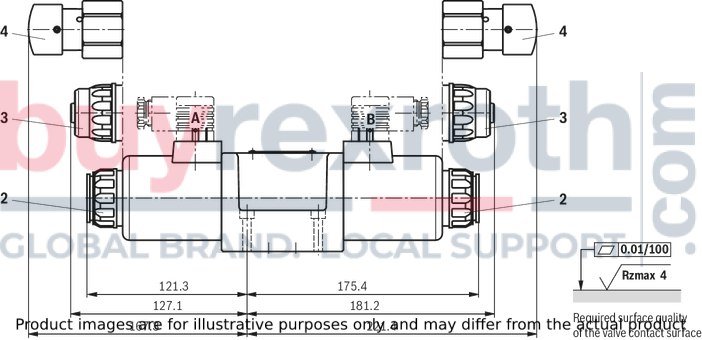

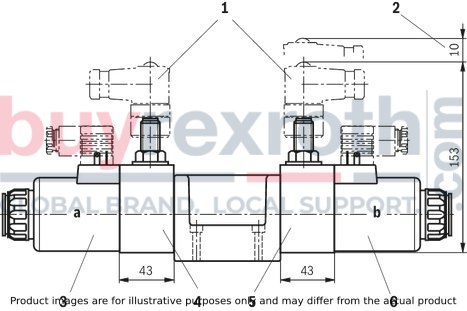

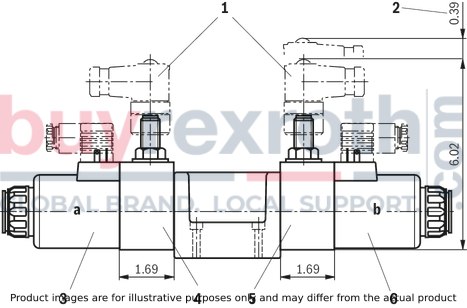

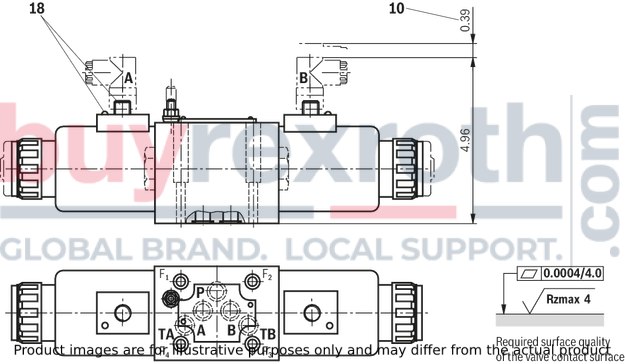

Depending on the control spool, increasing the performance limit is possible. With version "G24" (energy saving), the coil temperature is reduced by ≥ [si]30 °C[s/i][imp]86 °F[/imp] for 100 % duty cycle.Dimensions in mm

|

1.1 |

Solenoid “a” |

|

1.2 |

Solenoid “b” |

|

5.1 |

Mating connector without circuitry for connector "K4", separate order, see "Accessories" |

|

5.2 |

Mating connector without circuitry for connector "K4K" (separate order, see data sheet 08006) |

|

5.3 |

Mating connector angled with M12x1 plug-in connection and status LED for connector "K72L", separate order, see "Accessories" |

|

5.4 |

Double valve mating connector without/with circuitry for “K4” connector (separate order, see data sheet 08006) |

|

5.5 |

Mating connector (AMP Junior Timer) for connector "C4Z" (separate order, see data sheet 08006) |

|

6 |

Mating connector with circuitry for “K4” connector, separate order, see "Accessories" |

|

7 |

Name plate |

|

8 |

Identical seal rings for ports A, B, P, TA, TB |

|

9.1 |

Name plate |

|

9.2 |

Plug screw for valves with one solenoid |

|

10 |

Identical seal rings for ports A, B, P, TA, TB |

|

11 |

Plug screw for valves with one solenoid |

|

12 |

Space required to remove the mating connector/angled socket |

|

13 |

Space required to remove the coil |

|

14 |

Mounting nut, tightening torque MA = 14.5±1.5 Nm |

Notice:

Deviating from ISO 4401, port T is referred to as TA and port T1 is referred to as TB in this data sheet. The dimensions are nominal dimensions which are subject to tolerances.Subplates according to data sheet 45054 (separate order)

G 66/01 (G3/8)

G 67/01 (G1/2)

G 534/01 (G3/4)

G 66/12 (SAE-6; 9/16-18)1)

G 67/12 (SAE-8; 3/4-16)1)

G 534/12 (SAE-12; 1-1/16-12)1)

1) upon request

Valve mounting screws (separate order)

4 hexagon socket head cap screws, metric

ISO 4762 - M6 x 40 - 10.9-flZn-240h-L

(friction coefficient μtotal = 0.09 to 0.14);

tightening torque MA = 12.5 Nm ± 10 %,

material no. R913000058

or

4 hexagon socket head cap screws

ISO 4762 - M6 x 40 - 10.9 (self procurement)

(friction coefficient µtotal = 0.12 to 0.17);

tightening torque MA = 15.5 Nm ± 10 %

4 hexagon socket head cap screws UNC

1/4-20 UNC x 1-1/2″ ASTM-A574

(friction coefficient µtotal = 0.19 to 0.24);

Tightening torque MA = 25 Nm ± 15 %,

(friction coefficient µtotal = 0.12 to 0.17);

tightening torque MA = 19 Nm ± 10 %,

material no. R978800710

With different friction coefficients, the tightening torques are to be adjusted accordingly!

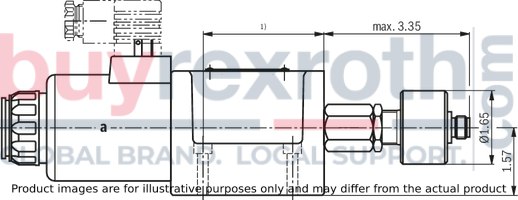

Manual override

Dimensions in mm

|

2 |

Version without and with concealed manual override "N9" (standard) |

|

3 |

Version with concealed manual override and protective cap "N8". (The protective cap must be removed prior to actuation.) |

|

4 |

Version with manual override "N5" and “N6” |

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

Subplates according to data sheet 45054 (separate order)

G 66/01 (G3/8)

G 67/01 (G1/2)

G 534/01 (G3/4)

G 66/12 (SAE-6; 9/16-18)1)

G 67/12 (SAE-8; 3/4-16)1)

G 534/12 (SAE-12; 1-1/16-12)1)

1) upon request

Valve mounting screws (separate order)

4 hexagon socket head cap screws, metric

ISO 4762 - M6 x 40 - 10.9-flZn-240h-L

(friction coefficient μtotal = 0.09 to 0.14);

tightening torque MA = 12.5 Nm ± 10 %,

material no. R913000058

or

4 hexagon socket head cap screws

ISO 4762 - M6 x 40 - 10.9 (self procurement)

(friction coefficient µtotal = 0.12 to 0.17);

tightening torque MA = 15.5 Nm ± 10 %

4 hexagon socket head cap screws UNC

1/4-20 UNC x 1-1/2″ ASTM-A574

(friction coefficient µtotal = 0.19 to 0.24);

Tightening torque MA = 25 Nm ± 15 %,

(friction coefficient µtotal = 0.12 to 0.17);

tightening torque MA = 19 Nm ± 10 %,

material no. R978800710

With different friction coefficients, the tightening torques are to be adjusted accordingly!

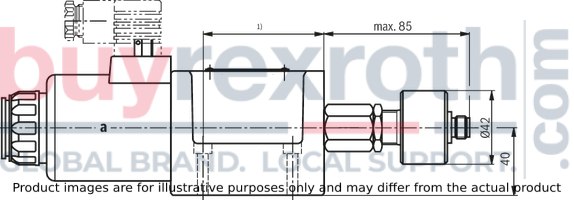

Spool position monitoring

Dimensions in mm

Inductive position switch type QM

Dimensions in mm

| 1) | For dimensions, see valve dimensions |

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

Spool position monitoring

Inductive position switch type QL

Dimensions in mm

| 1) | For dimensions, see valve dimensions |

Mounting cavity R/T-11A; 3 main ports; thread M20 x 1.5 mm

Dimensions in mm

Notice!

The dimensions are nominal dimensions which are subject to tolerances.

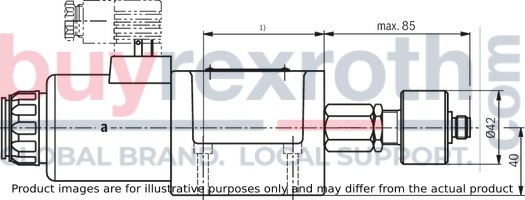

Spool position monitoring

Inductive position switch type QS

Dimensions in mm

Mounting cavity, 2 main ports; M20 x 1.5 thread

Version "C"

Dimensions in mm

|

1 |

Mating connector, material no. R900082899 (separate order) |

|

2 |

Space required to remove the mating connector |

|

3 |

Solenoid side “a” |

|

4 |

Switch side "a" |

|

5 |

Switch side "b" |

|

6 |

Solenoid side "b" |

|

Mounting options: |

|||||

|

Monitored spool position |

Ordering code |

3-spool position valve with 2 solenoids |

2-spool position valve .../O...; .../OF... |

||

|

Switch side "a" |

Switch side "b" |

Switch side "a" |

Switch side "b" |

||

|

"a" |

QSAG24W |

– |

X |

– |

X |

|

"b" |

QSBG24W |

X |

– |

X |

– |

|

"0" |

QS0G24W |

X |

X |

– |

– |

|

"0" and "a" |

QS0AG24W |

X |

X |

– |

– |

|

"0" and "b" |

QS0BG24W |

X |

X |

– |

– |

|

"a" and "b" |

QSABG24W |

X |

X |

X |

X |

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

M12x1 plug-in connection ‒ Individual connection

Dimensions in mm

Type 5-.WE 10 .3X/.CG24.K72L…

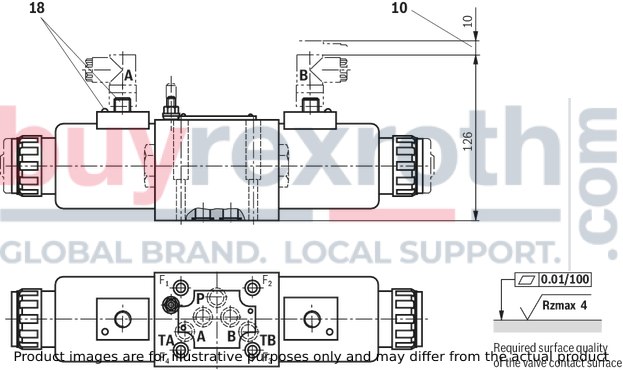

Dimensions in mm

|

10 |

Space required to remove the mating connector |

|

18 |

M12x1 plug-in connection with status LED (mating connector according to IEC 60947-5-2, separate order, see data sheet 08006); electrical connections “K72L”: see Electrical connections |

|

Temperature range and maximum operating pressure in case of use at low temperatures |

||

|

Port |

Pressure |

Temperature range in °C |

|

‒ P, A, B, T |

static 100 bar |

–40 … –35 |

|

‒ P, A, B |

dynamic from 100 bar to 350 barin linear form as a function of the temperature |

–35 … –30 |

|

‒ T |

dynamic from 100 bar to 210 bar in linear form as a function of the temperature |

–35 … –30 |

|

‒ P, A, B, T |

Maximum operating pressure |

–30 … +50 |

Mating connectors for valves with connector “K4”, without circuitry, standard

3P Z4

Mating connectors for valves with connector “K4”, without circuitry, standard

3P Z4

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Mating connectors for valves with connector “K4”, without circuitry, standard

3P Z45

Mating connectors for valves with connector “K4”, without circuitry, standard

3P Z45

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Mating connectors for valves with connector “K4”, with indicator light

3P Z5L

Mating connectors for valves with connector “K4”, with indicator light

3P Z5L

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Mating connectors for valves with connector “K4”, with indicator light

3P Z55L

Mating connectors for valves with connector “K4”, with indicator light

3P Z55L

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Mating connectors for valves with connector “K4”, with indicator light and Zener diode suppression circuit

3P Z5L1

Mating connectors for valves with connector “K4”, with indicator light and Zener diode suppression circuit

3P Z5L1

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Mating connectors for valves with connector “K4”, with rectifier

3P RZ5

Mating connectors for valves with connector “K4”, with rectifier

3P RZ5

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Mating connectors for valves with connector “K4”, with rectifier

3P RZ55

Mating connectors for valves with connector “K4”, with rectifier

3P RZ55

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Related Products

R978018531

$1,067.00 USD

R900724817

$558.00 USD

R978015606

$529.00 USD

R901160944

$685.00 USD

R901332092

$3,104.00 USD