DIRECTIONAL SPOOL VALVE H-4WEH25Y6X/6EW230N9K4

Manufacturer: Bosch Rexroth

Material #: R901347990

Model : H-4WEH25Y6X/6EW230N9K4

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

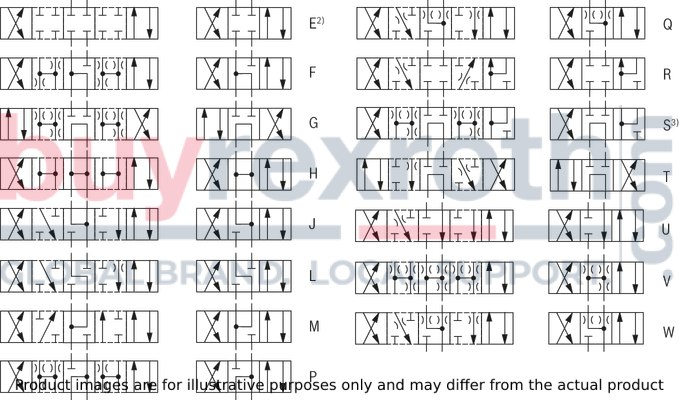

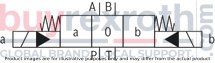

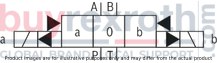

The Bosch Rexroth H-4WEH25Y6X/6EW230N9K4 (R901347990) is a high-performance industrial hydraulic valve designed for reliable switching of oil flow direction in accordance with its hydraulic symbol Y. This electromechanically operated spool valve is pilot-operated, featuring external pilot oil supply and return. It conforms to CE standards, including the Low-Voltage Directive EU and has CSA approval according to CSA C. No. 0.

With a maximum pressure capacity and a maximum flow rate, the H-4WEH25Y6X/6EW230N9K4 is equipped with a connector pole PE for electrical connections, adhering to EN standards. The valve has multiple ports for versatile connectivity and can be mounted on a subplate. It supports various hydraulic fluids such as HL, HLP, HLPD, HVLP, HVLPD, and HFC.

The model includes an integrated spring mechanism that ensures the main control spool remains in its central position without pilot pressure. Additionally, it features a pressure centering design for the main control spool which maintains zero position through pressurization of both front faces until one side is relieved to move the spool into its switching position.

It also offers flexibility with internal or external pilot oil supply options and comes with various actuation types including electrohydraulic WEH suitable for subplate mounting. The porting pattern is in line with ISO standards. The valve can be configured as either 3-way or 4-way based on requirements and offers additional optional features such as manual override, switching time adjustment, preload valve in channel P of the main valve, stroke setting, and spool position monitoring.

The Bosch Rexroth H-4WEH25Y6X/6EW230N9K4 valve caters to demanding applications requiring precise control of hydraulic systems with robust performance and multiple customization options to suit specific operational needs.

$1,880.00 USD

More are expected on August 10, 2026

| Qty | Price | Savings |

|---|---|---|

| 5-24 | $1,833.00 USD | $47.00 USD |

| 25+ | $1,786.00 USD | $94.00 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as August 10, 2026 when ordered in

This product is eligible for factory repair.

Size 25, symbol Y, electrical with solenoid, 230 V AC

Industrial hydraulic valve in a high performance range. Reliable switching of the oil flow direction according to hydraulic symbol.

Unpacked Weight: 16.968 kg

Types of actuation (internal or external pilot control): Electro-hydraulic (type WEH) For subplate mounting Porting pattern according toISO 4401 4/3-, 4/2- or 3/2-way version Spring or pressure centering, spring end position or hydraulic end position Wet-pin DC or AC solenoids, optional Electrical connection as individual or central connection Optional versions:

- Manual override

- Switching time adjustment

- Preload valve in channel P of the main valve

- Stroke setting and/or spool position monitoring

Notices:

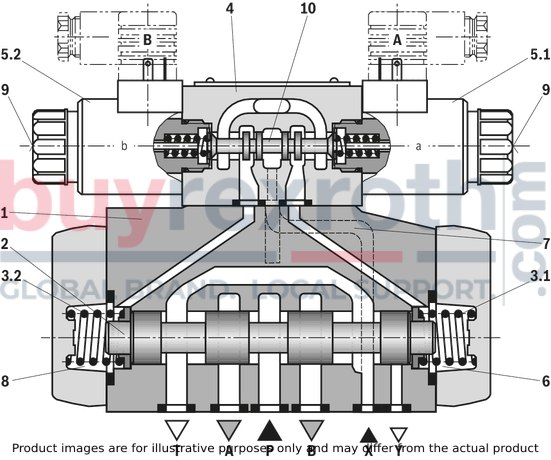

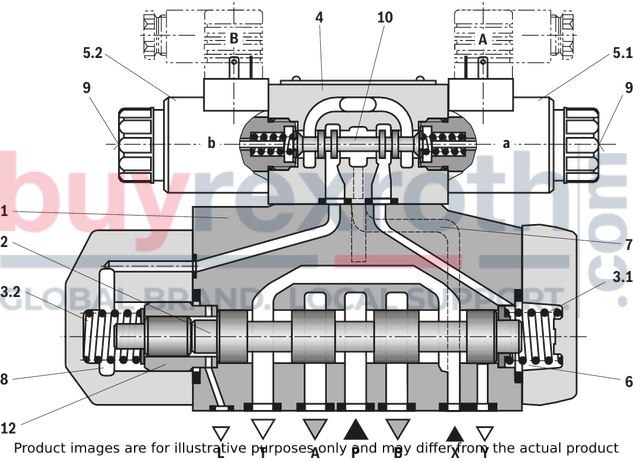

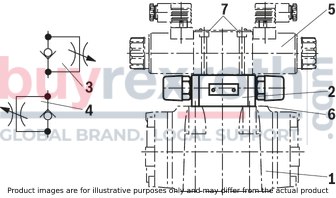

The return springs (3.1) and (3.2) in the spring chambers (6) and (8) hold the main control spool (2) in central position without pilot pressure even with, for example, vertical valve positioning.

Due to the design principle, internal leakage is inherent to the valves, which may increase over the life cycle.

4/3 directional valve with pressure centering of the main control spool, type H-WEH…H

The main control spool (2) in the main valve is kept in the zero position by pressurization of the two front faces. One centering bush (12) rests on the housing and fixes the control spool position. By pressure relief of one front face, the main control spool (2) is moved to the switching position. The unloaded control spool face displaces the returning pilot oil into channel Y (external) via the pilot control valve.

Notices:

The springs (3.1) and (3.2) do not have a return function in this version. They hold the main control spool (2) in central position in the depressurized condition and with horizontal installation.

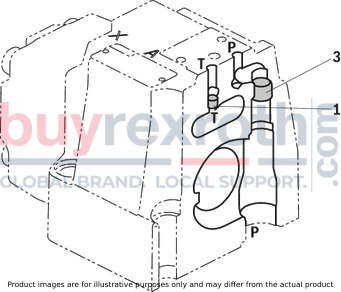

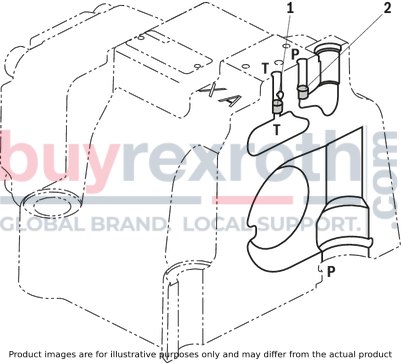

Pilot oil supply (schematic illustration)

NG10

Pilot oil supply (schematic illustration)

NG16

Pilot oil supply (schematic illustration)

NG25 („W.H 22“)

Pilot oil supply (schematic illustration)

NG25 („W.H 25“)

Pilot oil supply (schematic illustration)

Size 32

|

1 |

Plug screw M6 according to DIN 906, wrench size 3 - Pilot oil return |

|

2 |

Plug screw M6 according to DIN 906, wrench size 3 - Pilot oil supply |

|

3 |

Plug screw M12 x 1.5 according DIN 906, wrench size 6 |

|

Pilot oil supply |

Pilot oil return |

||

|

External |

2 closed |

External |

1 closed |

|

Internal |

2 open |

Internal |

1 open |

Type H-WEH...

The pilot oil supply is implemented externally - via channel X - from a separate pressure supply.

The pilot oil return is implemented externally via the Y channel into the tank.

Type H-WEH…E…

The pilot oil supply is implemented internally from channel P of the main valve. (see Technical data)

The pilot oil return is implemented externally - via channel Y - in the tank. In the subplate, port X is closed.

Type H-WEH...ET...

The pilot oil supply is implemented internally from channel P of the main valve.

The pilot oil return is implemented internally via the channel T into the tank. In the subplate, ports X and Y are closed.

Type H-WEH...T...

The pilot oil supply is implemented externally - via channel X - from a separate pressure supply.

The pilot oil return is implemented internally via the channel T into the tank. In the subplate, port Y is closed.

Throttle insert

Use of the throttle insert (5) is necessary if the pilot oil supply in channel P of the pilot control valve is to be limited (see below). The throttle insert (5) is inserted in channel P of the pilot control valve.

Notices:

The modification of the pilot oil supply may only be performed by authorized specialists or at the factory!

Pilot oil supply X or return Y external: The maximum admissible operating parameters of the pilot control valve must be observed (see data sheet 23178)! Maximum pilot pressure: please observe the Technical data! Pilot oil supply internal (version "ET" and "E"): Minimum pilot pressure: please observe the Technical data! In order to prevent inadmissibly high pressure peaks, a "B10" throttleinsert has to be provided in port P of the pilot control valve. In connection with version "H", the pressure reducing valve "D3" (see switching time adjustment) is also required.|

3 |

Pilot control valve |

|

4 |

Main valve |

|

5 |

Throttle insert |

| External pilot oil supply, external pilot oil return |

| Spool valve |

| Pilot-operated |

| Size 10 … 32 |

| Maximum operating pressure 350 bar |

| Maximum flow 1100 l/min |

| Component series 4X, 7X, 6X |

| Data Sheet | Download Data Sheet |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Connection diagram | ISO 4401-08-08-0-05 |

| Max. pressure | 350 |

| Max. flow | 700 |

| Spool symbol | Symbol Y |

| Type of connection | Subplate mounting |

| Size | 25 |

| Type of actuation | with solenoid actuation |

| Number of ports | 4 |

| Number of switching positions | 2 |

| Supply voltage | 230 VAC |

| Electrical connector | Connector 3-pole (2 + PE) |

| Electrical connection description | Connector 3-pole (2 + PE) according to EN 175301-803 |

| Conformity description | CE – Low-Voltage Directive 2014/35/EU CSA approval according to CSA C22.2 No. 139-1982 |

| Conformity | CE |

| Conformity | CE |

| Hydraulic fluid | HL,HLP,HLPD,HVLP,HVLPD,HFC |

| Seals | NBR |

| Productgroup ID | 9,10,11,12,13,14 |

| Connection diagram NFPA | NFPA T3.5.1 R2-2002 D08 |

| Size_CETOP | 0 |

| Weight | 16.968 |

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

21 |

22 |

||

|

H – |

WEH |

/ |

K4 |

/ |

* |

|

01 |

350 bar |

H ‑ |

|

02 |

3-way version |

3 |

|

4-way version |

4 |

|

|

Types of actuation |

||

|

03 |

electro-hydraulic |

WEH |

|

Size |

||

|

04 |

NG10 |

10 |

|

NG16 |

16 |

|

|

NG25 (version "H-WEH 22") |

22 |

|

|

NG25 (version "H-WEH 25") |

25 |

|

|

Size 32 |

32 |

|

|

Spool return in the main valve |

||

|

05 |

by means of springs |

no code |

|

hydraulic 1) |

H |

|

|

06 |

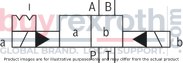

Symbols; for the possible version, see "Symbols/Circuit diagrams" |

|

|

07 |

Component series 40 … 49 (40 … 49: unchanged installation and connection dimension) – NG10 |

4X |

|

Component series 60 … 69 (60 … 69: unchanged installation and connection dimension) – NG25 ("H-WEH 25") and NG32 |

6X |

|

|

Component series 70 … 79 (70 … 79: unchanged installation and connection dimension) – NG16 (from series 72) andNG25 ("H-WEH 22") |

7X |

|

|

Control spool return in the pilot control valve with 2 spool positions and 2 solenoids (only possible with symbols C, D, K, Z and hydraulic control spool return in the main valve) |

||

|

08 |

With spring return |

no code |

|

Without spring return |

O |

|

|

Without spring return with detent 2) |

OF |

|

|

Pilot control valve 2) |

||

|

09 |

High-power valve |

6E |

|

10 |

Direct voltage 24 V 2) |

G24 |

|

Alternating voltage 230 V, 50/60 Hz 2) |

W230 |

|

|

For other voltages, frequencies and electric data, see data sheet of high-power valve |

||

|

11 |

Without manual override |

no code |

|

With manual override |

N |

|

|

With concealed manual override |

N9 |

|

|

Pilot oil flow |

||

|

12 |

External pilot oil supply, external pilot oil return 3) |

no code |

|

Internal pilot oil supply, external pilot oil return 3; 4) |

E |

|

|

Pilot oil supply internal, pilot oil return internal 4) |

ET |

|

|

External pilot oil supply, internal pilot oil return 3) |

T |

|

|

version “ET” and “T” with 3-spool position valve, pressure-centered, only possible if ppilot ≥ 2 x ptank + ppilot min!) |

||

|

Switching time adjustment |

||

|

13 |

without switching time adjustment |

no code |

|

Switching time adjustment as supply control |

S |

|

|

Switching time adjustment as discharge control |

S2 |

|

|

Corrosion resistance |

||

|

14 |

None (valve housing primed) |

no code |

|

Improved corrosion protection (240 h salt spray test according to EN ISO 9227) |

J3 |

|

|

Electrical connection 2) |

||

|

15 |

Individual connection |

|

|

Without mating connector; connector DIN EN 175301-803 |

K4 6) |

|

|

For further electrical connections, see data sheet 23178 and 08010 |

||

|

Spool position monitoring |

||

|

16 |

Without position switch |

no code |

|

Monitored spool position "a" |

QMAG24 |

|

|

Monitored spool position "b" |

QMBG24 |

|

|

Monitored spool position "a" and "b" |

QMABG24 |

|

|

Monitored rest position |

QM0G24 |

|

|

Stroke setting |

||

|

17 |

For ordering code, see stroke setting |

|

|

Throttle insert 2) |

||

|

18 |

Without throttle insert |

no code |

|

Throttle Ø 0.8 mm |

B08 |

|

|

Throttle Ø 1.0 mm |

B10 |

|

|

Throttle Ø 1.2 mm |

B12 |

|

|

Throttle Ø 1.5 mm |

B15 |

|

|

Throttle Ø 2.0 mm |

B20 |

|

|

Throttle Ø 2.5 mm |

B25 |

|

|

preload valve (not for NG10) 2) |

||

|

19 |

without preload valve |

no code |

|

with preload valve (pö = 4.5 bar) |

P4,5 |

|

|

20 |

without pressure reducing valve |

no code |

|

with pressure reducing valve |

D3 5) |

|

|

Seal material |

||

|

21 |

NBR seals |

no code |

|

FKM seals |

V |

|

|

Observe compatibility of seals with hydraulic fluid used. (Other seals upon request) |

||

|

22 |

Further details in the plain text |

* |

|

pSt |

Pilot pressure |

|

ppilot min |

Pilot pressure, minimum |

|

ptank |

Tank pressure |

|

pö |

Cracking pressure |

| 1) - 2 spool positions (hydraulic end position): only symbols C, D, K, Z, Y | |

| - 3 switching positions (hydraulically centered): only NG16, NG25 ("4W.H 25") and NG32 | |

| 2) Only with electro-hydraulic actuation (type WEH) | |

| 3) Pilot oil supply X or return Y external: | |

| - The maximum admissible operating parameters of the pilot control valve must be observed (see data sheet 23178)! | |

| - Minimum pilot pressure: please see technical data! | |

| - Maximum pilot pressure: please see technical data! | |

| 4) Pilot oil supply internal (version "ET" and "E"): | |

| - Minimum pilot pressure: please see technical data! | |

| - Maximum pilot pressure: please see technical data! | |

| With a higher pilot pressure, use of a pressure reducing valve "D3" is required (if it is not used pilot pressure = operating pressure at the port!). | |

| - In order to prevent inadmissibly high pressure peaks, a "B10" throttle insert has to be provided in port P of the pilot control valve (see Pilot oil supply). | |

| - In connection with version "H", the pressure reducing valve "D3" is also required. | |

| 5) Only in connection with the "B10" throttle insert | |

| 6) Mating connectors, separate order, see data sheet 23178 |

general

|

Size |

10 | 16 | 25 (H-WEH22) | 25 (H-WEH25) | 32 | ||

|

Weight (approx.) |

Valve with one solenoid |

kg |

6.4 | 8.5 | 11.5 | 17.6 | |

|

Valve with two solenoids, spring-centered |

kg |

6.8 | 8.9 | 11.9 | 19 | 41 | |

|

Valve with two solenoids, pressure-centered |

kg |

6.8 | 8.9 | 11.9 | 19 | 41 | |

|

Switching time adjustment "S" and "S2" |

kg |

0.8 | |||||

|

Pressure reducing valve "D3" |

kg |

0.4 | |||||

|

Installation position |

Any; horizontal with valves with hydraulic control spool return "H" and symbol A, B, C, D, K, Z, Y. With suspended installation, higher sensitivity to contamination – horizontal is recommended. | ||||||

|

Ambient temperature range |

Standard version |

°C |

-20 … +70 | ||||

|

Storage temperature range |

°C |

+5 … +40 | |||||

|

Surface protection |

Valve body |

Coating, layer thickness max. 100 μm | |||||

|

MTTFD values according to EN ISO 13849 |

Years |

100 | |||||

hydraulic

|

Size |

10 | 16 | 25 (H-WEH22) | 25 (H-WEH25) | 32 | |||

|

Maximum operating pressure |

Port P |

bar |

350 | |||||

|

Anschluss A |

bar |

350 | ||||||

|

Port B |

bar |

350 | ||||||

|

Port T |

External pilot oil return Y |

bar |

315 | 250 | ||||

|

Internal pilot oil return Y (with direct voltage) 1) |

bar |

210 | ||||||

|

Internal pilot oil return Y (with alternating voltage) 1) |

bar |

160 | ||||||

|

Port Y |

Pilot oil return, external (with direct voltage) |

bar |

210 | |||||

|

Pilot oil return, external (with alternating voltage) |

bar |

160 | ||||||

|

Hydraulic fluid |

see table | |||||||

|

Hydraulic fluid temperature range |

NBR seals 2) |

°C |

-20 … +80 | |||||

|

FKM seals 2) |

°C |

-15 … +80 | ||||||

|

HFC hydraulic fluid |

°C |

-20 … +50 | ||||||

|

Viscosity range |

mm²/s |

2.8 … 500 | ||||||

|

Maximum admissible degree of contamination of the hydraulic fluid 3) |

Class 20/18/15 according to ISO 4406 (c) | |||||||

|

Maximum pilot pressure 4) |

bar |

250 | 210 | 250 | ||||

|

Minimum pilot pressure |

Pilot oil supply X external or internal (with symbols D, K, E, J, L, M, Q, R, U, W) |

3-spool position valve, spring-centered |

bar |

12 | 14 | 12.5 | 13 | 8.5 |

|

3-spool position valve, pressure-centered |

bar |

- | 14 | - | 18 | 8.5 | ||

|

2-spool position valve, spring end position |

bar |

10 | 14 | 13 | 10 | |||

|

2-spool position valve, hydraulic end position |

bar |

7 | 14 | 8 | 5 | |||

|

Internal pilot oil supply X (with symbols C, F, G, H, P, T, V, Z, S) 6) |

bar |

7.5 5) | 4.5 7) | |||||

|

Pilot volume for switching process |

3-spool position valve, spring-centered |

cm³ |

2.04 | 5.72 | 7.64 | 14.2 | 29.4 | |

|

2-spool position valve |

cm³ |

4.08 | 11.45 | 15.28 | 28.4 | 58.8 | ||

|

3-spool position valve, pressure-centered |

from zero position in switching position “a” |

cm³ |

- | 2.83 | - | 7.15 | 14.4 | |

|

from switching position “a” in zero position |

cm³ |

- | 2.9 | - | 7 | 15.1 | ||

|

from zero position in switching position “b” |

cm³ |

- | 5.72 | - | 14.15 | 29.4 | ||

|

from switching position “b” in zero position |

cm³ |

- | 2.83 | - | 5.73 | 14.4 | ||

|

Pilot flow for shortest switching time, approx. |

l/min |

35 | 45 | |||||

| 1) | As a 3-spool position valve, pressure-centered only possible if ppilot ≥ 2 x ptank + ppilot min |

| 2) | If type WH is used in potentially explosion-proof areas, see data sheet 07011. |

| 3) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

| 4) | Internal pilot oil supply:– With a higher pilot pressure, use of a pressure reducing valve "D3" is required (if it is not usedpilot pressure = operating pressure at the port).– the pressure reducing valve "D3" is also required.External pilot oil supply:– In connection with version "H-", compliance with the maximum pilot pressure must be ensured by appropriate measures (e. g. protection of the separate pilot oil circuit by means of a pressure relief valve)! |

| 5) | For symbols C, F, G, H, P, T, V, Z, an internal pilot oil supply is only possible if the flow from P to T in the central position (for 3-spool position valve) or while crossing the central position (for2-spool position valve) is so large that the pressure differential of P to T reaches a value of at least 7,5 bar and the pilot oilreturn Y is implemented externally. |

| 6) | Symbol S only for NG16 |

| 7) | For symbols C, F, G, J, H, P, T, V, Z, S 5) – by means of preload valve (not NG10) or correspondingly high flow. (Determination ofthe required flow, see "Preload valve" characteristic curves.) For NG10, a check valve with a cracking pressure of 7,5 bar is to be provided in the return line to the tank.The pilot oil return Y must be implemented externally. |

Free flow cross-sections in zero position with spools Q, V and W

|

Size |

10 | 16 | 25 (H-WEH22) | 25 (H-WEH25) | 32 | ||

|

Spool Q |

A – T; B – T |

mm² |

13 | 32 | 78 | 83 | 78 |

|

Spool V |

P – A |

mm² |

13 | 32 | 73 | 83 | 73 |

|

A – T; B – T |

mm² |

13 | 32 | 84 | 83 | 84 | |

|

Spool W |

A – T; B – T |

mm² |

2.4 | 6 | 10 | 14 | 20 |

|

Hydraulic fluid |

Classification |

Suitable sealing materials |

Standards |

Data sheet |

|

|

Mineral oil |

HL, HLP, HLPD, HVLP, HVLPD |

NBR, FKM |

DIN 51524 |

90220 |

|

|

Bio-degradable |

Insoluble in water |

HETG |

FKM |

ISO 15380 |

90221 |

|

HEES |

FKM |

||||

|

Soluble in water |

HEPG |

FKM |

ISO 15380 |

||

|

Flame-resistant |

Water-free |

HFDU (glycol base) |

FKM |

ISO 12922 |

90222 |

|

HFDU (ester base) |

FKM |

||||

|

HFDR |

FKM |

||||

Important notice on hydraulic fluids:

For more information and data on the use of other hydraulic fluids, please refer to the data sheets above or contact us. There may be limitations regarding the technical valve data (temperature, pressure range, life cycle, maintenance intervals, etc.). The ignition temperature of the hydraulic fluid used must be 50 K higher than the maximum solenoid surface temperature. Flame-resistant – containing water: Maximum pressure differential per control edge 50 bar Pressure pre-loading at the tank port >20% of the pressure differential, otherwise increased cavitation erosion Life cycle as compared to operation with mineral oil HL, HLP 30 ... 100% Bio-degradable and flame-resistant: If these hydraulic fluids are used, small amounts of dissolved zinc may get into the hydraulic system (700 mg zinc per pole tube).|

Switching times |

||||||

|

Pilot pressure |

bar |

70 |

210 |

250 |

Spring |

|

|

ON |

OFF |

|||||

|

NG10 |

Without throttle insert |

ms |

40 ... 60 |

– |

40 ... 60 |

20 ... 30 |

|

With throttle insert |

ms |

60 ... 90 |

– |

50 ... 70 |

20 ... 30 |

|

|

NG16 |

Without throttle insert |

ms |

50 ... 80 |

– |

40 ... 60 |

50 ... 80 |

|

With throttle insert |

ms |

110 ... 130 |

– |

80 ... 100 |

50 ... 80 |

|

|

NG25 (H-WEH 22) |

Without throttle insert |

ms |

40 ... 70 |

40 ... 60 |

– |

50 ... 70 |

|

With throttle insert |

ms |

140 ... 160 |

80 ... 110 |

– |

50 ... 70 |

|

|

NG25 (H-WEH 25) |

Without throttle insert |

ms |

70 ... 100 |

– |

50 ... 70 |

100 ... 130 |

|

With throttle insert |

ms |

200 ... 250 |

– |

120 ... 150 |

100 ... 130 |

|

|

NG32 |

Without throttle insert |

ms |

80 ... 130 |

– |

70 ... 100 |

140 ... 160 |

|

With throttle insert |

ms |

420 ... 560 |

– |

230 ... 350 |

140 ... 160 |

|

Notices:

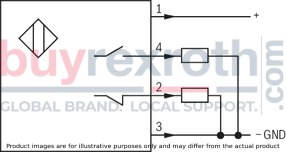

Switching times = Contacting at the pilot control valve until start of opening of the control edge in the main valve and change in the control spool stroke by 95%) The switching times are measured according to ISO 6403 with HLP46, ϑoil = 40 °C ± 5 °C. With different oil temperatures, variations are possible! The switching times were determined using DC solenoids. They decrease by approx. 20 ms if AC solenoids are used. The shut-off of the solenoids creates voltage peaks, which can be reduced by the use of suitable diodes. The switching times increase by approx. 30 ms if the pressure reducing valve "D3" is used. The switching times have been determined under ideal conditions and may differ in the system, depending on the application conditions.Inductive position switch type QM: electrical connection

The electric connection is realized via a 4-pole mating connector (separate order) with connection thread M12 x 1.

electrical

|

Connection voltage (DC voltage) |

V |

24 | ||

|

Voltage tolerance (connection voltage) |

+30 %/-15 % | |||

|

Admissible residual ripple |

% |

≤ 10 | ||

|

Max. load capacity |

mA |

400 | ||

|

Switching outputs

|

PNP transistor outputs, load between switching outputs and GND | |||

|

Pinout

|

1 |

V |

24 | |

|

2, 4 |

Switching output |

mA |

400 | |

|

3 |

Earthing (GND) |

V |

0 | |

For applications outside these parameters, please consult us!

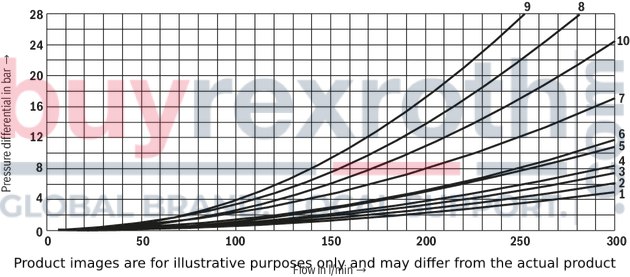

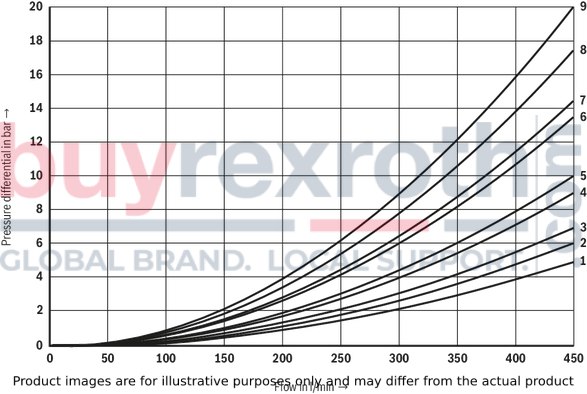

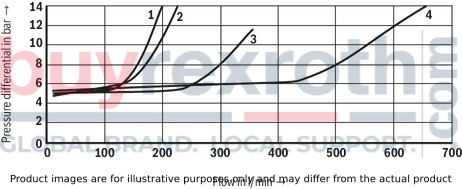

(measured with HLP46, ϑOil = 40 °C ± 5 °C)

NG10

Δp-qV characteristic curves

|

Piston |

Spool position |

Zero position |

|||||

|

P – A |

P – B |

A – T 1) |

B – T 1) |

A – T |

B – T |

P – T |

|

|

E, Y, D, Q, V, W, Z |

1 |

1 |

3 |

5 |

|||

|

F |

1 |

3 |

1 |

4 |

3 |

– |

6 |

|

G, T |

4 |

2 |

4 |

7 |

– |

– |

8 |

|

H, C |

3 |

3 |

1 |

7 |

1 |

5 |

5 |

|

J, K |

1 |

2 |

1 |

6 |

|||

|

L |

2 |

2 |

1 |

4 |

2 |

– |

– |

|

M |

3 |

3 |

2 |

5 |

|||

|

P |

3 |

1 |

2 |

7 |

– |

5 |

7 |

|

R |

1 |

2 |

3 |

– |

|||

|

U |

2 |

2 |

3 |

6 |

– |

6 |

– |

|

A, B |

1 |

1 |

– |

– |

|||

| 1) | The pressure differential refers to the use of port T. If port T1 is additionally used, the pressure differential maybe lower. If only port T1 is used, the relations A – T and B – T may be reversed. |

Performance limits: (measured with HLP46, ϑOil = 40 °C ±5 °C)

NG10

|

2-spool position valve – qV maxin l/min |

|||||

|

Symbol |

Operating pressure pmax in bar |

||||

|

70 |

140 |

210 |

280 |

350 |

|

|

X external – spring end position in the main valve1) (with ppilot min = 12 bar) |

|||||

|

C, D, K, Y, Z |

160 |

160 |

160 |

160 |

160 |

|

X external – hydraulic end position in the main valve |

|||||

|

HC, HD, HK, HZ, HY |

160 |

160 |

160 |

160 |

160 |

| 1) | If the specified flow values are exceeded, the function of the return spring is no longer guaranteed if the pilot pressure fails! |

NG10

|

3-spool position valves – qV max in l/min |

|||||

|

Symbol |

Operating pressure pmax in bar |

||||

|

70 |

140 |

210 |

280 |

350 |

|

|

X external – spring-centered |

|||||

|

E, J, L, M, Q, U, V, W, R |

160 |

160 |

160 |

160 |

160 |

|

F, P |

160 |

120 |

100 |

90 |

90 |

|

G, T |

160 |

160 |

160 |

130 |

120 |

|

H |

160 |

160 |

120 |

110 |

100 |

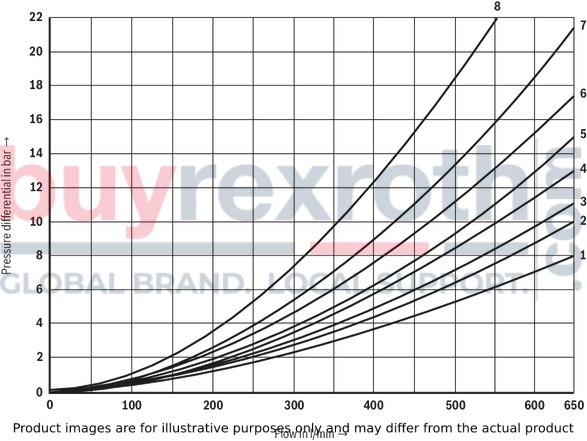

(measured with HLP46, ϑOil = 40 °C ± 5 °C)

NG16

Δp-qV characteristic curves

|

Symbol |

Spool position |

Zero position |

|||||

|

P – A |

P – B |

A – T |

B – T |

P – T |

A – T |

B – T |

|

|

D, E, Y |

1 |

1 |

3 |

3 |

|||

|

F |

1 |

2 |

5 |

5 |

4 |

3 |

– |

|

G |

4 |

1 |

5 |

5 |

7 |

– |

– |

|

C, H |

1 |

1 |

5 |

6 |

2 |

4 |

4 |

|

K, J |

2 |

2 |

6 |

6 |

– |

3 |

– |

|

L |

2 |

2 |

5 |

4 |

– |

3 |

– |

|

M |

1 |

1 |

3 |

4 |

|||

|

P |

2 |

1 |

3 |

6 |

5 |

– |

– |

|

Q |

1 |

1 |

6 |

6 |

|||

|

R |

2 |

4 |

7 |

– |

|||

|

S |

3 |

3 |

3 |

– |

9 |

– |

– |

|

T |

4 |

1 |

5 |

5 |

7 |

– |

– |

|

U |

2 |

2 |

3 |

4 |

6 |

||

|

V, Z |

1 |

1 |

6 |

6 |

10 |

8 |

8 |

|

W |

1 |

1 |

3 |

4 |

|||

Performance limits: (measured with HLP46, ϑOil = 40 °C ±5 °C)

NG16

|

2-spool position valve – qV maxin l/min |

|||||

|

Symbol |

Operating pressure pmax in bar |

||||

|

70 |

140 |

210 |

280 |

350 |

|

|

X external – spring end position in the main valve1) (with ppilot min = 12 bar) |

|||||

|

C, D, K, Y, Z |

300 |

300 |

300 |

300 |

300 |

|

X external – spring end position in the main valve |

|||||

|

C |

300 |

300 |

300 |

300 |

300 |

|

D, Y |

300 |

270 |

260 |

250 |

230 |

|

K |

300 |

250 |

240 |

230 |

210 |

|

Z |

300 |

260 |

190 |

180 |

160 |

|

X external – hydraulic end position in the main valve |

|||||

|

HC, HD, HK, HZ, HY |

300 |

300 |

300 |

300 |

300 |

| 1) | If the specified flow values are exceeded, the function of the return spring is no longer guaranteed if the pilot pressure fails! |

NG16

|

3-spool position valves – qV max in l/min |

|||||

|

Symbol |

Operating pressure pmax in bar |

||||

|

70 |

140 |

210 |

280 |

350 |

|

|

X external – spring-centered |

|||||

|

E, H, J, L, M, Q, U, W, R |

300 |

300 |

300 |

300 |

300 |

|

F, P |

300 |

250 |

180 |

170 |

150 |

|

G, T |

300 |

300 |

240 |

210 |

190 |

|

S |

300 |

300 |

300 |

250 |

220 |

|

V |

300 |

250 |

210 |

200 |

180 |

|

X external – pressure-centered (at minimum pilot pressure of 16 bar) |

|||||

|

all 1) |

300 |

300 |

300 |

300 |

300 |

| 1) | With symbol V, the pilot control valve is not required for flows >160 l/min. |

(measured with HLP46, ϑOil = 40 °C ± 5 °C)

NG25 (type W.H 22)

Δp-qV characteristic curves

|

Symbol |

Spool position |

Symbol |

Zero position |

||||||

|

P – A |

P – B |

A – T |

B – T |

B – A |

A – T |

B – T |

P – T |

||

|

E, D |

2 |

2 |

3 |

5 |

– |

F |

2 |

– |

4 |

|

J, Q, K |

2 |

2 |

4 |

6 |

– |

G, T |

– |

– |

9 |

|

M, W |

1 |

1 |

3 |

5 |

– |

H |

– |

– |

3 |

|

H, V, C, Z |

1 |

1 |

4 |

6 |

– |

L |

7 |

– |

– |

|

F |

1 |

2 |

4 |

5 |

– |

U |

– |

6 |

– |

|

G |

3 |

4 |

5 |

6 |

– |

J |

8 |

8 |

– |

|

R |

1 |

2 |

2 |

– |

– |

P |

– |

4 |

6 |

|

L |

2 |

2 |

4 |

5 |

– |

V, Z |

– |

– |

8 |

|

U |

2 |

2 |

2 |

6 |

– |

||||

|

P |

2 |

2 |

2 |

7 |

– |

||||

|

T |

4 |

4 |

5 |

6 |

– |

||||

Performance limits: (measured with HLP46, ϑOil = 40 °C ±5 °C)

NG25 (type W.H 22)

|

2-spool position valve – qV maxin l/min |

|||||

|

Symbol |

Operating pressure pmax in bar |

||||

|

70 |

140 |

210 |

280 |

350 |

|

|

X external – spring end position in the main valve (with ppilot min = 11 bar / 14 bar) |

|||||

|

C, D, K, Y, Z |

450 |

450 |

450 |

450 |

450 |

|

X external – spring end position in the main valve 1) |

|||||

|

C |

450 |

450 |

320 |

250 |

200 |

|

D, Y |

450 |

450 |

450 |

400 |

320 |

|

K |

450 |

215 |

150 |

120 |

100 |

|

Z |

350 |

300 |

290 |

260 |

160 |

|

X external – hydraulic end position in the main valve |

|||||

|

HC, HD, HK, HZ, HY |

450 |

450 |

450 |

450 |

450 |

|

HC./O…, HD./O…, HK./O…, HZ./O… |

450 |

450 |

450 |

450 |

450 |

|

HC./OF…, HD./OF…, HK./OF…, HZ./OF… |

450 |

450 |

450 |

450 |

450 |

| 1) | If the specified flow values are exceeded, the function of the return spring is no longer guaranteed if the pilot pressure fails! |

NG25 (type W.H 22)

|

3-spool position valves – qV max in l/min |

|||||

|

Symbol |

Operating pressure pmax in bar |

||||

|

70 |

140 |

210 |

280 |

350 |

|

|

X external – spring-centered |

|||||

|

E, J, L, M, Q, U, W, R |

450 |

450 |

450 |

450 |

450 |

|

H |

450 |

450 |

300 |

260 |

230 |

|

G |

400 |

350 |

250 |

200 |

180 |

|

F |

450 |

270 |

175 |

130 |

110 |

|

V |

450 |

300 |

240 |

220 |

160 |

|

T |

400 |

300 |

240 |

200 |

160 |

|

P |

450 |

270 |

180 |

170 |

110 |

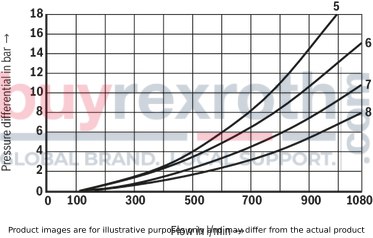

(measured with HLP46, ϑOil = 40 °C ± 5 °C)

NG25 (type W.H 25)

Δp-qV characteristic curves

|

Symbol |

Spool position |

Zero position |

|||||

|

P – A |

P – B |

A – T 1) |

B – T 1) |

A – T |

B – T |

P – T |

|

|

E, Y, D |

1 |

1 |

3 |

4 |

|||

|

F |

1 |

1 |

2 |

4 |

2 |

– |

5 |

|

G, T |

1 |

1 |

2 |

5 |

– |

– |

7 |

|

H |

1 |

1 |

2 |

5 |

2 |

2 |

4 |

|

C |

1 |

1 |

2 |

5 |

|||

|

J |

1 |

1 |

2 |

5 |

6 |

5 |

– |

|

K |

1 |

1 |

2 |

5 |

|||

|

L |

1 |

1 |

2 |

4 |

5 |

– |

– |

|

M |

1 |

1 |

3 |

4 |

|||

|

P |

1 |

1 |

3 |

5 |

– |

3 |

5 |

|

Q |

1 |

1 |

2 |

3 |

|||

|

R |

1 |

1 |

3 |

– |

|||

|

U |

1 |

1 |

2 |

5 |

– |

5 |

– |

|

V |

1 |

1 |

2 |

5 |

8 |

7 |

– |

|

Z |

1 |

1 |

2 |

5 |

|||

|

W |

1 |

1 |

3 |

4 |

|||

|

8 Symbol R, spool position B – A |

|||||||

| 1) | The pressure differential refers to the use of port T. If port T1 is additionally used, the pressure differential maybe lower. If only port T1 is used, the relations A – T and B – T may be reversed. |

Performance limits: (measured with HLP46, ϑOil = 40 °C ±5 °C)

NG25 (type W.H 25)

|

2-spool position valve – qV maxin l/min |

|||||

|

Symbol |

Operating pressure pmax in bar |

||||

|

70 |

140 |

210 |

280 |

350 |

|

|

X external – spring end position in the main valve (with ppilotmin = 13 bar) |

|||||

|

C, D, K, Y, Z |

700 |

700 |

700 |

700 |

650 |

|

X external – spring end position in the main valve 1) |

|||||

|

C |

700 |

700 |

700 |

700 |

650 |

|

D, Y |

700 |

650 |

400 |

350 |

300 |

|

K |

700 |

650 |

420 |

370 |

320 |

|

Z |

700 |

700 |

650 |

480 |

400 |

|

X external – hydraulic end position in the main valve |

|||||

|

HC, HD, HK, HZ, HY |

700 |

700 |

700 |

700 |

700 |

|

HC./O…, HD./O…, HK./O…, HZ./O… |

700 |

700 |

700 |

700 |

700 |

|

HC./OF…, HD./OF…, HK./OF…, HZ./OF… |

700 |

700 |

700 |

700 |

700 |

| 1) | If the specified flow values are exceeded, the function of the return spring is no longer guaranteed if the pilot pressure fails! |

NG25 (type W.H 25)

|

3-spool position valves – qV max in l/min |

|||||

|

Symbol |

Operating pressure pmax in bar |

||||

|

70 |

140 |

210 |

280 |

350 |

|

|

X external – spring-centered |

|||||

|

E, L, M, Q, U, W |

700 |

700 |

700 |

700 |

650 |

|

G, T |

400 |

400 |

400 |

400 |

400 |

|

F |

650 |

550 |

430 |

330 |

300 |

|

H |

700 |

650 |

550 |

400 |

360 |

|

J |

700 |

700 |

650 |

600 |

520 |

|

P |

650 |

550 |

430 |

430 |

300 |

|

V |

650 |

550 |

400 |

350 |

310 |

|

R |

700 |

700 |

700 |

650 |

580 |

|

X external – pressure-centered (at minimum pilot pressure of 18 bar) |

|||||

|

E, F, H, J, L, M, P, Q, R, U, V, W |

700 |

700 |

700 |

700 |

650 |

|

G, T |

400 |

400 |

400 |

400 |

400 |

|

X external – pressure-centered (with pilot pressure > 30 bar) |

|||||

|

G, T |

700 |

700 |

700 |

700 |

650 |

(measured with HLP46, ϑOil = 40 °C ± 5 °C)

Size 32

∆p-qv-characteristic curves – Symbol E, R and W

|

Piston |

Spool position |

||||

|

P – A |

P – B |

A – T |

B – T |

B – A |

|

|

E |

4 |

4 |

3 |

2 |

– |

|

R |

4 |

4 |

3 |

– |

1 |

|

W |

4 |

4 |

3 |

2 |

– |

Size 32

∆p-qv- characteristic curves – Symbol G and T

|

Piston |

Spool position |

||||

|

P – A |

P – B |

A – T |

B – T |

P – T |

|

|

G |

7 |

8 |

7 |

5 |

6 |

|

T |

7 |

8 |

7 |

5 |

6 |

Performance limits: (measured with HLP46, ϑOil = 40 °C ±5 °C)

Size 32

|

2-spool position valve – qV maxin l/min |

|||||

|

Symbol |

Operating pressure pmax in bar |

||||

|

70 |

140 |

210 |

280 |

350 |

|

|

X external – spring end position in the main valve (with ppilot min = 10 bar) |

|||||

|

C, D, K, Y, Z |

1100 |

1040 |

860 |

750 |

680 |

|

X external – spring end position in the main valve 1) |

|||||

|

C |

1100 |

1040 |

860 |

800 |

700 |

|

D, Y |

1100 |

1040 |

540 |

480 |

420 |

|

K |

1100 |

1040 |

860 |

500 |

450 |

|

Z |

1100 |

1040 |

860 |

700 |

650 |

|

X external – hydraulic end position in the main valve |

|||||

|

HC, HD, HK, HZ, HY |

1100 |

1040 |

860 |

750 |

680 |

| 1) | If the specified flow values are exceeded, the function of the return spring is no longer guaranteed if the pilot pressure fails! |

Size 32

|

3-spool position valves – qV max in l/min |

|||||

|

Symbol |

Operating pressure pmax in bar |

||||

|

70 |

140 |

210 |

280 |

350 |

|

|

X external – spring-centered |

|||||

|

E, J, L, M, Q, R, U, W |

1100 |

1040 |

860 |

750 |

680 |

|

G, T, H, F, P |

900 |

900 |

800 |

650 |

450 |

|

V |

1100 |

1000 |

680 |

500 |

450 |

|

X external – pressure-centered (at minimum pilot pressure of 8.5 bar) |

|||||

|

all |

1100 |

1040 |

860 |

750 |

680 |

Performance limits: important information

Notice (applies to all sizes):

The specified switching power limits apply to the use with two directions of flow (e. g. from P to A and simultaneous return flow from B to T at a ratio of 1:1). Due to the flow forces acting within the valves, the admissible switching power limit may be considerably lower with only one direction of flow (e. g. from P to A while port B is blocked, with flow in the same or in different directions)! In such cases of application, please consult us!

The switching power limit was established while the solenoids were at operating temperature, at 10% undervoltage, and without tank preloading.

|

NG16 |

With pilot oil supply X internal, a preload valve has to be used for flows < 160 l/min due to the negative overlap of the symbols C, Z and HC, HZ. 4/3 directional valves with pressure centering of the control spool in the main valve can be used above the indicated performance limit. In this case, a higher pilot pressure is required (values see performance limits of the corresponding size). With pilot oil supply X internal, sufficient flow needs to be ensured due to the negative overlap of symbols F, G, H, P, S and T (for determination of the required flow, see "Preload valve" characteristic curves. If the required flow is not reached, a preload valve has to be used (see technical data). |

|

NG25 („H-WEH 22“) |

With pilot oil supply X internal a preload valve has to be used for flows < 180 l/min due to the negative overlap of spools Z, HZ and V. With pilot oil supply X internal sufficient flow needs to be ensured due to the negative overlap of symbols C, HC, F, G, H, P and T (for determination of the required flow, see “Preload valve” characteristic curves. If the required flow is not reached, a preload valve has to be used (see technical data). |

|

NG25 („H-WEH 25“) |

With pilot oil supply X internal, a preload valve has to be used for flows < 180 l/min due to the negative overlap of symbols Z, HZ and V. 4/3 directional valves with pressure centering of the control spool in the main valve can be used above the indicated performance limit. In this case, a higher pilot pressure is required (values see performance limits of the corresponding size). With pilot oil supply X internal, sufficient flow needs to be ensured due to the negative overlap of symbols C, HC, F, G, H, P and T (for determination of the required flow, see "Preload valve"characteristic curves. If the required flow is not reached, a preload valve has to be used (see technical data). |

|

NG32 |

With pilot oil supply X internal, a preload valve has to be used for flows < 180 l/min due to the negative overlap of symbols Z, HZ and V. 4/3 directional valves with pressure centering of the control spool in the main valve can be used above the indicated performance limit. In this case, a higher pilot pressure is required (values see performance limits of the corresponding size). With pilot oil supply X internal, sufficient flow needs to be ensured due to the negative overlap of symbols C, HC, F, G, H, P and T (for determination of the required flow, see "Preload valve" characteristic curves. If the required flow is not reached, a preload valve has to be used (see technical data). |

|

NG16 |

With pilot oil supply X internal, a preload valve has to be used for flows < 160 l/min due to the negative overlap of the symbols C, Z and HC, HZ. 4/3 directional valves with pressure centering of the control spool in the main valve can be used above the indicated performance limit. In this case, a higher pilot pressure is required (values see performance limits of the corresponding size). With pilot oil supply X internal, sufficient flow needs to be ensured due to the negative overlap of symbols F, G, H, P, S and T (for determination of the required flow, see "Preload valve" characteristic curves. If the required flow is not reached, a preload valve has to be used (see technical data). |

|

NG25 („WEH 22“) |

With pilot oil supply X internal a preload valve has to be used for flows < 180 l/min due to the negative overlap of spools Z, HZ and V. With pilot oil supply X internal sufficient flow needs to be ensured due to the negative overlap of symbols C, HC, F, G, H, P and T (for determination of the required flow, see “Preload valve” characteristic curves. If the required flow is not reached, a preload valve has to be used (see technical data). |

|

NG25 („WEH 25“) |

With pilot oil supply X internal, a preload valve has to be used for flows < 180 l/min due to the negative overlap of symbols Z, HZ and V. 4/3 directional valves with pressure centering of the control spool in the main valve can be used above the indicated performance limit. In this case, a higher pilot pressure is required (values see performance limits of the corresponding size). With pilot oil supply X internal, sufficient flow needs to be ensured due to the negative overlap of symbols C, HC, F, G, H, P and T (for determination of the required flow, see "Preload valve"characteristic curves. If the required flow is not reached, a preload valve has to be used (see technical data). |

|

NG32 |

With pilot oil supply X internal, a preload valve has to be used for flows < 180 l/min due to the negative overlap of symbols Z, HZ and V. 4/3 directional valves with pressure centering of the control spool in the main valve can be used above the indicated performance limit. In this case, a higher pilot pressure is required (values see performance limits of the corresponding size). With pilot oil supply X internal, sufficient flow needs to be ensured due to the negative overlap of symbols C, HC, F, G, H, P and T (for determination of the required flow, see "Preload valve" characteristic curves. If the required flow is not reached, a preload valve has to be used (see technical data). |

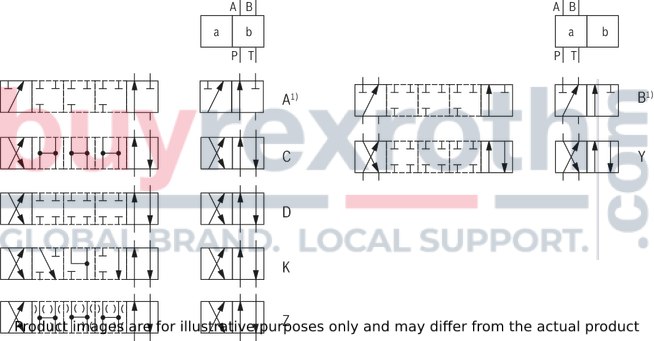

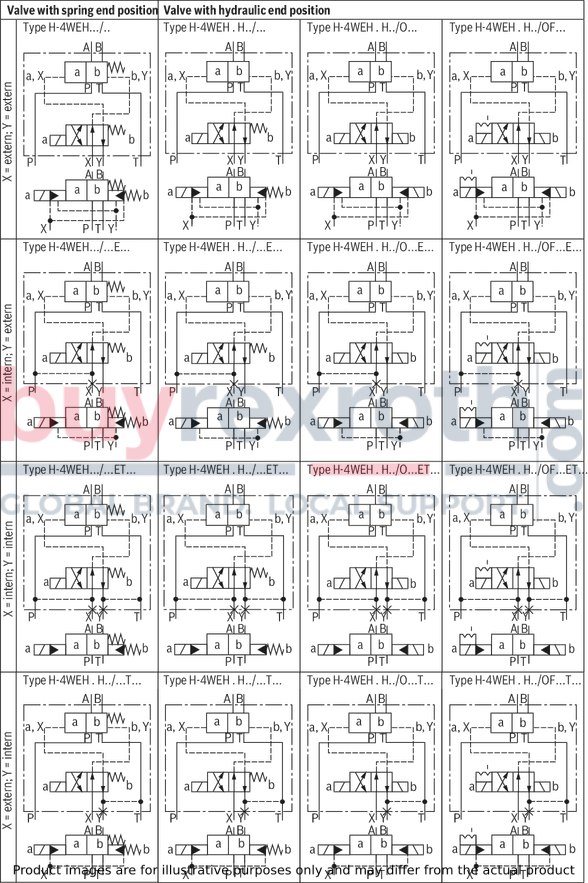

2 spool positions

| 1) | Only for NG10 and 25 ("H-W.H 22") with 3/2-way version; if operating pressure > tank pressure, port T is to be used as a leakage port. |

|

Ordering code |

Type of actuation |

|

|

Symbol |

Spool return |

Type H-WEH (electro-hydraulic) |

|

A 1), C, D, K, Z |

../.. |

|

|

..H../.. |

|

|

|

..H../O |

|

|

|

..H../OF |

|

|

|

B 1), Y |

../.. |

|

|

..H../.. |

|

|

3 spool positions

| 2)Example: Symbol E with actuating side “a” → ordering code ..EA.. | |

| 3) Symbol S only for NG16 |

|

Ordering code |

Type of actuation |

||

|

Symbol |

Actuating side |

Spool return |

Type H-WEH (electro-hydraulic) |

|

E, F, G, H, J, L, M, P, Q, R, S, T, U, V, W |

../.. |

|

|

|

.A |

|

||

|

.B |

|

||

|

..H../.. |

|

||

|

H.A |

|

||

|

H.B |

|

||

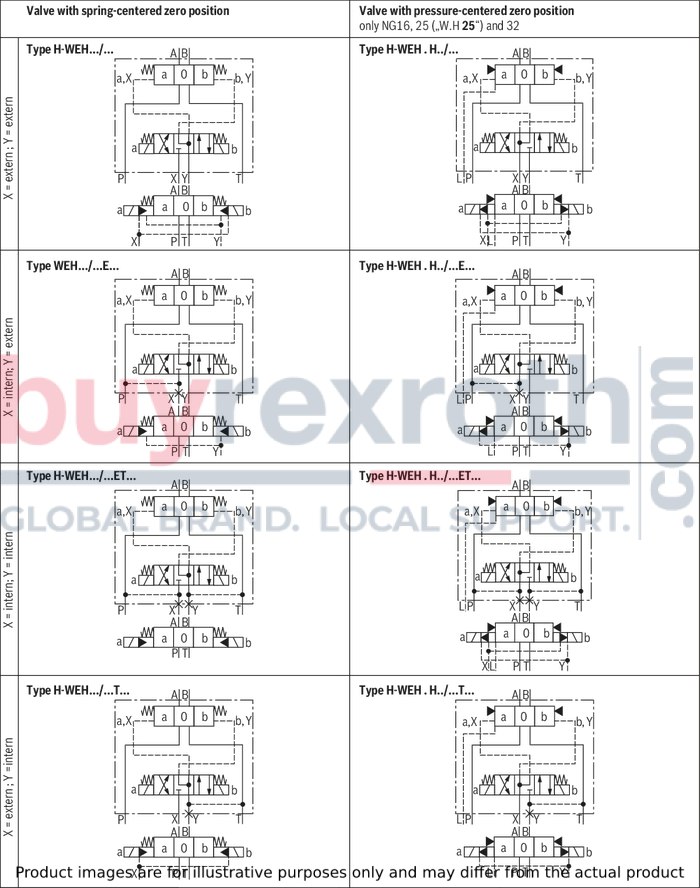

Symbols for valves with 2 spool positions

Symbols for valves with 3 spool positions

Notice:

3-spool position valves, pressure-centered, preferably with external pilot oil supply and or return (“no code”, “E”) Precondition for internal pilot oil supply and/or return (“ET”, “T”).

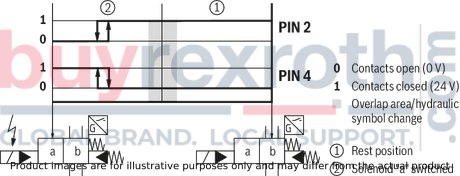

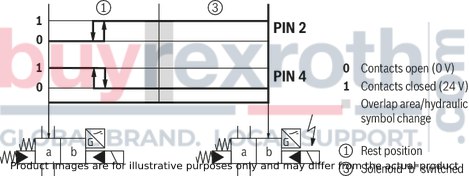

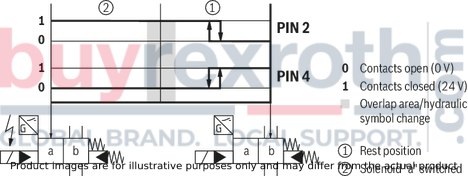

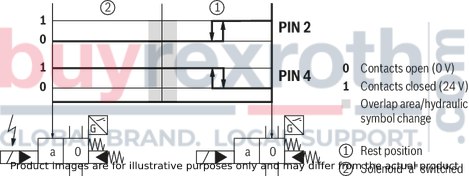

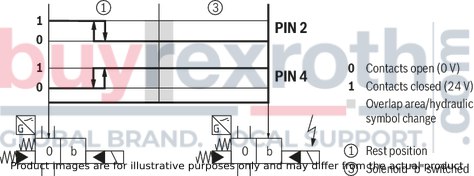

Inductive position switch type QM Switching logics

Version QMA

(Position switch on side B, monitored spool position of the main stage "a")

Version QMA

(Position switch on side B, monitored spool position of the main stage "a")

Version QMB

(Position switch on side A, monitored spool position of the main stage "b")

Version QMB

(Position switch on side A, monitored spool position of the main stage "b")

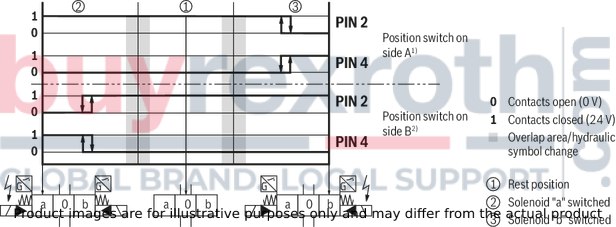

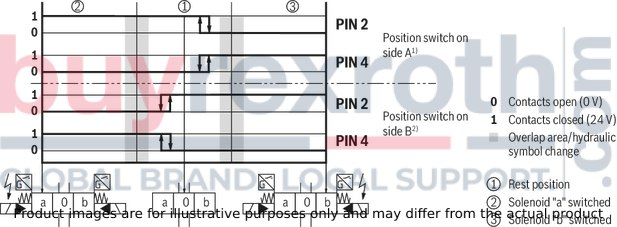

version QMAB

(Position switch on side A and B, monitored spool position "a" and "b")

Version QM0

(Position switch on side A and B, monitored spool position "0")

| 1) No signal change at the position switch on side B with spool position "a" | |

| 2) No signal change at the position switch on side A with spool position "b" |

Version QM0

(Position switch on side B, monitored spool position of the main stage "0")

Version QM0

(Position switch on side A, monitored spool position of the main stage "0")

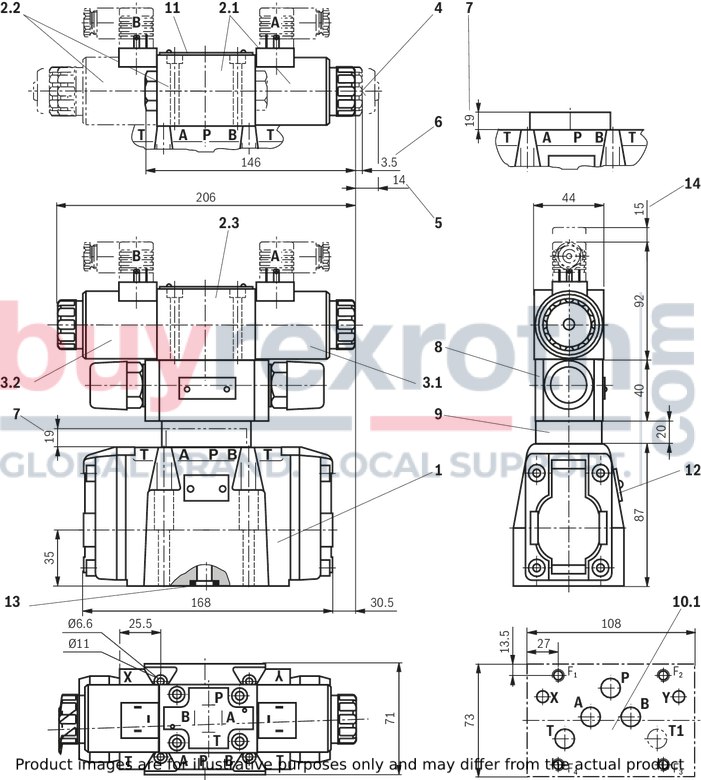

NG10

Dimensions in mm

|

|

Required surface quality of the valve contact surface |

|

1 |

Main valve |

|

2 |

Pilot control valve type 4WE 6... according to data sheet 23178: |

|

2.1 |

Pilot control valve type 4WE 6 D… (1 solenoid) for main valves with symbols C, D, K, Z Symbols HC, HD, HK, HZ Pilot control valve type 4WE 6 JA... (1 solenoid “a”) for main valves with symbols EA, FA, etc., spring return Pilot control valve type 4WE 6 MA... (1 solenoid “a”) for main valves with symbols HEA, HFA, etc., hydraulic control spool return |

|

2.2 |

Pilot control valve type 4WE 6 Y... (1 solenoid) for main valves with symbol Y symbol HY Pilot control valve type 4WE 6 JB... (1 solenoid “b”) for main valves with symbol EB, FB, etc., spring return Pilot control valve type 4WE 6 MB... (1 solenoid “b”) for main valves with symbol HEB, HFB, etc., hydraulic control spool return |

|

2.3 |

Pilot control valve type 4WE 6J… (2 solenoids) for main valves with 3 spool positions, spring-centered Pilot control valve type 4WE 6 M… (2 solenoids) for main valves with 3 spool positions, pressure-centered |

|

3.1 |

Solenoid “a” |

|

3.2 |

Solenoid “b” |

|

4 |

Manual override, “N”, optional Actuation of the manual override is only possible up to a tank pressure of approx. 50 bar. Avoid damage to the bore of the manual override! (Special tool for actuation, separate order, material no. R900024943). When the manual override is blocked, the operation of the solenoid must be prevented! The simultaneous actuation of the solenoids must be prevented! |

|

5 |

Solenoid without manual override |

|

6 |

Solenoid with manual override |

|

8 |

Switching time adjustment (wrench size 6), optional |

|

9 |

Pressure reducing valve, optional |

|

10.1 |

Machined valve contact surface; porting pattern according to ISO 4401-05-05-0-05 |

|

11 |

Name plate pilot control valve |

|

12 |

Name plate complete valve |

|

13 |

Seal rings |

|

14 |

Space required to remove the mating connector |

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

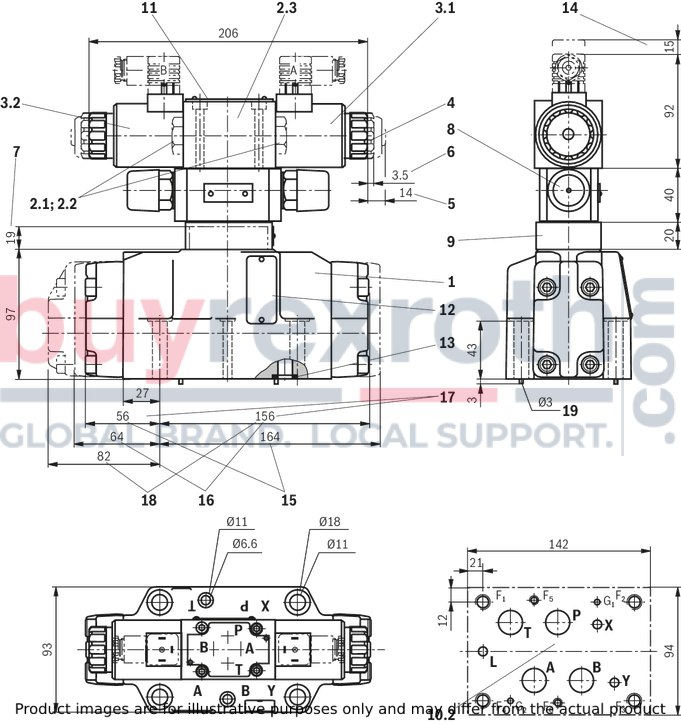

NG16

Dimensions in mm

|

|

Required surface quality of the valve contact surface |

|

1 |

Main valve |

|

2 |

Pilot control valve type 4WE 6... according to data sheet 23178: |

|

2.1 |

Pilot control valve type 4WE 6 D… (1 solenoid) for main valves with symbols C, D, K, Z Symbols HC, HD, HK, HZ Pilot control valve type 4WE 6 JA... (1 solenoid “a”) for main valves with symbols EA, FA, etc., spring return Pilot control valve type 4WE 6 MA... (1 solenoid “a”) for main valves with symbols HEA, HFA, etc., hydraulic control spool return |

|

2.2 |

Pilot control valve type 4WE 6 Y... (1 solenoid) for main valves with symbol Y symbol HY Pilot control valve type 4WE 6 JB... (1 solenoid “b”) for main valves with symbol EB, FB, etc., spring return Pilot control valve type 4WE 6 MB... (1 solenoid “b”) for main valves with symbol HEB, HFB, etc., hydraulic control spool return |

|

2.3 |

Pilot control valve type 4WE 6J… (2 solenoids) for main valves with 3 spool positions, spring-centered Pilot control valve type 4WE 6 M… (2 solenoids) for main valves with 3 spool positions, pressure-centered |

|

3.1 |

Solenoid “a” |

|

3.2 |

Solenoid “b” |

|

4 |

Manual override, “N”, optional Actuation of the manual override is only possible up to a tank pressure of approx. 50 bar. Avoid damage to the bore of the manual override! (Special tool for actuation, separate order, material no. R900024943). When the manual override is blocked, the operation of the solenoid must be prevented! The simultaneous actuation of the solenoids must be prevented! |

|

5 |

Solenoid without manual override |

|

6 |

Solenoid with manual override |

|

8 |

Switching time adjustment (wrench size 6), optional |

|

9 |

Pressure reducing valve, optional |

|

10.2 |

machined valve contact surface; porting pattern according to ISO 4401-07-07-0-05 |

|

11 |

Name plate pilot control valve |

|

12 |

Name plate complete valve |

|

13 |

Seal rings |

|

14 |

Space required to remove the mating connector |

|

15 |

2-spool position valves with spring end position in the main valve (spool symbols A, C, D, K, Z) |

|

16 |

2-spool position valves with spring end position in the main valve (spool symbols B, Y) |

|

17 |

3-spool position valves, spring-centered; |

|

19 |

Locking pin |

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

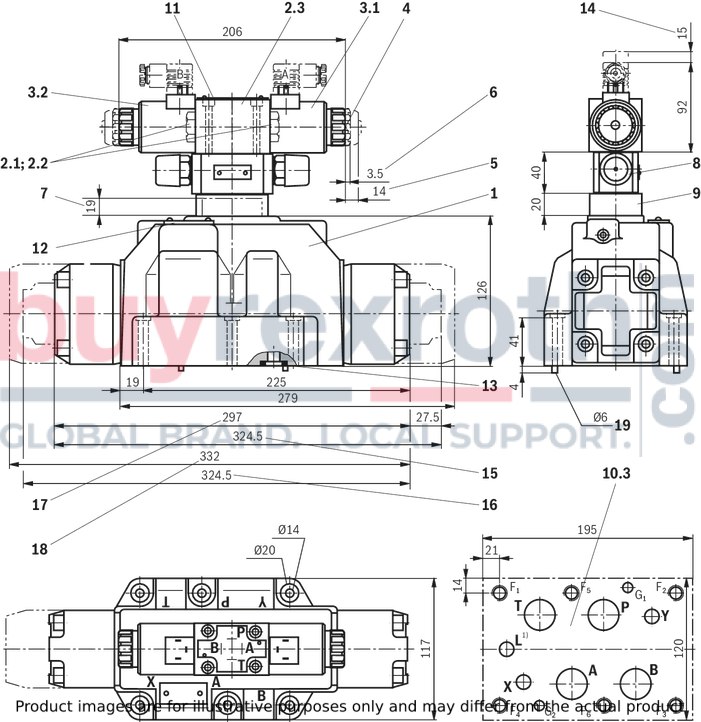

NG25 (type W.H 22)

Dimensions in mm

| 1) | Port L only for valves with pressure-centered zero position |

|

|

Required surface quality of the valve contact surface |

|

1 |

Main valve |

|

2 |

Pilot control valve type 4WE 6... according to data sheet 23178: |

|

2.1 |

Pilot control valve type 4WE 6 D… (1 solenoid) for main valves with symbols C, D, K, Z Symbols HC, HD, HK, HZ Pilot control valve type 4WE 6 JA... (1 solenoid “a”) for main valves with symbols EA, FA, etc., spring return Pilot control valve type 4WE 6 MA... (1 solenoid “a”) for main valves with symbols HEA, HFA, etc., hydraulic control spool return |

|

2.2 |

Pilot control valve type 4WE 6 Y... (1 solenoid) for main valves with symbol Y symbol HY Pilot control valve type 4WE 6 JB... (1 solenoid “b”) for main valves with symbol EB, FB, etc., spring return Pilot control valve type 4WE 6 MB... (1 solenoid “b”) for main valves with symbol HEB, HFB, etc., hydraulic control spool return |

|

2.3 |

Pilot control valve type 4WE 6J… (2 solenoids) for main valves with 3 spool positions, spring-centered Pilot control valve type 4WE 6 M… (2 solenoids) for main valves with 3 spool positions, pressure-centered |

|

3.1 |

Solenoid “a” |

|

3.2 |

Solenoid “b” |

|

4 |

Manual override, “N”, optional Actuation of the manual override is only possible up to a tank pressure of approx. 50 bar. Avoid damage to the bore of the manual override! (Special tool for actuation, separate order, material no. R900024943). When the manual override is blocked, the operation of the solenoid must be prevented! The simultaneous actuation of the solenoids must be prevented! |

|

5 |

Solenoid without manual override |

|

6 |

Solenoid with manual override |

|

8 |

Switching time adjustment (wrench size 6), optional |

|

9 |

Pressure reducing valve, optional |

|

10.3 |

machined valve contact surface; porting pattern according to ISO 4401-08-08-0-05 |

|

11 |

Name plate pilot control valve |

|

12 |

Name plate complete valve |

|

13 |

Seal rings |

|

14 |

Space required to remove the mating connector |

|

19 |

Locking pin |

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

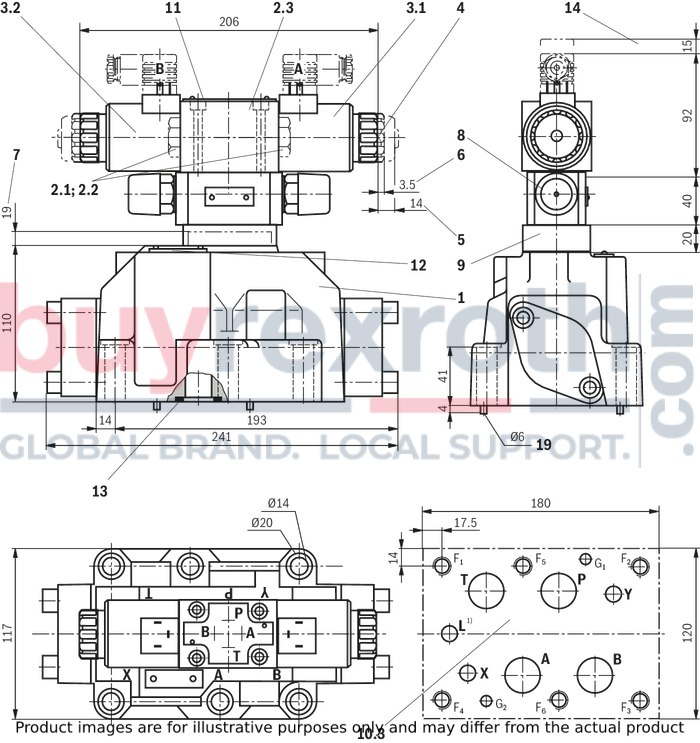

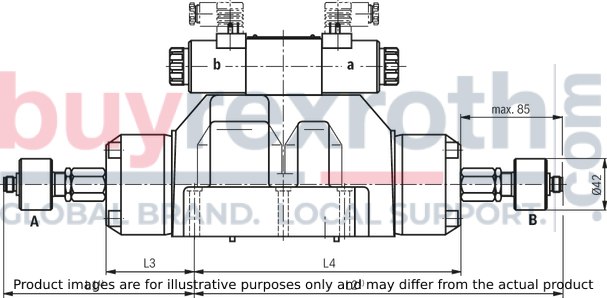

NG25 (type W.H 25)

Dimensions in mm

| 1) | Port L only for valves with pressure-centered zero position |

|

|

Required surface quality of the valve contact surface |

|

1 |

Main valve |

|

2 |

Pilot control valve type 4WE 6... according to data sheet 23178: |

|

2.1 |

Pilot control valve type 4WE 6 D… (1 solenoid) for main valves with symbols C, D, K, Z Symbols HC, HD, HK, HZ Pilot control valve type 4WE 6 JA... (1 solenoid “a”) for main valves with symbols EA, FA, etc., spring return Pilot control valve type 4WE 6 MA... (1 solenoid “a”) for main valves with symbols HEA, HFA, etc., hydraulic control spool return |

|

2.2 |

Pilot control valve type 4WE 6 Y... (1 solenoid) for main valves with symbol Y symbol HY Pilot control valve type 4WE 6 JB... (1 solenoid “b”) for main valves with symbol EB, FB, etc., spring return Pilot control valve type 4WE 6 MB... (1 solenoid “b”) for main valves with symbol HEB, HFB, etc., hydraulic control spool return |

|

2.3 |

Pilot control valve type 4WE 6J… (2 solenoids) for main valves with 3 spool positions, spring-centered Pilot control valve type 4WE 6 M… (2 solenoids) for main valves with 3 spool positions, pressure-centered |

|

3.1 |

Solenoid “a” |

|

3.2 |

Solenoid “b” |

|

4 |

Manual override, “N”, optional Actuation of the manual override is only possible up to a tank pressure of approx. 50 bar. Avoid damage to the bore of the manual override! (Special tool for actuation, separate order, material no. R900024943). When the manual override is blocked, the operation of the solenoid must be prevented! The simultaneous actuation of the solenoids must be prevented! |

|

5 |

Solenoid without manual override |

|

6 |

Solenoid with manual override |

|

8 |

Switching time adjustment (wrench size 6), optional |

|

9 |

Pressure reducing valve, optional |

|

10.3 |

machined valve contact surface; porting pattern according to ISO 4401-08-08-0-05 |

|

11 |

Name plate pilot control valve |

|

12 |

Name plate complete valve |

|

13 |

Seal rings |

|

14 |

Space required to remove the mating connector |

|

15 |

2-spool position valves with spring end position in the main valve (spool symbols A, C, D, K, Z) |

|

16 |

2-spool position valves with spring end position in the main valve (spool symbols B, Y) |

|

17 |

3-spool position valves, spring-centered; |

|

18 |

3-spool position valve, pressure-centered |

|

19 |

Locking pin |

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

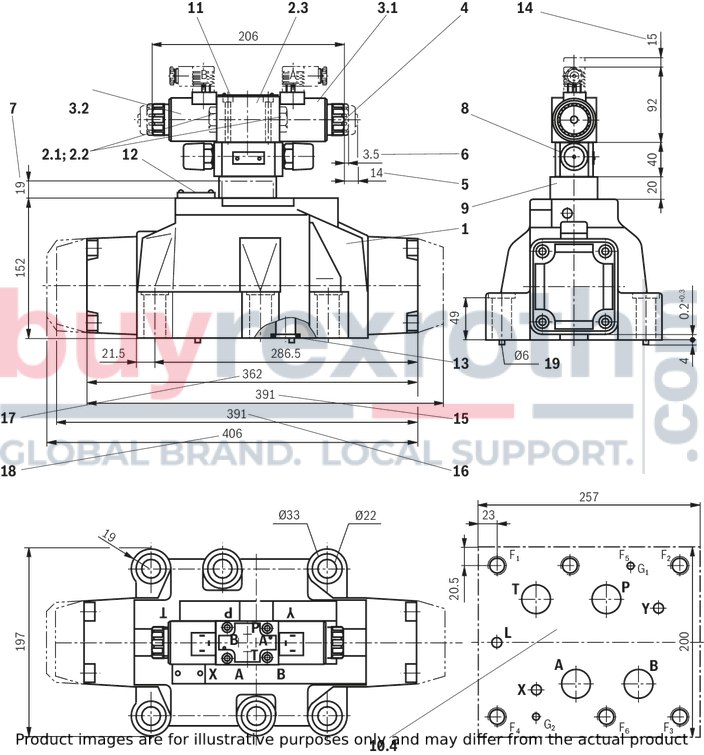

Size 32

Dimensions in mm

|

|

Required surface quality of the valve contact surface |

|

1 |

Main valve |

|

2 |

Pilot control valve type 4WE 6... according to data sheet 23178: |

|

2.1 |

Pilot control valve type 4WE 6 D… (1 solenoid) for main valves with symbols C, D, K, Z Symbols HC, HD, HK, HZ Pilot control valve type 4WE 6 JA... (1 solenoid “a”) for main valves with symbols EA, FA, etc., spring return Pilot control valve type 4WE 6 MA... (1 solenoid “a”) for main valves with symbols HEA, HFA, etc., hydraulic control spool return |

|

2.2 |

Pilot control valve type 4WE 6 Y... (1 solenoid) for main valves with symbol Y symbol HY Pilot control valve type 4WE 6 JB... (1 solenoid “b”) for main valves with symbol EB, FB, etc., spring return Pilot control valve type 4WE 6 MB... (1 solenoid “b”) for main valves with symbol HEB, HFB, etc., hydraulic control spool return |

|

2.3 |

Pilot control valve type 4WE 6J… (2 solenoids) for main valves with 3 spool positions, spring-centered Pilot control valve type 4WE 6 M… (2 solenoids) for main valves with 3 spool positions, pressure-centered |

|

3.1 |

Solenoid “a” |

|

3.2 |

Solenoid “b” |

|

4 |

Manual override, “N”, optional Actuation of the manual override is only possible up to a tank pressure of approx. 50 bar. Avoid damage to the bore of the manual override! (Special tool for actuation, separate order, material no. R900024943). When the manual override is blocked, the operation of the solenoid must be prevented! The simultaneous actuation of the solenoids must be prevented! |

|

5 |

Solenoid without manual override |

|

6 |

Solenoid with manual override |

|

8 |

Switching time adjustment (wrench size 6), optional |

|

9 |

Pressure reducing valve, optional |

|

10.4 |

machined valve contact surface; porting pattern according to ISO 4401-10-09-0-05 |

|

11 |

Name plate pilot control valve |

|

12 |

Name plate complete valve |

|

13 |

Seal rings |

|

14 |

Space required to remove the mating connector |

|

15 |

2-spool position valves with spring end position in the main valve (spool symbols A, C, D, K, Z) |

|

16 |

2-spool position valves with spring end position in the main valve (spool symbols B, Y) |

|

17 |

3-spool position valves, spring-centered; |

|

18 |

3-spool position valve, pressure-centered |

|

19 |

Locking pin |

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

Subplates (separate order) with porting pattern according to ISO 4401 see data sheet 45100.

Valve mounting screws (separate order)

– NG10:

4 hexagon socket head cap screws, metric

ISO 4762 - M6 x 45 - 10.9-flZn-240h-L

(Friction coefficientμtotal = 0.09 to 0.14);

Tightening torque MA = 12.5 Nm ± 10%,

material no. R913000258

4 hexagon socket head cap screws UNC 1/4-20 UNC x 1 3/4″ ASTM-A574

upon request

– NG16:

4 hexagon socket head cap screws, metric

ISO 4762 - M10 x 60 - 10.9-flZn-240h-L

(friction coefficientμtotal = 0.09 to 0.14);

Tightening torque MA = 75 Nm ± 10%,

Material no. R913000116

2 hexagon socket head cap screws, metric

ISO 4762 - M6 x 60 - 10.9-flZn-240h-L

(Friction coefficient μtotal = 0.09 to 0.14);

Tightening torque MA = 12,5 Nm ± 10%,

material no. R913000115

4 hexagon socket head cap screws UNC 3/8-16 UNC x 2 1/4″ ASTM-A574

upon request

2 hexagon socket head cap screws UNC 1/4-20 UNC x 1/4″ ASTM-A574

upon request

– NG25:

6 hexagon socket head cap screws, metric

ISO 4762 - M12 x 60 - 10.9-flZn-240h-L

(friction coefficient μtotal = 0.09 to 0.14);

Tightening torque MA = 130 Nm ± 10%,

Material no. R913000121

6 hexagon socket head cap screws UNC 1/2-13 UNC x 2 1/2″ ASTM-A574

upon request

– NG32:

6 hexagon socket head cap screws, metric

ISO 4762 - M20 x 80 - 10.9-flZn-240h-L

(friction coefficient μtotal = 0.09 to 0.14);

Tightening torque MA = 430 Nm ± 10%,

Material no. R901035246

6 hexagon socket head cap screws UNC 3/4-10 UNC x 3 1/4″ ASTM-A574

upon request

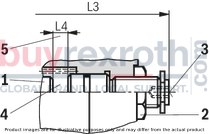

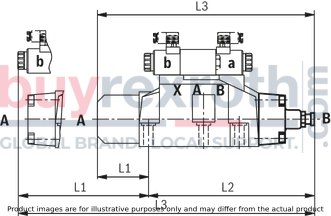

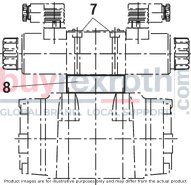

Stroke setting, mounting options

The stroke of the control spool is limited by the stroke setting (1). The control spool stroke is shortened by loosening the lock nut (2) and clockwise rotation of the adjustment spindle (3). The control chamber (4) must be depressurized for this.

|

NG |

L4 |

|

mm |

|

| 10 | 6.5 |

| 16 | 10 |

| 25 (H-WEH22) | 9.5 |

| 25 (H-WEH25) | 12.5 |

| 32 | 15 |

5 adjustment range

NG10: 1 rotation = 1 mm adjustment travel NG16 to 32: 1 rotation = 1.5 mm adjustment travelStroke setting, mounting options

Stroke limitation on side A

Stroke setting, mounting options

Stroke limitation on side B

|

Mounting options |

NG |

3-spool position valve 1) |

|||||

|

Spring-centered |

Pressure-centered |

||||||

|

L1 (mm) |

L2 (mm) |

L3 (mm) |

L1 (mm) |

L2 (mm) |

L3 (mm) |

||

|

Stroke setting on valve side A and B |

10 |

90 |

144 |

234 |

|

|

|

|

16 |

100 |

200 |

300 |

|

|

|

|

|

25 2) |

96 |

241 |

337 |

|

|

|

|

|

25 3) |

123 |

276 |

399 |

|

|

|

|

|

32 |

133 |

344 |

477 |

|

|

|

|

|

Stroke setting on valve side A |

10 |

90 |

106 |

196 |

|

|

|

|

16 |

100 |

156 |

256 |

|

|

|

|

|

25 2) |

96 |

193 |

289 |

|

|

|

|

|

25 3) |

123 |

225 |

348 |

|

|

|

|

|

32 |

133 |

287 |

420 |

|

|

|

|

|

Stroke setting on valve side B |

10 |

52 |

144 |

196 |

– |

– |

– |

|

16 |

56 |

200 |

256 |

81 |

200 |

281 |

|

|

25 2) |

48 |

241 |

289 |

– |

– |

– |

|

|

25 3) |

72 |

276 |

348 |

107 |

276 |

283 |

|

|

32 |

76 |

344 |

420 |

120 |

344 |

464 |

|

| 1) | With symbol A only version "11", with symbol B only version "12" possible. |

| 2) | Version "W.H 22" |

| 3) | Version "W.H 25" |

| 1) With symbol A only version "11", with symbol B only version "12" possible. | |

| 2) Version "H-WEH 22" | |

| 3) Version "H-WEH 25" |

|

Mounting options |

NG |

2-spool position valve |

||||||||

|

Spring end position |

Hydraulic end position |

|||||||||

|

A, C, D, K, Z |

B, Y |

HC, HD, HK, HZ, HY |

||||||||

|

L1 (mm) |

L2 (mm) |

L3 (mm) |

L1 (mm) |

L2 (mm) |

L3 (mm) |

L1 (mm) |

L2 (mm) |

L3 (mm) |

||

|

Stroke setting on valve side A and B |

10 |

90 |

144 |

234 |

90 |

144 |

234 |

90 |

144 |

234 |

|

16 |

– |

– |

– |

– |

– |

– |

100 |

200 |

300 |

|

|

25 1) |

96 |

241 |

337 |

96 |

241 |

337 |

96 |

241 |

337 |

|

|

25 2) |

– |

– |

– |

– |

– |

– |

123 |

276 |

399 |

|

|

32 |

– |

– |

– |

– |

– |

– |

133 |

344 |

477 |

|

|

Stroke setting on valve side A |

10 |

90 |

106 |

196 |

– |

– |

– |

90 |

106 |

196 |

|

16 |

100 |

180 |

280 |

– |

– |

– |

100 |

156 |

256 |

|

|

25 1) |

96 |

193 |

289 |

96 |

193 |

289 |

96 |

193 |

289 |

|

|

25 2) |

123 |

253 |

376 |

– |

– |

– |

123 |

225 |

348 |

|

|

32 |

133 |

316 |

449 |

– |

– |

– |

133 |

287 |

420 |

|

|

Stroke setting on valve side B |

10 |

52 |

144 |

196 |

52 |

144 |

196 |

52 |

144 |

196 |

|

16 |

– |

– |

– |

80 |

200 |

280 |

56 |

200 |

256 |

|

|

25 1) |

48 |

241 |

289 |

48 |

241 |

289 |

48 |

241 |

289 |

|

|

25 2) |

– |

– |

– |

100 |

276 |

376 |

72 |

276 |

348 |

|

|

32 |

– |

– |

– |

105 |

344 |

449 |

76 |

344 |

420 |

|

| 1) | Version "W.H 22" |

| 2) | Version "W.H 25" |

| 1) With symbol A only version "11", with symbol B only version "12" possible. | |

| 2) Version "H-WEH 22" | |

| 3) Version "H-WEH 25" |

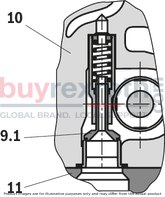

Spool position monitoring

Inductive position switch type QM

Dimensions in mm

| 1) | Without mating connector |

|

Mounting options – 2-spool position valve |

||||||||||||||

|

Monitored spool position |

Ordering code |

NG |

Hydraulic end position HC, HD, HK, HZ, HY |

Spring end position C, D, K, Z |

Spring end position Y |

|||||||||

|

L1 (mm) 1) |

L2 (mm) 1) |

L3 (mm) |

L4 (mm) |

L1 (mm) 1) |

L2 (mm) 1) |

L3 (mm) |

L4 (mm) |

L1 (mm) 1) |

L2 (mm) 1) |

L3 (mm) |

L4 (mm) |

|||

|

„a“ Position switch on side B |

QMAG24 |

10 |

211 |

57 |

211 |

57 |

211 |

57 |

||||||

|

16 |

259 |

55 |

259 |

55 |

||||||||||

|

25 2) |

294 |

47 |

294 |

47 |

294 |

47 |

||||||||

|

25 3) |

325 |

72 |

325 |

72 |

||||||||||

|

32 |

371 |

76 |

371 |

76 |

||||||||||

|

„b“ Position switch on side A |

QMBG24 |

10 |

157 |

111 |

157 |

111 |

157 |

111 |

||||||

|

16 |

159 |

155 |

159 |

155 |

||||||||||

|

25 2) |

149 |

192 |

149 |

192 |

149 |

192 |

||||||||

|

25 3) |

172 |

225 |

172 |

225 |

||||||||||

|

32 |

161 |

287 |

161 |

287 |

||||||||||

|

"a" and "b" Position switch on side A and B |

QMABG24 |

10 |

157 |

211 |

157 |

211 |

157 |

211 |

||||||

|

16 |

159 |

259 |

||||||||||||

|

25 2) |

149 |

294 |

149 |

294 |

149 |

294 |

||||||||

|

25 3) |

172 |

325 |

||||||||||||

|

32 |

161 |

371 |

||||||||||||

| 1) Without mating connector | |

| 2) Type 4W.H 22.. | |

| 3) Type 4W.H 25.. |

|

Mounting options – 3-spool position valve |

||||||||||

|

Monitored spool position |

Ordering code |

NG |

Spring-centered |

Pressure-centered |

||||||

|

L1 (mm) 1) |

L2 (mm) 1) |

L3 (mm) |

L4 (mm) |

L1 (mm) 1) |

L2 (mm) 1) |

L3 (mm) |

L4 (mm) |

|||

|

„a“ Position switch on side B |

QMAG24 |

10 |

211 |

57 |

||||||

|

16 |

259 |

55 |

259 |

81 |

||||||

|

25 2) |

294 |

47 |

||||||||

|

25 3) |

325 |

72 |

325 |

107 |

||||||

|

32 |

371 |

76 |

371 |

120 |

||||||

|

„b“ Position switch on side A |

QMBG24 |

10 |

157 |

111 |

||||||

|

16 |

159 |

155 |

||||||||

|

25 2) |

149 |

192 |

||||||||

|

25 3) |

172 |

225 |

||||||||

|

32 |

161 |

287 |

||||||||

|

"a" and "b" Position switch on side A and B |

QMABG24 |

10 |

157 |

211 |

||||||

|

16 |

159 |

259 |

||||||||

|

25 2) |

149 |

294 |

||||||||

|

25 3) |

172 |

325 |

||||||||

|

32 |

161 |

371 |

||||||||

|

Zero position Position switch on side A and B 2 position switches |

QM0G24 4) |

10 |

157 |

211 |

||||||

|

16 |

159 |

259 |

||||||||

|

25 2) |

149 |

294 |

||||||||

|

25 3) |

172 |

325 |

||||||||

|

32 |

161 |

371 |

||||||||

| 1) | Without mating connector |

| 2) | Version "W.H 22" |

| 3) | Version "W.H 25" |

| 4) | 3-spool position valve |