Accessories for R901339086

PROPORTIONAL DIRECTIONAL VALVE 4WRPDH10C4B100L-2X/M/24ED6T

Manufacturer: Bosch Rexroth

Material #: R901339086

Model : 4WRPDH10C4B100L-2X/M/24ED6T

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

The Bosch Rexroth 4WRPDH10C4B100L-2X/M/24ED6T (R901339086) is a state-of-the-art industrial hydraulic valve designed for high-performance applications requiring reliable and quick control of oil flow direction. This direct actuated spool valve, with its integrated electronics and VDC power supply, is characterized by its exceptional precision due to internal piston position feedback. It features a spool symbol C, indicating its specific flow path configuration, and can handle a maximum pressure as detailed in its specifications.

With a nominal flow as per the provided data, the valve's size and CETOP D conform to standard mounting and connection requirements. It offers multiple ports for versatile connectivity and is operated electrically with integrated electronics that ensure responsive control. The product conforms to CE standards for electromagnetic compatibility within the EU, ensuring that it meets stringent regulatory requirements.

This robust valve is equipped with digital EtherNET/IP connectivity options and is compatible with a range of hydraulic fluids such as HL, HLP, HLPD, HVLP, HVLPD, and HFC. Its seals are made from NBR for durability under various operating conditions. The 4WRPDH10C4B100L-2X/M/24ED6T also boasts an internal safety function that can achieve up to category PL e according to EN standards.

Designed to be at the forefront of hydraulic control technology, this Bosch Rexroth valve integrates advanced features such as position control, pressure/force control, closed-loop speed control, and substitutional closed-loop control for both position pressure/force and flow pressure/force. These capabilities make it an indispensable component in complex hydraulic systems where precise movement and force management are critical.

$12,918.00 USD

Availability: 1 In Stock

| Qty | Price | Savings |

|---|---|---|

| 5-24 | $12,595.05 USD | $322.95 USD |

| 25+ | $12,272.10 USD | $645.90 USD |

Qty: Delivered as early as March 10, 2026 when ordered in

Qty: Delivered as early as September 25, 2026 when ordered in

This product is eligible for factory repair.

Size 10, symbol C4, integrated electronics, 24 V DC

Industrial hydraulic valve in a high performance range. Reliable and quick control of the direction of the oil flow according to hydraulic symbol. High accuracy thanks to internal piston position feedback

Unpacked Weight: 7.26 kg

Open

- Integrated digital axis control functionality (IAC-Multi-Ethernet)

- Bus connection/service interface (Sercos, EtherCAT, EtherNet/IP, PROFINET RT, POWERLINK, VARAN) Scalable

- 2 configurable analog sensor inputs

- 1 input for linear position measurement system (SSI, 1Vpp or EnDat 2.2) Safe

- Internal safety function (can be used up to category 4/PL e according to EN13849-1

- CE conformity according to EMC Directive 2014/30/EU Precise

- Best-in-class hydraulic controller

- High response sensitivity and little hysteresis

Set-up

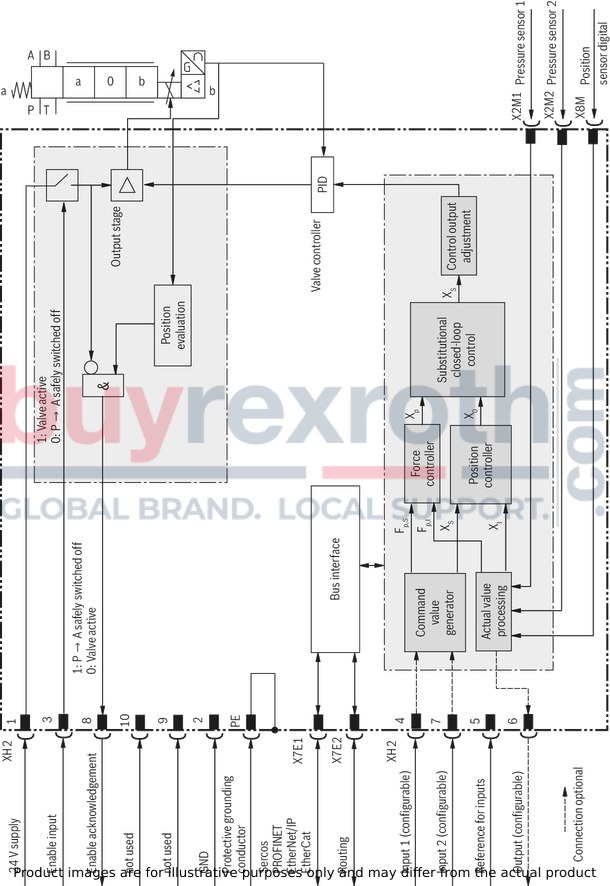

The directional control valve with IAC Multi Ethernet electronics mainly consists of:

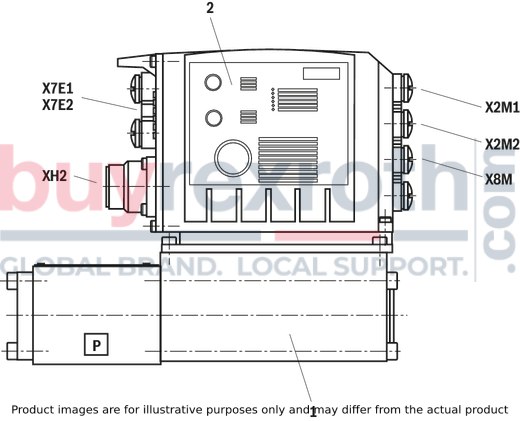

Direct operated directional control valve (1) with control spool and sleeve in servo quality Integrated digital axis controller (2) with: analog/digital interface (XH2) Ethernet interfaces (X7E1, X7E2) analog sensor interfaces (X2M1, X2M2) digital sensor interface (X8M)Directional control valve with integrated axis controller, analog interfaces (X2M1, X2M2), digital interfaces (XH2, X8M) and Ethernet interfaces (X7E1, X7E2)

Functional description

The IAC Multi Ethernet valve (Integrated Axis Controller based on directional control valves) is a digital directional control valve with integrated axis controller and the following functionalities:

Position control Pressure/force control Closed-loop speed control Substitutional closed-loop control (position - pressure/force) Substitutional control (flow - pressure/force) pQ function (flow-controlled)

This enables, amongst others, the following operating modes:

Valve direct control Drive-controlled position control Drive-controlled positioning Positioning block operation The command values are preset via the Ethernet interface (X7E1 or X7E2) or, alternatively, via the analog/digital interface (XH2) The feedback information of the actual value signals to the superior control system is provided optionally either via the Ethernet interface (X7E1 or X7E2) or the analog/digital interface (XH2) The controller parameters are set via the Ethernet interface (X7E1 or X7E2)

Monitoring

The digital control electronics enable comprehensive monitoring functions/error detection including:

Undervoltage Communication error Cable break for analog sensor inputs and digital position measurement system Short-circuit monitoring for analog/digital outputs Monitoring of the microcontroller (watchdog) Temperature of the integrated electronics

IndraWorks DS PC program

To implement the project planning task and to parameterize the IAC Multi Ethernet valves, the user may use the IndraWorks DS engineering tool (see accessories):

Project planning Parameterization Commissioning Diagnosis Comfortable management of all data on a PC PC operating systems: Windows XP (SP3), Windows 7

Safety function

The integrated control electronics of the valve enables the additional shut-off of a channel according to EN 13849-1 in the direction P to A (depending on the application, the fail-safe position must be adhered to).

For this purpose, a suitable control system must be provided to perform the plausibility check between the direction-dependent valve signals "enable input" and "enable acknowledgement" (signal fed back by the valve).

It is not possible to switch off direction P to B in a safety-relevant manner according to EN 13849-1 (depending on valve type).

| Spool valve |

| Direct actuated |

| Linear |

| Component series 2X |

| Maximum flow 100 l/min |

| Size 6, 10 |

| Maximum operating pressure 350 bar |

| Data Sheet | Download Data Sheet |

| 3D CAD | Download 3D CAD |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Connection diagram | ISO 4401-05-04-0-05 |

| Max. pressure | 315 |

| Spool symbol | Symbol C4 |

| Type of connection | Subplate mounting |

| Nominal flow | 100 |

| Size | 10 |

| Type of actuation | Electrical with integrated electronics |

| Number of ports | 4 |

| Number of switching positions | 4 |

| Supply voltage | 24 VDC |

| Electrical connector | Connector 12-pole (11 + PE) |

| Electrical connection description | Connector 12-pole (11 + PE) according to EN 175201-804 |

| Connectivity | Digital, EtherNET/IP |

| Conformity description | CE – electromagnetic compatibility 2014/30/EU |

| Conformity | CE,RoHS |

| Hydraulic fluid | HL,HLP,HLPD,HVLP,HVLPD,HFC (Fuchs: Hydrotherm 46M, Renosafe 500; Petrofer: Ultra Safe 620; Houghton: Safe 620; Union: Carbide HP5046) |

| Seals | NBR |

| Productgroup ID | 9,10,11,12,13,14 |

| Connection diagram NFPA | NFPA T3.5.1 R2-2002 D05 |

| Size_CETOP | D05 |

| Weight | 7.26 |

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

|||

|

4 |

WRP |

D |

H |

B |

‒ |

2X |

/ |

/ |

24 |

D6 |

* |

|

01 |

4 main ports |

4 |

|||

|

02 |

High-response directional valves |

WRP |

|||

|

03 |

With integrated digital axis controller |

D |

|||

|

04 |

Control spool/sleeve |

H |

|||

|

05 |

Size 6 |

6 |

|||

|

Size 10 |

10 |

||||

|

06 |

Symbols; for the possible version, see "Symbols/Circuit diagrams" |

||||

|

07 |

Installation side of the inductive position transducer |

B |

|||

|

Rated flow at 70 bar valve pressure differential (35 bar/control edge) |

|||||

|

08 |

Flow characteristic |

||||

|

„L" |

"P" (inflection 40 %) |

"P" (inflection 60 %) |

|||

|

Size 6 |

|||||

|

2 l/min |

✔ |

‒ |

‒ |

02 |

|

|

4 l/min |

✔ |

✔ |

‒ |

04 |

|

|

12 l/min |

✔ |

‒ |

‒ |

12 |

|

|

15 l/min |

‒ |

‒ |

✔ |

15 |

|

|

24 l/min |

✔ |

‒ |

‒ |

24 |

|

|

25 l/min |

‒ |

‒ |

✔ |

25 |

|

|

40 l/min |

✔ |

✔ |

‒ |

40 |

|

|

Size 10 |

|||||

|

50 l/min |

✔ |

✔ |

‒ |

50 |

|

|

100 l/min |

✔ |

✔ |

‒ |

100 |

|

|

Flow characteristic |

|||||

|

09 |

Linear |

L |

|||

|

Inflected characteristic curve (inflection 60 % for NG6 with rated flows "15" and "25", otherwise inflection 40 %) |

P |

||||

|

10 |

Component series 20 ... 29 (20 ... 29: unchanged installation and connection dimensions) - Size 6 |

2X |

|||

|

Seal material |

|||||

|

11 |

NBR seals |

M |

|||

|

FKM seals |

V |

||||

|

Observe compatibility of seals with hydraulic fluid used. (Other seals upon request) |

|||||

|

12 |

Supply voltage 24 V |

24 |

|||

|

Ethernet interface |

|||||

|

13 |

EtherNet/IP |

E |

|||

|

PROFINET RT |

N |

||||

|

Sercos |

S |

||||

|

EtherCAT (Profil CANopen) |

T |

||||

|

POWERLINK (CANopen profile) |

W |

||||

|

VARAN |

V |

||||

|

Electrical interface |

|||||

|

14 |

± 10 VDC or 4 ... 20 mA |

D6 |

|||

|

Sensor interfaces |

|||||

|

15 |

0 ... 10 V / 4 ... 20 mA / EnDat 2.2 |

S |

|||

|

0 ... 10 V / 4 ... 20 mA / SSI |

T |

||||

|

0 ... 10 V / 4 ... 20 mA / 1Vpp |

U |

||||

|

16 |

Further details in the plain text |

* |

|||

For applications outside these parameters, please consult us!

general

|

Type |

4WRPDH | ||

|

Size |

6 | 10 | |

|

Installation position |

Any | ||

|

Earth |

kg |

3.2 | 7.2 |

|

Storage temperature range |

°C |

+5 … +40 | |

|

Ambient temperature range |

°C |

-20 … +60 | |

|

Sine test according to DIN EN 60068-2-6 |

10 ... 2000 Hz / maximum 10 g / 10 cycles / 3 axes | ||

|

Noise test according to DIN EN 60068-2-64 |

20 ... 2000 Hz / 10 gRMS / 30 g peak / 30 min / 3 axes | ||

|

Transport shock according to DIN EN 60068-2-27 |

15 g / 11 ms / 3 axes | ||

|

Maximum relative humidity 1) |

% |

95 | |

|

Maximum surface temperature |

°C |

150 | |

|

MTTFD values according to EN ISO 13849 |

Years |

150 | |

| 1) | No condensation |

hydraulic

|

Type |

4WRPDH | |||

|

Size |

6 | 10 | ||

|

Maximum operating pressure |

Port P |

bar |

350 | 315 |

|

Port A |

bar |

350 | 315 | |

|

Port B |

bar |

350 | 315 | |

|

Port T |

bar |

250 | ||

|

Maximum flow |

l/min |

100 | ||

|

Hydraulic fluid |

see table "Hydraulic fluid" | |||

|

Hydraulic fluid temperature range |

°C |

-20 … +60 | ||

|

Viscosity range |

Maximum admissible |

mm²/s |

10 … 800 | |

|

Recommended |

mm²/s |

20 … 100 | ||

|

Maximum admissible degree of contamination of the hydraulic fluid, cleanliness class according to ISO 4406 (c) 1) |

Class 18/16/13 | |||

|

Hysteresis |

% |

≤ 0.2 | ||

|

Manufacturing tolerance |

% |

≤ 10 | ||

|

Temperature drift |

Zero shift < 0.25 % at Δϑ = 10 K | |||

|

Pressure drift |

Zero shift < 0.15 % at 100 bar | |||

|

Zero point calibration (set in the plant) |

% |

± 1 | ||

| 1) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

hydraulic

|

Nominal flow 1) |

l/min |

2 | 4 | 12 | 15 | 24 | 25 | 40 | 50 | 100 | ||

|

Limitation of use |

Symbols C3, C5 |

bar |

350 | 160 | 315 | 160 | ||||||

|

Symbols C1, C4 |

bar |

350 | 280 | 250 | 100 | 250 | 100 | |||||

|

Leakage flow (at 100 bar) |

Linear characteristic curve “L” |

l/min |

< 150 | < 180 | < 300 | - | < 500 | < 900 | < 1200 | < 1500 | ||

|

Inflected characteristic curve "P" |

l/min |

- | < 180 | < 300 | < 450 | < 600 | < 500 | < 600 | ||||

| 1) | With Δp = 35 bar/control edge; flow for deviating Δp see formula. |

|

Hydraulic fluid |

Classification |

Suitable sealing materials |

Standards |

Data sheet |

|

|

Mineral oils |

HL, HLP, HLPD, HVLP, HVLPD |

NBR, FKM |

DIN 51524 |

90220 |

|

|

Bio-degradable |

Insoluble in water |

HETG |

NBR, FKM |

ISO 15380 |

90221 |

|

HEES |

FKM |

||||

|

Soluble in water |

HEPG |

FKM |

ISO 15380 |

||

|

Containing water |

Water-free |

HFDU, HFDR |

FKM |

ISO 12922 |

90222 |

|

Containing water |

HFC (Fuchs Hydrotherm 46M, Petrofer Ultra Safe 620 ) |

NBR |

ISO 12922 |

90223 |

|

|

Important information on hydraulic fluids: For more information and data on the use of other hydraulic fluids, please refer to the data sheets above or contact us. There may be limitations regarding the technical valve data (temperature, pressure range, life cycle, maintenance intervals, etc.). The ignition temperature of the hydraulic fluid used must be 40 K higher than the maximum solenoid surface temperature. Flame-resistant – containing water: Maximum pressure differential per control edge 50 bar Pressure pre-loading at the tank port > 20 % of the pressure differential, otherwise increased cavitation Life cycle as compared to operation with mineral oil HL, HLP 50 … 100 % |

|||||

electrical

|

Type |

4WRPDH | |||

|

Size |

6 | 10 | ||

|

Power supply |

Nominal voltage 1) |

VDC |

24 | |

|

Lower limit value |

VDC |

18 | ||

|

Upper limit value |

VDC |

36 | ||

|

Maximum admissible residual ripple 2) |

2.5 Vpp | |||

|

Relative duty cycle 3) |

% |

100 | ||

|

Current consumption |

Imax 4) |

A |

2.5 | |

|

Impulse load |

A |

4 | ||

|

Required fuse protection |

A |

4 (time-lag) | ||

|

Maximum power consumption |

W |

40 | 60 | |

|

Protection class according to DIN EN 60529 |

IP65 (with mating connector mounted and locked) | |||

|

AD/DA resolution |

Analog inputs |

bits |

12 | |

|

Analog outputs |

bits |

10 | ||

|

Protective earthing conductor and screening |

see pin assignment under "Electrical connection" (CE-compliant installation) | |||

|

Adjustment |

calibrated in the plant, see "characteristic curves" | |||

|

Parameterization interface |

Ethernet | |||

|

Scan time pressure and force controller (minimum) |

0.5 ms | |||

|

Scan time position controller (minimum) |

1 ms | |||

|

Booting time |

< 15 s | |||

|

Conformity |

CE according to EMC Directive 2004/108/EC tested according to EN 61000-6-2 and EN 61000-6-3 | |||

| 1) | Supply voltage is used directly for sensor connections X2M1, X2M2 and X8M (no internal voltage limitation). Voltage limit values must be observed directly at the connector of the valve (observe line length and cable cross-section). |

| 2) | Observe the absolute limit values of the supply voltage. |

| 3) | Continuous operation |

| 4) | The maximum current consumption will increase when using the sensor inputs or the switching output according to the external load |

electrical, integrated electronics (OBE)

|

Digital inputs XH2 |

Quantity |

optionally up to 2, configurable (analog inputs are no longer required) |

|

|

Low level |

V |

-3 ... +5 |

|

|

High level |

V |

15 ... UB |

|

|

Current consumption at high level |

mA |

< 1 |

|

|

Reference potential |

Pin 5 |

||

|

Digital outputs XH2 |

Quantity |

1 |

|

|

Low level |

V |

0 ... 3 |

|

|

High level |

V |

15 ... UB |

|

|

Current carrying capacity, max. |

A |

1.5 (short-circuit-proof) |

|

|

Signal delay time |

ms |

< 2 (depending on set scan time) |

|

|

Reference potential |

GND |

||

|

Analog inputs XH2 |

Number (current and voltage input parameterizable) |

optionally up to 2, configurable (digital inputs are no longer required) |

|

|

AD resolution |

bit |

12 |

|

|

Voltage inputs (differential inputs) |

|||

|

Measurement range |

V |

-10 ... +10 |

|

|

Input resistance |

kΩ |

80 + 10 % |

|

|

Temperature drift |

< 14 mV/10 K |

||

|

Current inputs (reference to AGND) |

|||

|

Input current |

mA |

4 ... 20 (0 ... 20 physically) |

|

|

Input resistance |

Ω |

200, measuring resistance plus FET |

|

|

Temperature drift |

< 25 μA/10K |

||

|

Analog outputs XH2 |

Number (current and voltage input parameterizable) |

1 |

|

|

DA resolution |

bit |

14 |

|

|

Voltage outputs |

|||

|

Output range |

V |

-10 ... + 10 (0 ... 10 durch Software) |

|

|

Minimum load impedance |

kΩ |

10 |

|

|

Temperature drift |

< 5 mV/10 K |

||

|

Current outputs |

|||

|

Output range |

mA |

0 ... 20 (4 … 20 by software) |

|

|

Maximum load |

Ω |

200 |

|

|

Analog sensors X2M1, X2M2 |

Number (current and voltage input parameterizable) |

1 pro Stecker |

|

|

Power supply |

V |

24 (corresponding to supply voltage applied to XH2) |

|

|

Maximum supply current |

350 (total X2M1, X2M2, X8M) |

||

|

AD resolution |

bit |

12 |

|

|

Voltage inputs |

|||

|

Measurement range |

V |

0 ... 10 |

|

|

Input resistance |

kΩ |

80 +10 % |

|

|

Temperature drift |

< 15 mV/10 K |

||

|

Current inputs (reference to AGND) |

|||

|

Input current |

mA |

4 ... 20 (0 ... 20 physically) |

|

|

Input resistance |

Ω |

200, measuring resistance plus PTC |

|

|

Temperature drift |

< 10 μA/10 K |

||

|

Digital sensor X8M |

Power supply |

24 V or 5 V |

|

|

Maximum supply current at - 24 V |

mA |

350 (total X2M1, X2M2, X8M) |

|

|

Maximum supply current at - 5 V |

mA |

250 |

|

|

SSI-Aufnehmer |

|||

|

Coding |

Gray |

||

|

Data width |

Bit |

12 ... 28 |

|

|

Transfer frequency |

80 kHz ... 1 MHz |

||

|

Line receiver/driver |

RS485 |

||

|

Endat encoder |

2.2 |

||

|

Line receiver/driver |

RS485 |

||

|

Resolution |

minimum 10 nm and multiple |

||

|

1 Vpp encoder |

|||

|

Transfer frequency |

kHz |

250 |

|

(measured with HLP46, ϑÖl = 40 ±5 °C)

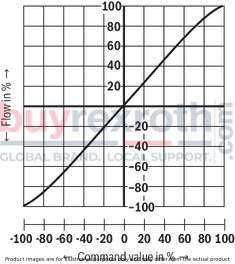

Size 6

Flow/signal function

Linear characteristic curve “L”

Flow/signal function

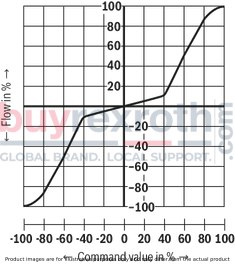

Inflected characteristic curve "P", inflection at 40 %

Flow/signal function

Inflected characteristic curve "P", inflection at 60 %

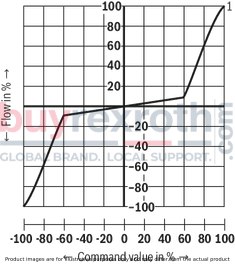

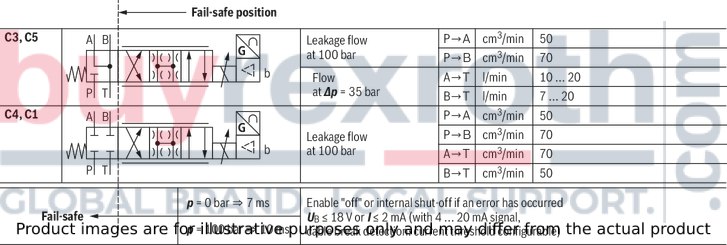

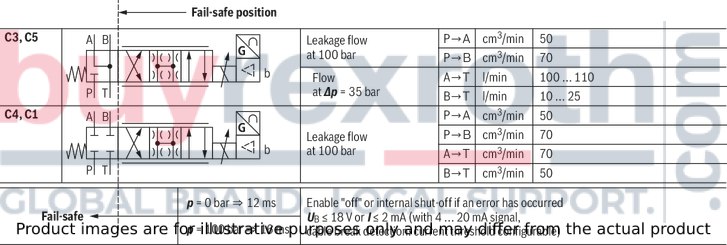

Fail-safe position

NG6

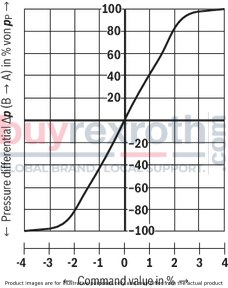

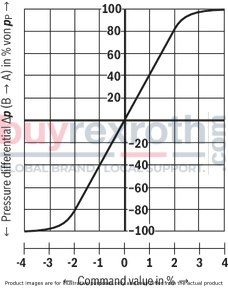

Pressure-signal characteristic curve

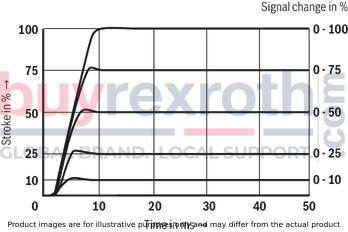

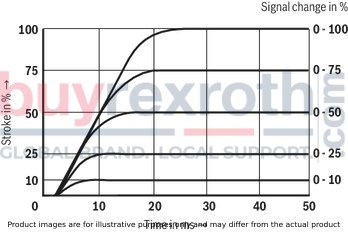

Transition function with stepped electric input signals

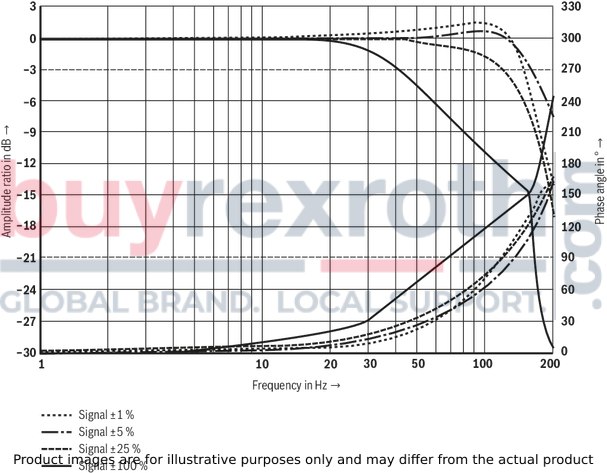

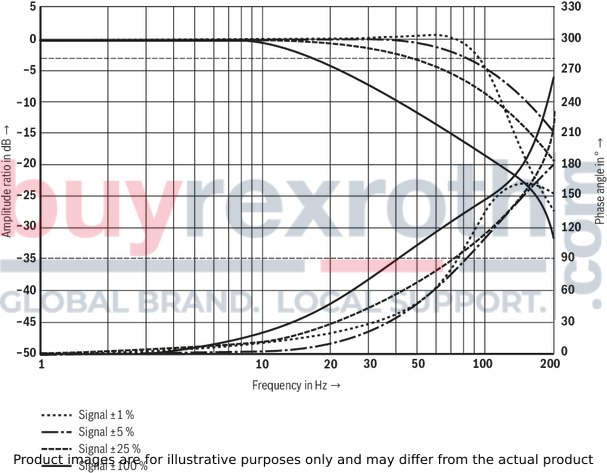

Frequency response

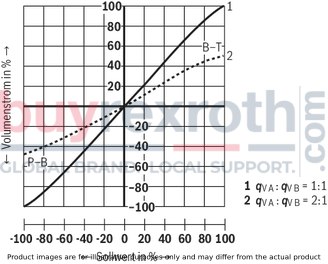

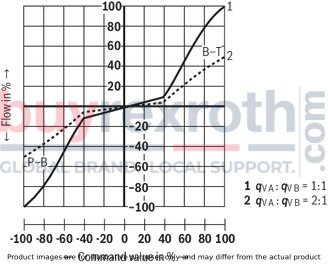

Size 10

Flow/signal function

Linear characteristic curve "L" (1:1)

Flow/signal function

Linear characteristic curve "L" (2:1)

Flow/signal function

Inflected characteristic curve "P", inflection at 40 % (1:1)

Flow/signal function

Inflected characteristic curve "P", inflection at 40 % (2:1)

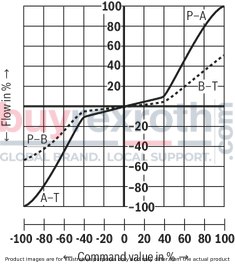

Fail-safe position

Size 10

Pressure-signal characteristic curve

Size 10

Transition function with stepped electric input signals

Size 10

Frequency response

Size 10

|

With control symbol C1 and C5, the following applies: |

|

|

P → A: qvmax |

B → T: qv/2 |

|

P → B: qv/2 |

A → T: qvmax |

|

Standard = 1:1, qVnom 2:1 only with rated flow 40 l/min (version "40") |

|

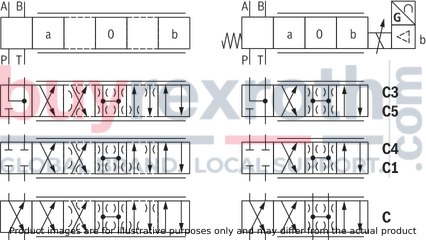

Notice:

Representation according to DIN ISO 1219-1.

Hydraulic interim positions are shown by dashes.

Flow characteristic

|

Symbol |

Linear characteristic curve (version "L") |

Inflected characteristic curve (version "P") |

|

|

Inflection 60 % (qV nom = 15.25 l/min) |

Inflection 40 % |

||

|

C3, C5 C4, C1 |

|

|

|

|

C |

|

- |

- |

Block diagram / pin assignment

Detailed description of the safety function:

After the signal at the enable input has been removed, the output stage, and thus the solenoid of the valve, are internally separated from the available supply voltage. The enable acknowledgment will only be activated after the safe valve spool position has been achieved.

For a detailed description of the safety function, refer to the operating instructions 29391-B.

Connector pin assignment XH2, 11-pole + PE according to EN 175201-804

|

Pin |

Core marking |

Assignment of interface D6 |

|

|

Cable, one-part 1) |

Cable, split 2) |

||

|

1 |

1 |

1 |

24 VDC supply voltage |

|

2 |

2 |

2 |

GND |

|

3 |

3 |

white |

Enable input 24 V DC (high ≥ 15 V; low < 2 V) |

|

4 |

4 |

yellow |

Command value 1 (4 ... 20 mA/±10 V) 3) |

|

5 |

5 |

green |

Reference for command values |

|

6 |

6 |

Violet |

Actual value (4 ... 20 mA/±10 V) 3; 4) |

|

7 |

7 |

pink |

Command value 2 (4 ... 20 mA/±10 V) 3) |

|

8 |

8 |

red |

Enable acknowledgement 24 VDC (Imax 50 mA) 5) |

|

9 |

9 |

brown |

not assigned |

|

10 |

10 |

black |

not assigned |

|

11 |

11 |

blue |

Switching output 24 V, configurable (fault-free operation (24 V)/error (0 V) or power circuit signal), maximum 1.5 A 3; 5) |

|

PE |

green-yellow |

green-yellow |

Functional ground (directly connected to the valve housing) |

| 1) | Core marking of the connection lines for mating connector with cable set (see "Accessories", material numbers R901268000, R901272854, R901272852) |

| 2) | Core marking of the connection lines for mating connector with cable set (see "Accessories", material numbers R900884671, R900032356, R900860399) |

| 3) | Selection via commissioning software |

| 4) | For diagnostic purposes, precise actual value response via Ethernet interface |

| 5) | A load increases the current consumption on pin 1 |

Connector pin assignment: M12 x 1, 4-pole, coding D (for Ethernet interface “X7E1” and “X7E2”)

|

Pin |

Assignment |

|

1 |

TxD + |

|

2 |

RxD + |

|

3 |

TxD - |

|

4 |

RxD - |

|

5 |

not assigned |

Analog configurable sensor interfaces, connections "X2M1", "X2M2" (coding A), M12, 5-pole, socket

|

Pin |

Assignment |

|

1 |

+24 V Spannungsausgang (Sensorversorgung) 1, 2) |

|

2 |

Sensorsignal-Eingang Strom (4 ... 20 mA) 3) |

|

3 |

GND |

|

4 |

Sensorsignal-Eingang Spannung (0 ... 10 V) 3) |

|

5 |

negativer Differenzverstärkereingang zu Pin 4 (optional) |

| 1) | Voltage output same as voltage supply connected to input XH2. |

| 2) | A load increases the current consumption of the valve (pin 1 on the connector XH2) |

| 3) | Only one signal input per interface, configurable |

Digital sensor interface SSI, EnDat 2.2 or 1 Vpp measurement system "X8M", M12, 8-pole, socket

|

Pin |

SSI assignment 1) |

EnDat 2.2 assignment 1; 2) |

Assignment 1 Vpp |

|

1 |

GND |

GND |

GND |

|

2 |

+24 V 3) |

+5 V 3) |

+5 V 3) |

|

3 |

Data + |

Data + |

A + |

|

4 |

Data - |

Data - |

A - |

|

5 |

GND |

GND |

B + |

|

6 |

Clock - |

Clock - |

B - |

|

7 |

Clock + |

Clock + |

R + |

|

8 |

+24 V 3) |

+5 V 3) |

R - |

| 1) | Pins 2, 8 and 1, 5 have the same assignment each |

| 2) | Supported resolution ≥ 10 nm |

| 3) | A load increases the current consumption of the valve (pin 1 on the connector XH2) |

Notice:

Reference potential for all signals: GND We recommend connecting the shields on both sides via the mechanical housings of the plug-in connectors.Using connector pins will affect the effectiveness of the shielding effect! Internal screens are not required.

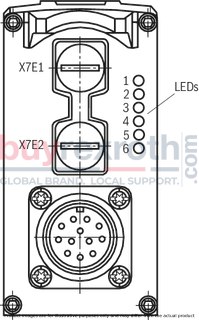

LED display

|

LED |

Interface |

Sercos |

EtherNet/IP |

EtherCAT |

PROFINET |

POWERLINK |

VARAN |

|

1 |

X7E1 |

Activity |

Activity |

not used |

Activity |

not used |

Activity |

|

2 |

Link |

Link |

Link/Activity |

Link |

Link/Data Activity |

Link |

|

|

3 |

Electronic module |

S |

Network Status |

Network Status |

Network Status |

Status/Error |

Network Status |

|

4 |

Module Status |

Module Status |

Module Status |

Module Status |

Module Status |

Module Status |

|

|

5 |

X7E2 |

Activity |

Activity |

not used |

Activity |

not used |

not used |

|

6 |

Link |

Link |

Link/Activity |

Link |

Link/Data Activity |

not used |

Displays of the Status LEDs

|

Module status LED |

Display status |

Network status LED |

Display status |

|

Off |

No voltage supply |

Off |

No voltage supply |

|

Green-red, flashing |

Initialization |

Green |

Operation |

|

Green, flashing |

Drive ready for operation |

||

|

Green |

Drive active |

||

|

Orange, flashing |

Warning |

||

|

Red, flashing |

Error |

||

Notice:

LEDs 1, 2, 5 and 6 relate to interfaces "X7E1" and "X7E2" Link: Cable plugged in, connection established (permanently lit) Activity: Data sent/received (flashing) Module status LEDs 3 and 4 relate to the electronics module For a detailed description of the diagnosis LEDs, please refer to the functional description Rexroth HydraulicDrive HDxSize 6

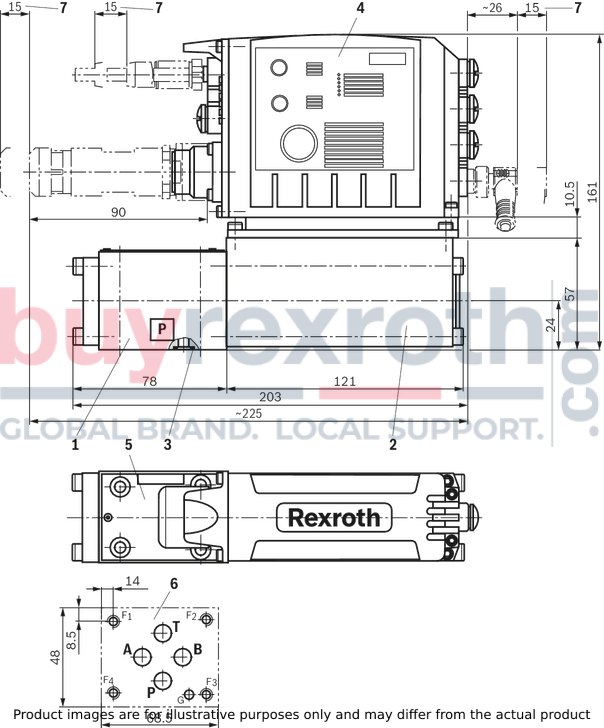

Dimensions in mm

|

|

Required surface quality of the valve contact surface |

|

1 |

Valve housing |

|

2 |

Control solenoid with position transducer |

|

3 |

Identical seal rings for ports A, B, P, and T |

|

4 |

Integrated digital control electronics |

|

5 |

Name plate |

|

6 |

Machined valve contact surface; Porting pattern according to ISO 4401-03-02-0-05 |

|

7 |

Space required to remove the mating connector |

Valve mounting screws (separate order)

|

Size |

Quantity |

Hexagon socket head cap screws |

Material number |

|

6 |

4 |

ISO 4762 - M5 x 30 - 10.9-N67F 821 70 (galvanized according to Bosch standard N67F 821 70) Tightening torque MA = 6+2 Nm |

2910151166 |

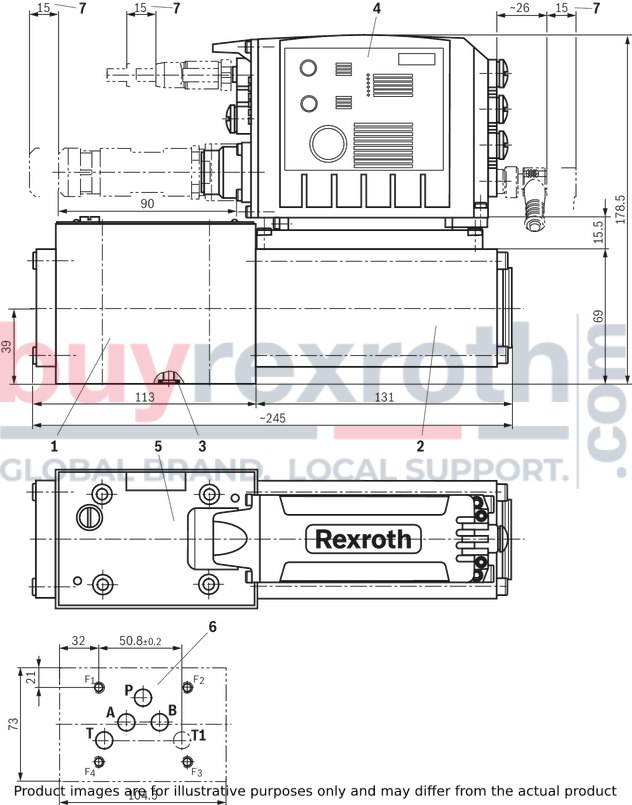

Size 10

Dimensions in mm

|

|

Required surface quality of the valve contact surface |

|

1 |

Valve housing |

|

2 |

Control solenoid with position transducer |

|

3 |

Identical seal rings for ports A, B, P and T (T1) |

|

4 |

Integrated digital control electronics |

|

5 |

Name plate |

|

6 |

Machined valve contact surface; Porting pattern according to ISO 4401-05-04-0-05 |

|

7 |

Space required to remove the mating connector |

Valve mounting screws (separate order)

|

Size |

Quantity |

Hexagon socket head cap screws |

Material number |

|

10 |

4 |

ISO 4762 - M6 x 40 - 10.9-N67F 821 70 (galvanized according to Bosch standard N67F 821 70) Tightening torque MA = 11+3 Nm |

2910151209 |

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

Project planning and maintenance instructions

The supply voltage must be permanently connected, as otherwise bus communication is not possible. If electro-magnetic interference is to be anticipated, suitable measures must be taken to ensure the function (depending on the application, e.g. shielding, filtration). The devices have been tested in the plant and are supplied with default settings. Only complete devices can be repaired. Repaired devices are returned with default settings. User-specific settings will not be applied. The machine end-user will have to retransfer the corresponding user parameters.Protective cap

|

Denomination |

Part number |

|

|

Protective cap |

|

R901075563 |

Mating connectors for valves with round connector, 11-pole + PE

12P N11

Mating connectors for valves with round connector, 11-pole + PE

12P N11

For valves with round connector according to EN 175201-804, 11-pole + PEData sheet

Spare parts & repair

Related Products

R900248412

$7,117.00 USD

R900954100

$2,606.00 USD

R900249373

$6,667.00 USD

R900934376

$1,989.00 USD

R901014935

$5,962.00 USD