***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

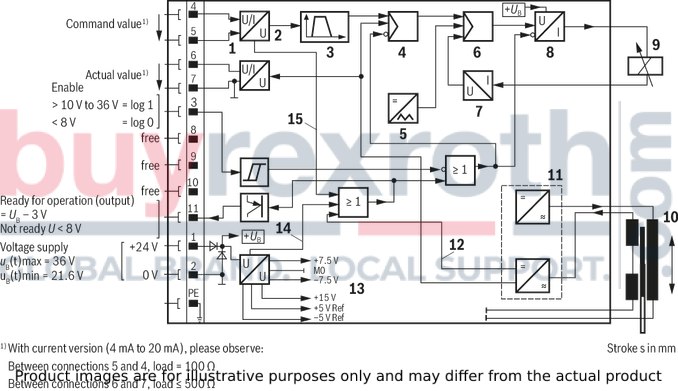

The Bosch Rexroth FESE63CA-3X/1800LK0G1V (R901276354) is a sophisticated pilot-operated way proportional throttle valve designed for block installation, offering precise flow control in hydraulic systems. This valve is engineered to regulate flow continuously by controlling the position of its orifice spool through command value-dependent feedback. The FESE63CA-3X/1800LK0G1V features integrated electronics with a position transducer that ensures accurate spool positioning by comparing actual and command values, making real-time adjustments via the proportional solenoid.

The valve's construction includes a cover with pilot oil connections, a main valve with an orifice spool, a pilot control valve with a proportional solenoid, and integrated electronics. Its area ratio allows for efficient flow control in various sizes (NG6 to NG25), and it offers the flexibility of external pilot oil supply via port X. In case of an enable signal disconnect, the orifice spool moves to block the flow direction from A to B without leakage.

This model is capable of operating in both flow directions A to B and B to A, ensuring versatility in application. It can be paired with a pressure compensator for load-compensated flow control, enhancing its capability in closed-loop systems. The unit comes fully adjusted with onboard electronics (OBE), and it offers options for voltage or current interface connections.

In terms of safety features, Bosch Rexroth has incorporated fail-safe measures that de-energize the solenoid during supply voltage failure or cable breakage in the position transducer, causing the spool to block the flow automatically. However, users should note that sudden stoppage due to voltage failure may result in machine damage due to acceleration forces.

Designed according to DIN ISO standards for installation dimensions, this model boasts maximum operating pressures up to 350 bar and is available in various sizes denoted by its component series X designation.

$28,128.00 USD

More are expected on June 23, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $27,424.80 USD | $703.20 USD |

| 25+ | $26,721.60 USD | $1,406.40 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as June 23, 2026 when ordered in