***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

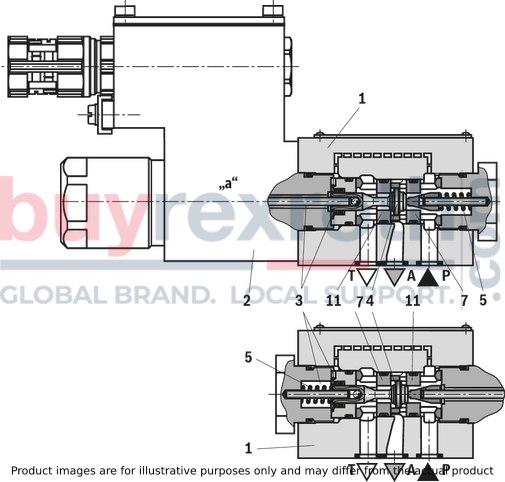

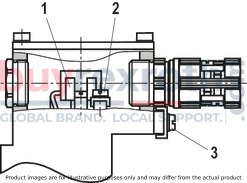

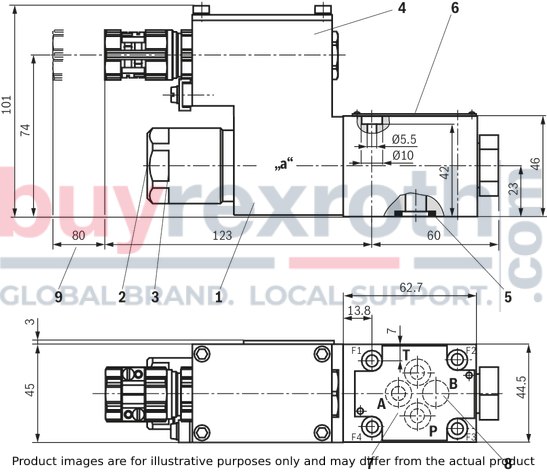

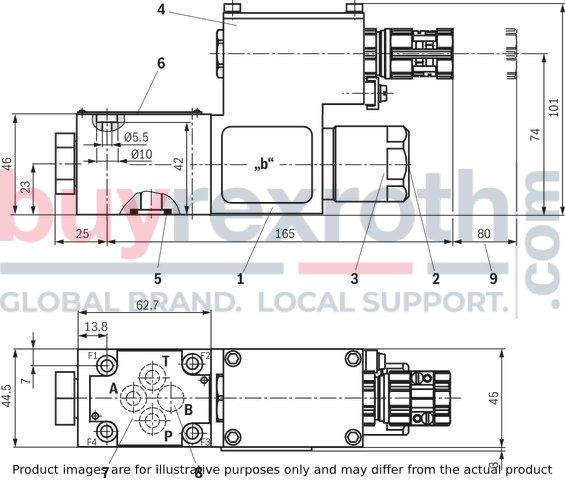

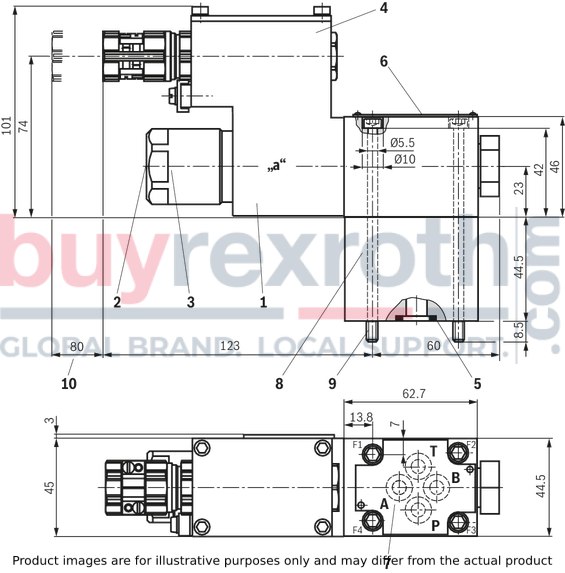

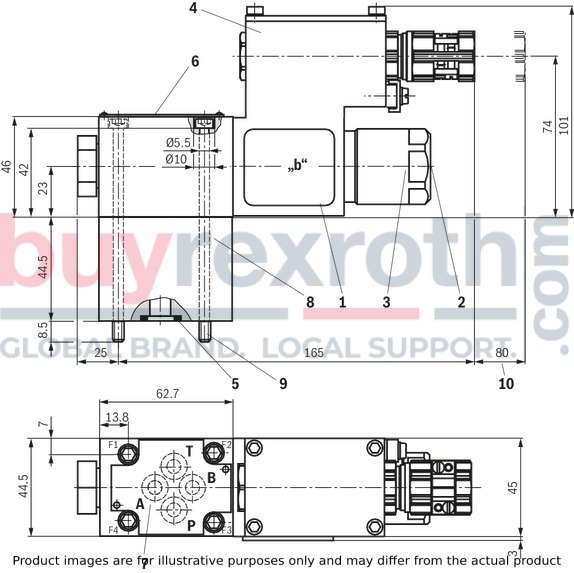

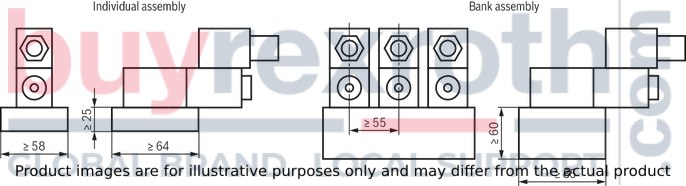

The Bosch Rexroth M-3SED6CK1X/350CW110RN9XEZ2/V (R901270798) is a high-performance directional seat valve that is direct operated with solenoid actuation. This valve is designed to control the start, stop, and direction of fluid flow within hydraulic systems. It consists of a durable housing, a robust solenoid, precision valve seats, and a control spool to ensure reliable operation under various conditions. The valve features a manual override for switching operations in the absence of solenoid power.

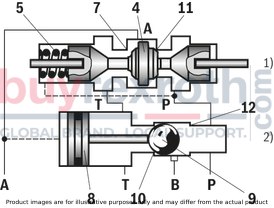

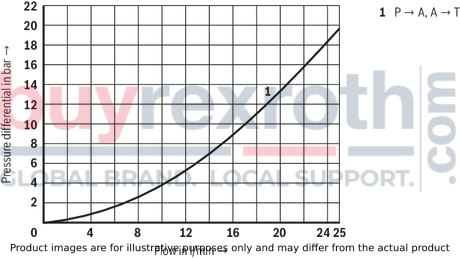

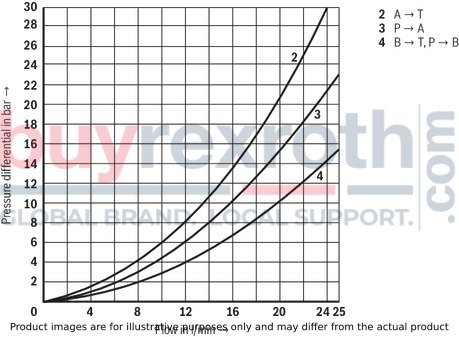

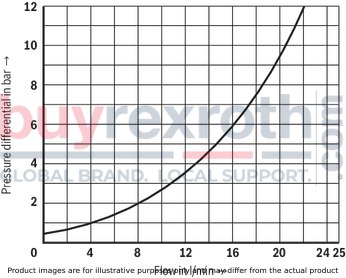

The M-3SED6CK1X/350CW110RN9XEZ2/V operates on the basic principle where its initial position—either normally open (UK) or normally closed (CK)—is determined by the spring arrangement. The pressure compensation feature allows for consistent performance despite varying actuating forces from the solenoid and spring. The control spool manages the flow through ports P, A, and T which can withstand maximum operating pressures.

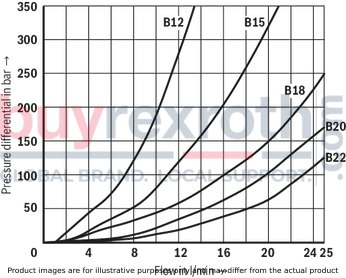

This model also includes an option for using a throttle insert when necessary to manage flow rates during switching processes that may exceed the valve's performance limits. Additionally, with the integration of a sandwich plate known as the Plus plate beneath the valve, further functional configurations can be achieved.

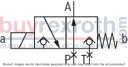

The M-3SED6CK1X/350CW110RN9XEZ2/V offers flexibility in application with symbols UK and CK for different seat arrangements and potential options D and Y when used with the Plus plate. It provides schematic illustrations for better understanding of initial positions and transitions during operation.

For applications requiring precise flow control in potentially explosive atmospheres, this directional seat valve adheres to ISO porting patterns (excluding locating hole) and features wet-pin DC or AC solenoids for electrical actuation. It allows individual connection customization with cable gland options and includes an optional concealed manual override.

In summary, this Bosch Rexroth directional seat valve stands out for its direct operability, robust design, pressure compensation feature, manual override option, flexible configurations with additional inserts like throttle or check valves, suitability for explosive environments, and customizable electrical connections—all encapsulated within part number R901270798.

$2,544.00 USD

More are expected on June 19, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.Status: This product is temporarily out of stock.

Qty: Delivered as early as June 19, 2026 when ordered in