1. General information

This project planning information refers to the specific properties of the Rexroth PGZ.-1X gerotor pump. Comprehensive general information and suggestions are contained in the Hydraulics Trainer, volume 3 "Project planning information and design of hydraulic systems", RE 00281.

1.1 Intended use

Rexroth gerotor pumps are intended for use in cooling, filter and lubricating circuits in machine and plant construction. During project planning, the basic principles of the EU Machinery Directive or comparable national regulations outside the EU must be observed. They must not be used in potentially explosive environments in accordance with directive 94/9/EC (ATEX). Use as hydraulic motor is not admissible!

1.2 Technical data

The plant or machine manufacturer must ensure compliance with the admissible technical data and operating conditions. The pump itself does not contain a device to prevent operation outside the admissible data.

All specified technical performance features are average values and apply with the specified boundary conditions. In case of modifications to the basic conditions (e.g. viscosity), the technical data may change as well. Distribution corresponding to the relevant state-of-the-art is possible.

Operating the pump outside of the admissible Technical data is possible to a certain extent, however, this requires the explicit written approval by Bosch Rexroth.

2. Hydraulic project planning

2.1 Place of installation

When installing the pump more than 10 m below the tank, the reduction of the inlet pressure to the maximum admissible value must be ensured by means of additional measures.

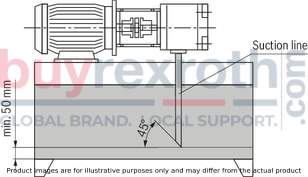

2.2 Suction line

The line cross-sections must be rated for the designed flows in a manner that an ideal suction speed of 0.6 to 1.2 m/s is achieved on average. The suction speed must not exceed a maximum value of 2 m/s.

The suction cross-sections at the pump itself are designed for the maximum flow and can therefore only be used as reference. In case of continuous operation with speeds lower than the admissible maximum speed, the suction tube diameter is to be dimensioned smaller than the suction port of the pump in accordance with the actual suction speed.

All in all, the suction line is to be designed so that the admissible input operating pressure is complied with (0.7 to 2 bar abs.)! Bends and the combination of the suction pipes of several pumps are to be avoided.

If suction filters must be used, make sure that the lowest admissible inlet operating pressure is not exceeded on the system side, even if the filter is contaminated.

Please ensure air tightness of the transitions and dimensional stability of the suction tube to the external air pressure.

The immersion depth of the suction pipe should be as large as possible. Dependent on the internal tank pressure, the viscosity of the hydraulic fluid and the flow ratios within the tank, no vortex must be formed even during maximum flow. Otherwise, there is the risk that air is sucked in.

We recommend selecting suction pipes according to AB 23-03.

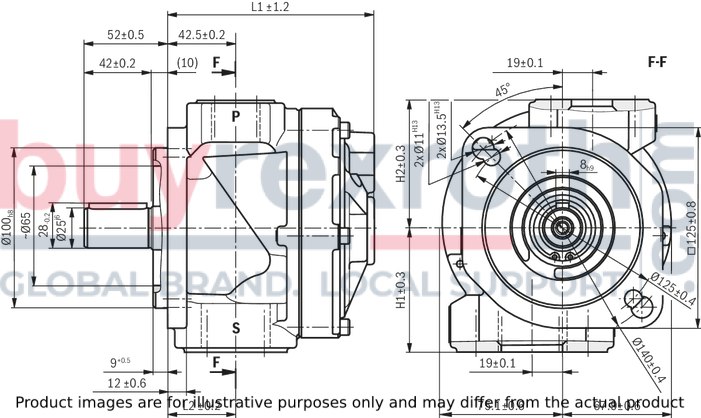

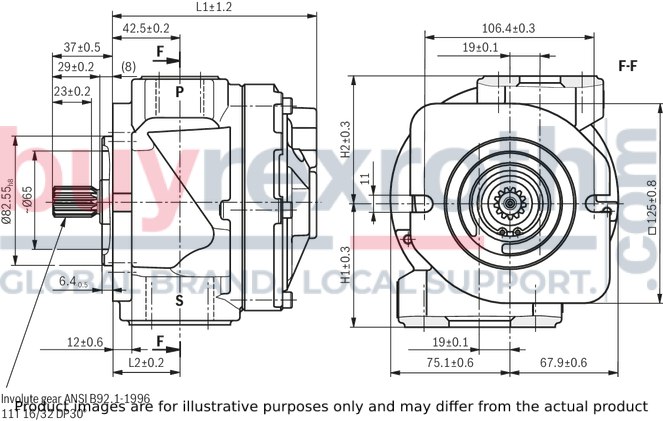

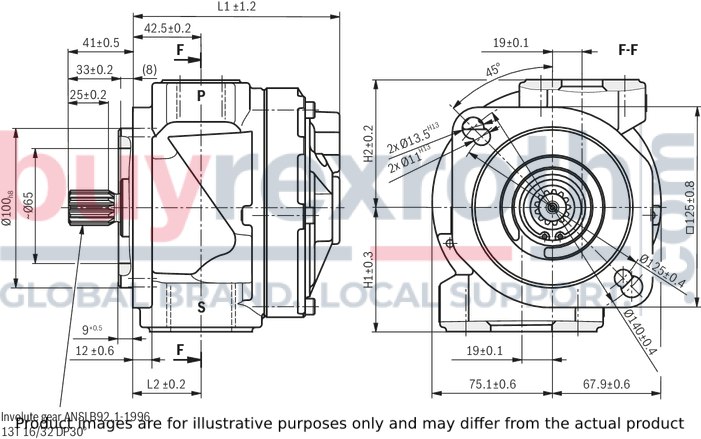

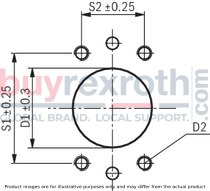

Dimensions in mm

2.3 Pressure limitation

The PGZ gerotor pump does not comprise any device for compliance with the maximum operating pressure. Setting and limiting the admissible operating pressure has to be ensured on the system side.

3. Mechanical project planning

3.1 Disassembly and installation option

For disassembling and mounting the pump on the drive, accessibility has to be ensured on the system side. Screws of property class 8.8 or 10.9 have to be provided for mounting purposes.

3.2 Mounting

The screws must be accessible on the machine side so that the required tightening torque can be applied. The tightening torque of the screws is based on the operating conditions and involved elements of the

screw connection and has to be specified by the manufacturer in the power unit, machine or system project planning.

3.3 Required power unit functions

Hydraulic power units should at least be equipped with the following features:

Tanks, the internal pressure of which corresponds to the ambient pressure in accordance with the design, have to be equipped with breathing filters for pressure compensation purposes. The hydraulic fluid should only be filled in using filling connections excluding filling with unfiltered hydraulic fluid. The ingress of contamination or humidity must be avoided. In case of use in highly contaminated environments, the tank must to this end be pre-tensioned by means of air pressure. If cleansing of the external tank side is intended or to be expected during the period of use, tank fittings for pipes, lines, or hoses have to be selected, which ensure safe sealing against external pressurization with water jet.

3.4. Environmental conditions

When operating the pump in salt-containing or corrosive environments or when pressure loading with strongly abrasive substances is possible, it has to be ensured on the system side that the shaft seal ring and the sealing area of the shaft do not make direct contact with the environment and that the pump is provided with suitable corrosion protection.

3.5 Installation positions

B3

B5

V1

IM V2

4. Maintenance schedule and operational safety

For safe operation and a long life cycle of the pump, a maintenance schedule has to be developed for the power unit, the machine, or the system. The maintenance schedule must ensure that the intended or admissible operating conditions of the pump are complied with over the entire period of use.

In particular, compliance with the following operating parameters has to be ensured:

the required oil cleanliness the operating temperature range the hydraulic fluid filling level

Furthermore, the pump and the system have to be checked for modifications of the following parameters on a regular basis:

Vibrations Noise Temperature pump – hydraulic fluid in the tank Foam formation in the tank Leak-tightness Operating pressure for use in lubrication systems

Modifications of these parameters indicate wear of components (e.g. drive motor, coupling, pump, etc.). The cause must be identified and remedied immediately. In order to achieve high operational safety of the pump in the machine or system, we recommend checking the parameters mentioned above continuously and automatically

and shutting the system off automatically in case of modifications exceeding the usual fluctuations in the intended operating range.

Plastic components of drive couplings should be replaced regularly, however, after 5 years at the latest. The relevant manufacturer's specifications must be considered and be given priority.

For preventive maintenance of the pump, we recommend having the seals replaced after a maximum operating time of 5 years by an authorized Bosch Rexroth service company.

5. Accessories

5.1 SAE connection flanges

We recommend selecting the SAE flanges for suction and pressure port according to AB 22-15 (with welded connection) or AB 22-13 (with threaded connection).

5.2 Other accessories

To install the Rexroth PGZ.-1X gerotor pump on electric motors, we recommend selecting the pump carriers according to AB 41-20 and torsionally flexible couplings according to AB 33-22.

Notice!

Please also observe the following documentation:

Data sheet RE 07008 General information on hydraulic products Data sheet RE 07900 General information on assembly, commissioning

and maintenance of hydraulic systems

Data sheet RE 90220 General information on hydraulic fluids on mineral oil basis