***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

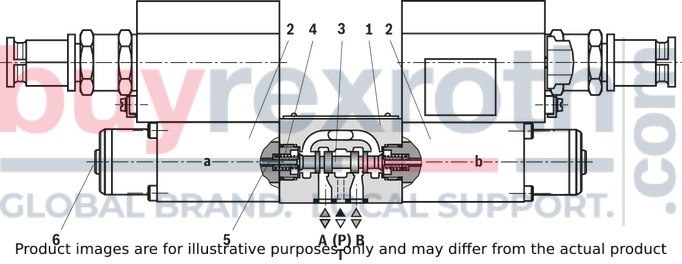

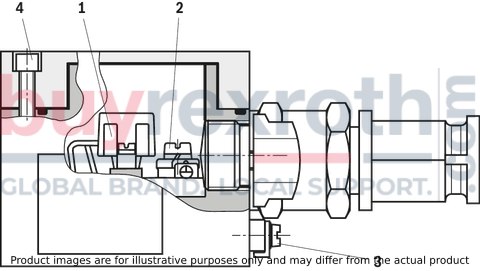

The Bosch Rexroth 3WE6B9-6X/BG24NXDZ2/V (R901166817) is a direct operated directional spool valve designed for precise control of fluid flow in hydraulic systems. This model is equipped with two solenoids that, when energized, actuate the control spool to manage the start, stop, and direction of fluid flow. The solenoids operate in wet-pin conditions within the hydraulic fluid, ensuring smooth operation and reliable performance. The valve's construction includes a housing, control spool, one or two return springs, and the option for manual override.

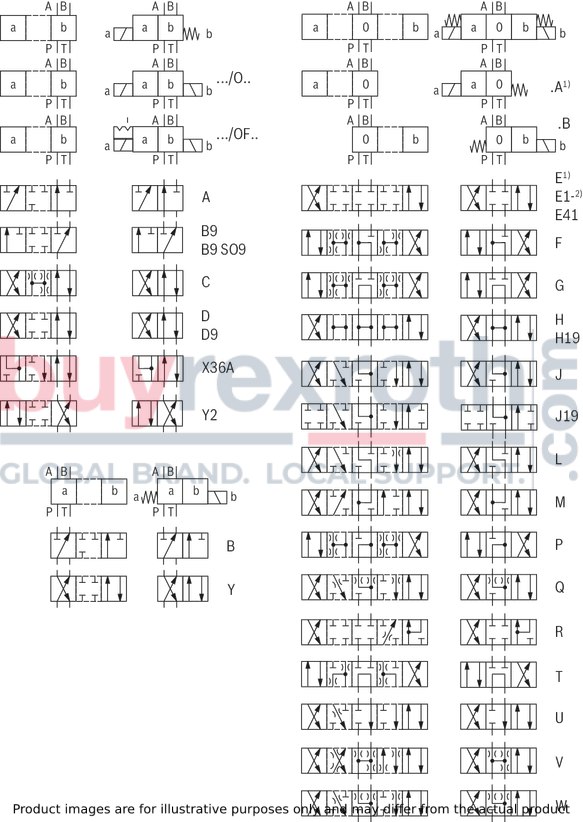

The 3WE6B9-6X/BG24NXDZ2/V valve is characterized by its ability to alternate between two spool positions without detent in its deenergized state. This means that there is no defined spool position when the solenoids are not powered. It also features an impulse spool version with detent for locking the spool positions, reducing the need for continuous solenoid energization.

For proper functionality and safety, it's important to maintain a filled pressure chamber with hydraulic fluid and consider separate return lines or check valves to prevent unwanted movements due to pressure peaks. Additionally, if operating conditions may exceed performance limits during switching processes, a throttle insert can be used in channel P of the valve.

This particular model adheres to ISO standards for porting patterns and is suitable for use in potentially explosive atmospheres as designated by EU directives IM and IIG. It offers maximum operating pressures up to bar and can handle maximum flow rates of l/min. The solenoids' type of protection includes Ex db I Mb / Ex db II C T Gb according to EN standards. This makes it an ideal solution for applications requiring robust performance with stringent safety requirements in hazardous environments.

$8,635.00 USD

More are expected on June 8, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $8,419.12 USD | $215.88 USD |

| 25+ | $8,203.25 USD | $431.75 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as June 8, 2026 when ordered in