***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

The Bosch Rexroth DBAW30BH1N1X/315S6EG24N9K4R12E (R901143290) is a sophisticated pump safety block designed for direct mounting onto the SAE pressure port of pumps. As a pilot-operated pressure relief valve, it is crucial for limiting the operating pressure to ensure system safety and efficiency. The DBAW30BH1N1X/315S6EG24N9K4R12E consists of a valve block, a main spool insert, and a pilot control valve that allows for precise pressure adjustments. This model features various adjustment types, including rotary knobs and sleeves with protective caps, providing flexibility and security in setting the desired pressure levels.

The unit's capability to switch from pressure limiting to depressurized circulation by controlling the built-in directional valve enables zero-pressure startup of the pump, which can be particularly beneficial in preventing hydraulic shock during system initiation. Moreover, it comes with an integrated shock damping sandwich plate that mitigates pressure peaks and reduces acoustic decompression shocks in the return line, enhancing system longevity and performance.

This model also offers quick pressure buildup with multiple adjustment types for user convenience. Optional features include solenoid-actuated unloading via the built-in directional valve, an integrated check valve for preventing reverse flow, and switching shock damping to further cushion the hydraulic system against sudden changes in pressure.

The DBAW30BH1N1X/315S6EG24N9K4R12E is designed to handle maximum operating pressures up to 315 bar and can accommodate maximum flow rates as specified by user requirements. Its robust construction ensures reliability in various hydraulic applications where precise control of operating pressures is essential.

$4,049.00 USD

More are expected on September 30, 2026

| Qty | Price | Savings |

|---|---|---|

| 5-24 | $3,947.77 USD | $101.23 USD |

| 25+ | $3,846.55 USD | $202.45 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as September 30, 2026 when ordered in

This product is eligible for factory repair.

Zero-pressure start-up and circulation of the pump For direct mounting to the SAE pressure port of the pump Quick pressure build-up 4 adjustment types for pressure adjustment, optionally

• Rotary knob

• Sleeve with hexagon and protective cap

• Lockable rotary knob with scale

• Rotary knob with scale 5 pressure ratings, optional Solenoid-actuated unloading via a built-on directional valve Integrated check valve, optional Switching shock damping, optional

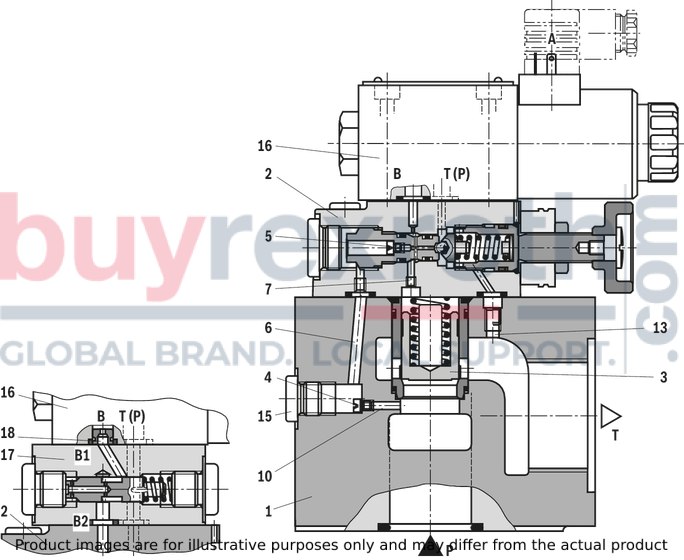

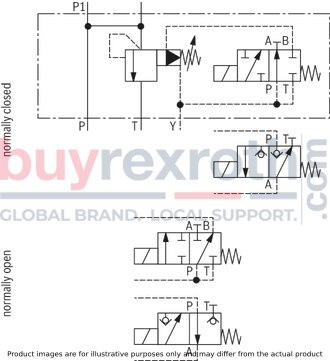

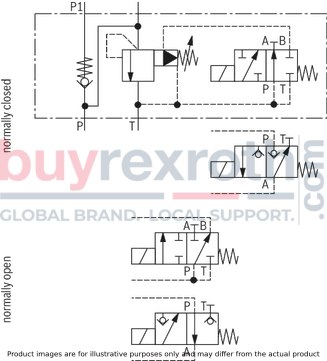

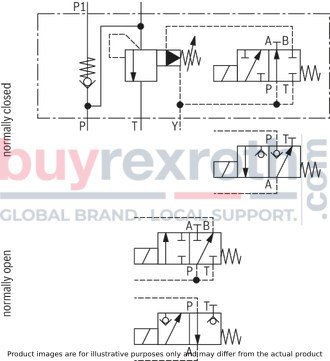

Pump safety blocks of type DBAW are pilot-operated pressure relief valves which are integrated into a block and intended to be mounted directly onto the SAE pressure port of pumps.

They are used for limiting the operating pressure. The pump safety blocks (DBAW) basically consist of a valve block (1), main spool insert (3) and pilot control valve (2) with adjustment type for pressure adjustment. The valve housing has a port P for the hydraulic fluid input and port P1 for the output. In a branch of the through-bore between these two ports there is the main spool insert. When this is open there is a connection to port T (tank line).

Pump safety block type DBAW...

In addition, it can be switched from the pressure limiting function to depressurized circulation by controlling the built-on directional valve (16). Thus, a depressurized start-up of the pump is possible.

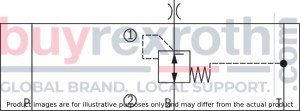

Representation: directional valve open

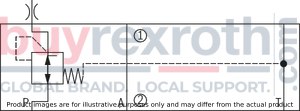

Pump safety block with switching shock damping (sandwich plate), type DBAW…S6E...R12 and type DBAW…S6SM...B12

The opening of the connection from B2 to B1 or P2 to P1 is delayed by means of the switching shock damping valve (17). Pressure peaks and acoustic decompression shocks in the return line can thus be avoided. It is installed between the pilot control valve (2) and the directional valve (16).

The degree of damping (decompression shock) is determined by the size of the nozzle (18). By default, a nozzle Ø1.2 mm is installed (ordering code ..R12.. or ..B12..).

Type DBAW…S6E...R12

Type DBAW…S6SM...B12

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

21 |

|

|

DBA |

W |

1X |

/ |

* |

|

01 |

Pump safety block |

DBA |

|

02 |

With attached directional valve |

W |

|

03 |

Without check valve |

no code |

|

With check valve |

R 1) |

|

|

04 |

Size 32 |

30 |

|

Size 40 |

40 |

|

|

05 |

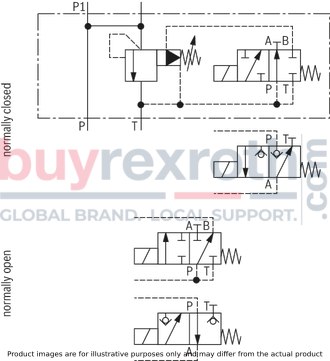

Normally closed |

A 2) |

|

Normally open |

B 2) |

|

|

Connection / SAE flange 3) |

||

|

06 |

Standard flange (200 … 350 bar) |

F |

|

High-pressure flange (350 bar) |

H |

|

|

Adjustment type for pressure adjustment |

||

|

07 |

Rotary knob |

1 |

|

Sleeve with hexagon and protective cap |

2 |

|

|

Lockable rotary knob with scale |

3 4) |

|

|

Rotary knob with scale |

7 |

|

|

08 |

With main spool Ø24 mm |

– |

|

With main spool Ø28 mm |

N |

|

|

09 |

Component series 10 ... 19 (10 ... 19: unchanged installation and connection dimensions) |

1X |

|

Pressure rating |

||

|

10 |

Set pressure … 50 bar |

50 |

|

Set pressure … 100 bar |

100 |

|

|

Set pressure … 200 bar |

200 |

|

|

Set pressure … 250 bar |

250 |

|

|

Set pressure … 315 bar |

315 |

|

|

Set pressure … 350 bar (only version “H”) |

350 |

|

|

Pilot flow |

||

|

11 |

Pilot oil supply and pilot oil return internal (standard) |

– 5) |

|

Internal pilot oil supply, external pilot oil return |

Y |

|

|

12 |

Standard version |

no code |

|

Valve for minimum cracking pressure (not suitable for mutual relief!) |

U |

|

|

13 |

Without switching shock damping |

no code |

|

With switching shock damping |

S |

|

|

14 |

With directional spool valve (data sheet 23178) |

6E 2) |

|

With directional seat valve (data sheet 22058) |

6SM 2) |

|

|

15 |

Direct voltage 24 V |

G24 2) |

|

Direct voltage 205 V |

G205 2) |

|

|

Alternating voltage 230 V 50/60 Hz (version "6E" only) |

W230 2) |

|

|

16 |

Without manual override |

no code |

|

With manual override (version "6E“ only) |

N 2) |

|

|

With concealed manual override (standard) |

N9 2) |

|

|

Electrical connection |

||

|

17 |

Without mating connector, with connector DIN EN 175301-803 |

K4 2;6) |

|

18 |

Nozzle Ø1.2 mm in channel B of the directional spool valve |

R12 7) |

|

Nozzle Ø1.2 mm in channel P of the directional seat valve |

B12 7) |

|

|

Seal material |

||

|

19 |

NBR seals |

no code |

|

FKM seals |

V |

|

|

(other seals upon request) Attention! Observe compatibility of seals with hydraulic fluid used! |

||

|

Type-examination procedure |

||

|

20 |

Without type-examination procedure |

no code |

|

Type-examination tested safety valve according to PED 2014/68/EU |

E |

|

|

21 |

Further details in the plain text |

* |

| 1) Only … 315 bar | |

| 2) Ordering code only required if 02 = “W” | |

| 3) Please observe pressure ratings and connection dimensions! (see dimensions) | |

| 4) H-key with the material no. R900008158 is included in the scope of delivery. | |

| 5) Hyphen “–” only required if 02 = “W” and 12 and 13 = “no code” | |

| 6) Mating connectors, separate order. | |

| 7) Ordering code only required if 02 = “W” and 13 = “S” |

Preferred types and standard units are contained in the EPS (standard price list).

|

Hydraulic fluid |

Classification |

Suitable sealing materials |

Standards |

|

|

Mineral oils and related hydrocarbons |

HL, HLP, HLPD

|

NBR, FKM |

DIN 51524 |

|

|

Bio-degradable |

Insoluble in water |

HETG |

NBR, FKM |

VDMA 24568

|

|

HEES |

FKM |

|||

|

Soluble in water |

HEPG |

FKM |

VDMA 24568

|

|

|

Containing water |

Water-free |

HFDU, HFDR |

FKM |

ISO 12922

|

|

Containing water |

HFC (Fuchs Hydrotherm 46M, Petrofer Ultra Safe 620) |

NBR

|

ISO 12922 |

|

|

Important information on hydraulic fluids! For further information and data on the use of other hydraulic fluids, please refer to data sheet 90220 or contact us! There may be limitations regarding the technical valve data (temperature, pressure range, life cycle, maintenance intervals, etc.)!Flame-resistant – containing water: Maximum operating pressure 210 bar Maximum hydraulic fluid temperature 60 °C Expected life cycle as compared to HLP hydraulic oil 30 % to 100 % |

||||

Technical data for directional seat valves see data sheet 22058, directional spool valves data sheet 23178.

Also see Deviating technical data for type-examination tested safety valves.

hydraulic

|

Size |

32 | 40 | |||

|

Maximum operating pressure |

Port P |

bar |

350 | ||

|

Port T |

bar |

315 | |||

|

Cracking pressure |

(with DBAR...) |

0.5 bar | |||

|

Maximum counter pressure |

Port Y |

DC solenoid |

bar |

210 | |

|

AC solenoid |

bar |

160 | |||

|

Port T |

DC solenoid |

bar |

210 | ||

|

AC solenoid |

bar |

160 | |||

|

Maximum set pressure |

bar |

50 100 200 315 350 |

|||

|

Minimum set pressure |

flow-dependent, see characteristic curves | ||||

|

Maximum flow |

DBAW, DBAWR |

l/min |

600 350 |

650 450 |

|

|

Hydraulic fluid |

see table | ||||

|

Hydraulic fluid temperature range |

NBR seals |

°C |

-30 … +80 | ||

|

FKM seals |

°C |

-15 … +80 | |||

|

Viscosity range |

mm²/s |

10 … 800 | |||

|

Maximum admissible degree of contamination of the hydraulic fluid 1) |

Class 20/18/15 according to ISO 4406 (c) | ||||

| 1) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

Deviating technical data: Type-examination tested safety valves type DBA…E, component series 1X according to Pressure Equipment Directive 97/23/EG 1)

hydraulic

|

Maximum counter pressure |

Port Y |

bar |

0 |

|

Port T |

bar |

10 | |

|

Maximum flow |

See ordering code, safety instructions and characteristic curves "Type-examination tested safety valve" | ||

|

Hydraulic fluid |

Mineral oil (HL, HLP) to DIN 51524 | ||

|

Hydraulic fluid temperature range |

NBR seals |

°C |

-20 … +60 |

|

FKM seals |

°C |

-15 … +60 | |

|

Viscosity range |

mm²/s |

12 … 230 | |

general

|

Size |

32 | 40 | ||

|

Weight |

kg |

9.2 | 12.6 | |

|

Check valve "R" |

kg |

0.3 | 0.4 | |

|

Switching shock damping "S" |

kg |

0.6 | ||

|

Installation position |

any | |||

|

Ambient temperature range |

NBR seals |

°C |

-30 … +50 | |

|

FKM seals |

°C |

-15 … +50 | ||

|

Minimum stability of the housing materials |

Housing materials are to be selected so that there is sufficient safety for all imaginable operating conditions (e.g. with regard to pressure resistance, thread stripping strengths and tightening torques). | |||

For applications outside these parameters, please consult us!

(measured with HLP46, ϑOil = 40 ±5 °C)

Standard version

Minimum set pressure and circulation pressure dependent on the flow

Notice!

The characteristic curves were measured with external, depressurized pilot oil return. Due to the internal pilot oil return, the inlet pressure increases by the output pressure present in port T. The characteristic curves apply to the pressure at the valve output pT = 0 bar across the entire flow range.Version “U”

Minimum set pressure and circulation pressure dependent on the flow

Inlet pressure dependent on the flow

Maximum admissible flow qV max dependent on the counter pressure pT in the discharge line with internal pilot oil return

Type DBA 30 …-1X/…E

Characteristic curves for intermediate values can be generated by interpolation.

Further explanations see explanation of the diagrams.

Type DBA 40 …-1X/…E

|

pA |

Response pressure in bar |

|

pT |

maximum admissible counter pressure in bar) (sum of all possible counter pressures; also see AD2000 - data sheet A2) |

|

maximum admissible flow in l/min |

|

|

10 % x pA (with qV = 0) according to PED 97/23/EC |

|

Explanation of the diagram |

|

|

(Example: type DBA…E, above): |

|

|

known: |

Flow of the system/accumulator that has to be secured qVmax = 320 l/min |

|

Set response pressure of the safety valve pA = 350 bar |

|

|

unknown: |

pTadmissible |

|

Solution: |

see arrows in diagram above |

|

pT admissible (320 l/min; 350 bar) = 16.2 bar |

|

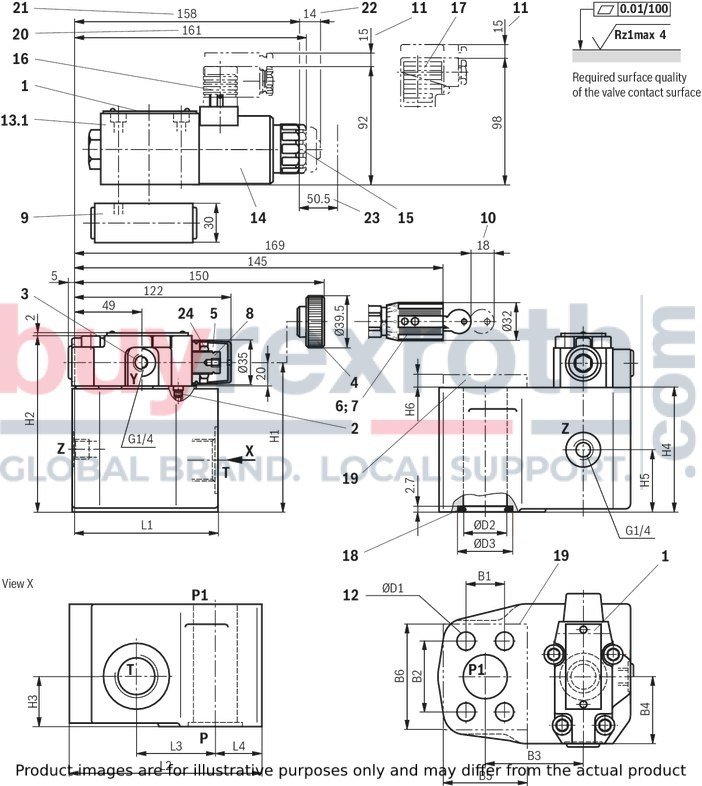

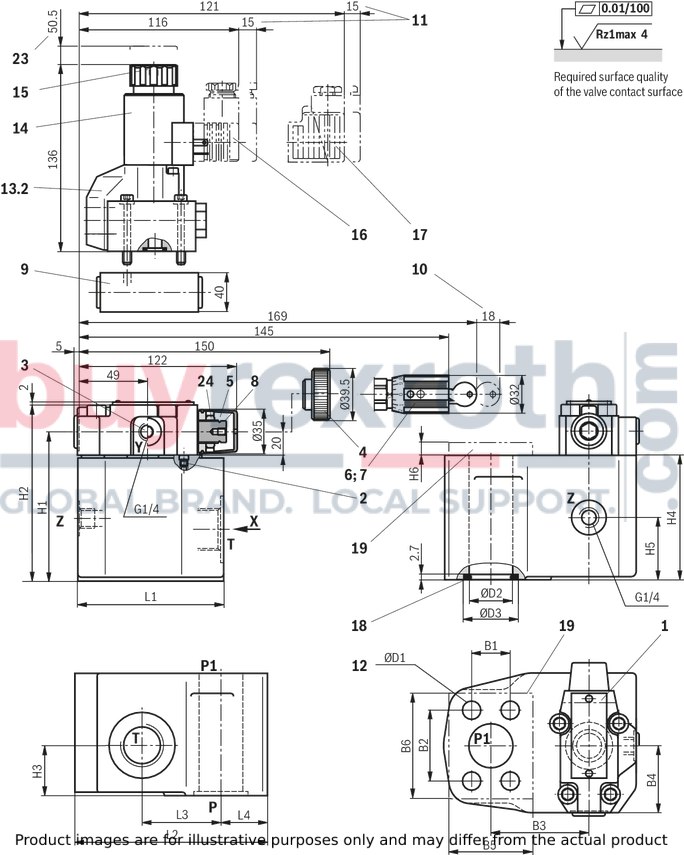

Type DBAW…–…

Type DBAW…Y…

Type DBAWR…–…

Type DBAWR…Y…

With directional spool valve

Dimensions in mm

|

1 |

Name plate |

|

2 |

Omitted with internal pilot oil return |

|

3 |

Y port for pilot oil return, external |

|

4 |

Adjustment type "1" |

|

5 |

Adjustment type "2" |

|

6 |

Adjustment type "3" |

|

7 |

Adjustment type "7" |

|

8 |

Hexagon SW10 |

|

9 |

Switching shock damping sandwich plate, optional |

|

10 |

Space required to remove the key |

|

11 |

Space required to remove the mating connector |

|

12 |

Valve mounting bores |

|

13.1 |

Directional spool valve NG6 (data sheet 23178) |

|

14 |

Solenoid “a” |

|

15 |

Optional auxiliary operating device |

|

16 |

Mating connector without circuitry (separate order) |

|

17 |

Mating connector with circuitry (separate order) |

|

18 |

Seal ring |

|

19 |

Integrated check valve, version "R" |

|

20 |

Dimension for valve without manual override |

|

21 |

Dimension for valve with concealed manual override "N9" |

|

22 |

Dimension for valve with manual override "N" |

|

23 |

Space required to remove the coil |

|

24 |

Lock nut SW17, tightening torque MA = 10+5 Nm |

With directional seat valve

Dimensions in mm

|

1 |

Name plate |

|

2 |

Omitted with internal pilot oil return |

|

3 |

Y port for pilot oil return, external |

|

4 |

Adjustment type "1" |

|

5 |

Adjustment type "2" |

|

6 |

Adjustment type "3" |

|

7 |

Adjustment type "7" |

|

8 |

Hexagon SW10 |

|

9 |

Switching shock damping sandwich plate, optional |

|

10 |

Space required to remove the key |

|

11 |

Space required to remove the mating connector |

|

12 |

Valve mounting bores |

|

13.2 |

Directional seat valve NG6 (data sheet 22058) |

|

14 |

Solenoid “a” |

|

15 |

Optional auxiliary operating device |

|

16 |

Mating connector without circuitry (separate order) |

|

17 |

Mating connector with circuitry (separate order) |

|

18 |

Seal ring |

|

19 |

Integrated check valve, version "R" |

|

23 |

Space required to remove the coil |

|

24 |

Lock nut SW17, tightening torque MA = 10+5 Nm |

|

NG |

Version |

Ports |

4 valve mounting screws ISO 4762 - 10.9 1) |

Tightening torqueMA in Nm 2) |

||

|

P and P1 |

T |

Part number |

||||

|

32 |

„DBA“ |

SAE 1 1/4“ |

G1 1/4 |

M10 x 120 |

R913000074 |

52 |

|

„DBAR“ |

M10 x 125 |

R913000668 |

||||

|

40 |

„DBA“ |

SAE 1 1/2“ |

G1 1/2 |

M12 x 135 |

R913024229 |

77 |

|

„DBAR“ |

M12 x 140 |

R913000312 |

||||

Admissible pressures (flange connections according to DIN ISO 6162-2)

|

Pressure |

|

|

bar |

|

| SAE 1 1/4″ | 250 |

| SAE 1 1/2″ | 200 |

|

NG |

Version |

Ports |

4 valve mounting screws ISO 4762 - 10.9 1) |

Tightening torqueMA in Nm 2) |

||

|

P and P1 |

T |

Part number |

||||

|

32 |

„DBA“ |

SAE 1 1/4“ |

G1 1/4 |

M14 x 135 |

R913024230 |

113 |

|

„DBAR“ |

M14 x 145 |

R913024233 |

||||

|

40 |

„DBA“ |

SAE 1 1/2“ |

G1 1/2 |

M16 x 155 |

R913024234 |

184 |

|

„DBAR“ |

M16 x 160 |

R913000354 |

||||

Admissible pressures (flange connections according to DIN ISO 6162-2)

|

Pressure |

|

|

bar |

|

| SAE 1 1/4″ | 350 |

| SAE 1 1/2″ | 350 |

Standardflansche, Ausführung „DBA(R)…F“

|

Version |

L1 |

L2 |

L3 |

L4 |

B1 |

B2 |

B3 |

B4 |

B5 |

B6 |

H1 |

H2 |

H3 |

H4 |

H5 |

H6 |

ØD1 |

ØD3 |

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

|

| DBA32...F | 121 | 138 | 55 | 38.5 | 30.2 | 58.7 | 65 | 48.3 | - | - | 105 | 125 | 43 | 85 | 43 | - | 11 | 45 |

| DBA40...F | 138 | 156 | 54.5 | 49.5 | 35.8 | 69.9 | 74.5 | 54.7 | - | - | 118 | 138 | 50 | 98 | 56 | - | 13 | 54 |

| DBAR32...F | 121 | 138 | 55 | 38.5 | 30.2 | 58.7 | 65 | 48.3 | 60 | 80 | 105 | 125 | 43 | 85 | 43 | 9 | 11 | 40 |

| DBAR40...F | 138 | 156 | 54.5 | 49.5 | 35.8 | 69.9 | 74.5 | 54.7 | 60 | 100 | 118 | 138 | 50 | 98 | 56 | 8 | 13 | 54 |

High-pressure flanges, version “DBA(R)…H“

|

Version |

L1 |

L2 |

L3 |

L4 |

B1 |

B2 |

B3 |

B4 |

B5 |

B6 |

H1 |

H2 |

H3 |

H4 |

H5 |

H6 |

ØD1 |

ØD3 |

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

|

| DBA32...H | 121 | 138 | 55 | 38.5 | 31.8 | 66.7 | 65 | 48.3 | - | - | 105 | 125 | 43 | 85 | 43 | - | 15 | 45 |

| DBA40...H | 138 | 156 | 54.5 | 49.5 | 36.6 | 79.4 | 74.5 | 54.7 | - | - | 118 | 138 | 50 | 98 | 56 | - | 17 | 54 |

| DBAR32...H | 121 | 138 | 55 | 38.5 | 31.8 | 66.7 | 65 | 48.3 | 60 | 90 | 105 | 125 | 43 | 85 | 43 | 8 | 15 | 40 |

| DBAR40...H | 138 | 156 | 54.5 | 49.5 | 36.6 | 79.4 | 74.5 | 54.7 | 65 | 110 | 118 | 138 | 50 | 98 | 56 | 8 | 17 | 54 |

Safety instructions: Type-examination tested safety valves type DBA…E, component series 1X according to Pressure Equipment Directive 97/23/EC

Before ordering a type-examination tested safety valve, it must be ensured that at the desired response pressure p, the maximum admissible flowqV max (= numerical value at the position of letter "G" in the component marking) of the safety valve is higher than the maximum possible flow of the system/accumulator to be secured. In this respect, the applicable regulations must be observed! According to PED 97/23/EC, the increase in the system pressure due to the flow must not exceed 10 % of the set response pressure (see component marking). The maximum admissible flow qV max stated in the component marking must not be exceeded. Discharge lines of safety valves must end in a risk-free manner. The accumulation of fluids in the discharge lines must not be possible (see AD2000 - data sheet A2). The unloading function (directional valve function with version "W") must not be used for safety functions! With version "B", the lowest adjustable pressure (circulation pressure) is set in case of power failure or cable break. With version "A", the pressure limiting function is set in case of power failure or cable break. Hydraulic counter pressures in port T with internal pilot oil return and/or port Y with external pilot oil return add 1:1 to the response pressure of the valve set at the pilot control.Example:

Pressure adjustment of the valve due to spring pretensioning in the pilot control valve/adjustment type

pspring =200 bar

Hydraulic counter pressure in port T with internal pilot oil return

phydraulic =50 bar

⇒ Response pressure= pspring+ phydraulic =250 bar

It is imperative to observe the application notes!

In the plant, the response pressure specified in the component marking is set at a flow of 2 l/min. The maximum admissible flow specified in the component marking applies to:External pilot oil return “Y” without counter pressure in the pilot oil return line, admissible counter pressure in the discharge line (port T) <15 bar

Internal pilot oil return "–“ without counter pressure in the discharge line (port T) With internal pilot oil return, the system pressure increases by the counter pressure in the discharge line (port T) due to the increasing flow (observe AD2000 - data sheet; A2, item 6.3).

To ensure that this increase in system pressure caused by the flow does not exceed the value of 10 % of the set response pressure, the admissible flow has to be reduced dependent on the counter pressure in the discharge line (port T) (see characteristic curves Safety instructions, Type-examination tested safety valves).

By removing a lead seal at the safety valve, the approval according to the PED becomes void Basically, the requirements of the Pressure Equipment Directive and of data sheet AD2000 A2 have to be observed! Before ordering a type-examination tested safety valve, it must be ensured that at the desired response pressure p, the maximum admissible flowqV max (= numerical value at the position of letter "G" in the component marking) of the safety valve is higher than the maximum possible flow of the system/accumulator to be secured. In this respect, the applicable regulations must be observed! According to PED 97/23/EC, the increase in the system pressure due to the flow must not exceed 10 % of the set response pressure (see component marking). The maximum admissible flow qV max stated in the component marking must not be exceeded. Discharge lines of safety valves must end in a risk-free manner. The accumulation of fluids in the discharge lines must not be possible (see AD2000 - data sheet A2). The unloading function (directional valve function with version "W") must not be used for safety functions! With version "B", the lowest adjustable pressure (circulation pressure) is set in case of power failure or cable break. With version "A", the pressure limiting function is set in case of power failure or cable break. Hydraulic counter pressures in port T with internal pilot oil return and/or port Y with external pilot oil return add 1:1 to the response pressure of the valve set at the pilot control.Example:

Pressure adjustment of the valve due to spring pretensioning in the pilot control valve/adjustment type

pspring =200 bar

Hydraulic counter pressure in port T with internal pilot oil return

phydraulic =50 bar

⇒ Response pressure= pspring+ phydraulic =250 bar

Mating connectors for valves with connector “K4”, without circuitry, standard

3P Z4

Mating connectors for valves with connector “K4”, without circuitry, standard

3P Z4

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Mating connectors for valves with connector “K4”, with indicator light

3P Z5L

Mating connectors for valves with connector “K4”, with indicator light

3P Z5L

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Mating connectors for valves with connector “K4”, with indicator light and Zener diode suppression circuit

3P Z5L1

Mating connectors for valves with connector “K4”, with indicator light and Zener diode suppression circuit

3P Z5L1

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Mating connectors for valves with connector “K4”, with rectifier

3P RZ5

Mating connectors for valves with connector “K4”, with rectifier

3P RZ5

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Ordering code: Type-examination tested safety valves type DBA…E, component series 1X according to Pressure Equipment Directive 97/23/EC

|

NG |

Type designation |

Component marking |

Maximum flow qVmax in l/min with pilot oil return |

Set response overpressurep in bar |

|

|

external "Y" |

internal "–" |

||||

|

32 |

1 2 3 4 5 * 6 DBAW 30 ▢▢▢N1X/▢▢6▢▢E |

TÜV.SV.▢–938.22.F.G.p |

600 |

360 |

111 ... 210 |

|

1 2 3 4 5 * 6 DBAWR 30 ▢▢▢N1X/▢▢6▢▢E |

700 |

520 |

211 ... 350 |

||

|

40 |

1 2 3 4 5 * 6 DBAW 40 ▢▢▢N1X/▢▢6▢▢E |

TÜV.SV.▢–939.22.F.G.p |

550 |

500 |

111 ... 210 |

|

1 2 3 4 5 * 6 DBAWR 40 ▢▢▢N1X/▢▢6▢▢E |

700 |

600 |

211 ... 350 |

||

|

1 |

Directional valve, normally closed |

A |

|

Directional valve, normally open |

B |

|

|

2 |

Standard flange |

F |

|

High-pressure flange |

H |

|

|

Adjustment type |

||

|

3 |

Hand wheel (pressure adjustment sealed, unloading or setting of a lower response pressure possible!) |

1 |

|

With sealed protective cap (no adjustment/unloading possible) |

2 |

|

|

4 |

Pressure in the designation is to be entered by the customer, pressure adjustment ≥ 30 ... 350 bar and possible in 5 bar steps. |

z. B. 150 |

|

Pilot oil supply and return |

||

|

5 |

Internal |

– 1) |

|

Recommendation: Internal pilot oil supply, external pilot oil return (ordering code according to symbols) |

Y |

|

|

* |

Ordering code of the electric data |

z. B. EG24N9K4 |

|

6 |

NBR seals |

no code |

|

FKM seals |

V |

|

|

Value entered at the factory |

1X |

|

| 1) Dash “–” only required if 02= “W” and 12 and 13 = “no code” (see ordering code) |

Related Products

R900958702

$2,019.00 USD

R900404826

$1,163.00 USD

R978917421

$715.00 USD

R978890772

$544.00 USD

R900413674

$1,309.00 USD