***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

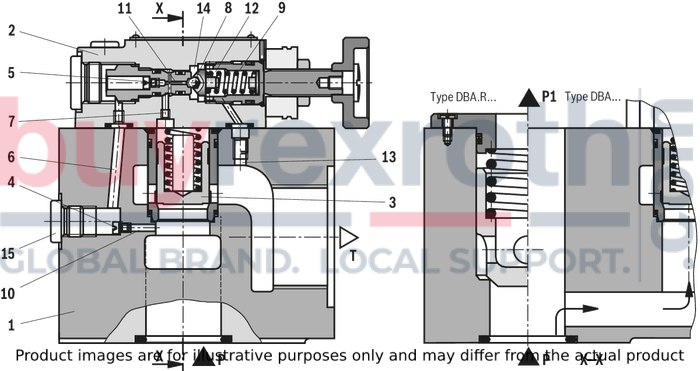

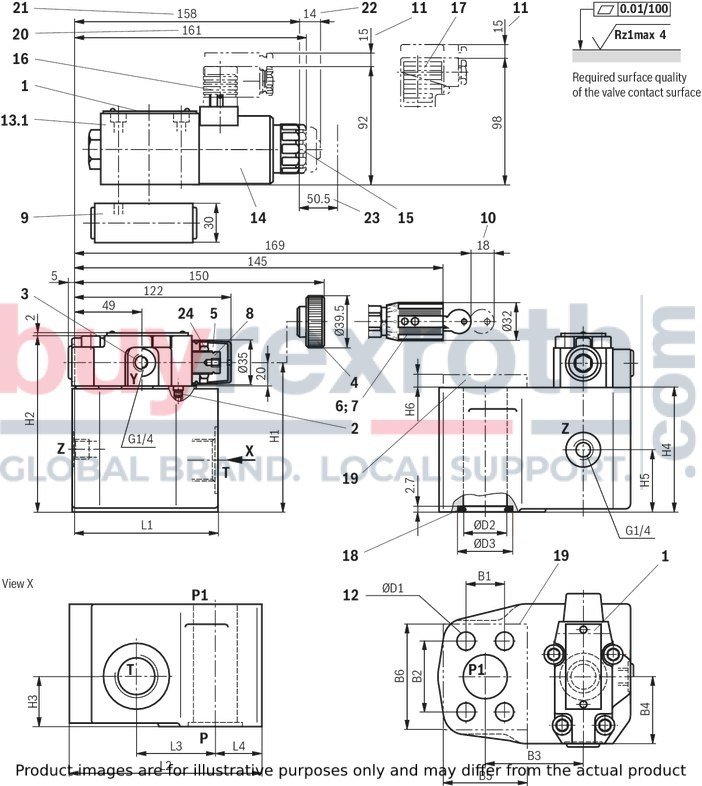

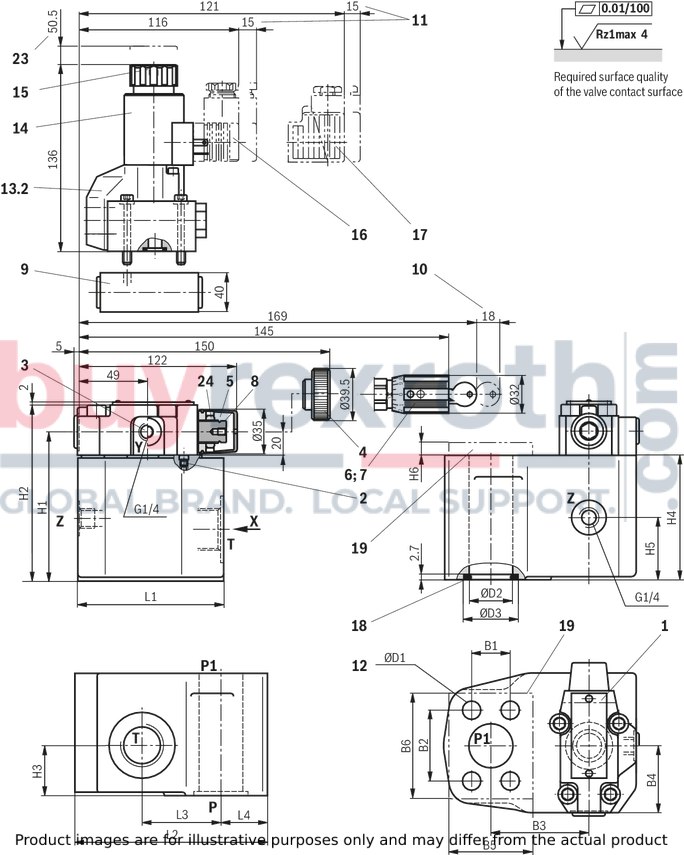

The Bosch Rexroth DBA30H2N1X/180E (R901126760) is a sophisticated pump safety block designed to be directly mounted onto the SAE pressure port of pumps. It functions as a pilot-operated pressure relief valve, primarily aimed at limiting the operational pressure within hydraulic systems. The unit comprises a valve block, a main spool insert, and a pilot control valve which facilitates precise pressure adjustments.

This model features a P port for hydraulic fluid input and an output port P, with the main spool insert located in between. This spool opens to connect to the T tank line when necessary. The DBA30H2N1X/180E operates by utilizing the pressure in the throughbore, which acts on both the main spool and ball in the pilot control valve through control lines equipped with nozzles.

When system pressure exceeds a predetermined setting on spring , the ball opens against its spring tension, allowing fluid from the main spool's spring-loaded side to flow into the tank, either internally or externally depending on type. This process helps maintain set operating pressures while allowing fluid flow from channel P to channel T.

Additionally, this pump safety block can be remotely controlled via port , and if required for connection to a pressure load cell or gauge shutoff valve, a specific version without nozzle (SO) should be selected to prevent delays or drops in pressure during operation.

The DBA30H2N1X/180E also offers an integrated check valve option that maintains system pressure when disconnected from the pump and negates the need for a separate check valve. It enables zero-pressure startup and efficient pump circulation with quick pressure buildup. Users can choose from various adjustment types for setting pressure including rotary knobs and lockable versions with scales. Furthermore, this model allows solenoid-actuated unloading through an additional directional valve and comes in size 30 with component series X capable of handling maximum operating pressures up to bar and maximum flow rates of l/min.

$2,078.00 USD

More are expected on October 6, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $2,026.05 USD | $51.95 USD |

| 25+ | $1,974.10 USD | $103.90 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as October 6, 2026 when ordered in