***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

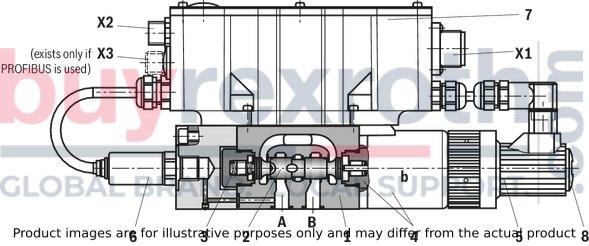

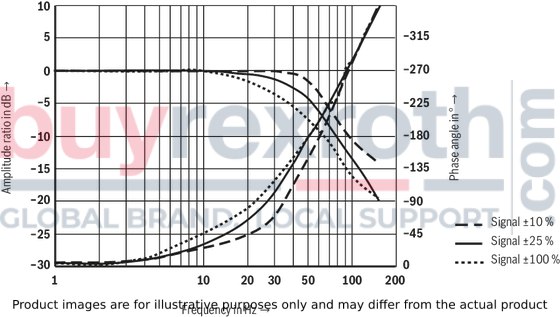

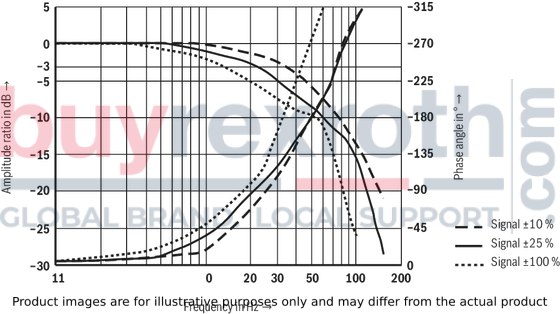

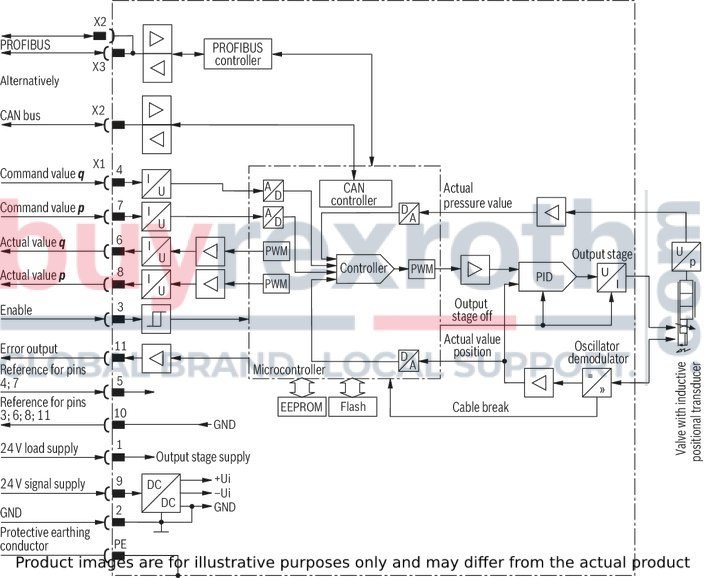

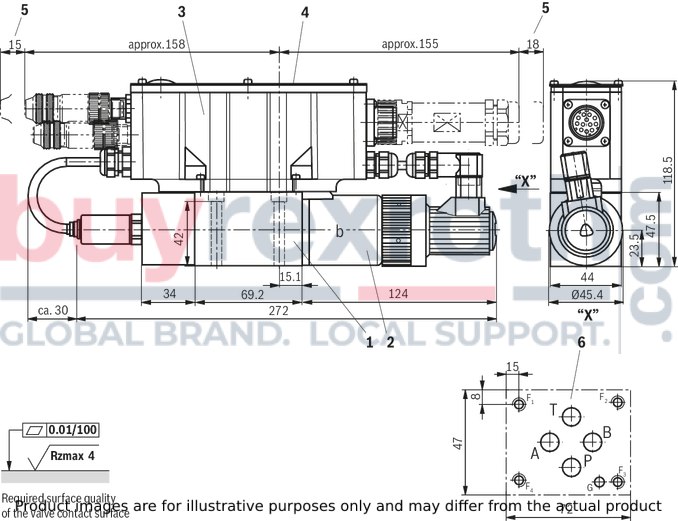

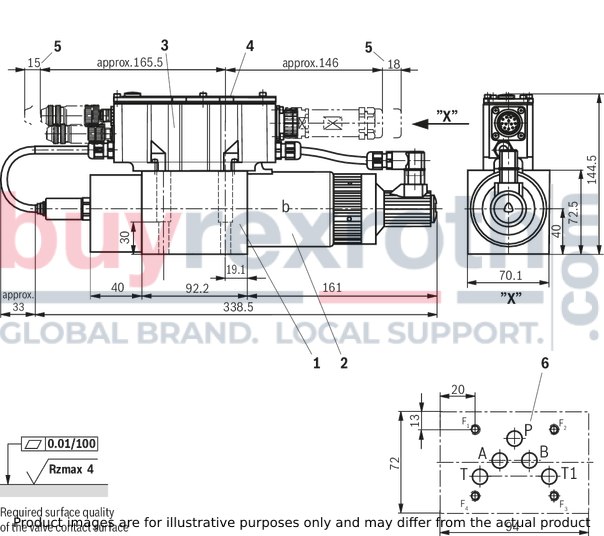

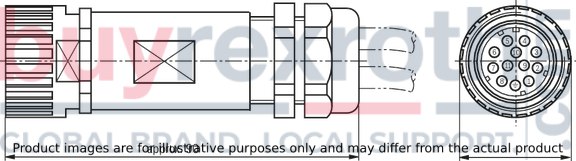

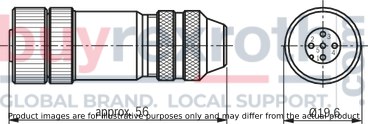

The Bosch Rexroth STW0195-2X/1V5-24PF6 (R901105881) is a state-of-the-art 4-way proportional directional valve equipped with an integrated digital control electronics IACP, designed for precision flow and pressure control in hydraulic systems. This advanced component features a robust housing with a connection surface, a control spool with a compression spring, solenoid and pole tube with central thread, position transducer, pressure sensor, and integrated digital control electronics IACP with bus connections.

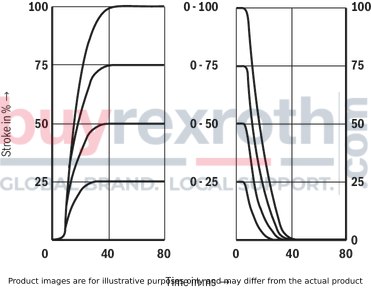

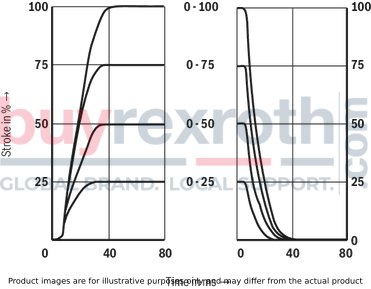

The valve operates effectively when the solenoids are not engaged, maintaining spool position A-T and optionally B-T for versatile functions including flow control (Q), pressure control (p), and substitutional control (pQ). It allows command value presetting through either an analog interface or via field bus interfaces. Actual value signals are also provided through these interfaces while controller parameters can be set via the field bus.

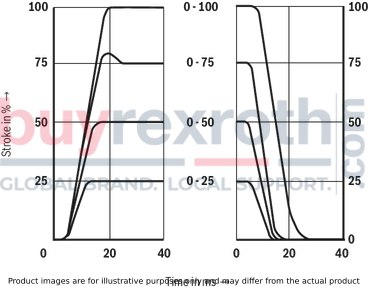

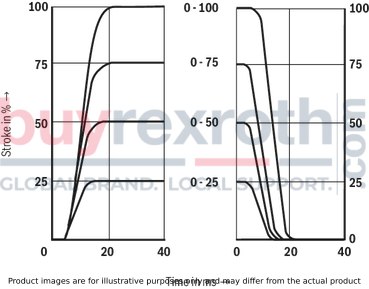

Bosch Rexroth has incorporated error detection diagnostics within the valve's digital electronics to identify issues such as cable breaks or communication errors. Additional features include pressure ramps, internal command value profiles, enable functions for analog/digital inputs, and an error output.

For project planning and parameterization of the IACP valves, users can utilize the WINPED commissioning software compatible with Windows operating systems. This software simplifies parameterization and diagnosis while offering comfortable data management on a PC.

This valve is designed according to ISO porting patterns and includes an analog interface for command and actual value transmission. It supports CAN bus with CANopen protocol DS 301 or Profibus-DP for seamless integration into existing systems. The quick commissioning feature is facilitated by the PC-based WINPED software.

Please note that due to its design principle, internal leakage may occur over time; therefore, it is essential that the tank line does not run empty. If necessary based on installation conditions, a preload valve should be installed. Additionally, it is crucial not to open the PG fitting or adjust the adjustment nut below as this could damage the valve.

$8,209.00 USD

More are expected on September 15, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $8,003.77 USD | $205.23 USD |

| 25+ | $7,798.55 USD | $410.45 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as September 15, 2026 when ordered in