Accessories for R901091138

R901017012

R901017012

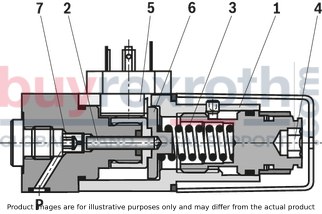

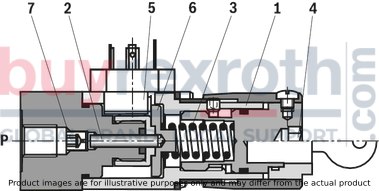

PRESSURE SWITCH HED 8 OP-2X/350K14AS

Manufacturer: Bosch Rexroth

Material #: R901091138

Model : HED 8 OP-2X/350K14AS

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

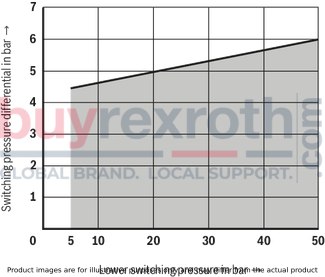

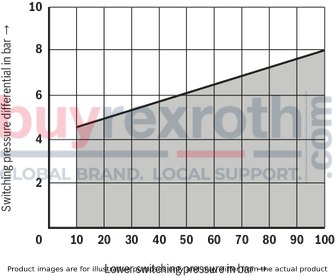

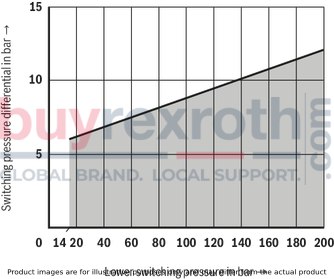

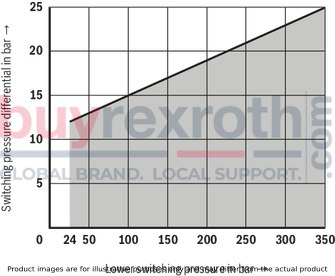

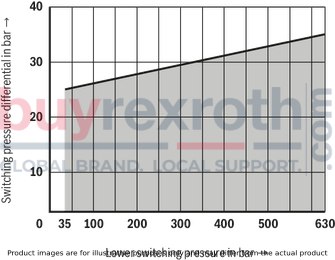

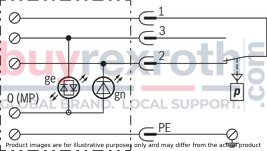

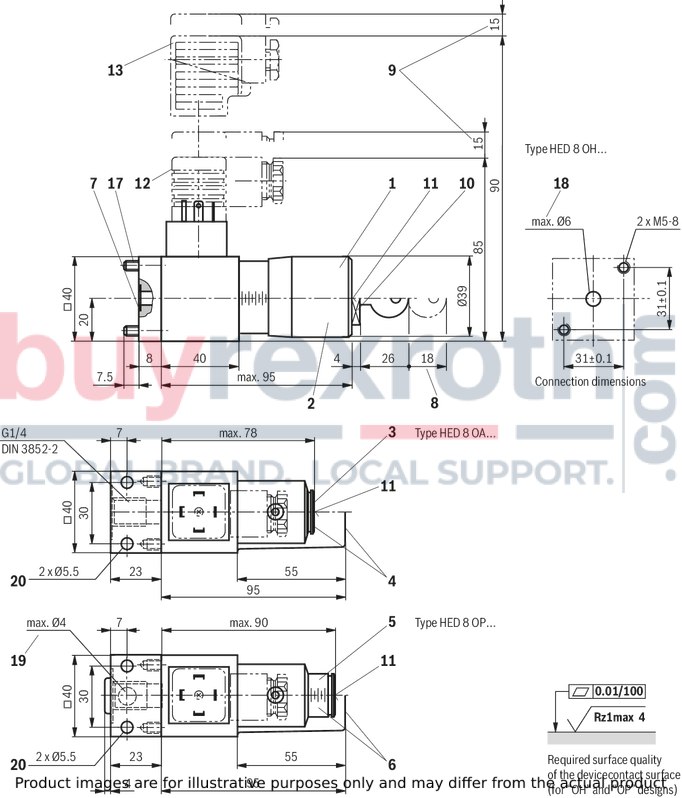

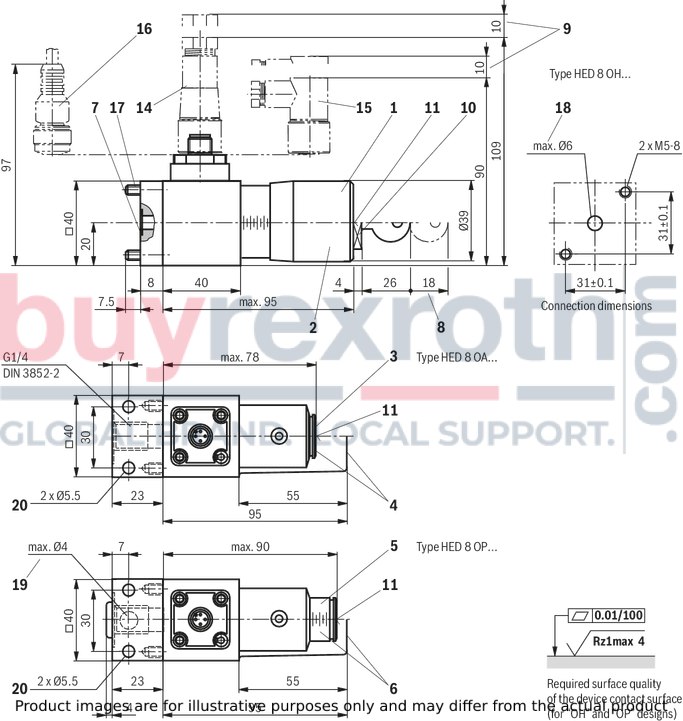

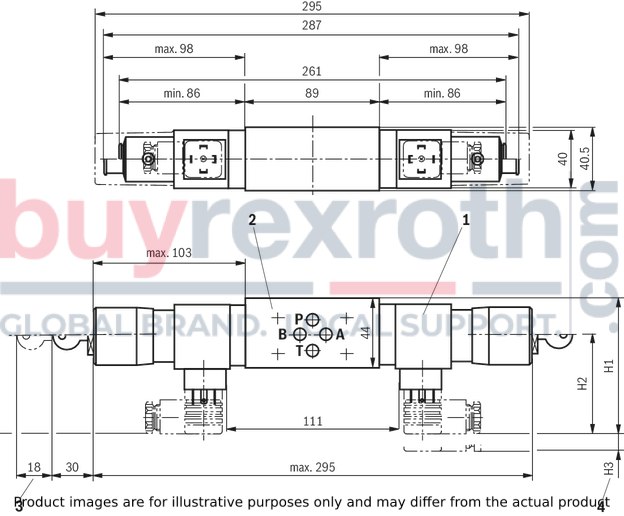

The Bosch Rexroth HED 8 OP-2X/350K14AS (R901091138) is a high-performance piston type hydraulic pressure switch designed for precise monitoring and control of system pressure within hydraulic circuits. This model features a micro switch with both normally closed (NC) and normally open (NO) contact functions, allowing for the potential-free switching of currents ranging from milliamps to 0.5 amps. The switch ensures high repetition accuracy, less than 1% of the set pressure, and a small hysteresis which contributes to its reliable performance.

This particular model boasts subplate mounting capabilities and comes equipped with NBR seals suitable for various hydraulic fluids including HL, HLP, HLPD, HVLP, and HVLPD. The adjustment type is a spindle with scale covered by a protective cap to ensure settings are maintained accurately during operation. It does not include a mating connector but is designed to work with a large cubic connector according to DIN EN standard.

The HED 8 OP-2X/350K14AS operates within a supply voltage range of 24 to 240 V AC/DC and has an electrical connection that conforms with Connector pole PE according to DIN EN standards. The unit's weight is approximately 0.6 kg, making it suitable for various applications without adding significant weight.

This Bosch Rexroth pressure switch also meets multiple conformity standards including CE according to the Low Voltage Directive EU, as well as CCC, UL, and RoHS certifications. Its robust design allows it to handle maximum operating pressures up to 350 bar and it offers multiple pressure ratings for versatile application use.

For system integrators and maintenance personnel seeking reliable pressure monitoring solutions in their hydraulic systems, the Bosch Rexroth HED 8 OP-2X/350K14AS provides an efficient solution with its durable construction, precise control features, and compliance with international safety standards.

$573.00 USD

More are expected on August 21, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $558.67 USD | $14.33 USD |

| 25+ | $544.35 USD | $28.65 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as August 21, 2026 when ordered in