DIRECTIONAL SPOOL VALVE Z4WEH10E63-4X/6EW110N9ETK4/B10V

Manufacturer: Bosch Rexroth

Material #: R901081099

Model : Z4WEH10E63-4X/6EW110N9ETK4/B10V

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

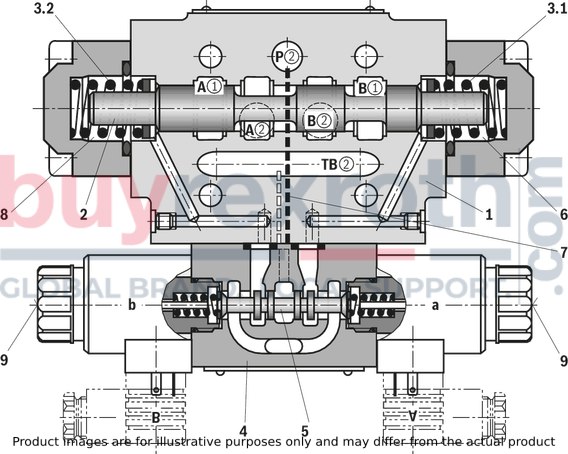

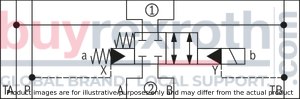

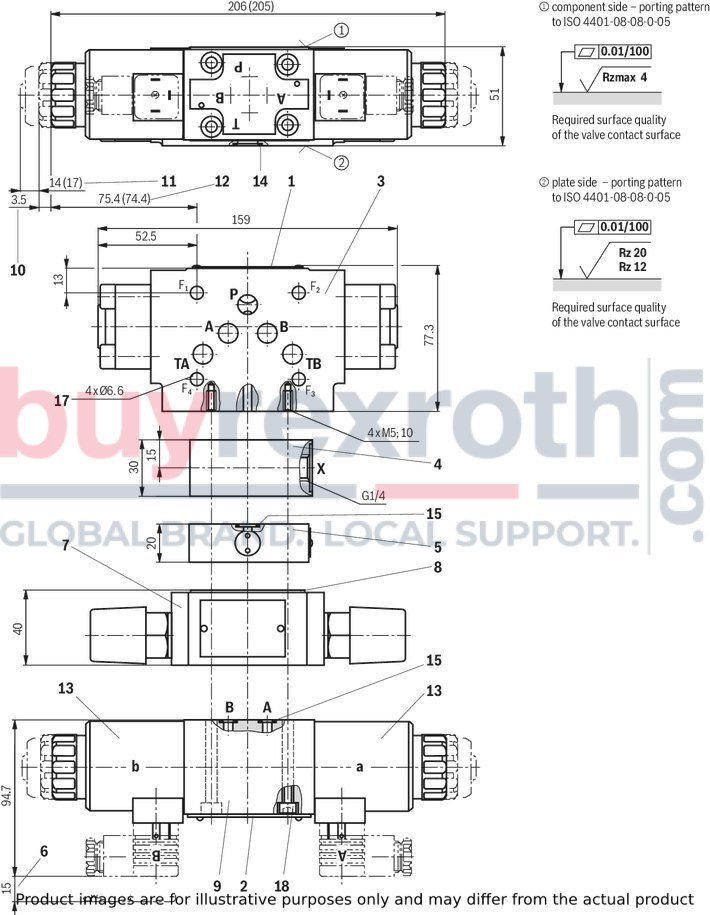

The Bosch Rexroth Z4WEH10E63-4X/6EW110N9ETK4/B10V (R901081099) is a high-performance directional spool valve that is pilot-operated and designed for electrohydraulic actuation. This valve is adept at functioning as either a shutoff through valve or a shutoff short-circuit through valve, ensuring versatile application in controlling the direction of hydraulic flow. It features free flow in every spool position for ports P and T, enhancing its operational flexibility.

The Z4WEH10E63-4X/6EW110N9ETK4/B10V conforms to the ISO porting pattern, ensuring compatibility with standardized connections and simplifying installation processes. It supports both wet-pin DC or AC solenoids, providing options to suit various electrical system requirements. Additionally, this model offers the possibility of including an auxiliary operating device according to specific user needs.

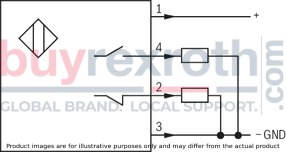

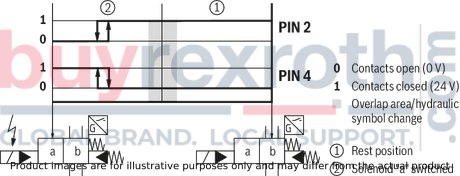

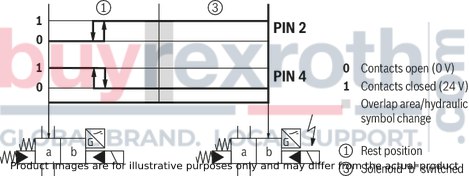

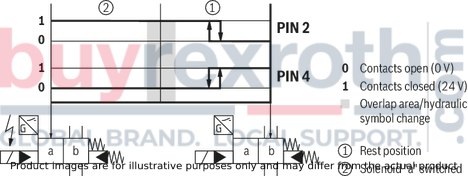

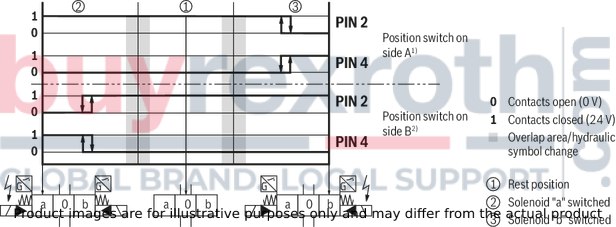

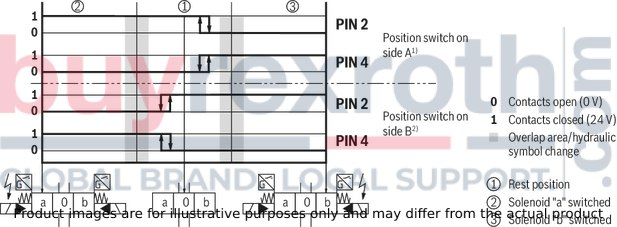

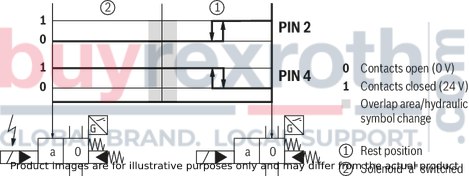

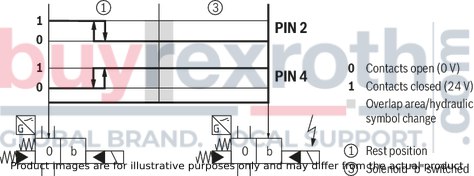

For electrical connections, users have the choice of individual or central connection configurations. The valve also boasts optional features such as switching time adjustment for precise control over transition times between states, as well as stroke setting adjustments on the main spool to fine-tune operational parameters. To further enhance its capabilities, inductive position switches and proximity sensors can be added for contactless detection of spool position.

This particular model is part of the component series X from Bosch Rexroth and can handle a maximum operating pressure of up to bar units and accommodate a maximum flow rate measured in liters per minute (l/min). These specifications indicate that it's built to withstand demanding conditions while maintaining efficient fluid control within hydraulic systems. The R901081099 is particularly suited for applications requiring robust performance and precise control over hydraulic operations.

$2,602.00 USD

More are expected on June 23, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.Status: This product is temporarily out of stock.

Qty: Delivered as early as June 23, 2026 when ordered in