***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

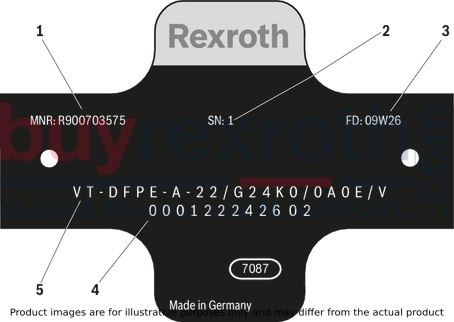

The Bosch Rexroth VT-DFPE-A-2X/G24K0/0A0C/V-018 (R901036937) is a high-performance pilot valve designed for precise pressure and flow control in hydraulic systems. It operates through a proportional solenoid with electrical feedback, ensuring accurate and responsive adjustments to system parameters. The integrated control electronics, specifically the VTDFPE, are tailored for use with the SYHDFEE system, providing smooth and efficient operation. This model boasts an analog interface for ease of integration into a variety of applications.

With its robust construction, the VT-DFPE-A-2X/G24K0/0A0C/V-018 is capable of handling maximum operating pressures with reliability and durability. Its design reflects Bosch Rexroth's commitment to quality and performance in hydraulic components. This pilot valve is an essential part for professionals seeking precise control in their hydraulic systems, offering both reliability and precision in managing flow rates and pressures within demanding operational environments.

$6,098.00 USD

More are expected on September 18, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $5,945.55 USD | $152.45 USD |

| 25+ | $5,793.10 USD | $304.90 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as September 18, 2026 when ordered in