INTERNAL GEAR PUMP PGH2-2X/005RE07VU2

Manufacturer: Bosch Rexroth

Material #: R900968999

Model : PGH2-2X/005RE07VU2

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

The Bosch Rexroth PGH2-2X/005RE07VU2 (R900968999) is an advanced internal gear pump designed for industrial applications that require reliable operation in an open circuit configuration. This robust pump is well-suited for variable-speed drives, providing a combination of low noise and minimal pulsation levels, while maintaining high efficiency through its gap compensation feature. The cast iron housing ensures durability and there's no limitation on load cycles, which makes it a versatile choice for continuous use. Its constant displacement design allows for precise fluid control, and the FKM seals offer compatibility with a variety of hydraulic fluids including HLP, HLPD, HVLP, HVLPD, HETG, HEES, HEPG, HFDR, and HFDU.

Featuring a cylindrical shaft with a fitting key and designed to operate with counterclockwise rotation, the PGH2-2X/005RE07VU2 has a maximum pressure capacity and supports a broad range of speeds from minimum to maximum RPMs. Its maximum flow rate is optimized by its constant displacement type engineering. The pump can be flexibly combined with other Rexroth pumps due to its through-drive capability.

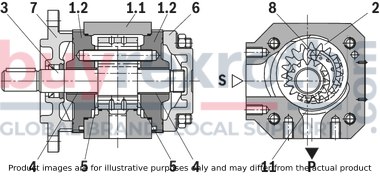

The internal structure of this pump includes components such as housing parts, bearing covers, internal gears, pinion shafts with hydrodynamic support during operation that drives the internal gear in the designated direction of rotation. The design also incorporates plain bearings and axial washers for efficient axial compensation ensuring excellent sealing of the pressure chamber even under varying pressure conditions.

In summary, the Bosch Rexroth PGH2-2X/005RE07VU2 offers exceptional performance characteristics suitable for industrial applications requiring high efficiency and reliability. Its construction allows for seamless integration within various hydraulic systems while promising low operational noise and reduced flow pulsation.

$1,641.00 USD

Availability: 4 In Stock

Qty: Delivered as early as February 9, 2026 when ordered in

Qty: Delivered as early as July 29, 2026 when ordered in

This product is eligible for factory repair.

Internal gear pump, size 5, pressure 350 bar for industrial applications, open circuit

Suitable for variable-speed drive. Low noise and pulsation level. High efficiency thanks to gap compensation. Cast iron housing, no load cycle limitation. Can be combined flexibly with other Rexroth pumps.

Unpacked Weight: 6.132 kg

Fixed displacement Low operating noise Low flow pulsation High efficiency also at low speed and viscosity due to sealing gap compensation Suitable for broad viscosity and speed ranges All frame sizes and sizes can be arbitrarily combined Can be combined with internal gear pumps, radial piston pumps and external gear pumps

Set-up

Hydraulic pumps of type PGH are gap-compensated internal gear pumps with constant displacement.

They basically comprise of housing (1.1), bearing cover (1.2), internal gear (2), pinion shaft (3), plain bearings (4), axial washers (5), end cover (6), mounting flange (7) and stop pin (8), as well as the segment filler element (9) consisting of segment (9.1), segment support (9.2) and the seal rolls (9.3).

Suction and displacement procedure

The hydrodynamically supported pinion shaft (3) drives the internally geared internal gear (2) in the displayed direction of rotation.

During the rotation, there is a volume increase over an angle of approx. 90° in the suction range. An underpressure results and fluid flows into the chambers.

The sickle-shaped segment filler element (9) separates suction and pressure chamber. In the pressure chamber, the teeth of the pinion shaft (3) engage in the space between the teeth of the internal gear (2) again. The liquid is displaced via the pressure channel (P).

Axial compensation

The axial compensation force FA takes effect in the area of the pressure chamber and is generated with the pressure field (10) in the axial washers (5).

So the axial longitudinal gaps between the rotating and the fixed parts are extraordinarily small and ensure perfect axial sealing of the pressure chamber.

Radial compensation

The radial compensation force FR acts on segment (9.1) and segment support (9.2).

Dependent on the operating pressure, the two segment filler elements (9.1) and (9.2) are pressed against the head diameters of pinion shaft (3) and internal gear (2).

The area ratios and the position of the seal rolls (9.3) between the segment and segment support are designed so that an almost leakage gap-free sealing between internal gear (2), segment filler element (9) and pinion shaft (3) is achieved.

Spring elements under the seal rolls (9.3) ensure sufficient contact pressure, also with very low pressures.

Hydrodynamic and hydrostatic mounting

The forces acting on the pinion shaft (3) are accepted by hydrodynamically lubricated radial plain bearings (4); the forces acting on the internal gear (2) by the hydrostatic bearing (11).

Gear tooth system

The toothing is an involute tooth system. Its large meshing length results in little flow and pressure pulsation; these little pulsation rates considerably contribute to the low-noise running.

PGH-type hydraulic pumps are gap-compensated internal gear pumps with fixed displacement. The hydrodynamically mounted pinion shaft drives the internal gear. The pinion shaft and internal gear tooth clearances opening in the suction range suck in the hydraulic fluid and transport it to the pressure range. The suction and pressure range are separated by the radial compensation elements and the tooth engagement between the internal gear and pinion shaft.

| Cast iron housing |

| Internal gear pump with constant displacement |

| For industrial applications in open circuit |

| With FKM seals |

| Maximum operating pressure 350 bar |

| Frame size 2, 3 |

| Size 5 … 16 |

| Data Sheet | Download Data Sheet |

| 3D CAD | Download 3D CAD |

| 3D CAD | Download 3D CAD |

| Displacement type | constant |

| Size | 5 |

| Max. pressure | 350 |

| Max. flow | 15.72 |

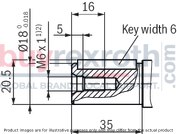

| Shaft end | Cylindrical Ø 18 with fitting key |

| Through-drive | with |

| Direction of rotation | counterclockwise rotation |

| Shaft end | Cylindrical Ø 18 mm with fitting key |

| Fastening | 2-hole mounting flange 101-2 according to ISO 3019-1 |

| Hydraulic fluid | HLP,HLPD,HVLP,HVLPD,HETG,HEES,HEPG,HFDR,HFDU |

| Seals | FKM |

| Fastening | 2-hole mounting flange 101-2, ISO 3019-1 |

| Speed min. | 600 |

| Productgroup ID | 9,10,11,12,13,14 |

| Speed max. | 3000 |

| Weight | 6.132 |

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

10 |

11 |

||

|

PG |

H |

– |

2X |

/ |

07 |

U2 |

|

Type |

|||

|

01 |

Internal gear pump, fixed displacement, gap-compensated |

PG |

|

|

Series |

|||

|

02 |

High-pressure pump, peak pressure 350 bar |

H |

|

|

Frame sizes BG |

|||

|

03 |

BG2 |

2 |

|

|

BG3 |

3 |

||

|

Component series |

|||

|

04 |

Component series 20 ... 29 (20 ... 29: unchanged installation and connection dimensions) |

2X |

|

|

Sizes |

|||

|

05 |

BG2 |

5 |

005 |

|

6 |

006 |

||

|

8 |

008 |

||

|

BG3 |

11 |

011 |

|

|

13 |

013 |

||

|

16 |

016 |

||

|

Directions of rotation |

|||

|

06 |

Viewed on drive shaft |

right |

R |

|

counterclockwise |

L |

||

|

Drive shafts |

|||

|

07 |

Cylindrical shaft with fitting key, DIN 6885 |

E |

|

|

Splined shaft SAE J744 with involute tooth system according to ANSI B92.1a |

16-4 (A) 9T 16/32DP |

R |

|

|

19-4 11T 16/32DP |

S |

||

|

Line connections |

|||

|

08 |

Suction and pressure port according to SAE, pressure port standard pressure series |

07 |

|

|

Seals |

|||

|

09 |

FKM (fluor-caoutchouc) |

V |

|

|

FKM (fluorocarbon rubber), shaft seal ring made of NBR (nitrile rubber) 1) |

W |

||

|

Mounting flange |

|||

|

10 |

SAE 2-hole |

U2 |

|

|

11 |

Further details in the plain text |

||

| 1) | For HFC hydraulic fluids |

Order example

PGH3-2X/016RE07VU2

Material number

R900951305

Not all variants according to the type key are possible! Please select the desired pump using the selection tables (dimensions) or after consultation with Bosch Rexroth.

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

10 |

11 |

12 |

13 |

14 |

15 |

|||||||

|

/ |

+ |

/ |

+ |

/ |

+ |

+ |

|

Type |

|||

|

01 |

2-fold |

P2 |

|

|

3-fold |

P3 |

||

|

02 |

Series of the 1st pump 1) |

||

|

03 |

Size of the 1st pump 1) |

||

|

04 |

Series of the 2nd pump 1) |

||

|

05 |

Size of the 2nd pump 1) |

||

|

06 |

Series of the 3rd pump 1) |

||

|

07 |

Size of the 3rd pump 1) |

||

|

Direction of rotation |

|||

|

08 |

Viewed on drive shaft |

right |

R |

|

counterclockwise |

L |

||

|

Drive shaft of the 1st pump |

|||

|

09 |

Cylindrical shaft with fitting key, DIN 6885 |

E |

|

|

Splined shaft SAE J744 with involute tooth system according to ANSI B92.1a |

16-4 (A) 9T 16/32DP |

R |

|

|

19-4 11T 16/32DP |

S |

||

|

Line connection of the 1st pump |

|||

|

10 |

Suction and pressure port according to SAE, pressure port standard pressure series |

07 |

|

|

Drive shaft of the 2nd pump 2) |

|||

|

11 |

Cylindrical shaft with fitting key, DIN 6885 |

A |

|

|

Splined shaft SAE J744 with involute tooth system according to ANSI B92.1a |

16-4 (A) 9T 16/32DP |

J |

|

|

R |

|||

|

Line connection of the 2nd pump |

|||

|

12 |

Suction and pressure port according to SAE, pressure port standard pressure series |

07 |

|

|

Drive shaft of the 3rd pump 2) |

|||

|

13 |

Cylindrical shaft with fitting key, DIN 6885 |

A |

|

|

Splined shaft SAE J744 with involute tooth system according to ANSI B92.1a |

16-4 (A) 9T 16/32DP |

J |

|

|

R |

|||

|

Line connection of the 3rd pump |

|||

|

14 |

Suction and pressure port according to SAE, pressure port standard pressure series |

07 |

|

|

Mounting flange of the 1st pump |

|||

|

15 |

SAE 2-hole 2) |

U2 |

|

| 1) | Detailed information see type key |

| 2) | See table Back pump of dimensions |

|

Frame size |

2 | 3 | |||||||||

|

Size |

|

5 | 6 | 8 | 11 | 13 | 16 | ||||

|

Displacement |

geometric |

Vg |

cm³ |

5.24 | 6.5 | 8.2 | 11 | 13.3 | 16 | ||

|

Drive speed |

nmin |

rpm |

600 | ||||||||

|

nmax |

rpm |

3000 | |||||||||

|

Operating pressure, absolute |

Inlet 1) |

p |

bar |

0.8 ... 2 | |||||||

|

Outlet |

continuous |

Standard liquid |

pN |

bar |

315 | ||||||

|

Special fluid 2) |

pN |

bar |

210 | ||||||||

|

Outlet |

intermittent |

Standard liquid |

pmax |

bar |

350 3) | 350 | |||||

|

Special fluid 2) |

pmax |

bar |

230 | ||||||||

|

Flow 4) |

qV |

l/min |

7.5 | 9.3 | 11.8 | 15.8 | 19.1 | 23 | |||

|

Mass |

m |

kg |

4.3 | 4.4 | 4.6 | 4.8 | 5 | 5.3 | |||

|

Shaft load |

Radial and axial forces (e.g. belt pulley) only after coordination | ||||||||||

|

Mounting type |

Flange mounting | ||||||||||

| 1) | Short-time, during start 0,6 bar |

| 2) | For special fluids, observe the restrictions of the technical data! |

| 3) | Maximum 10 s, at most 50 % of the duty cycle |

| 4) | at n = 1450 rpm, p = 10 bar, v = 45 mm2/s |

Hydraulic fluid

|

Hydraulic fluid |

|||

|

Permissible hydraulic fluid |

Mineral oil (HLP) to DIN 51524-2 | ||

|

Special fluid 1) |

HEES liquids according to DIN ISO 15380 Flame-resistant, water-free hydraulic fluid HFD-U according to VDMA 24317 Water polymer solutions HFC according to DIN EN ISO 12922 |

||

|

Operating temperature range |

Standard liquid |

°C |

-10 … +80 |

|

Special fluid |

°C |

-10 … +50 | |

|

Ambient temperature range |

°C |

-20 … +60 | |

|

Viscosity range |

mm²/s |

10 … 300 | |

|

Admissible start viscosity |

mm²/s |

2000 | |

|

Maximum admissible degree of contamination of the hydraulic fluid 2) |

Class 20/18/15 according to ISO 4406 (c) | ||

| 1) | Seal design W |

| 2) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

For applications outside these parameters, please consult us!

Average values of frame sizes 2 and 3

Flow

Efficiency

Drive power

Sound pressure level

Notice

Characteristic curves measured with n = 1450 min-1; ν = 41 mm2/s; θ = 50 °C Sound pressure level measured in the sound measuring chamber according to DIN 45635, sheet 26;Distance: Microphone ‒ pump = 1 m

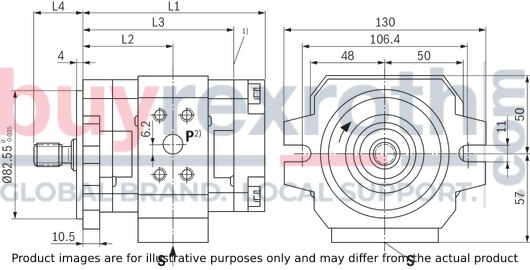

Frame size 2

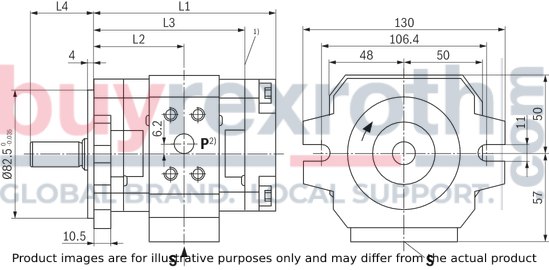

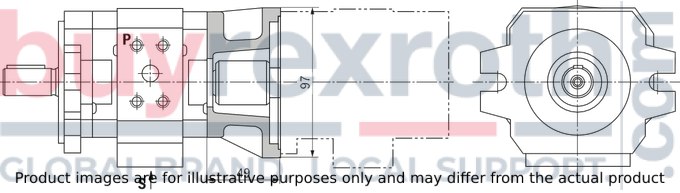

With cylindrical shaft or splined shaft SAE J744 and SAE mounting flange 82‒2

Dimensions in mm

| 1) | With multiple pumps, the combination part will start from here |

| 2) | The figure shows pumps with clockwise rotation; with pumps with counterclockwise rotation, the pressure port is on the opposite side! |

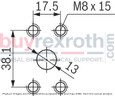

Partial view suction port S

Dimensions in mm

Partial view pressure port P

Dimensions in mm

|

Type |

Material numbers |

L1 |

L2 |

L3 |

L4 |

Suction port S 2) |

Pressure port P 2) |

||||

|

PGH2-2X/ |

005 |

R 1) |

E |

07VU2 |

R900968999 |

110 mm |

54,2 mm |

89,5 mm |

41 mm |

1/2 in 344,7 bar |

1/2 in 344,7 bar |

|

L |

R900703725 |

||||||||||

|

R 1) |

R |

07VU2 |

R900972378 |

31,5 mm |

|||||||

|

L |

R900703727 |

||||||||||

|

006 |

R 1) |

E |

07VU2 |

R900951301 |

112,5 mm |

55,5 mm |

92 mm |

41 mm |

1/2 in 344,7 bar |

1/2 in 344,7 bar |

|

|

L |

R900961547 |

||||||||||

|

R 1) |

R |

07VU2 |

R900961549 |

31,5 mm |

|||||||

|

L |

R900961550 |

||||||||||

|

008 |

R 1) |

E |

07VU2 |

R900951302 |

116 mm |

57,3 mm |

95,5 mm |

41 mm |

1/2 in 344,7 bar |

1/2 in 344,7 bar |

|

|

L |

R900961548 |

||||||||||

|

R 1) |

R |

07VU2 |

R900961551 |

31,5 mm |

|||||||

|

L |

R900961552 |

||||||||||

| 1) | Preferably available |

| 2) | Standard pressure series |

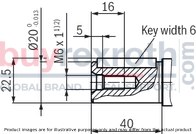

Cylindrical shaft with fitting key DIN 6885

Dimensions in mm

Splined shaft SAE J744

R - 16-4 (A) in 9T 16/32DP1)2)

Dimensions in mm

| 1) | Suitable as central and back pump for multiple pumps |

| 2) | Involute tooth system according to ANSI B92.1a, 30° pressure angle, flat root, side fit, tolerance class 5 |

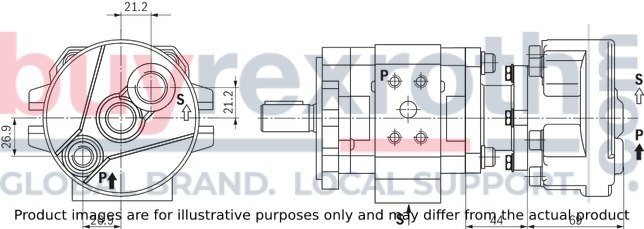

Frame size 3

With cylindrical shaft and SAE mounting flange 101‒2

Dimensions in mm

| 1) | With multiple pumps, the combination part will start from here |

| 2) | The figure shows pumps with clockwise rotation; with pumps with counterclockwise rotation, the pressure port is on the opposite side! |

Partial view suction port S

Dimensions in mm

Partial view pressure port P

Dimensions in mm

|

Type |

Material numbers |

L1 |

L2 |

L3 |

L4 |

Suction port S 2) |

Pressure port P 2) |

||||

|

PGH3-2X/ |

011 |

R 1) |

E |

07VU2 |

R900951303 |

128 mm |

66,5 mm |

107,5 mm |

41 mm |

1 in 208,6 bar |

1/2 in 344,7 bar |

|

L |

R900961553 |

||||||||||

|

013 |

R 1) |

E |

07VU2 |

R900951304 |

133 mm |

69 mm |

112,5 mm |

41 mm |

1 in 208,6 bar |

1/2 in 344,7 bar |

|

|

L |

R900961554 |

||||||||||

|

016 |

R 1) |

E |

07VU2 |

R900951305 |

138 mm |

71,5 mm |

117,5 mm |

41 mm |

1 in 208,6 bar |

1/2 in 344,7 bar |

|

|

L |

R900961555 |

||||||||||

| 1) | Preferably available |

| 2) | Standard pressure series |

Cylindrical shaft with fitting key DIN 6885

Dimensions in mm

With splined shaft SAE J744 and SAE mounting flange 82‒2

Dimensions in mm

| 1) | With multiple pumps, the combination part will start from here |

| 2) | The figure shows pumps with clockwise rotation; with pumps with counterclockwise rotation, the pressure port is on the opposite side! |

Partial view suction port S

Dimensions in mm

Partial view pressure port P

Dimensions in mm

|

Type |

Material numbers |

L1 |

L2 |

L3 |

L4 |

Suction port S 2) |

Pressure port P 2) |

||||

|

PGH3-2X/ |

011 |

R 1) |

R |

07VU2 |

R900961556 |

121,5 mm |

60 mm |

101 mm |

31,5 mm |

1 in 206,8 bar |

1/2 in 344,7 bar |

|

L |

R900961559 |

||||||||||

|

R |

S |

07VU2 |

R901267181 |

37 mm |

|||||||

|

013 |

R 1) |

R |

07VU2 |

R900961557 |

126,5 mm |

62,5 mm |

106 mm |

31,5 mm |

1 in 206,8 bar |

1/2 in 344,7 bar |

|

|

L |

R900961560 |

||||||||||

|

R |

S |

07VU2 |

R901281697 |

37 mm |

|||||||

|

016 |

R 1) |

R |

07VU2 |

R900961558 |

131,5 mm |

65 mm |

111 mm |

31,5 mm |

1 in 206,8 bar |

1/2 in 344,7 bar |

|

|

L |

R900961561 |

||||||||||

|

R |

S |

07VU2 |

R901281698 |

37 mm |

|||||||

| 1) | Preferably available |

| 2) | Standard pressure series |

Splined shaft SAE J744

R - 16-4 (A) in 9T 16/32DP1)2)

Dimensions in mm

| 1) | Suitable as central and back pump for multiple pumps |

| 2) | Involute tooth system according to ANSI B92.1a, 30° pressure angle, flat root, side fit, tolerance class 5 |

S - 19-4 in 11T 16/32DP1)

Dimensions in mm

| 1) | Involute tooth system according to ANSI B92.1a, 30° pressure angle, flat root, side fit, tolerance class 5 |

Multiple pumps

All internal gear pumps of type PGH can be combined, every pump is equipped with an output gear tooth system. The combination possibilities and die material numbers of the required combination parts are available in the following table.

|

Back pump |

Front pump |

|

|

PGH2-2X |

PGH3-2X |

|

|

PGH2-2X/...R...U2 |

R900886137 |

R900886137 |

|

PGH3-2X/...R...U2 |

R900886137 |

R900886137 |

|

PGP2-2X/...J...U2 |

R900886137 |

R900886137 |

|

PGF2-2X/...J...U2 |

R900886137 |

R900886137 |

|

AZPF...RR...B |

R900886137 |

R900886137 |

|

PR4-1X...WA |

R900886137 |

R900886137 |

The dimensional drawings show the front pump and the combination part.1)

PGH2/PGH3

PGH2 with combination part for PGH2, PGH3, PGF2, PGP2, AZPF

Dimensions in mm

PGH2/PGH3 + R4-Mini

Dimensions in mm

| 1) Dimensions of the single pumps see Dimensions or the corresponding data sheets of the back pump. |

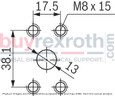

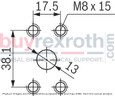

SAE connection flanges

Dimensions in mm

|

PGH |

Flange |

Material number1) for flange with |

Dimensioning |

|||||||||

|

Suction flange |

Pressure flange |

NG, pressure |

Welded connection |

Threaded connection 2) |

B1 |

B2 |

H1 |

H2 |

D1 |

D2 |

D3 |

D4 |

|

PGH2/005/ 006/008 |

PGH2/005/ 006/008 |

1/2 in 344,7 bar |

R900026298 |

R900024200 |

38,1 mm |

54 mm |

17,5 mm |

46 mm |

20 mm |

14 mm |

G1/2 |

M8 x 30 |

|

PGH3/011/013/016 |

– |

1 in 206,8 bar |

R900012937 |

R900014154 |

52,4 mm |

70 mm |

26,2 mm |

59 mm |

35 mm |

27 mm |

G1 |

M10 x 35 |

| 1) | The material numbers comprise the flange, the O-ring (NBR) and the mounting screws. |

| 2) | Pipe thread “G” according to DIN EN ISO 228/1 |

Pump safety block

For limitation of the operating pressure or (and) for the solenoid-actuated unloading of the operating pressure, we recommend our pump safety blocks according to data sheets 25880 and 25891.

Comprehensive information and suggestions are contained in the Hydraulics Trainer, volume 3 "Project planning information and design of hydraulic systems".

When using internal gear pumps, a manual, switchable or automatic bleeding option must moreover be provided. The bleeding point for manual bleeding must be provided in the pressure line in front of the first valve or check valve so that depressurized bleeding is possible.

Technical data

All specified technical data depend on production tolerances and are valid at certain boundary conditions.

Please note that consequently, fluctuations are possible and that with certain boundary conditions (e.g. viscosity), the technical data may also change.

Characteristic curves

When designing the drive motor, please observe the maximum application parameters possible shown by the presented characteristic curves.

Sound pressure level

The shown values for sound pressure level on characteristic curves have been measured based on DIN 45635, sheet 26.

That means that only the sound emission of the pump is shown. Environmental influences (place of installation, piping, etc.) have not been considered.

These values are in each case only valid for one pump.

With internal gear pumps, the excitation of valves, pipelines, machine parts, etc. is very low due to the little flow pulsation (approx. 2 to 3%).

With unfavorable influences, the sound pressure level at the place of installation of the power unit may, however, still be 5 to 10 db(A) higher than the values of the pump itself.

Multiple pump

The same general technical data apply as for single pumps (see Technical data). The combined pumps must all have the same direction of rotation. The pump with the largest torque should be intended as first pump. The maximum through-drive torque must be checked by the project planner for every application. This is also true for already existing (coded) multiple pumps. The total of the torques in a multiple pump must not exceed the maximum drive torque. Joint aspiration is not possible. Before operating pump combinations with different hydraulic fluids, please consult Bosch Rexroth. Medium and back pumps must be equipped with drive shafts version “R” (geared). The drive torque of a pump stage is calculated as follows:

|

Legende |

|

|

T |

Torque [Nm] |

|

Δp |

Operating pressure [bar] |

|

V |

Displacement [cm³] |

|

η |

Hydraulic-mechanical efficiency |

Maximum admissible torques [Nm]

|

Type |

Drive torque |

Drive torque |

||

|

Cyl. shaft E |

Splined shaft R |

Splined shaft S |

||

|

PGH2 |

100 |

80 |

155 |

75 |

|

PGH23 |

110 |

80 |

155 |

75 |

Fluid tank

Adjust useful volume of the tank to the operating conditions The admissible fluid temperature must not be exceeded; use coolers, if necessary.Lines and connections

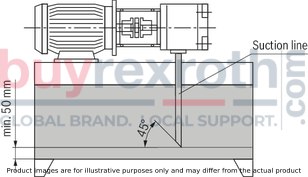

Remove the protective plug at the pump. Select the inner width of the pipes according to the connections (suction speed 1 to 1.5 m/s). For the inlet pressure refer to the Technical data Pipelines and fittings must be carefully cleaned before assembly.Proposal for piping layout

Dimensions in mm

Return fluid must not be directly sucked in again under any circumstances, i.e. select the largest distance possible between suction and return line. Suction line and return flow outlet must always lie clearly below the oil level. Ensure suction-tight assembly of the pipelines.

Return fluid must not be directly sucked in again under any circumstances, i.e. select the largest distance possible between suction and return line. Suction line and return flow outlet must always lie clearly below the oil level. Ensure suction-tight assembly of the pipelines.

Filter

Use return flow or pressure filter if possible.

(Only use suction filters in connection with underpressure switch / clogging indicator).

Hydraulic fluid

Please observe our provisions according to data sheet 90220. We recommend brand hydraulic fluids. Different hydraulic fluid types must not be mixed as this might result in degradation and deterioration of the lubricity. According to the operating conditions, the hydraulic fluid must be renewed at certain time intervals. In this connection, it is also necessary to clean the hydraulic fluid tank from residues.Drive

Electric motor + pump carrier + coupling + pump

No radial and axial forces on the pump drive shaft admissible! Motor and pump must be exactly aligned! Always use a coupling that is suitable for compensating shaft displacements! Avoid axial forces when attaching the coupling, i.e. do not assemble it using impact tools or by pressing it on! Use an internal thread of the drive shaft!

No radial and axial forces on the pump drive shaft admissible! Motor and pump must be exactly aligned! Always use a coupling that is suitable for compensating shaft displacements! Avoid axial forces when attaching the coupling, i.e. do not assemble it using impact tools or by pressing it on! Use an internal thread of the drive shaft!

Installation positions

B3

B5

V1

Preparation

Check whether the system has been assembled carefully and properly. Only fill in hydraulic fluid through filters with the required minimum retention rate. Completely fill the pump with hydraulic fluid through the suction or pressure pipe. Check the direction of rotation of the motor for compliance with the direction of rotation according to the pump type.Bleeding

Manually open the bleed port at the system or switch to depressurized circulation according to the operating instructions of the system. During the bleeding, depressurized discharge of entrapped air must be ensured. To bleed the pump, switch the motor on and immediately off again (jog mode). This process is to be repeated until complete bleeding of the pump is ensured. Close the manually opened bleed port again.Commissioning

If complete bleeding of the pump has been ensured, switch on the motor. Let the pump run at zero pressure until the system is completely bled. For system air bleeding, observe the operating instructions of the system. Commission the system according to the operating instructions of the system and load the pump. After some operating time, check the hydraulic fluid in the tank for bubble or foam formation at the surface.Operation

During operation, look out for changes in the noise characteristic. Due to the heating of the hydraulic fluid, slightly increasing noises are normal. A considerably increase in noise or short-time stochastic noise changes may be an indication of sucked in air. If suction pipes are too short or the filling level heights of the hydraulic fluid are too low, air may also be sucked in through a vortex. Changes in operating speeds, temperatures, increasing noises or power consumption are an indication of wear or damage at the system or the pump.Re-commissioning

Check the pump and system for leakage. Leaks are an indication of leakage below the hydraulic fluid level. An increased hydraulic fluid level in the tank is an indication of leakage above the hydraulic fluid level. If the pump is arranged above the hydraulic fluid level, the pump may run empty due to leakage, e.g. a worn shaft seal ring. In this case, the system must be bled again upon re-commissioning. Initiate the repair. After repair and maintenance works, bleeding is again necessary. If the system is intact, switch on the motor.General information

The pumps delivered by us have been checked for function and performance. The warranty only applies to the supplied configuration. Repair works may only be carried out by the manufacturer or their authorized dealers and agencies. The claim to warranty expires if the product is incorrectly repaired, assembled, commissioned and operated, not used as intended and/or handled improperly. Opening the internal gear pump and following an extension or a modification, the claim to warranty expires.Notes!

Assembly, maintenance and repair of the pump may only be carried out by authorized, trained and instructed personnel. Pump may only be operated with the admissible data (see Technical data). The pump may only be operated if it is in an unobjectionable condition. For all works at the pump, depressurize the system! Unauthorized modifications or changes which affect the safety and function are not admissible! Apply protective devices (e. g. coupling guard) and/or do not remove existing protective devices! Always ensure tight seat of all mounting screws! (Observe the specified tightening torque) The generally valid safety and accident prevention regulations must be imperatively complied with!Related Products

R901077322

$4,131.00 USD

R901230056

$3,640.00 USD

R900931136

$2,149.00 USD

R978011577

$1,557.00 USD

R901253293

$5,658.00 USD