PUMP SAFETY BLOCK DBA25H2-2X/200

Manufacturer: Bosch Rexroth

Material #: R900966021

Model : DBA25H2-2X/200

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

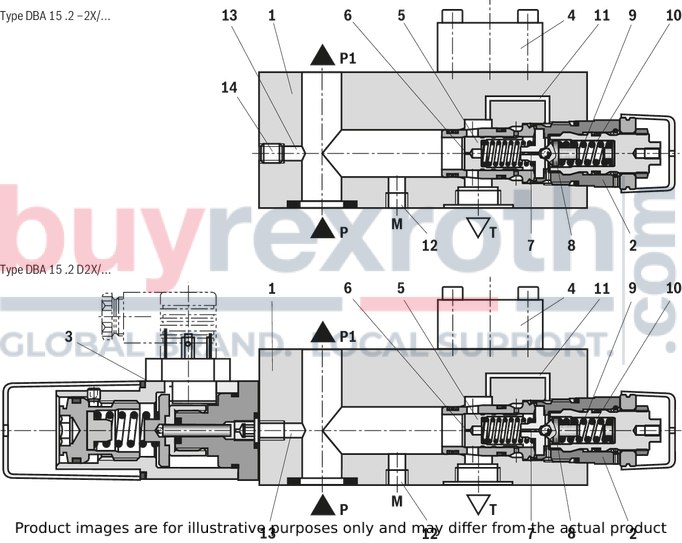

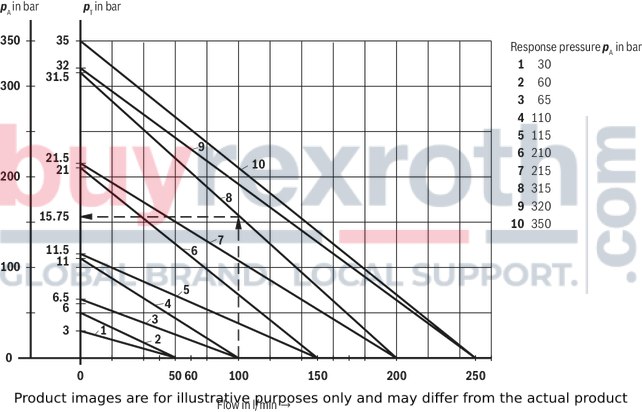

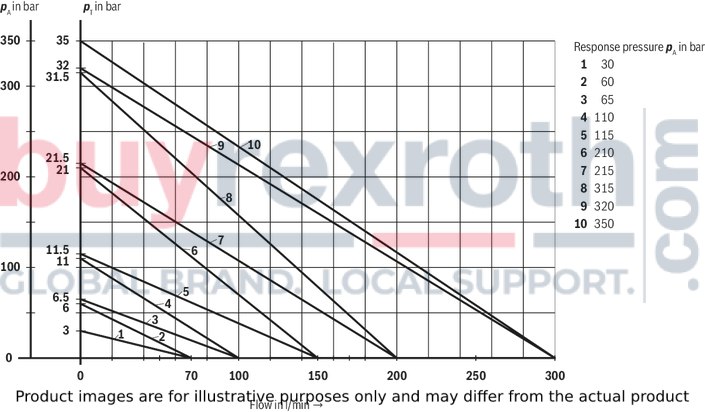

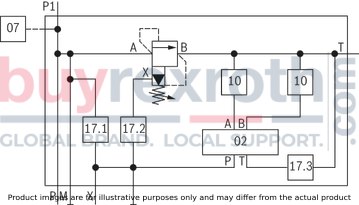

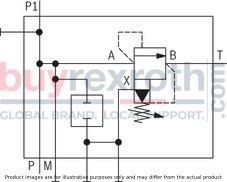

The Bosch Rexroth DBA25H2-2X/200 (R900966021) is a high-performance, pilot-operated industrial hydraulic valve designed for reliable pressure relief in various applications. This mechanically actuated valve falls under the product group ID DBA, indicating its role as a pump safety block intended for direct mounting onto SAE pressure ports of pumps. The valve's primary function is to limit and control operating pressure within hydraulic systems.

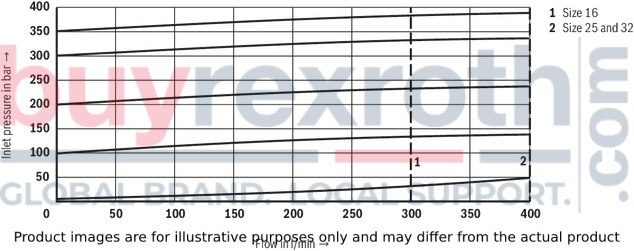

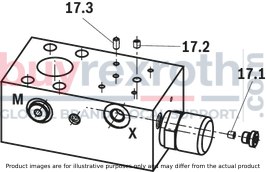

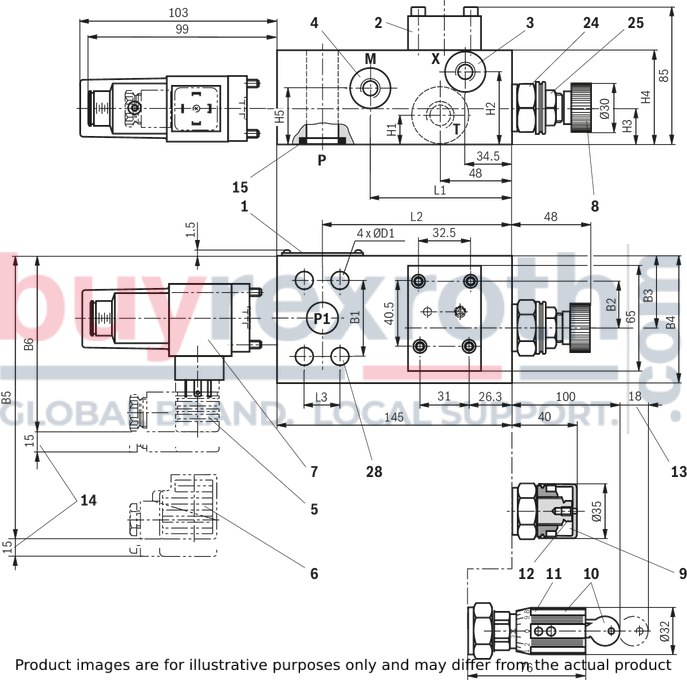

With a size specification of 25 and capable of handling maximum flow rates as specified by the manufacturer, this valve is equipped to manage substantial hydraulic fluid throughput. It features a flange connection type for secure installation and minimal leakage potential. The DBA25H2-2X/200 offers multiple ports for fluid transfer and is characterized by its durable NBR seals that are compatible with a range of hydraulic fluids including HL, HLP, HLPD, HVLP, HVLPD, and HFC.

The valve housing includes port P for fluid input and port T for output to the tank line. A distinctive feature of this model is the pressure limitation screw-in cartridge valve integrated within the block that opens to establish a connection to port T when necessary. This ensures that the set operating pressure is maintained consistently through the main control spool's state of equilibrium.

For monitoring purposes, there is a pressure gauge connection available on the unit. In terms of customization options for pressure adjustment, users can choose from rotary knobs or sleeves with hexagons among others, some featuring protective caps or scales for precise settings.

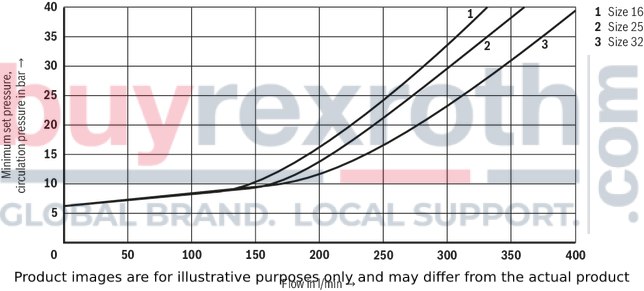

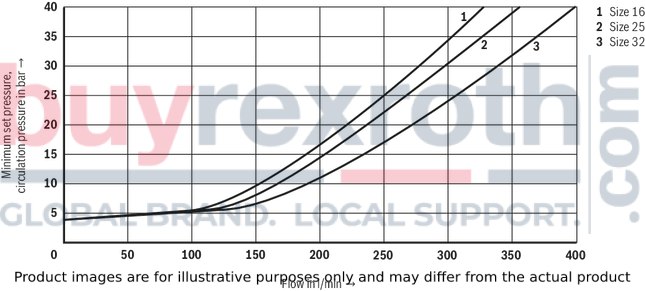

The DBA25H2-2X/200 series X can withstand maximum operating pressures up to the specified bar limit by Bosch Rexroth and demonstrates quick pressure buildup capabilities along with low circulation pressures due to its proximity to the pump when mounted. Its design also contributes to quiet operation—a considerable advantage in noise-sensitive environments.

$1,713.00 USD

More are expected on September 28, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $1,670.17 USD | $42.83 USD |

| 25+ | $1,627.35 USD | $85.65 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as September 28, 2026 when ordered in