Accessories for R900949286

SERVO DIRECTIONAL VALVE 4WS2EM10-5X/60B11ET315K31EV

Manufacturer: Bosch Rexroth

Material #: R900949286

Model : 4WS2EM10-5X/60B11ET315K31EV

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

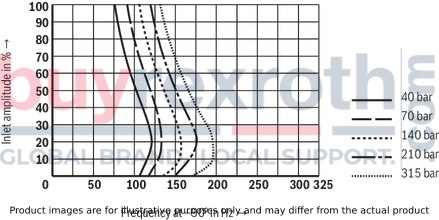

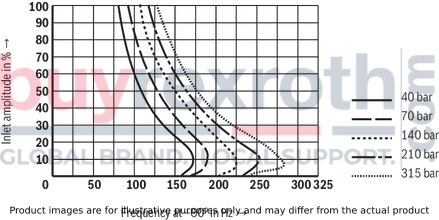

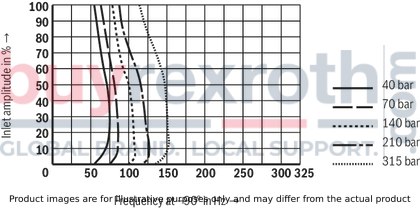

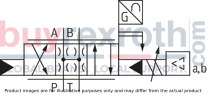

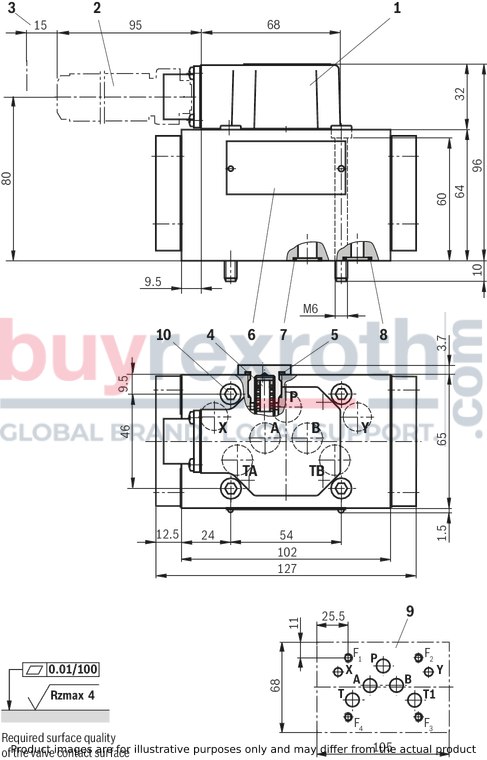

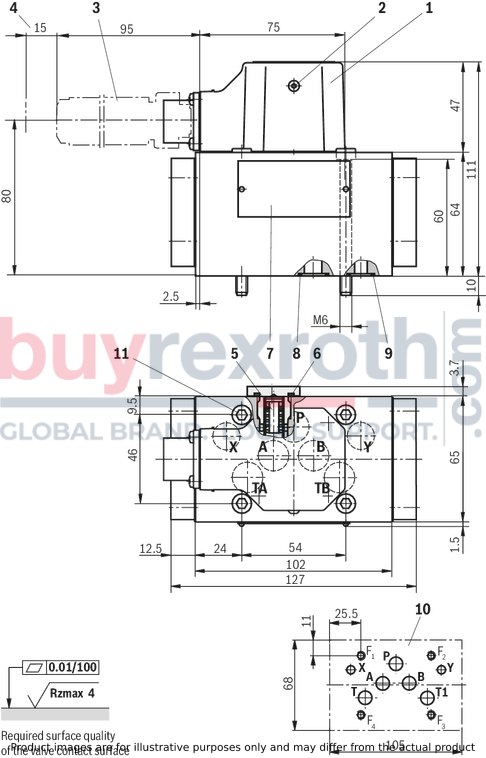

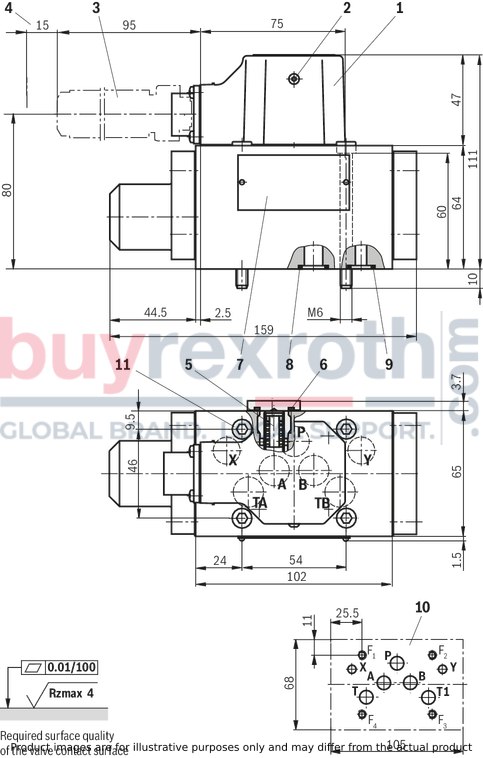

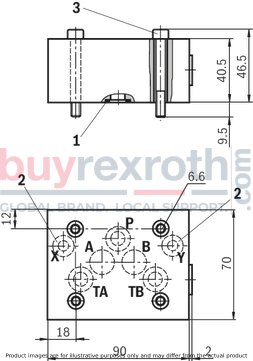

The Bosch Rexroth 4WS2EM10-5X/60B11ET315K31EV (R900949286) is a high-performance industrial hydraulic valve designed for reliable and quick control of oil flow direction, with a focus on accuracy due to its internal piston position feedback. The valve features a nozzle and flapper plate mechanism for direct actuation and operates at a maximum pressure, with electrical connection via a connector pole PE according to DIN EN. This model is suited for subplate mounting and follows the connection diagrams of NFPA T..R D Size CETOP D and ISO standards.

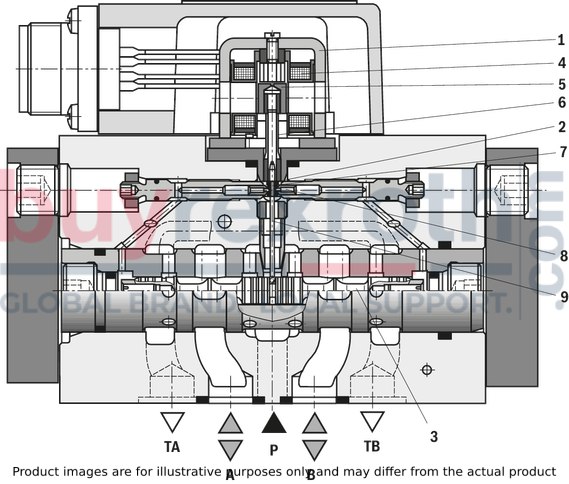

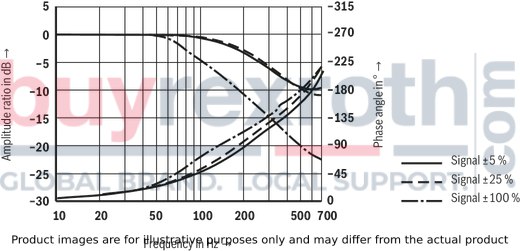

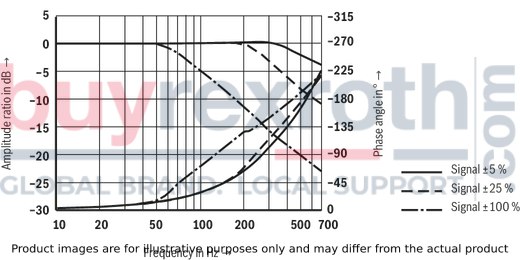

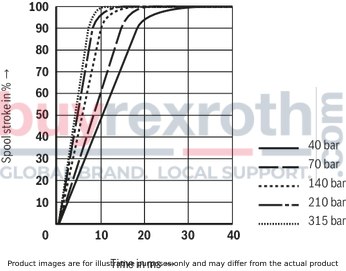

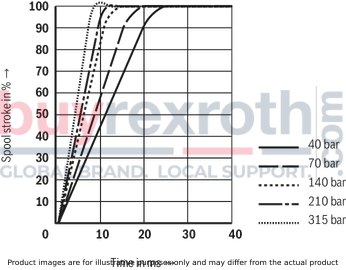

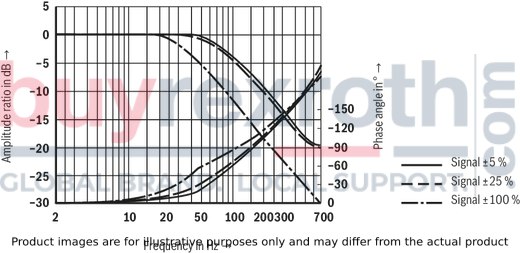

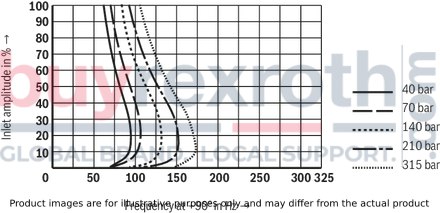

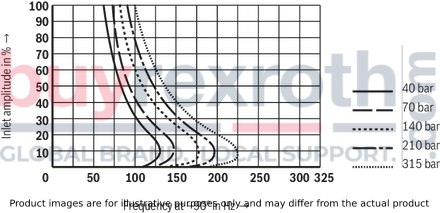

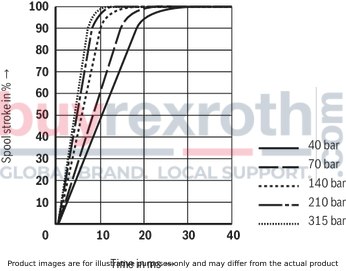

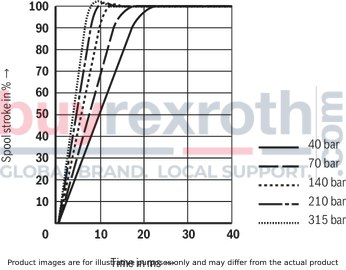

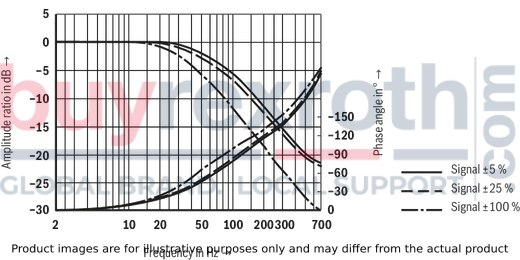

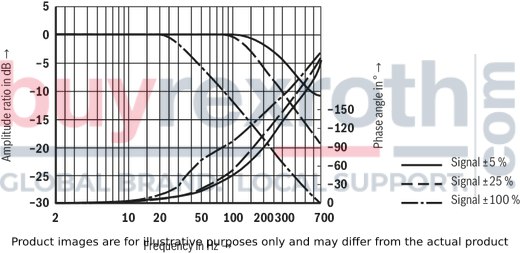

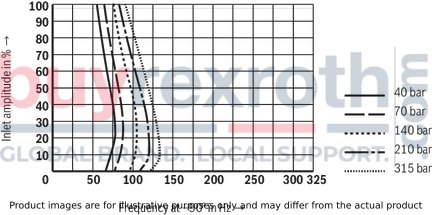

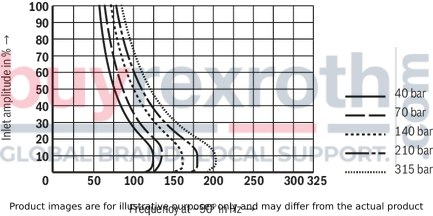

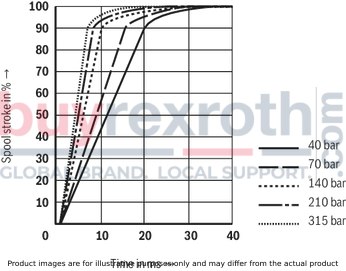

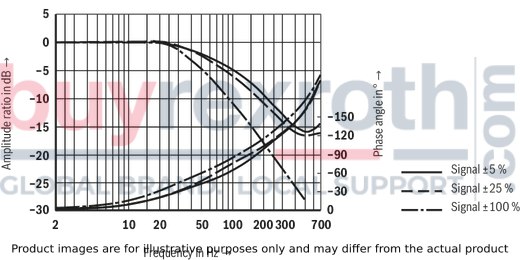

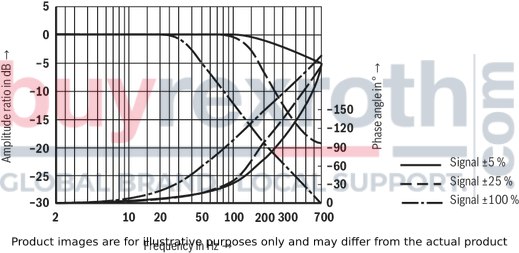

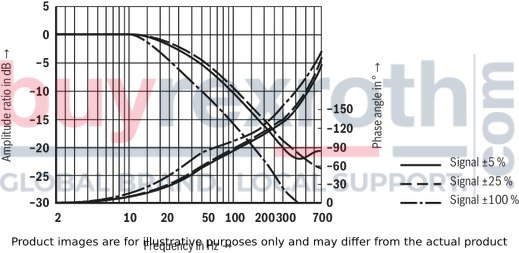

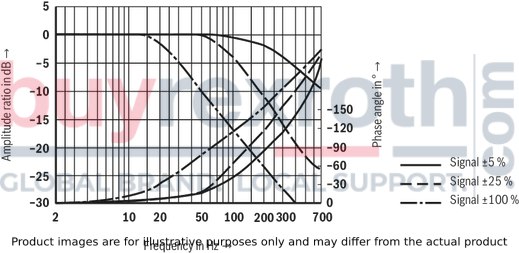

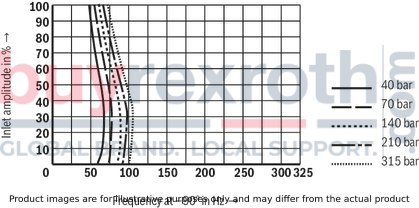

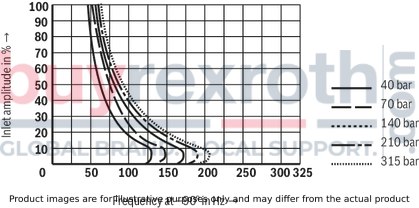

The 4WS2EM10-5X/60B11ET315K31EV valve is capable of controlling position, force, velocity, and pressure with its two-stage servo operation that includes mechanical or combined mechanical and electrical feedback systems. The first stage consists of a nozzle-flapper plate amplifier, while the second stage involves a control spool in a sleeve. It utilizes an electromechanical converter torque motor that translates electrical input signals into precise movement of the control spool through mechanical feedback.

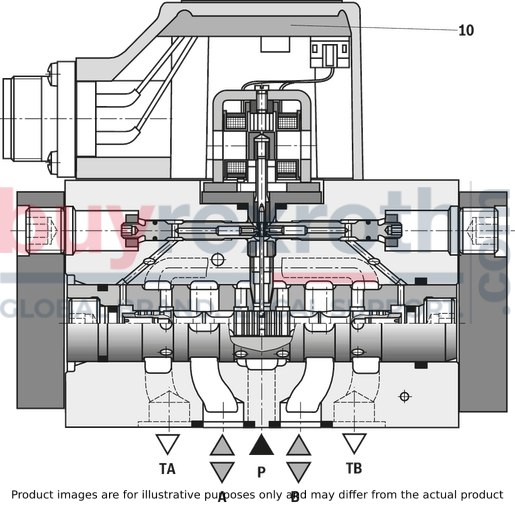

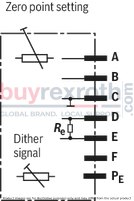

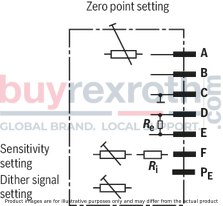

For external actuation, this valve requires separate order external control electronics (type WSEMX...), which amplify analog input signals ensuring controlled flow through the servo valve. Integrated control electronics models (WSEEMX... and WSEEDX...) come with specialized control electronics adjusted for this type of valve, featuring externally accessible potentiometers for zero point adjustments.

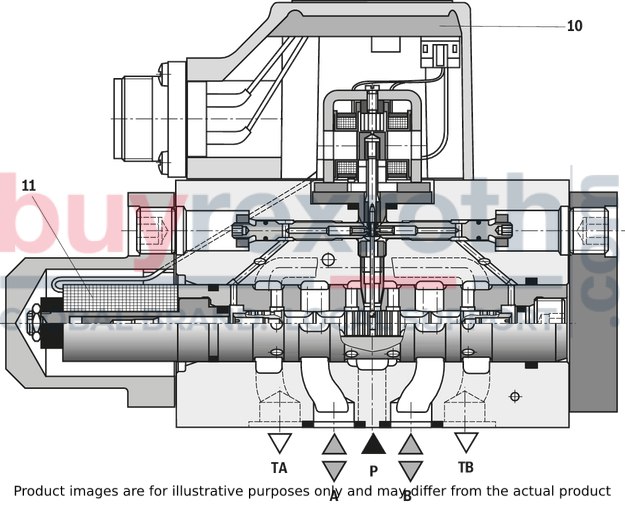

The WSEEDX variant includes electric spool position detection and control for enhanced dynamics compared to purely mechanical systems. In case of electric supply failure, its mechanical feedback ensures the valve spool remains within the zero range.

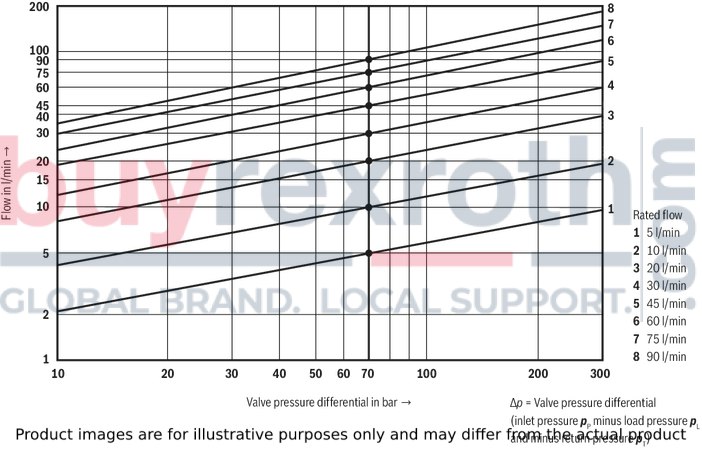

Key specifications include multiple ports for versatile connectivity, VDC supply voltage requirement, various switching positions available, FKM seals compatibility with different hydraulic fluids like HL, HLPD among others, and a nominal flow rate specification. The device's size corresponds to industry standards ensuring compatibility across various applications. Users should note that changes in the zero point are sensitive procedures that must be conducted by trained specialists to avoid system damage.

$9,076.00 USD

More are expected on September 10, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.Status: This product is temporarily out of stock.

Qty: Delivered as early as September 10, 2026 when ordered in