Intended use

Internal gear pumps are intended for the assembly of hydraulic drive systems in machine and system construction.

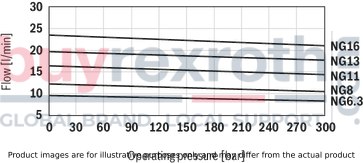

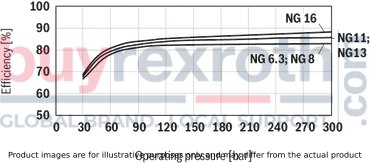

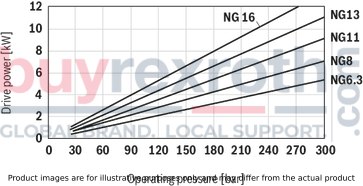

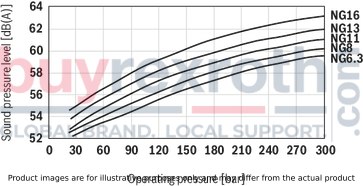

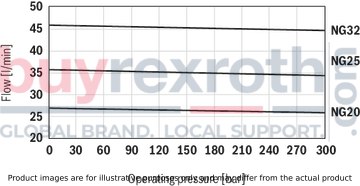

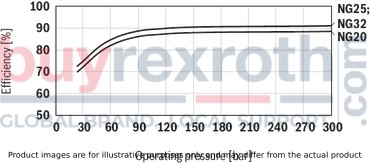

Technical data

The system or machine manufacturer must ensure compliance with the permissible technical data and operating conditions. The pump itself does not contain a device to prevent operation outside the permissible data. It is possible to operate the pump outside of the permissible technical data to a certain extent; the express written consent from Bosch Rexroth is, however, required.

All specified technical performance features are median values and apply with the specified general conditions. In case of modifications to the general conditions (e.g., viscosity), the technical data may change as well. Scatter corresponding to the relevant state of technology is possible.

Hydraulic project planning

Air bleeding option for commissioning

For Rexroth PGP2-2X internal gear pumps, a manual or switchable air bleeding option for the initial commissioning or any recommissioning after maintenance and repair work is to be provided. The air bleeding point is to be set in the pressure line before the first valve or check valve. Air bleeding may be performed with a maximum counter pressure of 0,2 bar.

Examples of air bleeding circuits

Switchable bleeding

Manually operated bleeding

Suction line

The line cross sections are to be dimensioned for the specified flows such that an ideal suction speed of 0.6 to 1.2 m/s is achieved on average. The suction speed should not exceed a maximum value of 2 m/s.

The suction cross sections at the pump itself are designed for the maximum flow and therefore serve only as reference. In case of continuous operation at rotational speeds lower than the permissible maximum speed, the suction tube diameter is also to be dimensioned smaller than the suction port of the pump depending on the actual suction speed.

Overall, the suction line is to be designed so that the permissible inlet operating pressure is maintained. Bends and a combination of suction pipes from several pumps are to be avoided. If the use of a suction filter is unavoidable, it must be ensured on the system side that the lowest permissible inlet operating pressure is not exceeded even if the filter is contaminated.

Ensure the air tightness of the transitions and the pressure resistance of the suction hose with respect to the external air pressure.

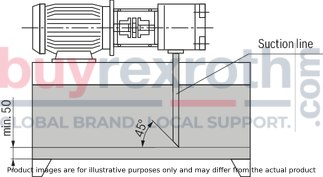

The immersion depth of the suction pipe should be selected as large as possible (at least 100 mm at the lowest fluid level). Depending on the internal reservoir pressure, the viscosity of the operating medium and the flow conditions within the reservoir, no vortex may form even at maximum flow. There is otherwise a risk of air being drawn in. Return fluid and case drain fluid must not be immediately be drawn in again.

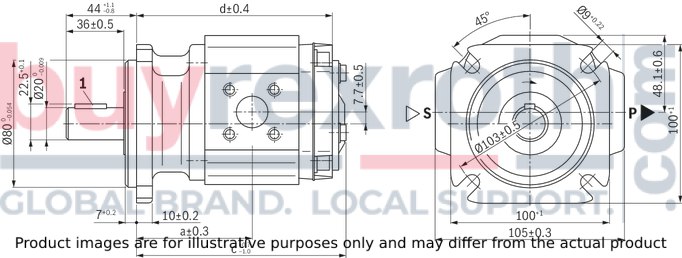

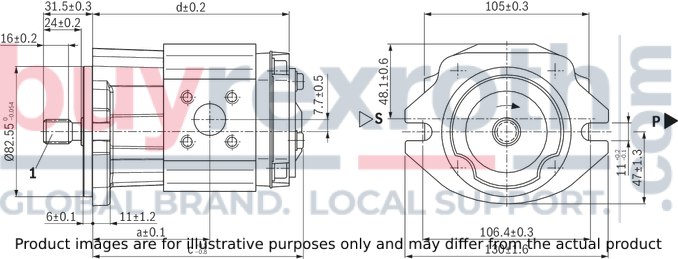

Dimensions in mm

Pressure line

Sufficient burst resistance of the pipes, hoses and connecting elements must be ensured for pressure lines. The cross sections should be based on the maximum flow in order to avoid additional excessive loading of the pump due to back-pressure. Here, you must also take into account the pipe losses over the entire pressure line length and other line resistances (e.g., bends, pressure filters).

Pressure safeguarding

The PGP internal gear pump does not include any devices for adherence to the maximum operating pressure. The setting and safeguarding of the permissible operating pressure must be ensured on the system side.

The pressure-relief valves necessary for this purpose are to be designed with consideration given to the maximum flow and the rate of pressure increase that will occur such that the permissible intermittent operating pressure is not exceeded.

Pressure holding function

In the variable-speed drive, the pump can also be temporarily operated in the pressure holding function below the specified minimum rotational speed. The holding time and the rotational speed necessary for this purpose are a function of the operating viscosity and the pressure level. For the design, please contact Bosch Rexroth‘s technical sales department.

In the deactivated state (rotational speed = 0), a leakage flow flows through the pump back into the reservoir, depending on the load pressure. If this is to be prevented, a check valve is to be used.

When using a check valve, please observe the note on the air bleeding option for commissioning.

Mechanical project planning

Mounting

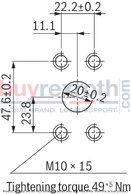

On the machine side, the screws are to be accessible in such a way that the required tightening torque can be applied. The screw tightening torque is oriented towards the operating conditions and elements involved in the screw connection and is to be specified by the manufacturer during project planning of the power unit, the machine, or the system.

Reservoir

When designing the reservoir or selecting a suitable standard reservoir, the following requirements are to be observed:

Select the largest possible reservoir volume, depending on the continuous or average flow, which is needed in order to allow separation of air bubbles by means of sufficient dwell time of the medium in the reservoir. The air separation ability of the used hydraulic fluid is also of importance here. Provide settling zones for the hydraulic fluid in the reservoir in order to allow for air separation. Provide guiding plates in order to allow contamination at the reservoir bottom to be deposited outside the pump suction area. Generously dimension the reservoir surfaces depending on the heat output to be dissipated via the reservoir walls.

Required power unit functions

At a minimum, the hydraulic power units should be equipped with the following features:

Reservoirs that are designed so that the internal pressure corresponds to the ambient pressure should be equipped with ventilation filters for pressure compensation purposes. The hydraulic fluid should only be filled using filling nozzles that eliminate the possibility of filling with unfiltered fluid. The ingress of contamination or moisture must be avoided. If used in highly contaminated environments, the reservoir must, for this purpose, be precharged by means of air pressure. If cleaning of the reservoir exterior is planned or anticipated during the period of use, reservoir bushings for pipes, lines, or hoses are to be selected so that a secure seal is ensured against external pressurization with a water jet.

Place of installation and ambient conditions

With places of installation at a geodetic height of more than 1000 m, the pump is to be arranged in or below the reservoir or the reservoir is to be precharged by means of compressed air in order to ensure the permissible minimum inlet pressure. A short suction line with large cross section is to be selected; bends should not be used.

When installing the pump more than 10 m below the reservoir, the reduction of the inlet pressure to the maximum permissible value must be ensured by means of additional measures.

If operating the pump in salt-containing or corrosive environments or if there is a possibility of pressurization with strongly abrasive substances, it must be ensured on the system side that the shaft seal ring and the sealing area of the shaft do not make direct contact with the environment.

Drive

Electric motor + pump support + coupling + pump

No radial or axial forces permissible on the pump drive shaft! Motor and pump must be exactly aligned! Always use a coupling that is suitable for compensating for shaft offsets!

Installation positions

B3

B5

V1

Pump combinations

With pump combinations, make sure that the operating data approved for the pump type concerned can be complied with in every step. Combined pumps must all have the same direction of rotation. The pump with the highest torque, variable pumps or pumps with intermittent pressure loading should be specified as the first step in the pump combination. The engineer must verify the maximum through-drive torque for every application. This also applies for existing (coded) pump combinations. The sum of all input torques in a pump combination may not exceed the permissible input torque of the first pump.

Maximum input torques

|

Shaft version E

|

140 Nm

|

|

Shaft version J

|

90 Nm

|

Formula for input torque

|

|

Key

|

|

T

|

Input torque [Nm]

|

|

Δp

|

Operating pressure [bar]

|

|

V

|

Displacement [cm³]

|

|

η

|

Hydraulic-mechanical efficiency

|

Maximum output torques

|

Shaft version E

|

70 Nm

|

|

Shaft version J

|

70 Nm

|

Common suction is not possible. For reasons of strength and stability, we recommend using ISO 4-hole mounting flanges according to VDMA “E4” for combinations of three or more pumps. Before operating pump combinations with different media, please consult Bosch Rexroth. PGF combinations are installed without combination parts and are not sealed against each other.

Selection

The front pump must have shaft version E or J. The middle pump must have shaft version L. The rear pump must have shaft version N. If a pump of the next smaller frame size is to be mounted, the designation of the first pump must end with “K” (e.g., PGP3 + PGF2 ⇒ front pump: PGP3-3X/032RE07VE4K)

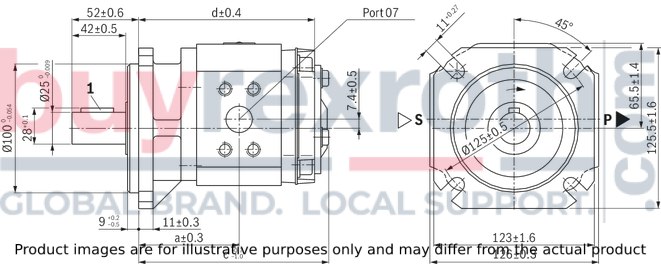

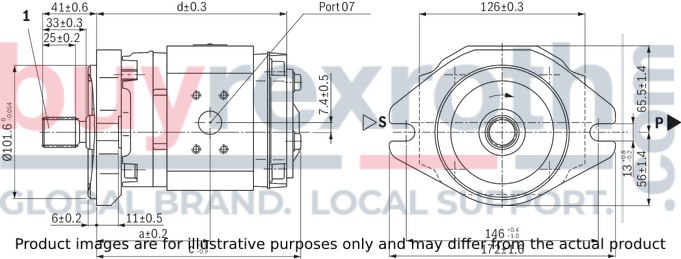

Dimensions

The dimensions of the ports are the same as for single pumps (see dimensions). The total length of the pump combination is calculated by adding up dimensions “d” of the single pumps (see dimensions). With the combination of PGP2 and PGF1, the installation length of the PGP2 (dimension d) increases by 4.5 mm.