***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

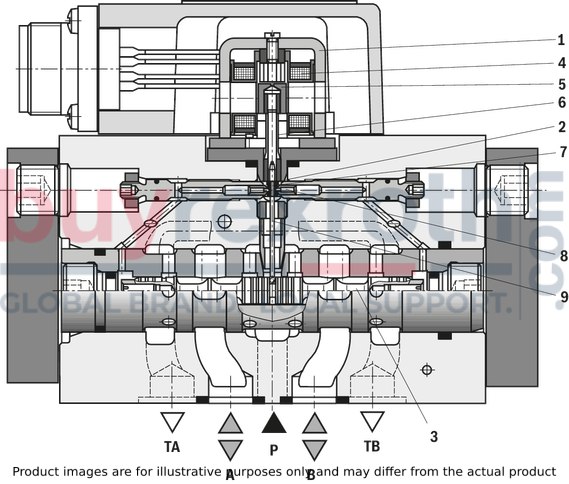

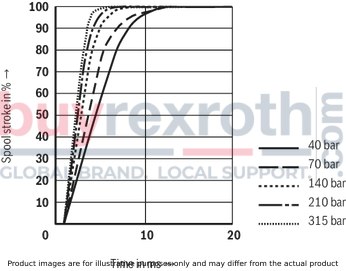

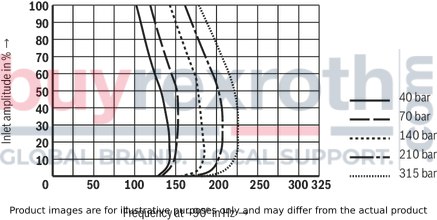

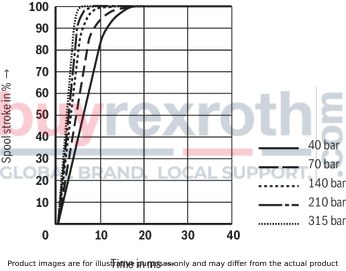

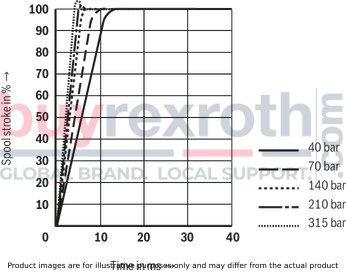

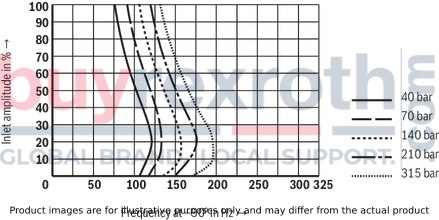

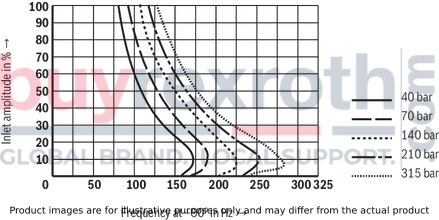

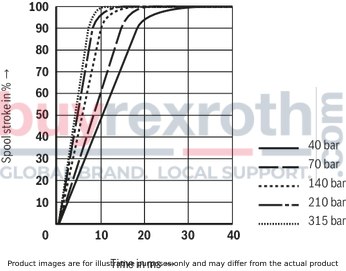

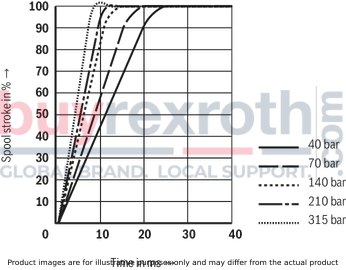

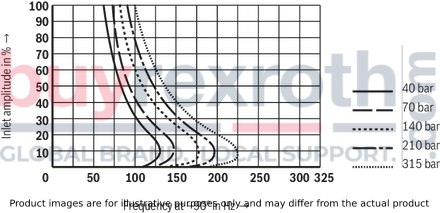

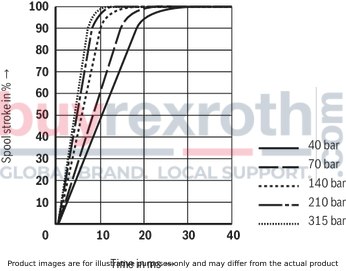

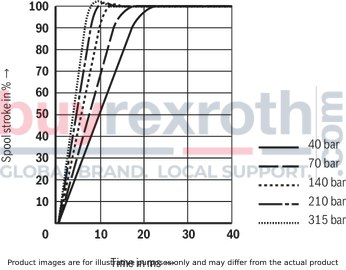

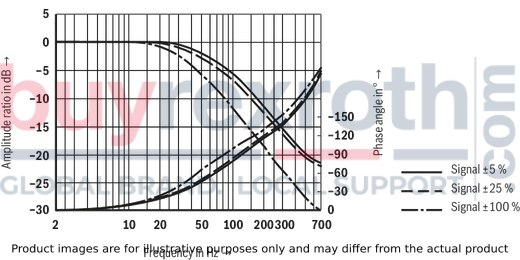

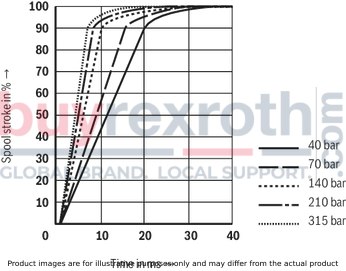

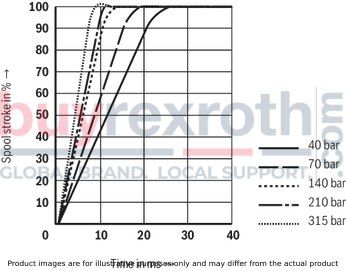

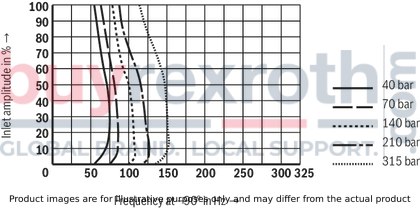

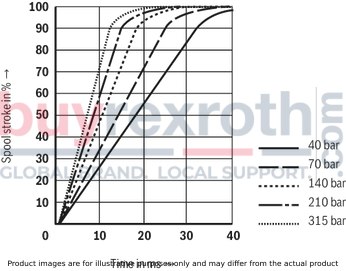

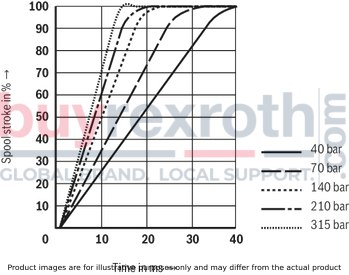

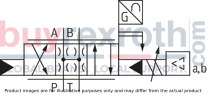

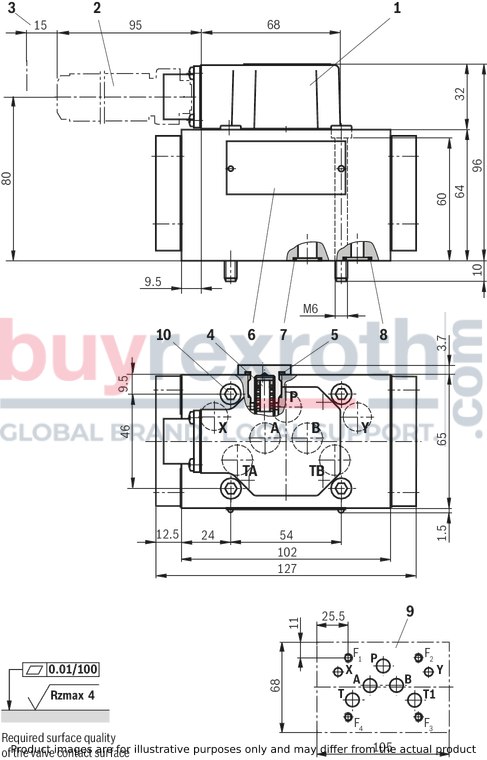

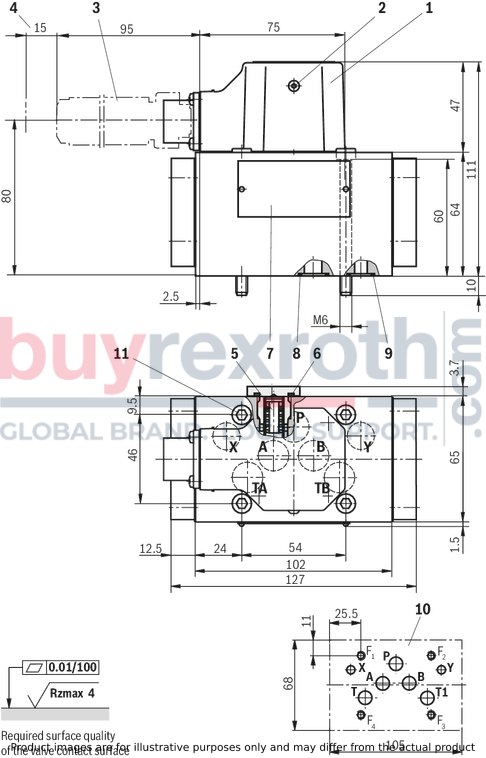

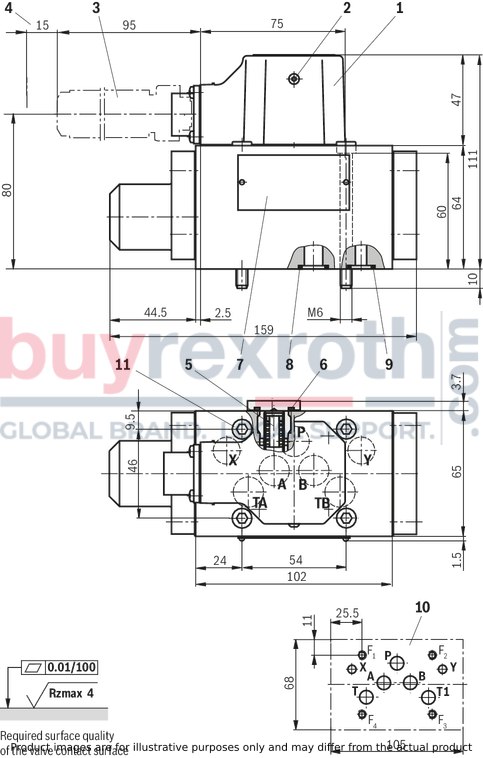

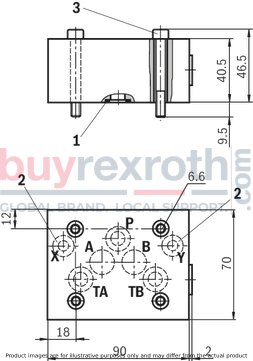

The Bosch Rexroth 4WS2EM10-5X/20B11T315K8DV (R900770650) is an advanced stage directional servo valve designed for precise control of position, force, and velocity in various applications. This valve features an electromechanical converter torque motor, a hydraulic amplifier utilizing the nozzle-flapper plate principle, and a control spool within a sleeve. The torque motor operates via an electrical input signal that generates force through a permanent magnet acting on the armature. This results in the movement of the flapper plate, which creates a pressure differential across the control spool, thus changing its position and controlling the pressure port's connection to the actuator ports.

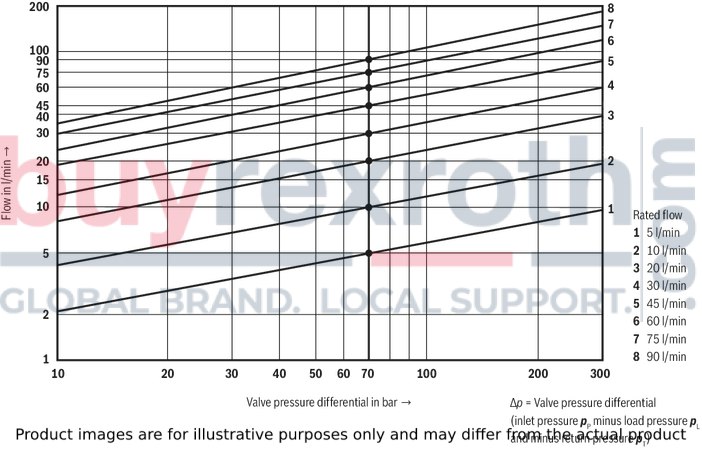

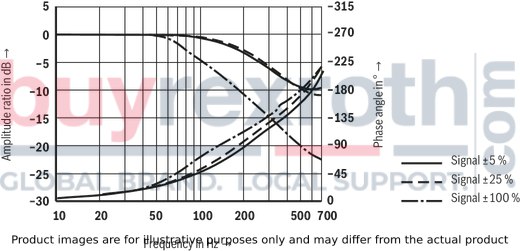

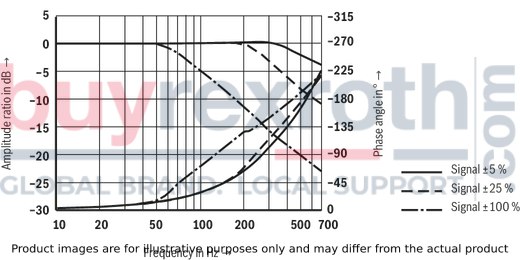

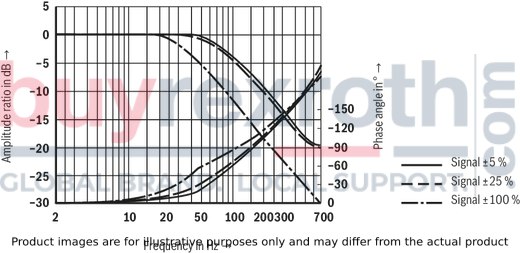

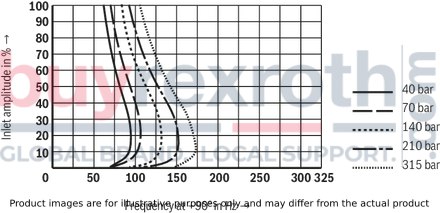

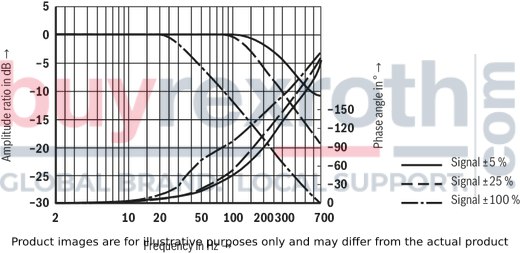

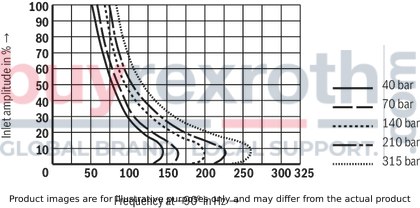

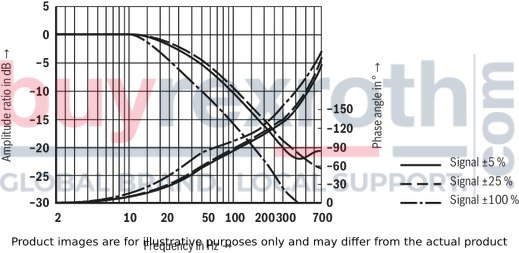

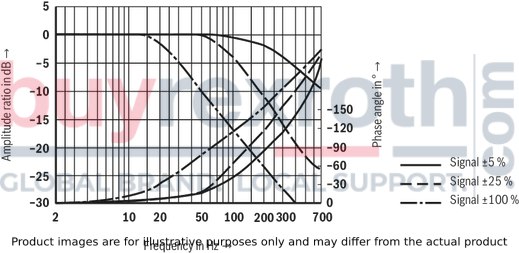

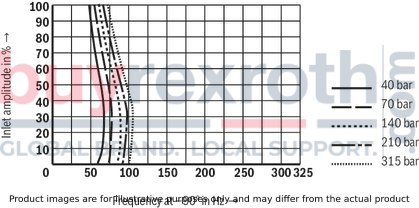

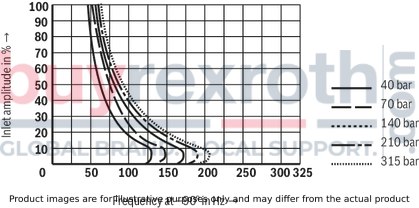

The control spool is mechanically linked to the flapper plate through a bending spring feedback mechanism. It adjusts its position until there is equilibrium between the feedback torque from the bending spring and the electromagnetic torque from the torque motor, at which point there is no pressure differential at the nozzle-flapper plate system. The flow through this servo valve is proportional to the electrical input signal but also dependent on valve pressure drop.

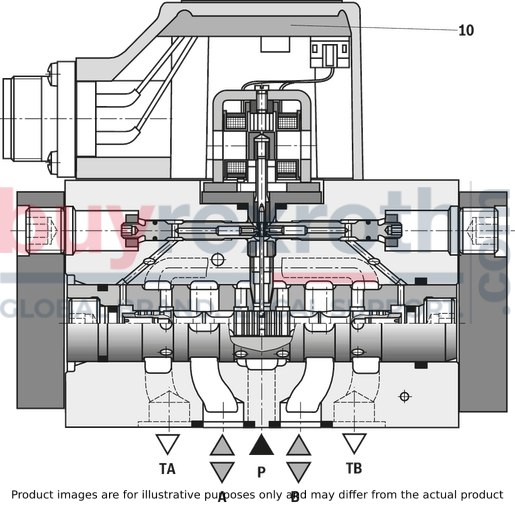

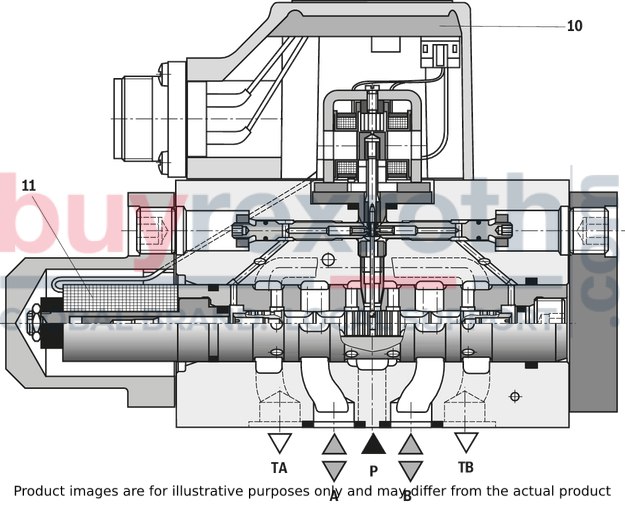

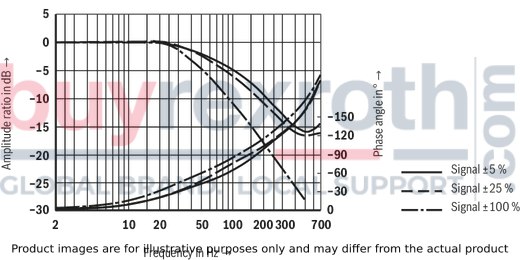

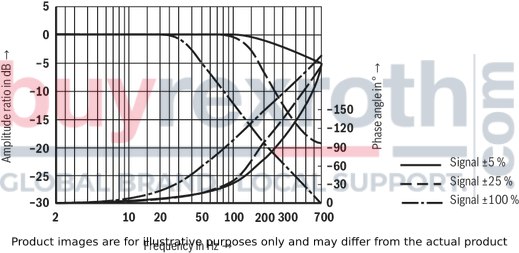

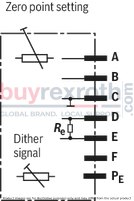

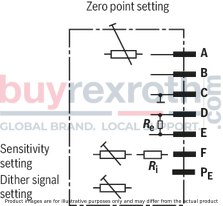

This model incorporates integrated control electronics specifically tailored for this valve type, which amplify analog input signals for precise actuation. An externally accessible potentiometer allows for zero-point adjustments. Additionally, it includes an electric spool position detection and control system for enhanced dynamic values and reliability.

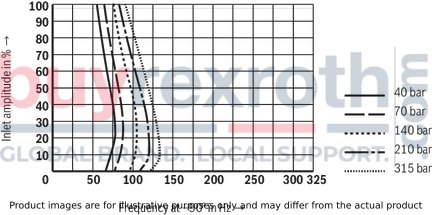

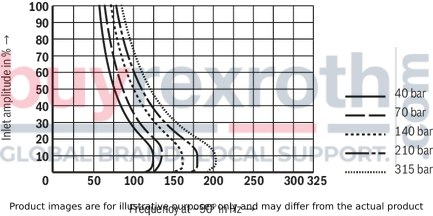

The 4WS2EM10-5X/20B11T315K8DV servo valve boasts several key features such as subplate mounting conforming to ISO standards, dry control motor preventing solenoid gap contamination by hydraulic fluid, flow force compensation in its control spool, and easily accessible filters for maintenance. It has a maximum operating pressure of 315 bar and can handle maximum flow rates of 20 liters per minute. It's important to note that any adjustments to this system should be performed by trained specialists due to potential risks of damage to equipment if improperly handled.

$7,895.00 USD

More are expected on October 7, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.Status: This product is temporarily out of stock.

Qty: Delivered as early as October 7, 2026 when ordered in