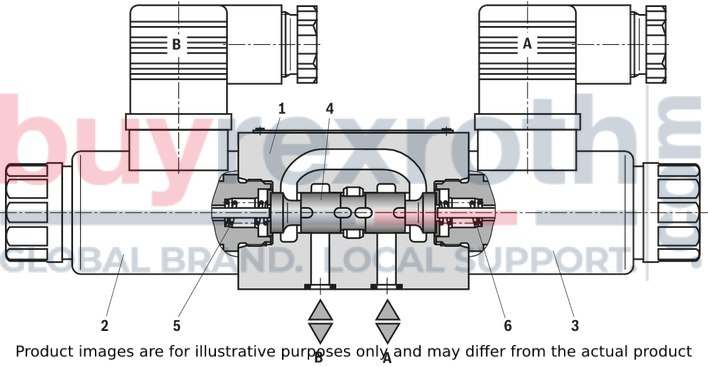

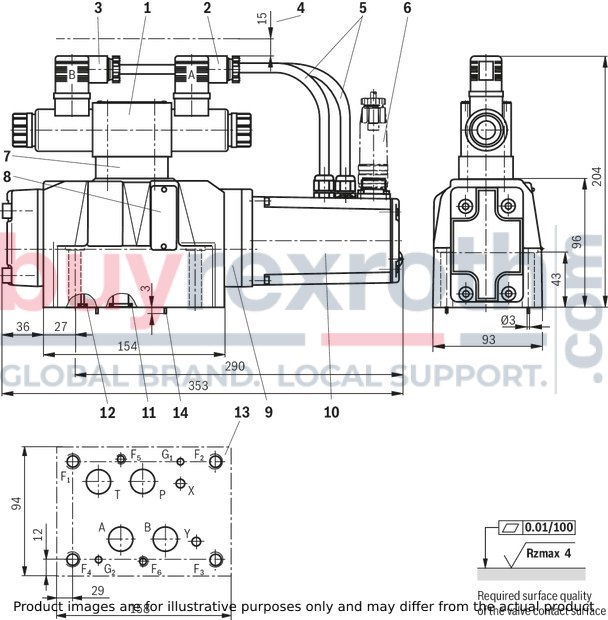

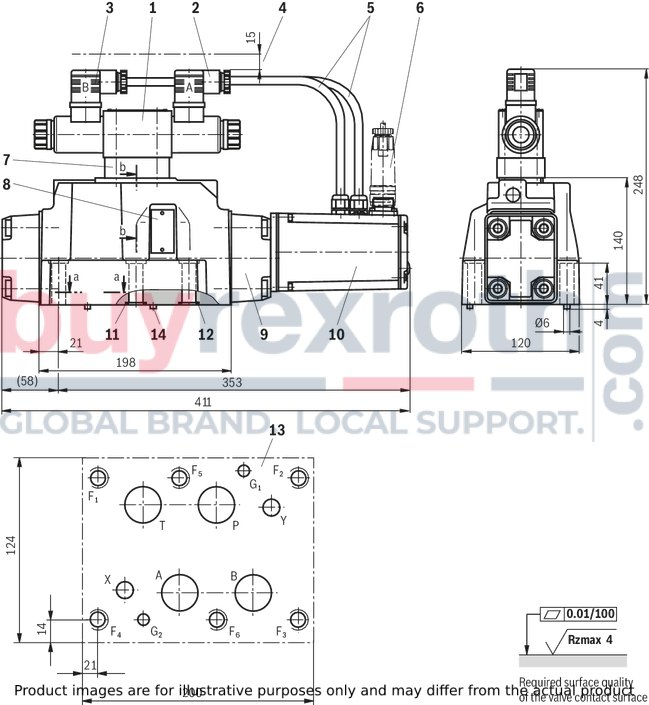

Size 10

Dimensions in mm

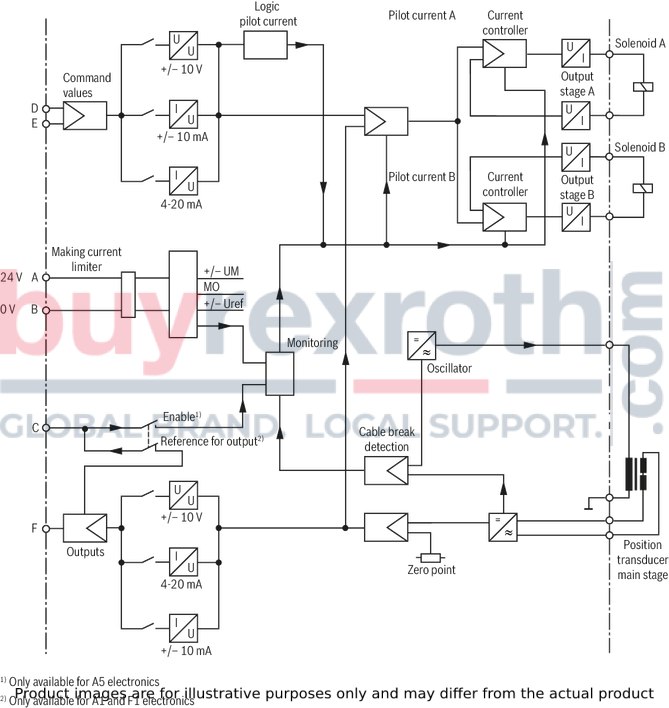

|

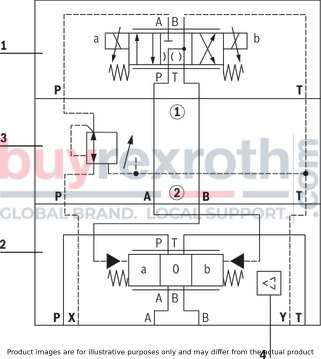

1

|

Pilot control valve

|

|

2

|

Mating connector "A", color gray

|

|

3

|

Mating connector "B", color black

|

|

4

|

Space required for the connection cable and to remove the mating connector

|

|

5

|

Cabling

|

|

6

|

Mating connector, separate order

|

|

7

|

"D3” pressure reducing valve

|

|

8

|

Name plate

|

|

9

|

Main valve

|

|

10

|

Integrated electronics (OBE)

|

|

11

|

Identical seal rings for ports A, B, P, and T

|

|

12

|

Identical seal rings for ports X and Y

|

|

13

|

Machined valve contact surface; Porting pattern according to ISO 4401-05-05-0-05

- Ports X and Y as required

|

Recommended valve mounting screws (separate order):

4 hexagon socket head cap screws ISO 4762 - M6 x 45 - 10.9-flZn-240h-L

Tightening torque MA = 13.5 Nm ± 10 %, material no. R913000258 or

4 hexagon socket head cap screws ISO 4762 - M6 x 45 - 10.9

Tightening torque MA = 15.5 Nm ± 10 %

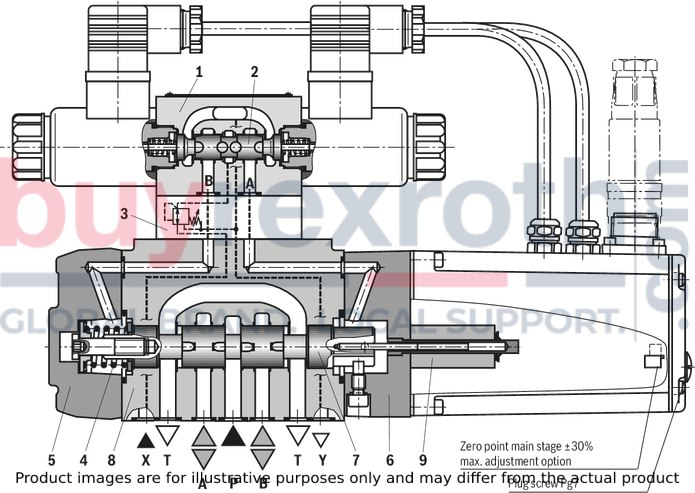

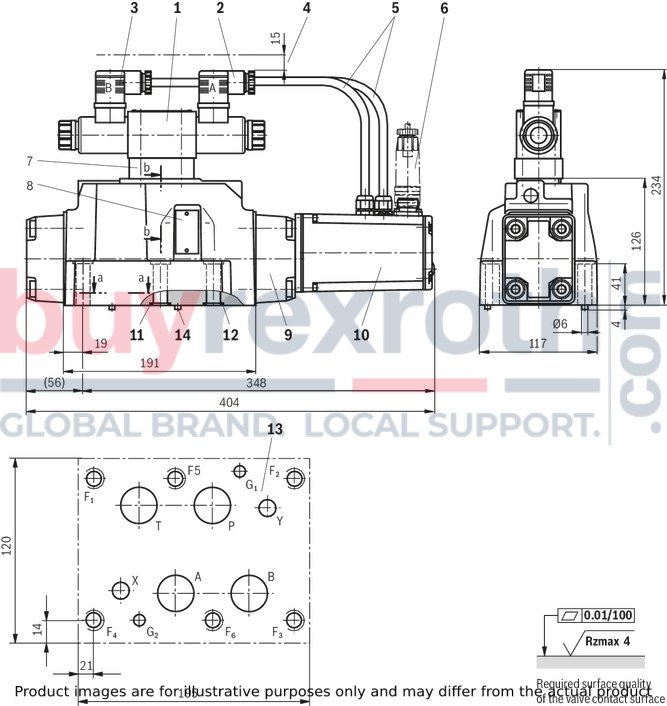

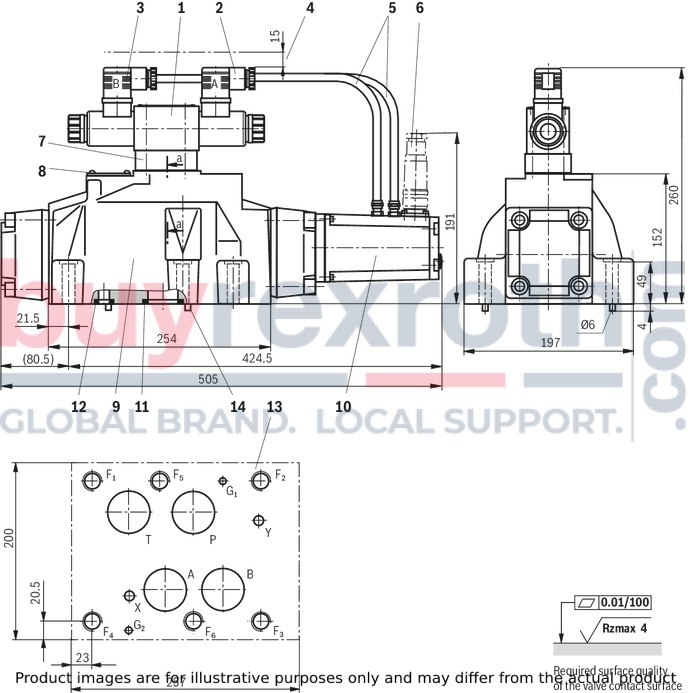

Size 16

Dimensions in mm

|

1

|

Pilot control valve

|

|

2

|

Mating connector "A", color gray

|

|

3

|

Mating connector "B", color black

|

|

4

|

Space required for the connection cable and to remove the mating connector

|

|

5

|

Cabling

|

|

6

|

Mating connector, separate order

|

|

7

|

"D3” pressure reducing valve

|

|

8

|

Name plate

|

|

9

|

Main valve

|

|

10

|

Integrated electronics (OBE)

|

|

11

|

Identical seal rings for ports A, B, P, and T

|

|

12

|

Identical seal rings for ports X and Y

|

|

13

|

Machined valve contact surface; Porting pattern according to ISO 4401-07-07-0-05

Deviating from the standard:

Ports P, A, B, T Ø20 mm

Minimum screw-in depth:

- Ferrous metal 1.5 x Ø

- Non-ferrous metal 2 x Ø

|

|

14

|

Locking pin

|

Recommended valve mounting screws (separate order):

2 hexagon socket head cap screws ISO 4762 - M6 x 60 - 10.9-flZn-240h-L

Tightening torque MA = 12.2 Nm ± 10 % , material no. R913000115

4 hexagon socket head cap screws ISO 4762 - M10 x 60 - 10.9-flZn-240h-L

Tightening torque MA = 58 Nm ± 20 %, material no. R913000116 or

2 hexagon socket head cap screws ISO 4762 - M6 x 60 - 10.9

Tightening torque MA = 15.5 Nm ± 10 %

4 hexagon socket head cap screws ISO 4762 - M10 x 60 - 10.9

Tightening torque MA = 75 Nm ± 20 %

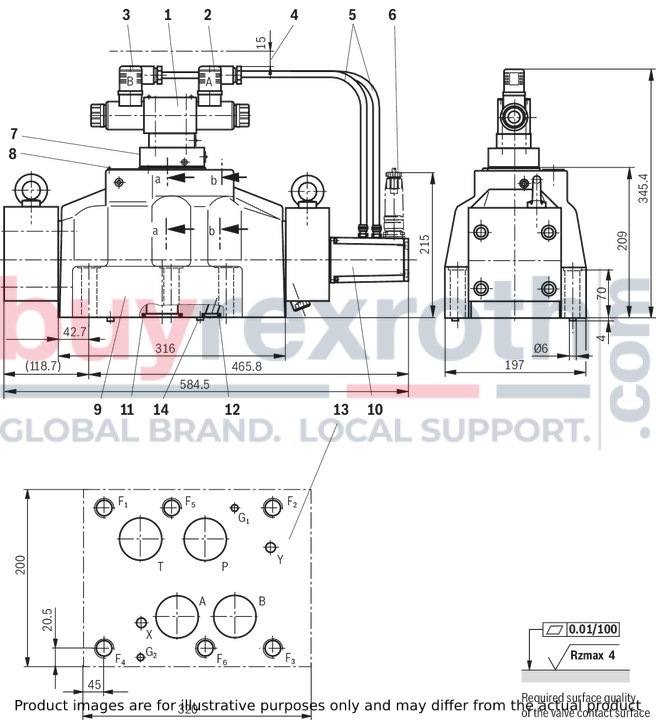

NG25

Dimensions in mm

|

1

|

Pilot control valve

|

|

2

|

Mating connector "A", color gray

|

|

3

|

Mating connector "B", color black

|

|

4

|

Space required for the connection cable and to remove the mating connector

|

|

5

|

Cabling

|

|

6

|

Mating connector, separate order

|

|

7

|

"D3” pressure reducing valve

|

|

8

|

Name plate

|

|

9

|

Main valve

|

|

10

|

Integrated electronics (OBE)

|

|

11

|

Identical seal rings for ports A, B, P, and T

|

|

12

|

Identical seal rings for ports X and Y

|

|

13

|

Machined valve contact surface; Porting pattern according to ISO 4401-08-08-0-05 (ports X and Y as required)

|

|

14

|

Locking pin

|

NG27

Dimensions in mm

|

1

|

Pilot control valve

|

|

2

|

Mating connector "A", color gray

|

|

3

|

Mating connector "B", color black

|

|

4

|

Space required for the connection cable and to remove the mating connector

|

|

5

|

Cabling

|

|

6

|

Mating connector, separate order

|

|

7

|

"D3” pressure reducing valve

|

|

8

|

Name plate

|

|

9

|

Main valve

|

|

10

|

Integrated electronics (OBE)

|

|

11

|

Identical seal rings for ports A, B, P, and T

|

|

12

|

Identical seal rings for ports X and Y

|

|

13

|

Machined valve contact surface; Porting pattern according to ISO 4401-08-08-0-05 (Ports X, Y as required)

Deviating from the standard:

Ports A, B, T and P Ø32 mm

|

|

14

|

Locking pin

|

Recommended valve mounting screws (separate order):

6 hexagon socket head cap screws ISO 4762 - M12 x 60 - 10.9-flZn-240h-L

Tightening torque MA = 100 Nm ± 20 %, material no. R913000121 or

6 hexagon socket head cap screws ISO 4762 - M12 x 60 - 10.9

Tightening torque MA = 130 Nm ± 20 %

Size 32

Dimensions in mm

|

1

|

Pilot control valve

|

|

2

|

Mating connector "A", color gray

|

|

3

|

Mating connector "B", color black

|

|

4

|

Space required for the connection cable and to remove the mating connector

|

|

5

|

Cabling

|

|

6

|

Mating connector, separate order

|

|

7

|

"D3” pressure reducing valve

|

|

8

|

Name plate

|

|

9

|

Main valve

|

|

10

|

Integrated electronics (OBE)

|

|

11

|

Identical seal rings for ports A, B, P, and T

|

|

12

|

Identical seal rings for ports X and Y

|

|

13

|

Machined valve contact surface; Porting pattern according to ISO 4401-10-09-0-05 (Ports X and Y as required)

Deviating from the standard:

‒ Ports P, A, B and T Ø38 mm

‒ position G11) according DIN 24340 Form A

|

|

14

|

Locking pin

|

Recommended valve mounting screws (separate order):

6 hexagon socket head cap screws ISO 4762 - M20 x 80 - 10.9-flZn-240h-L

Tightening torque MA = 340 Nm ± 20 %, material no. R901035246 or

4 hexagon socket head cap screws ISO 4762 - M20 x 80 - 10.9

Tightening torque MA = 430 Nm ± 20 %

Size 35

Dimensions in mm

|

1

|

Pilot control valve

|

|

2

|

Mating connector "A", color gray

|

|

3

|

Mating connector "B", color black

|

|

4

|

Space required for the connection cable and to remove the mating connector

|

|

5

|

Cabling

|

|

6

|

Mating connector, separate order

|

|

7

|

"D3” pressure reducing valve

|

|

8

|

Name plate

|

|

9

|

Main valve

|

|

10

|

Integrated electronics (OBE)

|

|

11

|

Identical seal rings for ports A, B, P, and T

|

|

12

|

Identical seal rings for ports X and Y

|

|

13

|

Machined valve contact surface; Porting pattern according to ISO 4401-10-09-0-05 (Ports X and Y as required)

Deviating from the standard:

‒ Ports P, A, B and T Ø50 mm

|

|

14

|

Locating pins

|

Recommended valve mounting screws (separate order):

6 hexagon socket head cap screws ISO 4762 - M20 x 100 - 10.9-flZn-240h-L

Tightening torque MA = 465 Nm ± 20 %, material no. R913000386 or

6 hexagon socket head cap screws ISO 4762 - M20 x 100 - 10.9

Tightening torque MA = 610 Nm ± 20 %