***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

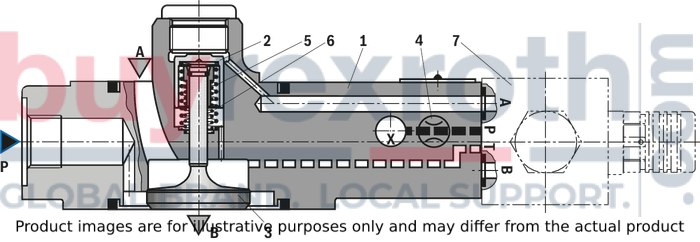

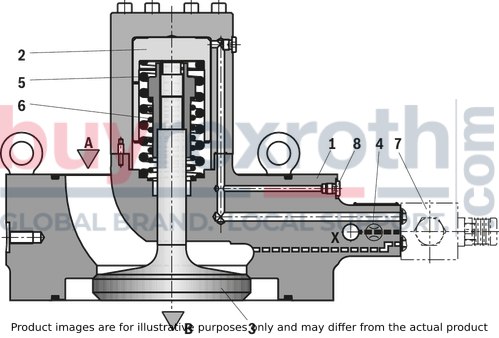

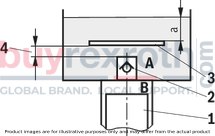

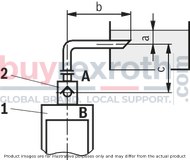

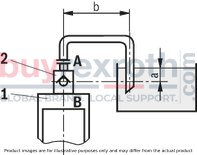

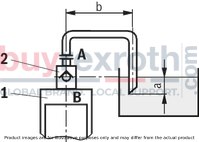

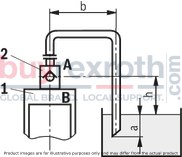

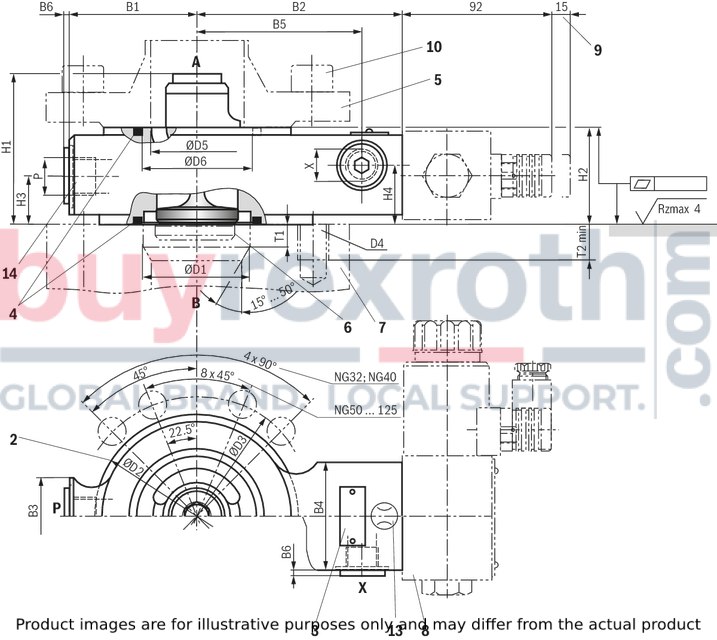

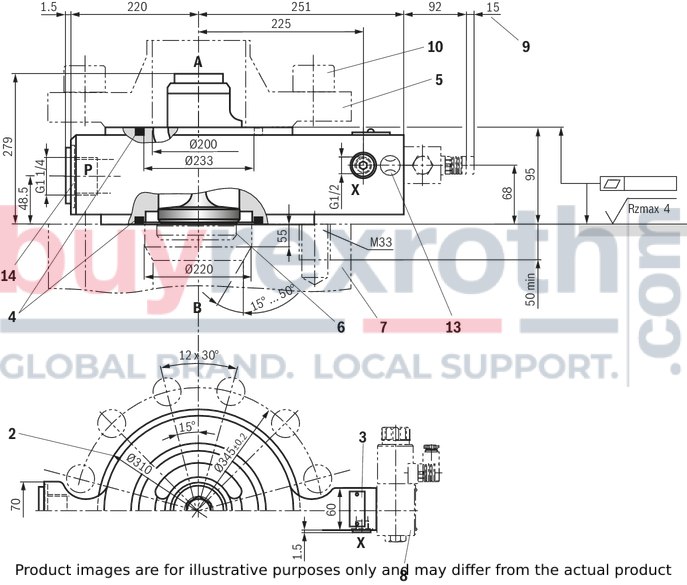

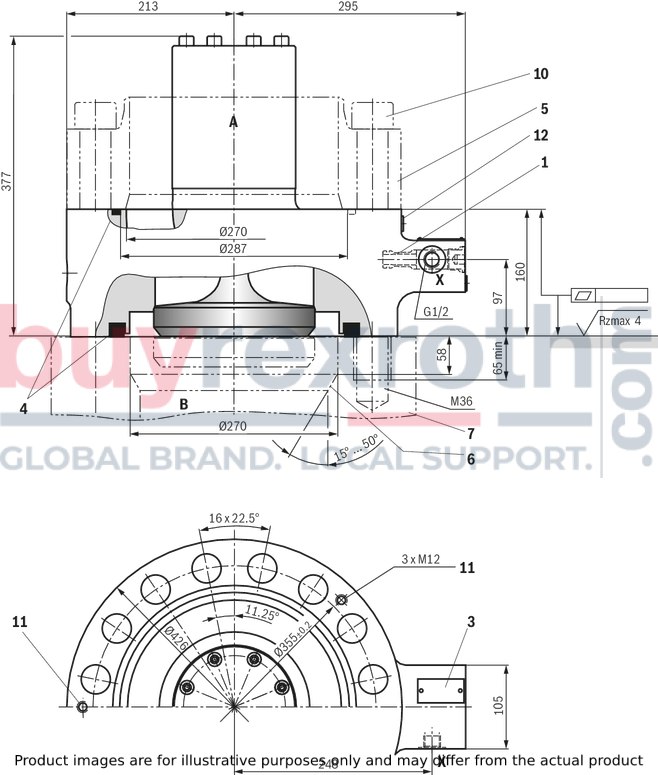

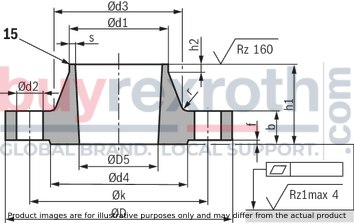

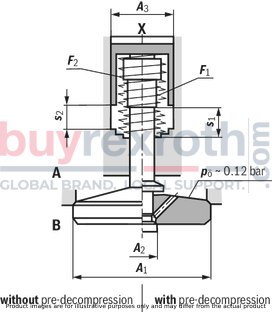

The Bosch Rexroth ZSFW100F1-1-1X/M/01 (R900532516) is a state-of-the-art pilot-operated check valve designed for seamless integration into hydraulic systems. This sandwich plate design valve falls under the Type ZSFW NG category, which is characterized by its lack of predecompression and a built-on directional valve. The control spool operates in a vertical direction, ensuring precise control and reliable operation for various applications.

The model boasts an optional directional valve setup, which must be ordered separately as the Directional valve type WE. This flexibility allows for customization to meet specific system requirements. The high-pressure connection capability of the NG size makes it suitable for demanding environments where maximum operating pressures reach up to 315 bar.

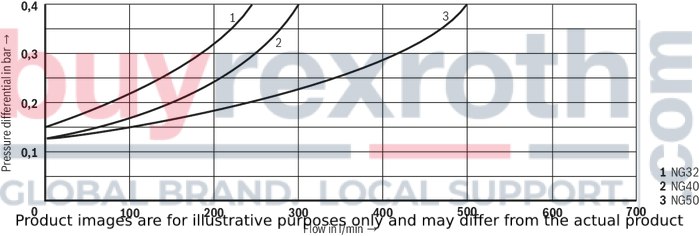

With a maximum flow rate of 100 liters per minute, the ZSFW100F1-1-1X/M/01 ensures efficient fluid control within hydraulic circuits. Its integrated throttle check valve provides additional regulation of the flow, contributing to the overall stability and performance of the system it is part of.

This component belongs to series X, which indicates its adherence to current engineering standards and innovations in hydraulic technology offered by Bosch Rexroth. Its robust design and versatile features make it an essential component for a wide range of hydraulic applications that require precise flow control and reliable backflow prevention mechanisms.

$4,490.00 USD

More are expected on September 30, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $4,377.75 USD | $112.25 USD |

| 25+ | $4,265.50 USD | $224.50 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as September 30, 2026 when ordered in