***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

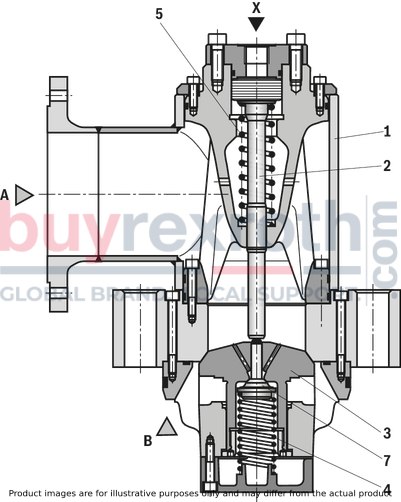

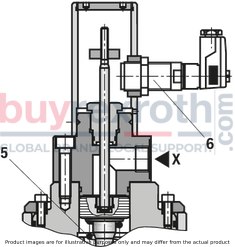

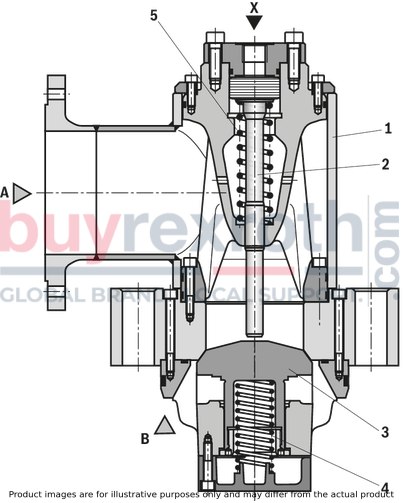

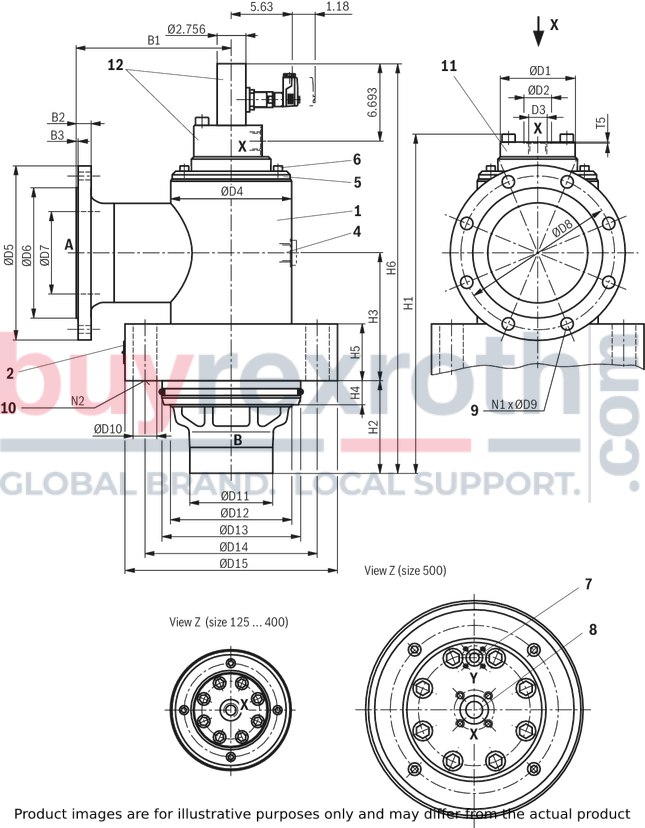

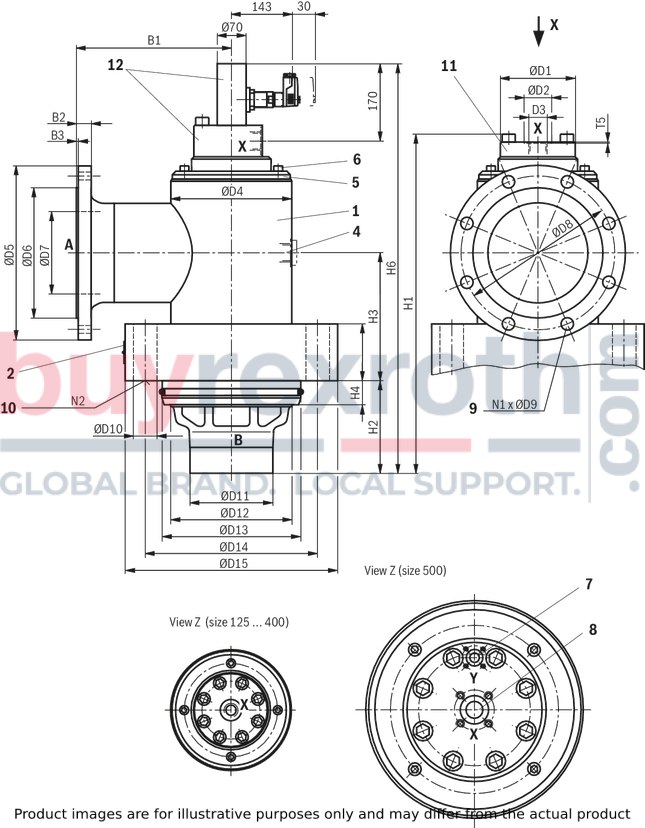

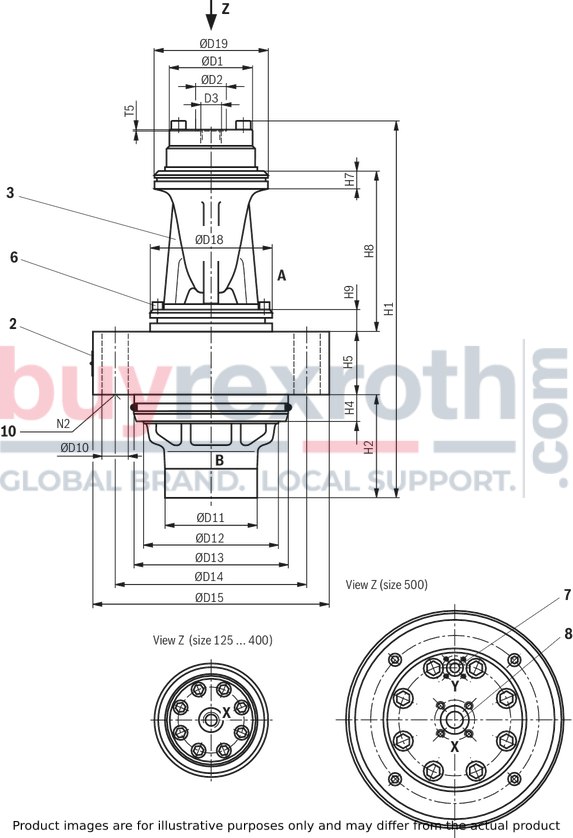

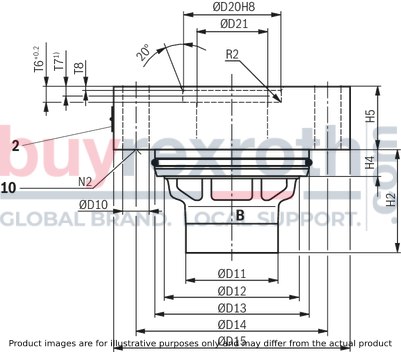

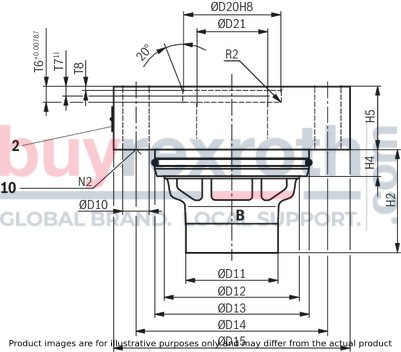

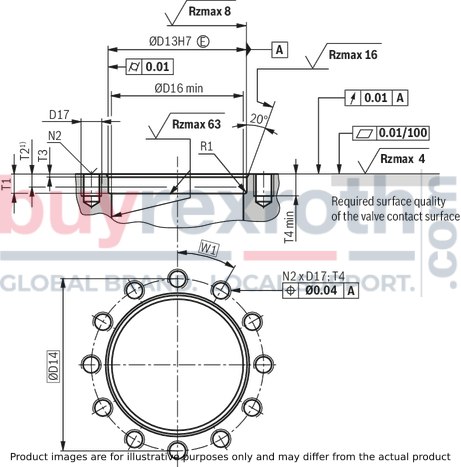

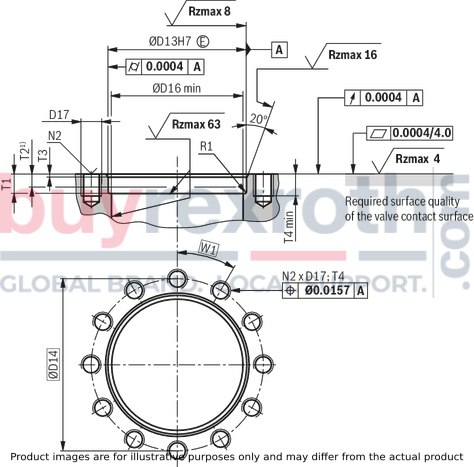

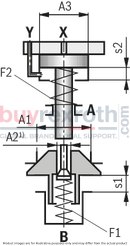

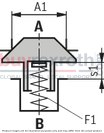

The Bosch Rexroth SF250B1-1-4X/ (R900520907) is a high-quality pilot-operated check valve designed for tank installation and flange connection applications. This model is part of the SF series, which is known for its robust construction and reliable performance in controlling fluid flow within hydraulic systems. The SF250B1-1-4X/ valve features a housing with a low-pressure flange that can be continuously rotated, providing flexibility in installation and maintenance.

Equipped with a control cylinder and designed for ease of use, it includes a nameplate for quick identification. The connection G draining ensures efficient operation, with specified tightening torque parameters to maintain secure connections. Additionally, the product comes with mounting screws and offers optional port Y and X connection flanges upon request. This model has been engineered to reduce switching noises through damping measures, enhancing the operational environment.

The valve's design includes a ring that ensures proper seating within the system, while the number of flange mounting screws are evenly arranged at the circumference type of connection A, ensuring stability and security when mounted. Furthermore, this version of the SF250B1-1-4X/ does not include a position switch but can be ordered in version QGZ if required.

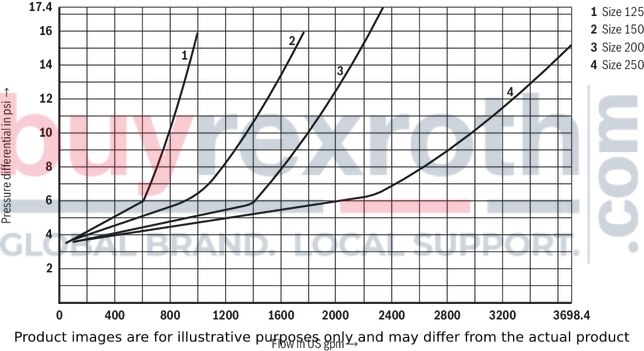

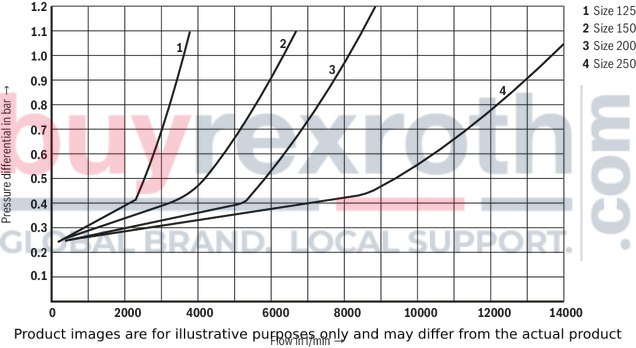

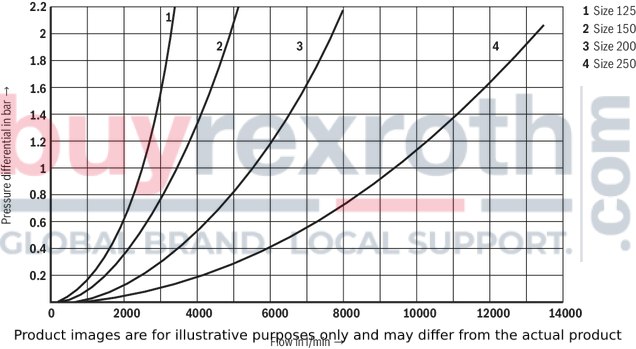

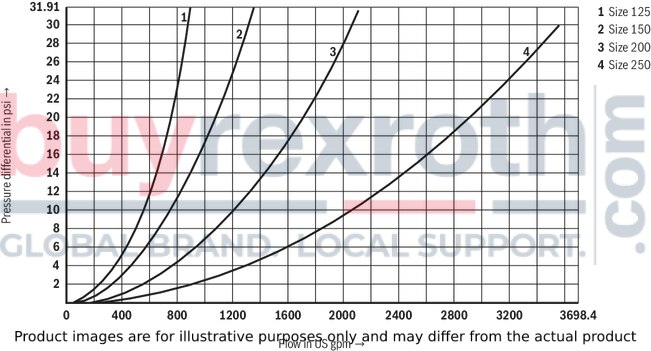

This cartridge valve operates without control open spool check valve functionality and boasts increased operating pressures upon request. Its maximum operating pressure capacity reaches up to bar levels with an impressive maximum flow rate measured in liters per minute. The Bosch Rexroth SF250B1-1-4X/ check valve is tailored for applications requiring precise flow control and reliability in various hydraulic systems.

$40,254.00 USD

More are expected on October 6, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.Status: This product is temporarily out of stock.

Qty: Delivered as early as October 6, 2026 when ordered in