***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

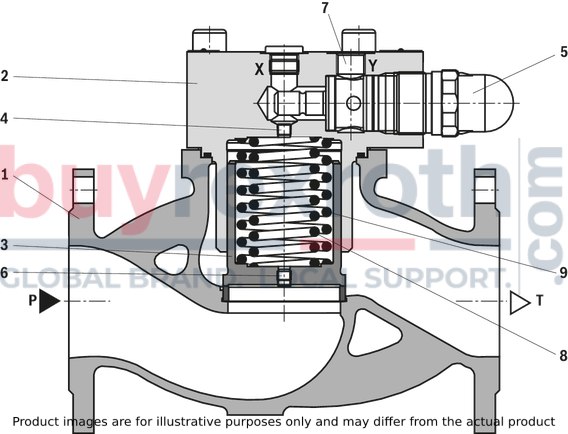

The Bosch Rexroth L-DB40F2-3X/16X (R900483452) is a sophisticated pressure relief valve designed to manage and regulate high flow systems with a low preload pressure. The valve features a pipeline installation housing, a main spool guide, and a main spool that work in unison to ensure stable operation under varying pressure conditions. The L-DB40F2-3X/16X operates by channeling the applied pressure through channel P onto the main spool while also directing it to the pilot control valve via internal nozzles.

When the pressure at channel P surpasses the preset value on the pilot control valve, it triggers the valve to open, allowing pilot oil to discharge directly into channel Y. This action causes the main spool to move upwards against the springs, creating a connection between channels P and T, which remains as long as the pressure continues to exceed the set value on the pilot control valve.

The L-DB40F2-3X/16X is also equipped with an external spring that keeps the main spool closed in its U version. This feature enables lower circulation pressure when the control channel is not loaded. Additionally, this model includes an adjustment type for pressure setting, which consists of a sleeve with hexagon and protective cap for precise control.

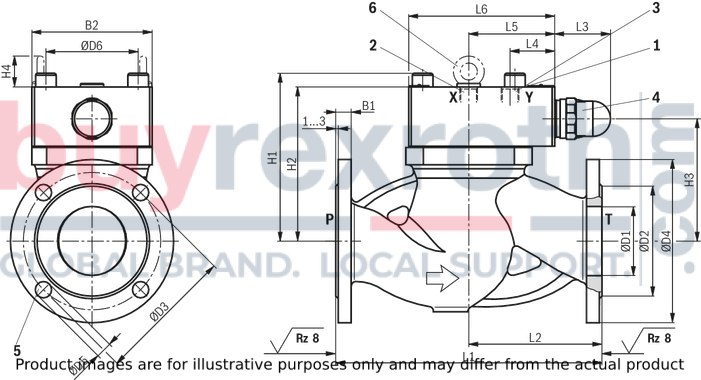

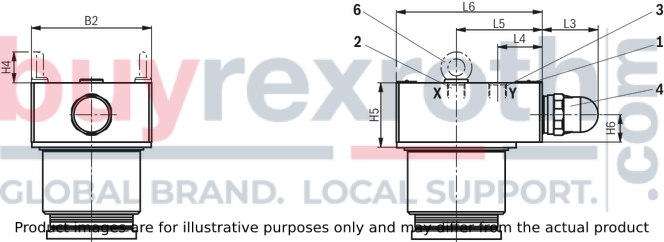

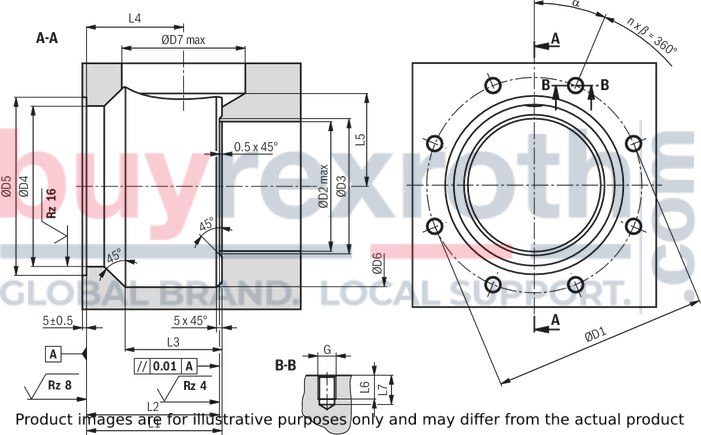

As for its physical configuration, this model can be used as a flange connection or as a cartridge valve without pipeline housing. It adheres to DIN EN standards for flange connections and is built to withstand maximum operating pressures of up to bar and maximum flow rates of l/min. The component series X indicates its place within Bosch Rexroth's product line-up, showcasing reliability and compatibility with various hydraulic applications where precise pressure relief is critical.

$5,841.00 USD

More are expected on August 19, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $5,694.97 USD | $146.03 USD |

| 25+ | $5,548.95 USD | $292.05 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as August 19, 2026 when ordered in