***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

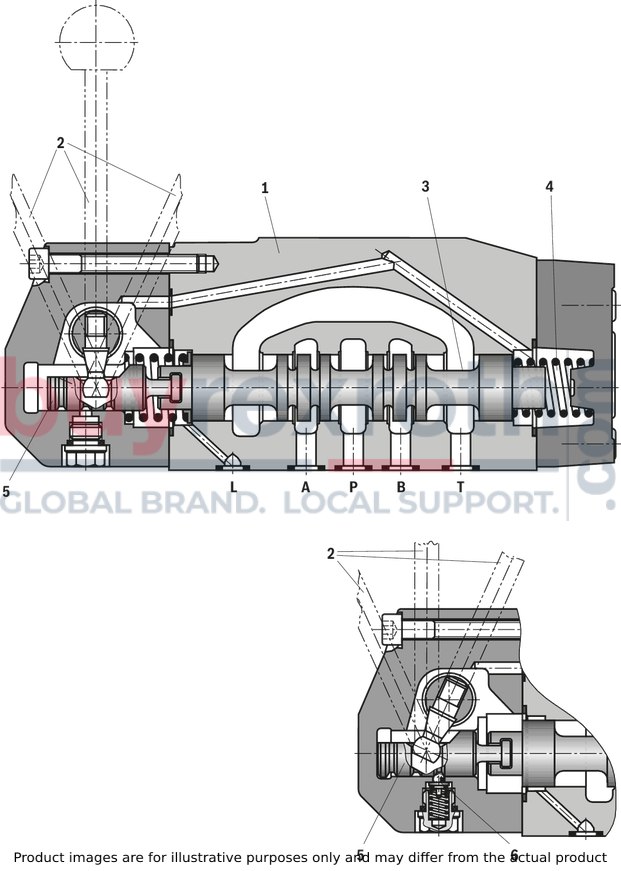

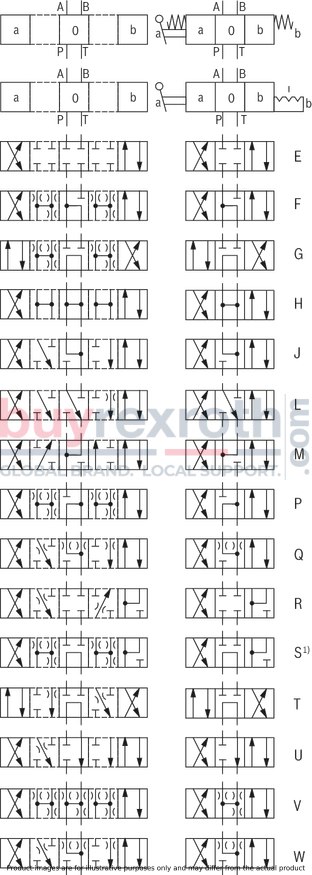

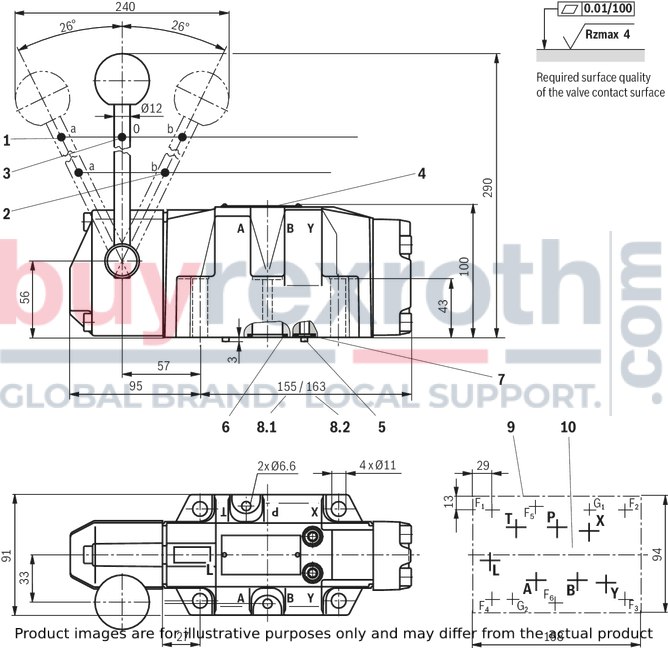

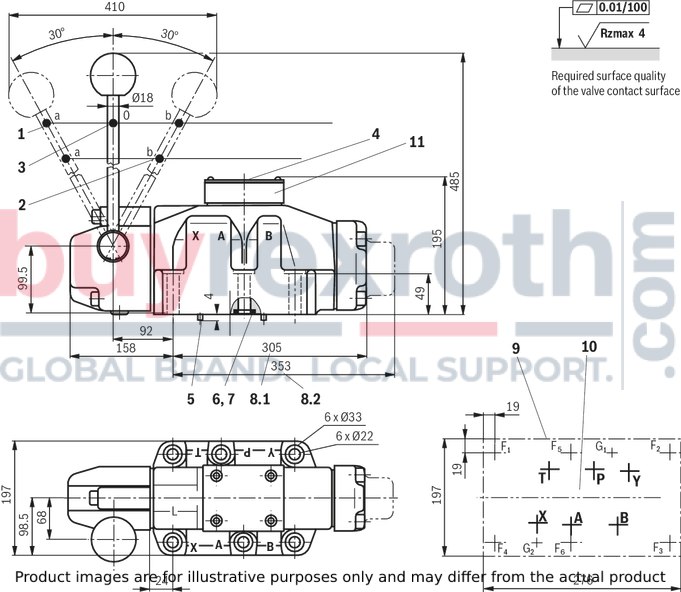

The Bosch Rexroth H-4WMM32E5X/F (R900452367) is a high-quality, direct operated directional spool valve characterized by manual actuation through a hand lever. This valve is designed to control the start, stop, and direction of fluid flow within a hydraulic system. It features a robust housing, a user-friendly hand lever for operation, and a control spool that is shifted directly by the operator's input. The valve's functionality is further supported by one or two return springs that ensure the spool returns to its rest position when the hand lever is released.

This particular model includes a detent mechanism that securely locks the spool in each selected position, providing stability and reliability in maintaining flow direction. The H-4WMM32E5X/F valve offers multiple spool positions for versatile application in various hydraulic circuits. Additionally, it boasts protection against contamination and humidity ingress, ensuring long-term durability and consistent performance even in harsh environments.

The porting pattern of this valve adheres to DIN form A and ISO standards, ensuring compatibility with a wide range of equipment and ease of integration into existing systems. With an exchangeable head end that does not require full disassembly for maintenance or replacement, this valve also simplifies servicing procedures.

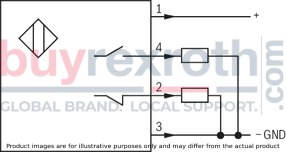

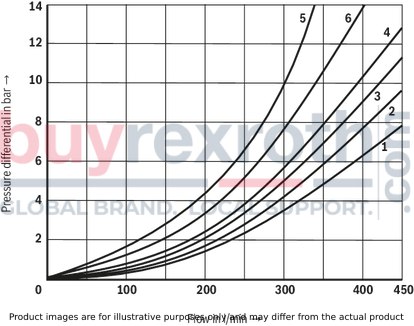

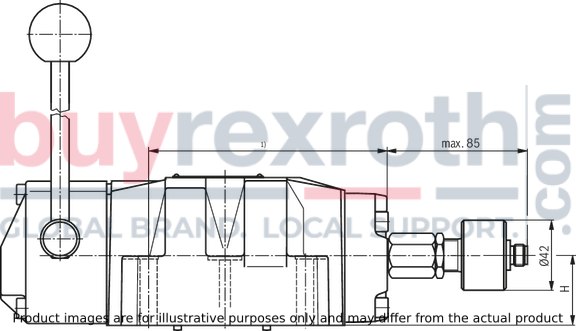

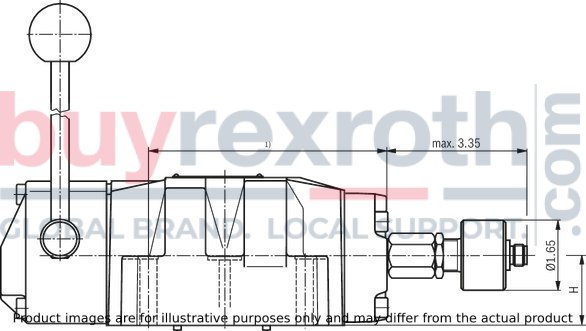

The Bosch Rexroth H-4WMM32E5X/F can handle maximum operating pressures up to 350 bar and allows for maximum flow rates up to 400 liters per minute. It belongs to component series X which signifies its advanced design features. For added versatility and precision control, it can be equipped with optional inductive position switches or proximity sensors for contactless detection of the spool position. This valve is suitable for various applications where manual control over hydraulic flow is necessary while providing reliable operation under substantial pressure and flow conditions.

$7,412.00 USD

More are expected on September 25, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $7,226.70 USD | $185.30 USD |

| 25+ | $7,041.40 USD | $370.60 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as September 25, 2026 when ordered in