***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

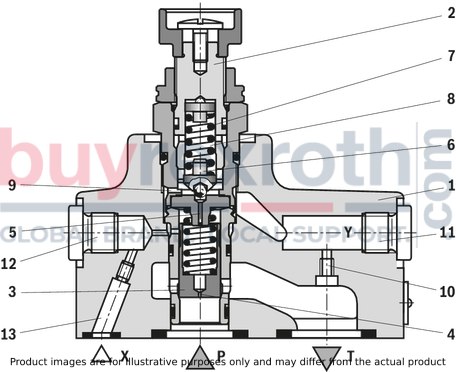

The Bosch Rexroth DB15G2-4X/50W65 (R900412321) is a high-performance pilot-operated pressure relief valve designed for effective limitation of operating pressure within hydraulic systems. This valve is characterized by its robust housing and a sensitive pilot control valve that ensures accurate pressure adjustment. The main spool within the valve responds to pressure changes in channel P, with the poppet mechanism opening against its spring when the set pressure is exceeded, allowing hydraulic fluid to flow into the tank either internally or externally, depending on the version.

This model offers versatility through its various adjustment types for setting the operating pressure. Users can select from options such as a rotary knob, a sleeve with hexagon and protective cap, a lockable rotary knob with scale, or a simple rotary knob with scale. The DB15G2-4X/50W65 valve also features a pressure gauge connection for monitoring system pressure and can be unloaded or switched to an alternate pressure setting via port X.

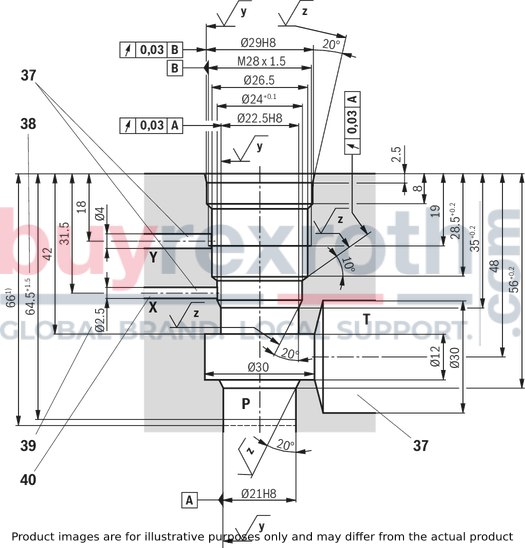

Designed for subplate mounting, it adheres to ISO NG and ISO NG porting patterns, ensuring compatibility with standardized configurations. The Bosch Rexroth DB15G2-4X/50W65 valve operates at maximum pressures up to bar and can handle maximum flow rates of l/min. Its size and component series X indicate its capacity to withstand demanding operational conditions while maintaining precise control over hydraulic system pressures.

$674.00 USD

More are expected on September 16, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $657.15 USD | $16.85 USD |

| 25+ | $640.30 USD | $33.70 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as September 16, 2026 when ordered in