***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

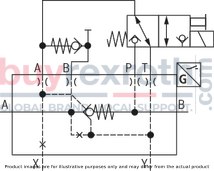

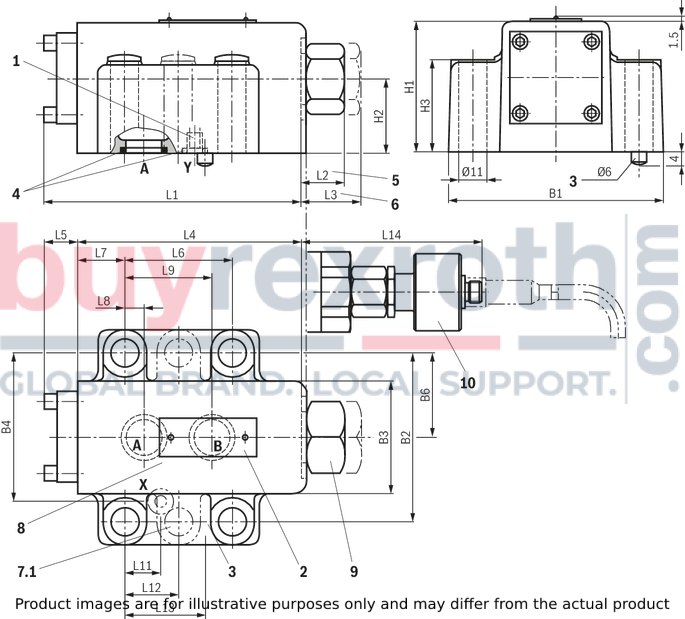

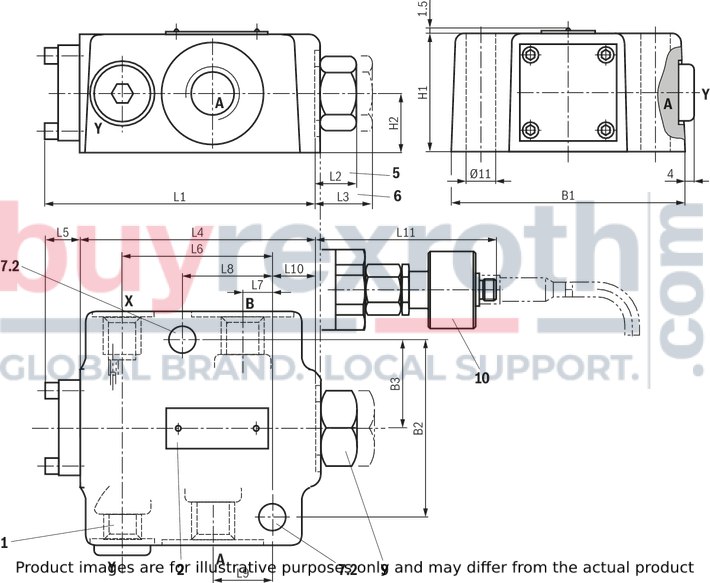

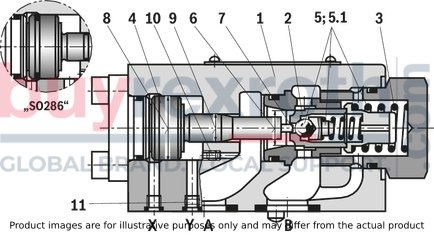

The Bosch Rexroth SV10PB2-4X/M (R900403672) is an advanced isolator valve designed for subplate mounting or threaded connection, which serves the purpose of leak-free blocking of one actuator port even during extended periods of inactivity. This valve is distinguished by its construction comprising a housing, seat poppet, compression spring, and control spool, with an optional preopening feature as a ball seat valve.

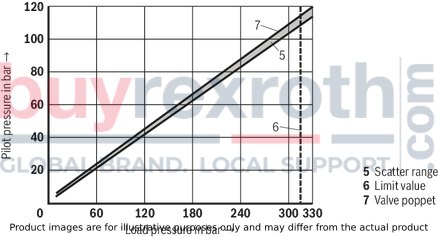

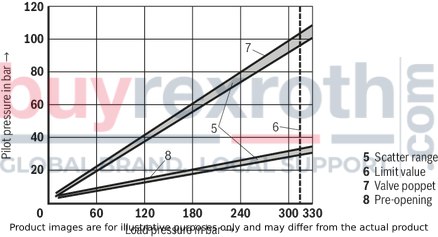

The SV10PB2-4X/M operates such that fluid can flow from port A to B without the need for external pilot pressure. Conversely, it seals hydraulically tight when the flow attempts to move from B to A unless a sufficient pilot pressure at port X is present. This pressure shifts the control spool towards the ball seat valve in version A and dislodges the seat poppet, allowing for bidirectional flow.

Particularly noteworthy are the two versions available: Version A includes a preopening that ensures secure unloading even at low pilot pressures and mitigates switching shocks by dampening decompression. Version B lacks this preopening feature and may result in abrupt unloading of pressure volumes, potentially causing premature wear on components and noise due to switching shocks.

This isolator valve accommodates various configurations with different annulus areas for the seat poppet, ball, and control spool to suit specific application needs. Additionally, it offers adaptability by allowing conversion from type SV to SL through plug exchange.

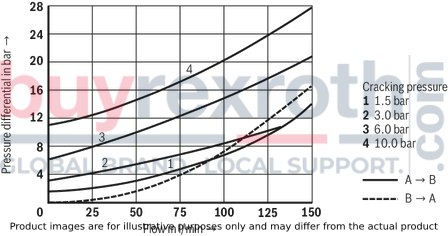

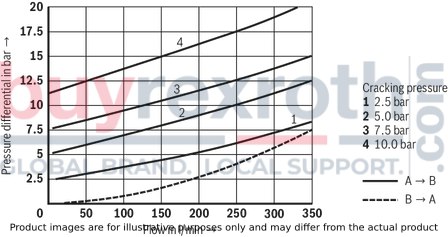

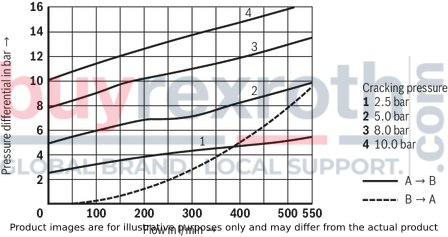

Designed for robust performance with corrosion protection in mind, the SV10PB2-4X/M supports maximum operating pressures up to a specified bar level and can handle maximum flow rates expressed in liters per minute. It conforms to ISO standards for mounting patterns (NG6, NG10), ensuring compatibility with industry norms. The product also features internal pilot oil return and offers optional variations in cracking pressures. For maintenance or customization purposes, check valve installation sets are available separately.

$840.00 USD

Availability: 3 In Stock

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $819.00 USD | $21.00 USD |

| 25+ | $798.00 USD | $42.00 USD |

Qty: Delivered as early as January 29, 2026 when ordered in

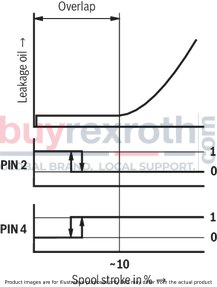

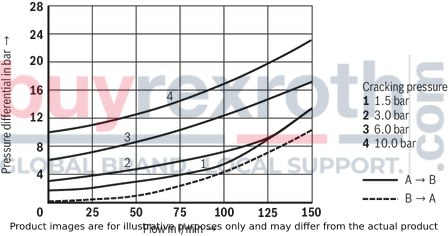

Simplified formula (Assumption pA = 0)

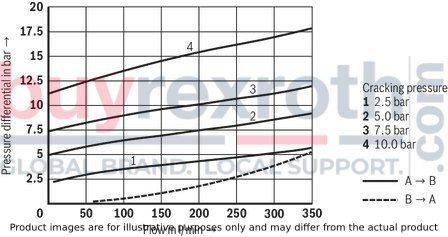

Simplified formula (Assumption pA = 0)

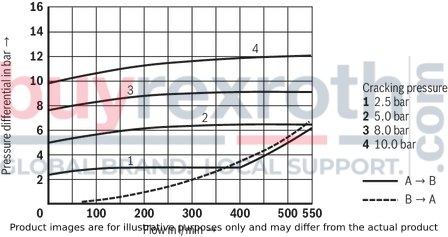

Simplified formula (Assumption pA = 0)

Simplified formula (Assumption pA = 0)