HY-CHECK VALVE M-SR 25 KE15-1X/

Manufacturer: Bosch Rexroth

Material #: R900348453

Model : M-SR 25 KE15-1X/

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

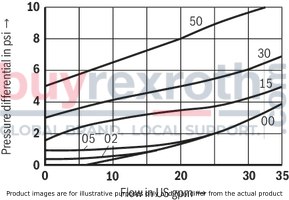

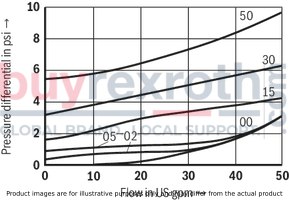

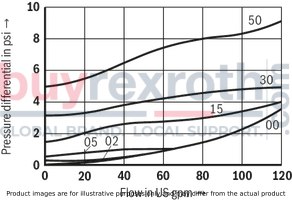

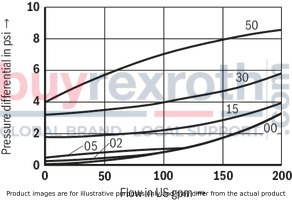

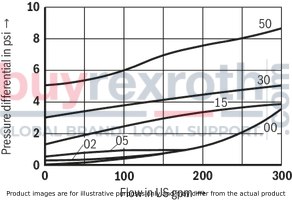

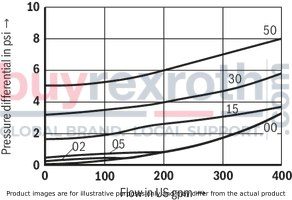

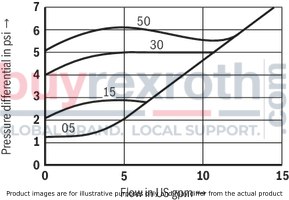

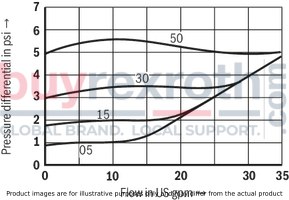

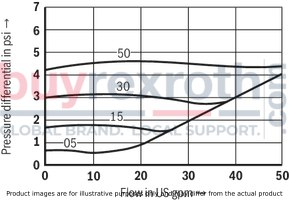

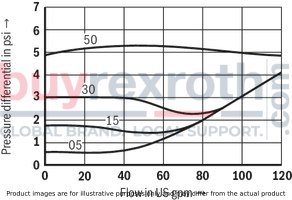

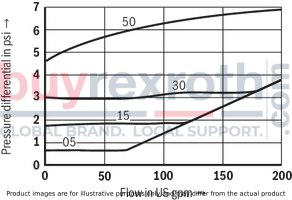

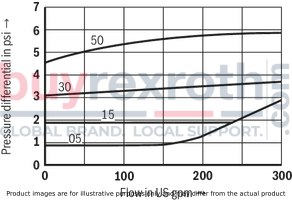

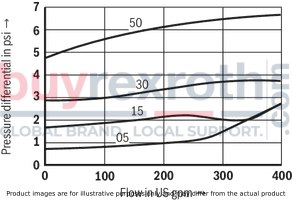

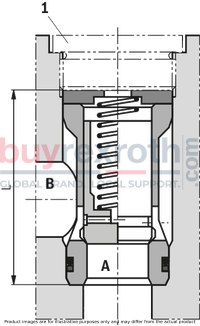

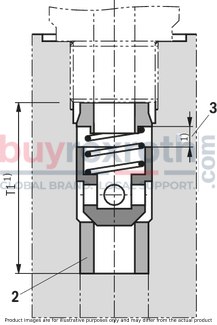

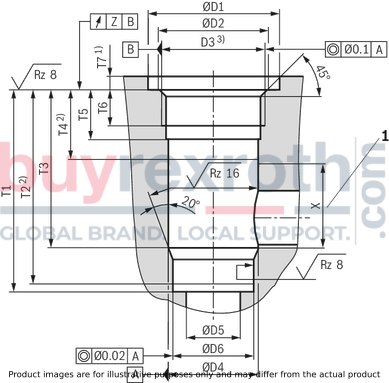

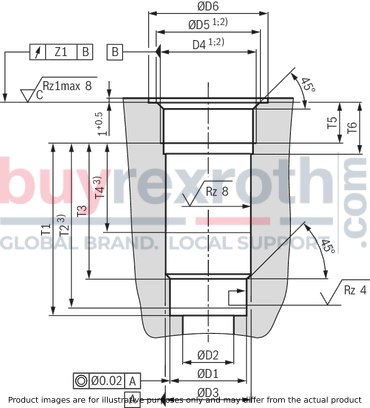

The Bosch Rexroth M-SR 25 KE15-1X (R900348453) is a high-performance check valve designed for hydraulic systems. This cartridge design valve is part of the MSR product family, known for its reliability and efficiency in controlling fluid flow. It operates as a direct-acting poppet-type valve, ensuring leak-free blocking in one direction while allowing free flow in the opposite direction. This makes it suitable for installation in block designs, either as an angle valve or a straight-through valve.

The M-SR 25 KE15-1X is engineered to handle a maximum operating pressure of up to bar psi and can accommodate maximum flow rates of lmin gpm, making it capable of functioning optimally within a range of demanding applications. The nominal flow rate further underscores its capacity to maintain system performance under various conditions. It does not come with pressure presetting, giving flexibility to users who may require various cracking pressures.

This Bosch Rexroth check valve features NBR sealing material, which offers excellent resistance to hydraulic fluids such as HL, HLP, and HFC. The robust construction ensures durability and longevity even in harsh working environments. Additionally, the unit's weight contributes to its ease of installation without compromising on structural integrity.

Ideal for applications requiring precise fluid control and prevention of reverse flow, the M-SR 25 KE15-1X serves as an essential component within hydraulic circuits. Its compatibility with different hydraulic fluids and adaptability to various installation configurations make it a versatile solution for ensuring efficient operation of hydraulic systems.

$388.00 USD

Availability: 7 In Stock

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $378.30 USD | $9.70 USD |

| 25+ | $368.60 USD | $19.40 USD |

Qty: Delivered as early as March 6, 2026 when ordered in