***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

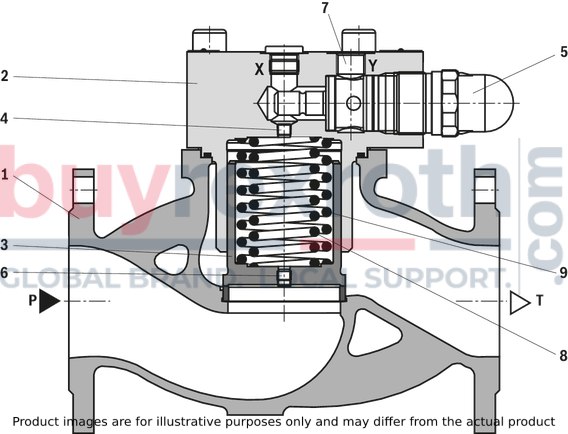

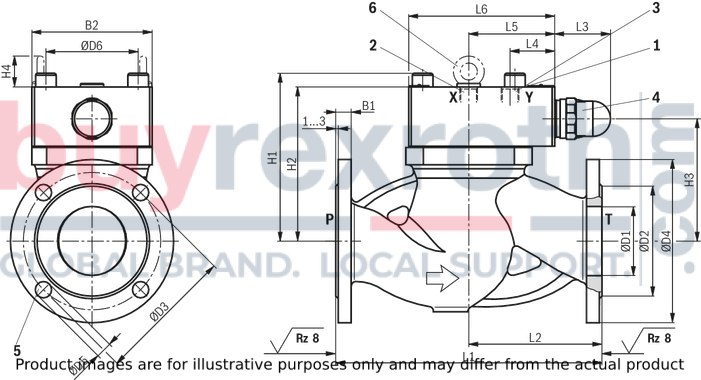

The Bosch Rexroth L-DB150F2-3X/16 (R900346976) is a state-of-the-art, pilot-operated pressure relief valve designed to manage low preload pressures while accommodating high-flow systems. This valve features a streamlined design that includes a main spool guide and a main spool within its pipeline installation housing. It operates by channeling the pressure applied to channel P onto the main spool and simultaneously directing it to the pilot control valve through integrated nozzles.

When the pressure in channel P surpasses the preset value at the pilot control valve, this triggers the valve to open, allowing pilot oil to discharge directly into channel Y. This action causes the main spool to ascend against springs, thereby connecting channel P with channel T whenever the pressure remains above the set value at the pilot control valve.

The L-DB150F2-3X/16 is also available in version U, where an external spring solely retains the closure of the main spool. This version enables a lower circulation pressure when unloading the control channel.

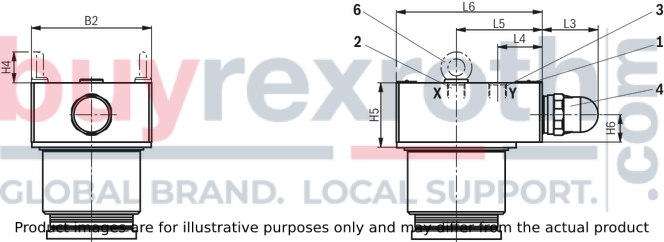

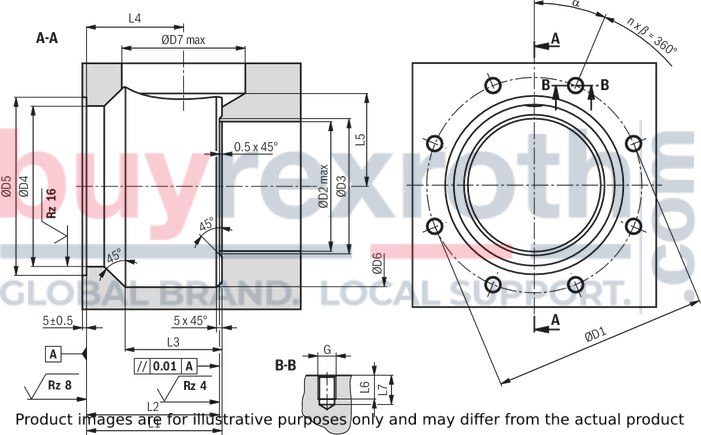

Additionally, there's version LDBF which mirrors LDB's functionality but is crafted as a cartridge valve without pipeline housing for flange connection. This design adheres to DIN EN standards for flange connections and offers different pressure ratings. The adjustment type for this model allows for precise pressure adjustments via a sleeve with hexagon and protective cap.

This Bosch Rexroth product is suitable for applications requiring reliable high-pressure relief with variable flow rates. It boasts an impressive maximum operating pressure and flow rate capacity, ensuring performance and durability in demanding operational conditions. The L-DB150F2-3X/16 represents Bosch Rexroth's commitment to quality and innovation in hydraulic system components.

$25,730.00 USD

More are expected on August 19, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $25,086.75 USD | $643.25 USD |

| 25+ | $24,443.50 USD | $1,286.50 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as August 19, 2026 when ordered in