Accessories for R900244192

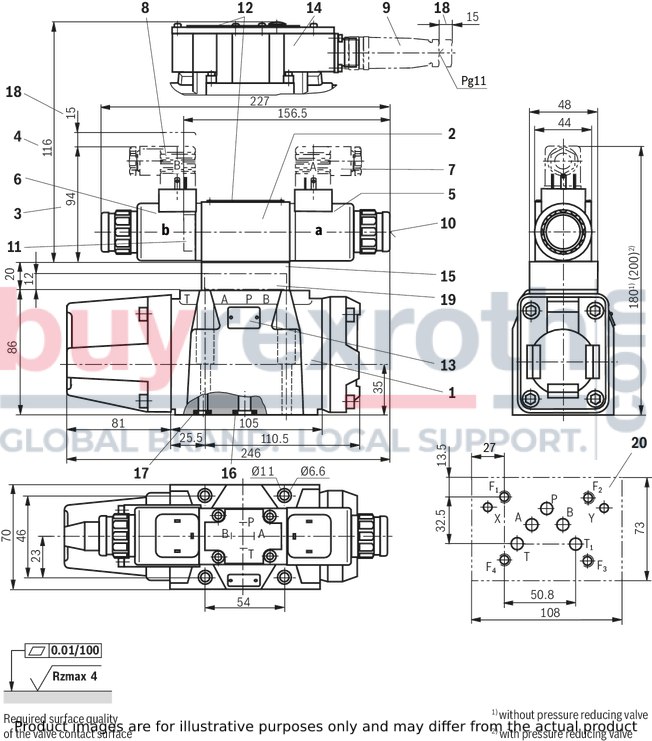

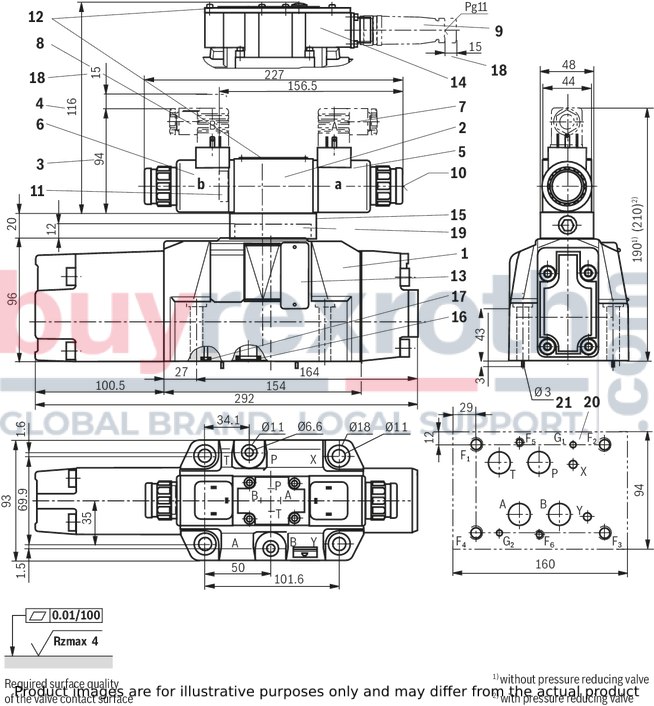

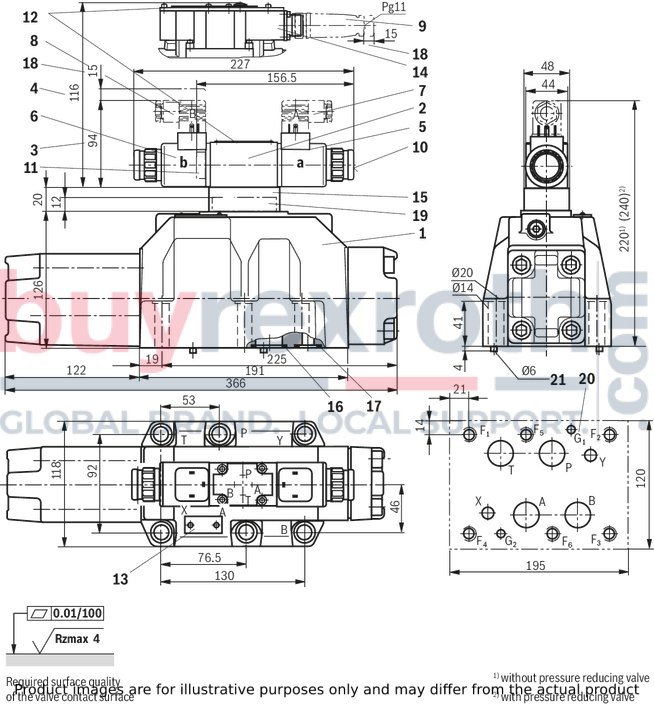

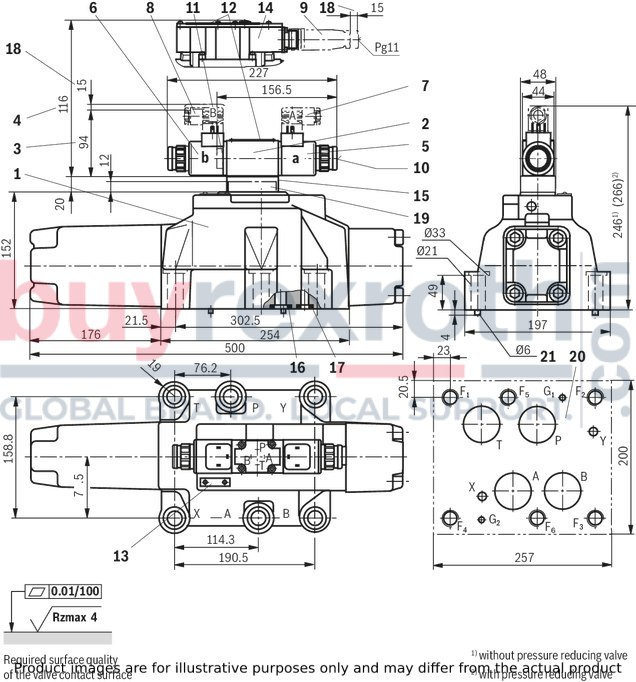

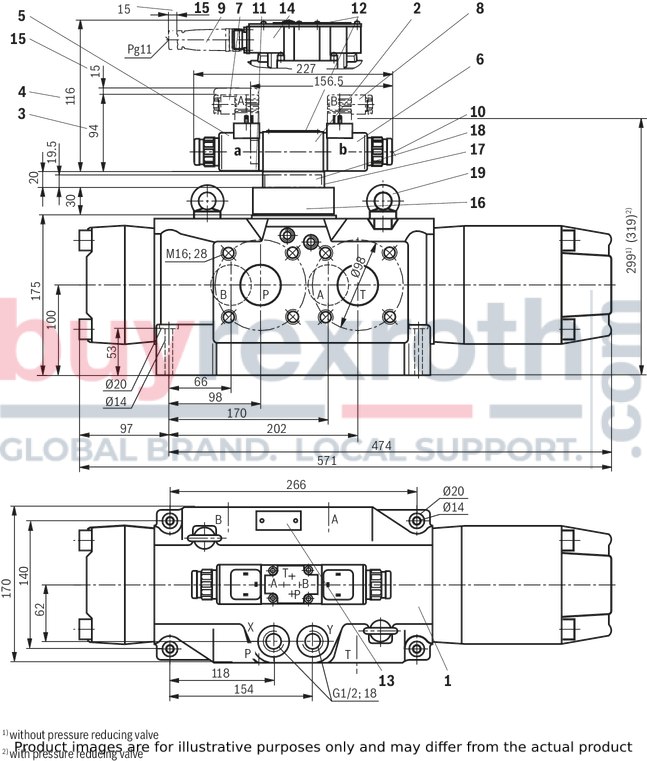

PROPORTIONAL DIRECTIONAL VALVE 4WRZ32E1-520-7X/6EG24N9K4/M

Manufacturer: Bosch Rexroth

Material #: R900244192

Model : 4WRZ32E1-520-7X/6EG24N9K4/M

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

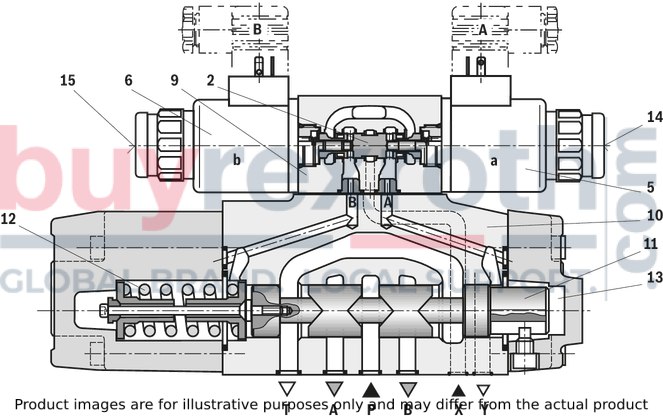

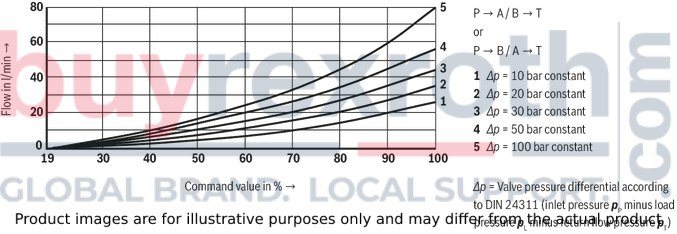

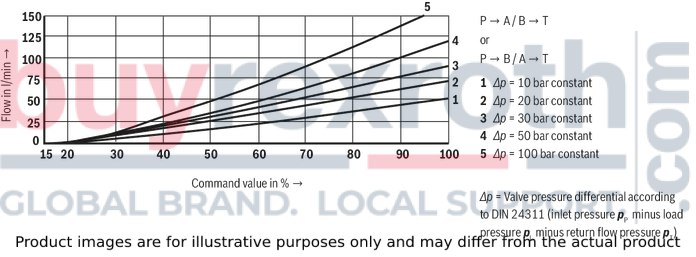

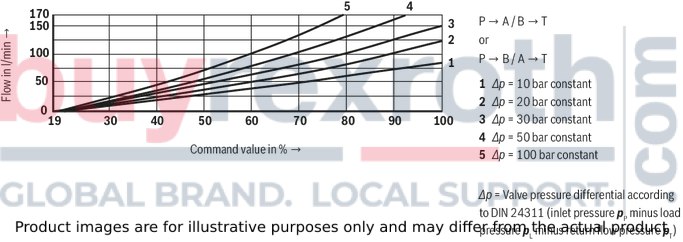

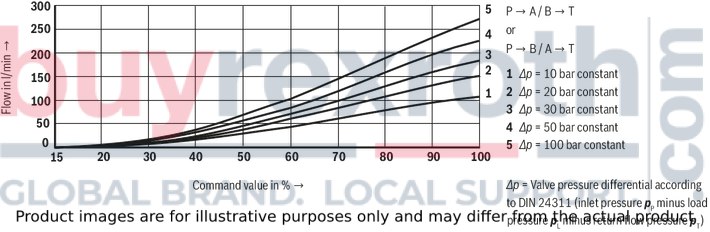

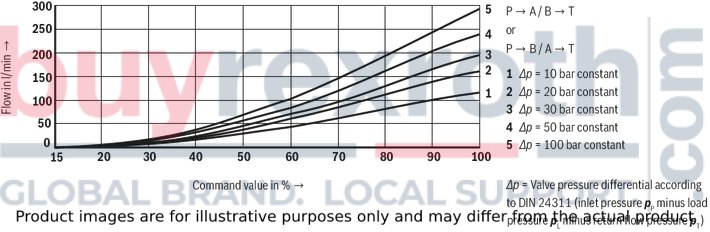

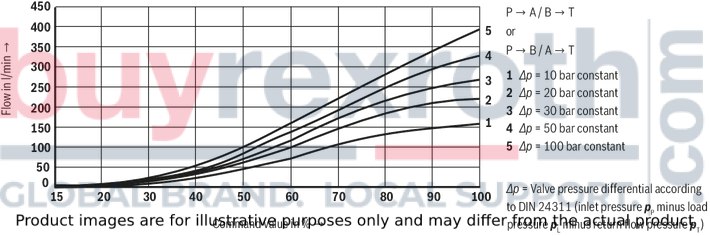

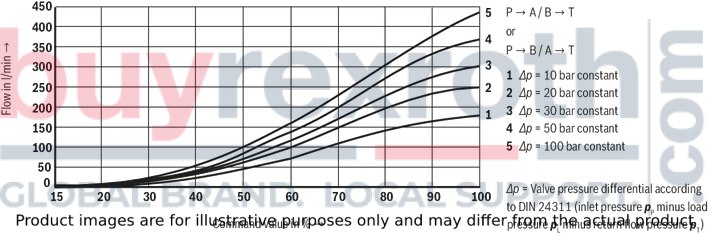

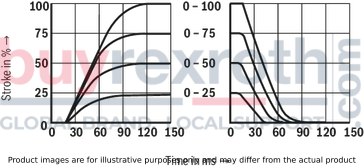

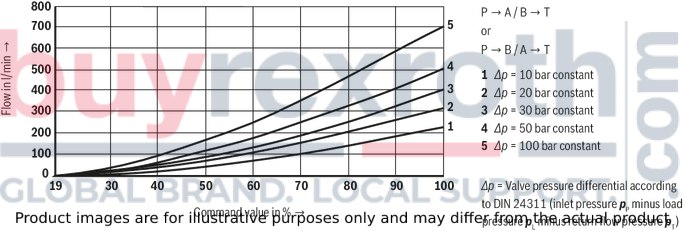

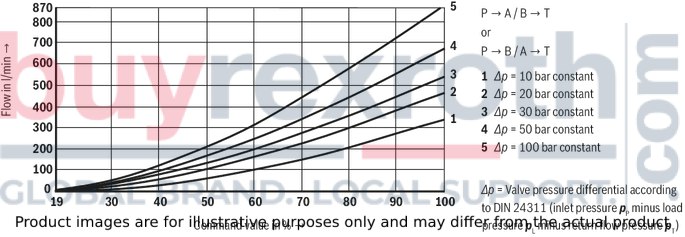

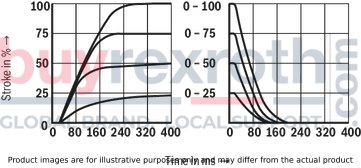

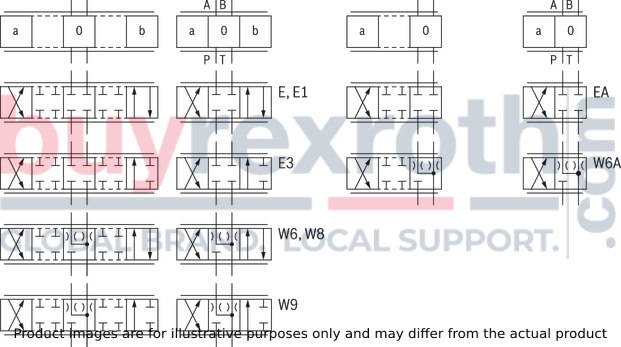

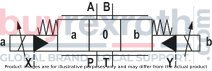

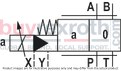

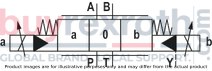

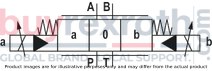

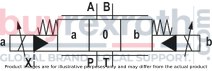

The Bosch Rexroth 4WRZ32E1-520-7X/6EG24N9K4/M (R900244192) is a high-performance industrial hydraulic valve designed for reliable control of oil flow direction, based on the hydraulic symbol E. This spool valve is pilot-operated, featuring external pilot oil supply and return, without an integrated pressure reducing valve. It includes a concealed manual override and auxiliary actuation for additional control flexibility.

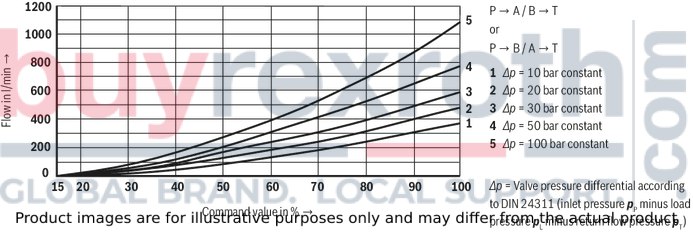

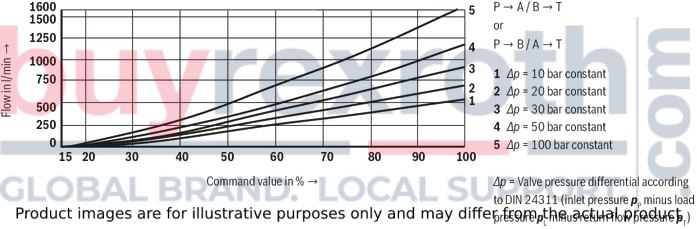

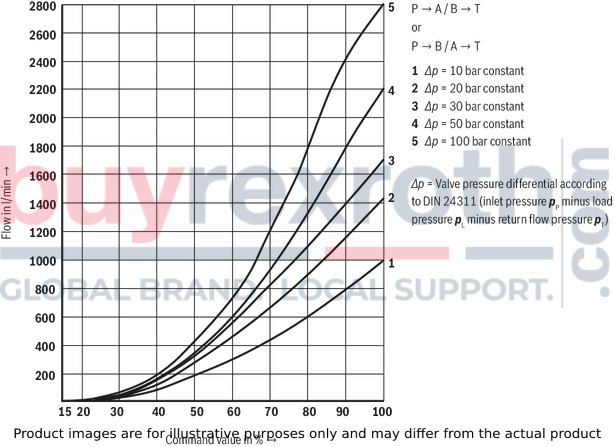

The 4WRZ32E1-520-7X/6EG24N9K4/M valve operates with an electrical connection described as connector pole PE according to EN standards and requires a supply voltage of 24 VDC. It is designed for subplate mounting with a connection diagram that complies with both NFPA T.. R D SizeCETOP D and ISO standards, ensuring compatibility with various systems. The nominal flow rate through the valve is specified by the manufacturer, and it can handle a maximum operating pressure of up to bar.

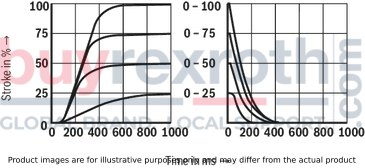

This Bosch Rexroth valve features a number of ports for comprehensive fluid control and utilizes NBR seals suitable for hydraulic fluids such as HL, HLP, HLPD, HVLP, HVLPD, and HFC. The electrical actuation is managed by external electronics, which allows proportional movement of the main control spool in response to electric input signals.

With its robust design and spring-centered control spool, the 4WRZ32E1-520-7X/6EG24N9K4/M provides precise operation even under demanding conditions. The optional auxiliary operating device enhances usability while ensuring safety measures are in place to prevent accidental activation that could lead to uncontrolled machine movements. Users should be aware that internal leakage is inherent in these valves due to their design principle and may increase over their lifecycle.

$10,842.00 USD

More are expected on September 23, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.| Qty | Price | Savings |

|---|---|---|

| 5-24 | $10,570.95 USD | $271.05 USD |

| 25+ | $10,299.90 USD | $542.10 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as September 23, 2026 when ordered in