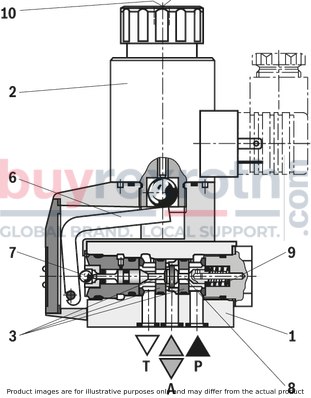

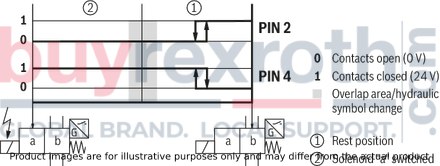

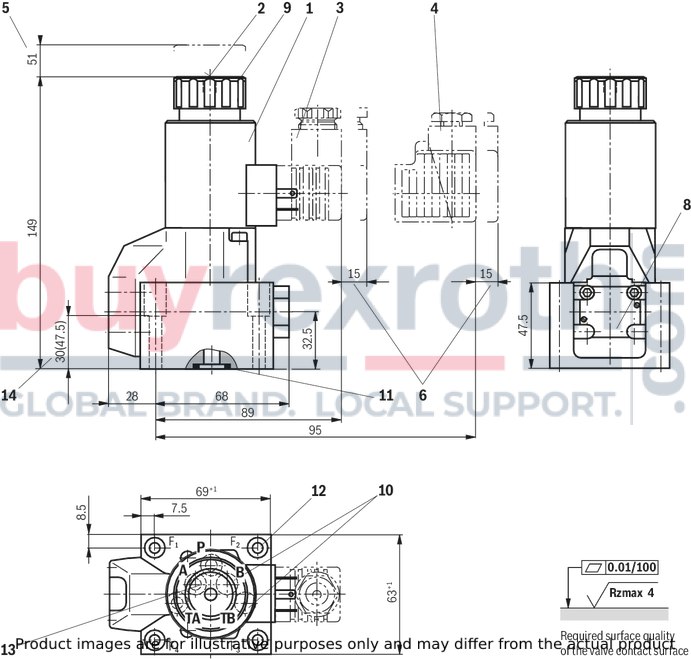

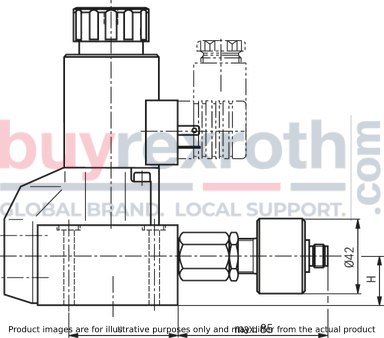

3/2 directional seat valve

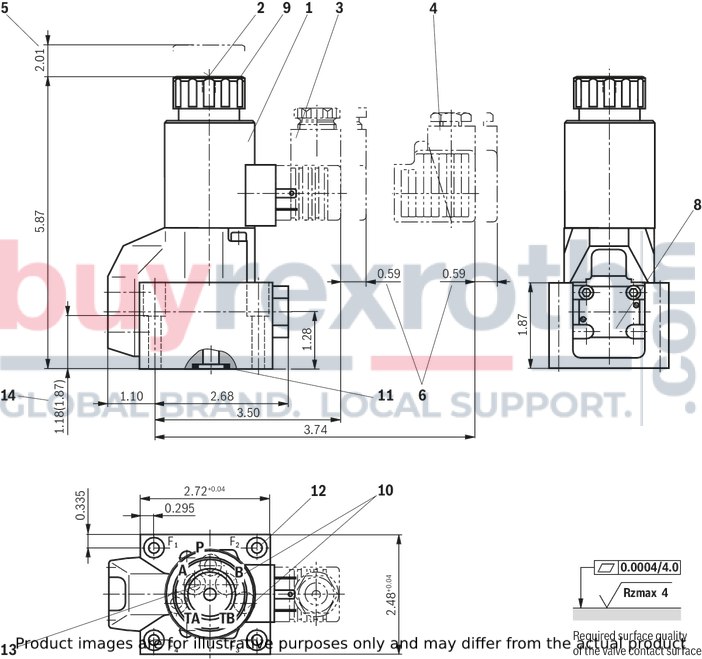

Dimensions in mm

3/2 directional seat valve

Dimensions in mm

|

1

|

Solenoid “a”

|

|

2

|

Concealed manual override “N9”

|

|

3

|

Mating connector without circuitry (separate order)

|

|

4

|

Mating connector with circuitry (separate order)

|

|

5

|

Space required to remove the coil

|

|

6

|

Space required to remove the mating connector

|

|

8

|

Name plate

|

|

9

|

Mounting nut, tightening torque MA = 4+1 Nm

|

|

10

|

Attention!

In 3/2 directional seat valves of version “420”, ports B and TB are available as blind counterbore; with version “630”, they are not available.

In 4/2 directional seat valves of version “420”, port TB is available as blind counterbore.

In 4/2 directional seat valves of version “630”, ports B and TB are not available.

|

|

11

|

Same seal rings for ports A, B, TA and TB; seal ring for port P

|

|

12

|

Valve mounting screws

|

|

13

|

Porting pattern according to ISO 4401-05-04-0-05

|

|

14

|

30 mm (420 bar); 47,5 mm (630 bar)

|

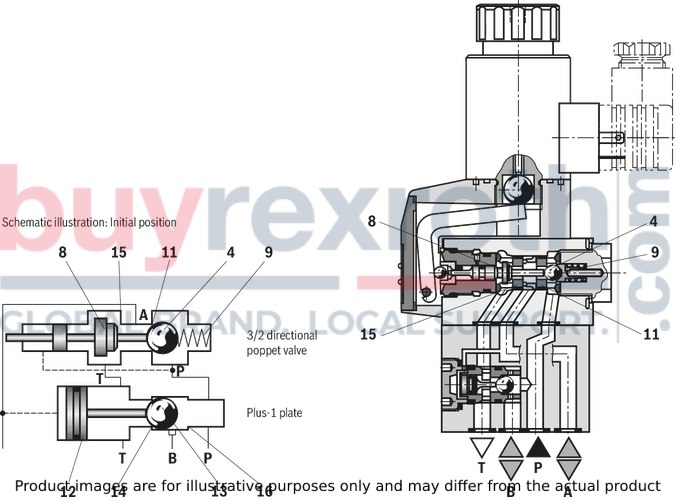

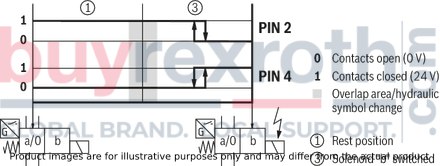

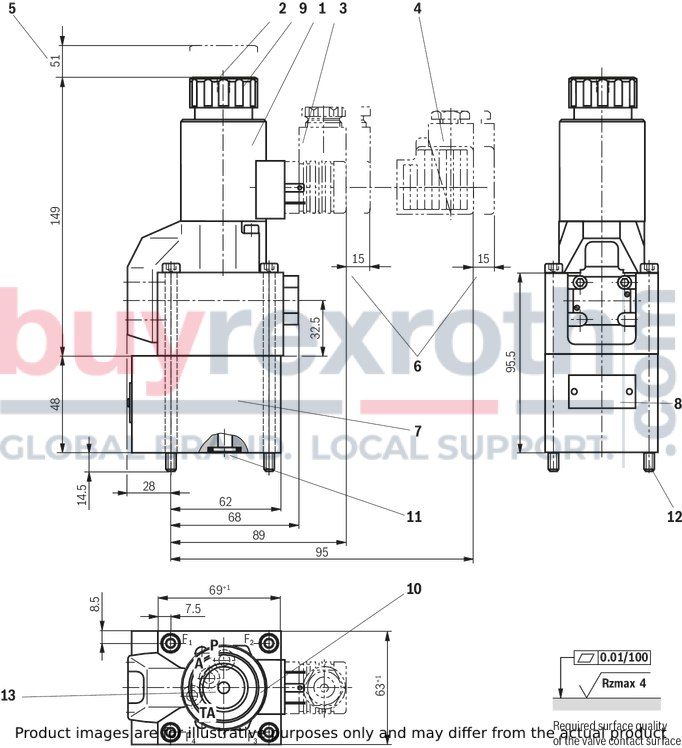

4/2 directional seat valve, version “420”

Dimensions in mm

4/2 directional seat valve, version “420”

Dimensions in mm

|

1

|

Solenoid “a”

|

|

2

|

Concealed manual override “N9”

|

|

3

|

Mating connector without circuitry (separate order)

|

|

4

|

Mating connector with circuitry (separate order)

|

|

5

|

Space required to remove the coil

|

|

6

|

Space required to remove the mating connector

|

|

7

|

Plus-1 plate

|

|

9

|

Mounting nut, tightening torque MA = 4+1 Nm

|

|

10

|

Attention!

In 3/2 directional seat valves of version “420”, ports B and TB are available as blind counterbore; with version “630”, they are not available.

In 4/2 directional seat valves of version “420”, port TB is available as blind counterbore.

In 4/2 directional seat valves of version “630”, ports B and TB are not available.

|

|

11

|

Same seal rings for ports A, B, TA and TB; seal ring for port P

|

|

12

|

Valve mounting screws

|

|

13

|

Porting pattern according to ISO 4401-05-04-0-05

|

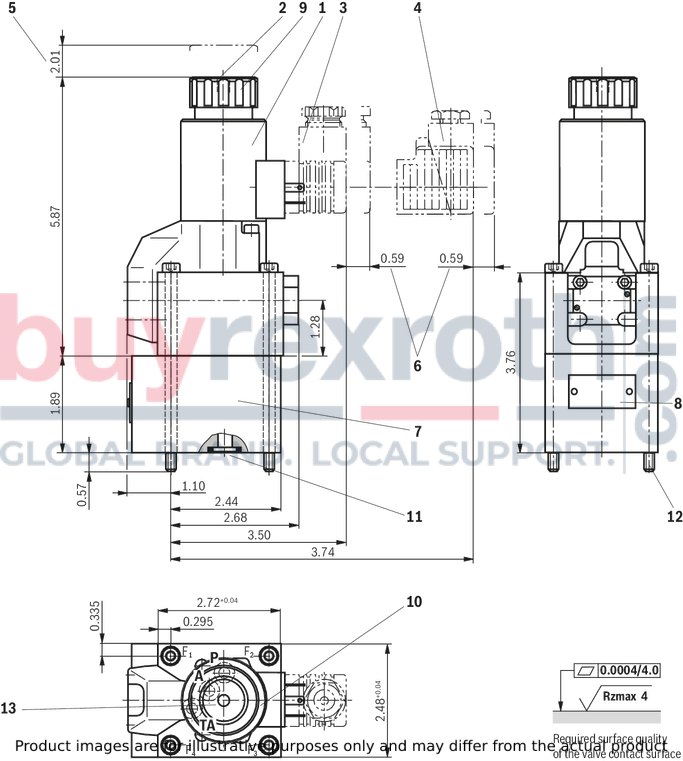

4/2 directional seat valve, version “630”

Dimensions in mm

4/2 directional seat valve, version “630”

Dimensions in mm

Valve mounting screws

3/2 directional seat valve (separate order)

[si]420 bar[/si][imp]6100 psi[/imp] version:

4 hexagon socket head cap screws metric

ISO 4762 - M6 x 40 - 10.9 - flZn - 240h - L

(friction coefficient μtotal = 0.09 to 0.14);

tightening torque MA = [si]12.5 Nm[/si][imp]9.2 ft - lbs[/imp] ± 10 %,

material no. R9130001058

or

4 hexagon socket head cap screws

ISO 4762 - M6 x 40 - 10.9 (self procurement)

(friction coefficient μtotal = 0.12 to 0.17);

tightening torque MA = [si]15.5 Nm[/si][imp]11.4 ft - lbs[/imp] ± 10 %

4 hexagon socket head cap screws UNC

1/4-20 UNC x 1 1/2” (self procurement)

(friction coefficient μtotal = 0.19 to 0.24 according to ASTM-574);

tightening torque MA = [si]20 Nm[/si][imp]14.8 ft - lbs[/imp] ± 15 %,

(friction coefficient μtotal = 0.12 to 0.17 according to ISO 4762);

tightening torque MA = [si]14 Nm[/si][imp]10.3 ft - lbs[/imp] ± 15 %,

material no. R978800710

[si]630 bar[/si][imp]9150 psi[/imp] version:

4 hexagon socket head cap screws metric

ISO 4762 - M8 x 60 - 10.9 - flZn - 240h - L

(friction coefficient μtotal = 0.09 to 0.14);

tightening torque MA = [si]30 Nm[/si][imp]22.1 ft - lbs[/imp] ± 10 %,

material no. metric R913000217

or

4 hexagon socket head cap screws

ISO 4762 - M8 x 60 - 10.9 (self procurement)

(friction coefficient μtotal = 0.12 to 0.17);

tightening torque MA = [si]37 Nm[si][imp]27.3 ft - lbs[/imp] ± 10 %

4 hexagon socket head cap screws UNC

5/16-18 UNC x 2” (self procurement)

(friction coefficient μtotal = 0.19 to 0.24 according to ASTM-574);

tightening torque MA = [si]40 Nm[/si][imp]29.5 ft - lbs[/imp] ± 15 %,

(friction coefficient μtotal = 0.12 to 0.17 according to ISO 4762);

tightening torque MA = [si]28 Nm[/si][imp]20.7 ft - lbs[/imp] ± 15 %,

material no. R978800730

4/2 directional seat valve (included in the scope of delivery)

[si]420 bar[/si][imp]6100 psi[/imp] version:

4 hexagon socket head cap screws metric

ISO 4762 - M6 x 90 - 10.9 - flZn - 240h - L

(friction coefficient μtotal = 0.09 to 0.14);

tightening torque MA = [si]12.5 Nm[/si] [imp]9.2 ft - lbs[/imp] ± 10 %,

material no. R913000259

or

4 hexagon socket head cap screws

ISO 4762 - M6 x 90 - 10.9 (self procurement)

(friction coefficient μtotal = 0.12 to 0.17);

tightening torque MA = [si]15.5 Nm[si][imp]11.4 ft - lbs[/imp] ± 10 %

4 hexagon socket head cap screws UNC

1/4-20 UNC x 3 1/2” (self procurement)

(friction coefficient μtotal = 0.19 to 0.24 according to ASTM-574);

tightening torque MA = [si]20 Nm[/si][imp]14.8 ft - lbs[/imp] ± 15 %,

(friction coefficient μtotal = 0.12 to 0.17 according to ISO 4762);

tightening torque MA = [si]14 Nm[/si][imp]10.3 ft - lbs[/imp] ± 15 %,

material no. R978800717

[si]630 bar[/si][imp]9150 psi[/imp] version:

4 hexagon socket head cap screws metric

ISO 4762 - M8 x 110 - 10.9 - flZn - 240h - L

(friction coefficient μtotal = 0.09 to 0.14);

tightening torque MA = [si]30 Nm[/si][imp]22.1 ft - lbs[/imp] ± 10 %,

material no. R913000260

or

4 hexagon socket head cap screws

ISO 4762 - M8 x 110 - 10.9 (self procurement)

(friction coefficient μtotal = 0.12 to 0.17);

tightening torque MA = [si]37 Nm[/si][imp]27.3 ft - lbs[/imp] ± 10 %

4 hexagon socket head cap screws UNC

5/16-18 UNC x 4 1/4” (self procurement)

(friction coefficient μtotal = 0.19 to 0.24);

tightening torque MA = [si]40 Nm[/si][imp]29.5 ft - lbs[/imp] ± 15 %,

(friction coefficient μtotal = 0.12 to 0.17);

tightening torque MA = [si]28 Nm[/si][imp]20.7 ft - lbs[i/mp] ± 15 %

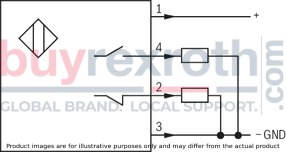

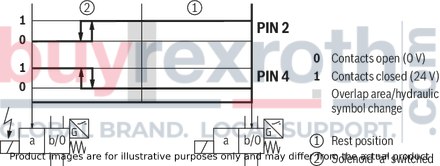

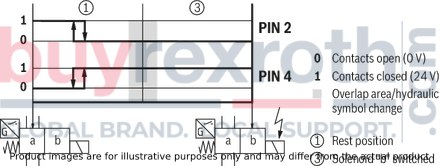

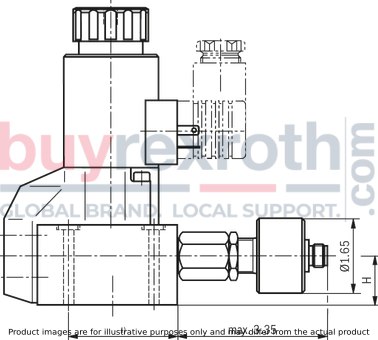

Spool position monitoring

Dimensions in mm

Inductive position switch type QM

Dimensions in mm

|

1)

|

For dimensions, see valve dimensions

|

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

M12x1 plug-in connection

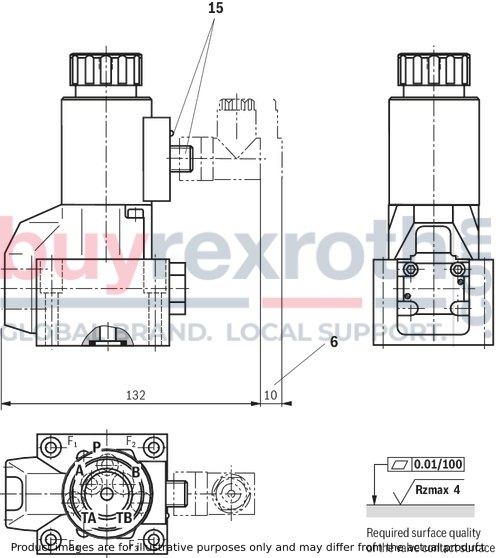

Type M-.SEW 10 .-1X/420MG24.K72L…

Dimensions in mm

Type M-.SEW 10 .-1X/420MG24.K72L…

Dimensions in mm

|

6

|

Space required to remove the mating connector

|

|

15

|

M12x1 plug-in connection with status LED (mating connector according to IEC 60947-5-2, separate order, see data sheet 08006); electrical connections “K72L”: see Electrical connections

|

|

6

|

Space required to remove the mating connector

|

|

15

|

M12x1 plug-in connection with status LED (mating connector according to IEC 60947-5-2, separate order, see data sheet 08006); electrical connections “K72L”: see Electrical connections

|

|

1

|

Solenoid “a”

|

|

2

|

Concealed manual override “N9”

|

|

3

|

Mating connector without circuitry (separate order)

|

|

4

|

Mating connector with circuitry (separate order)

|

|

5

|

Space required to remove the coil

|

|

6

|

Space required to remove the mating connector

|

|

7

|

Plus-1 plate

|

|

8

|

Name plate

|

|

9

|

Mounting nut, tightening torque MA = 4+1 Nm

|

|

10

|

Attention!

In 3/2 directional seat valves of version “420”, ports B and TB are available as blind counterbore; with version “630”, they are not available.

In 4/2 directional seat valves of version “420”, port TB is available as blind counterbore.

In 4/2 directional seat valves of version “630”, ports B and TB are not available.

|

|

11

|

Same seal rings for ports A, B, TA and TB; seal ring for port P

|

|

12

|

Valve mounting screws

|

|

13

|

Porting pattern according to ISO 4401-05-04-0-05

|