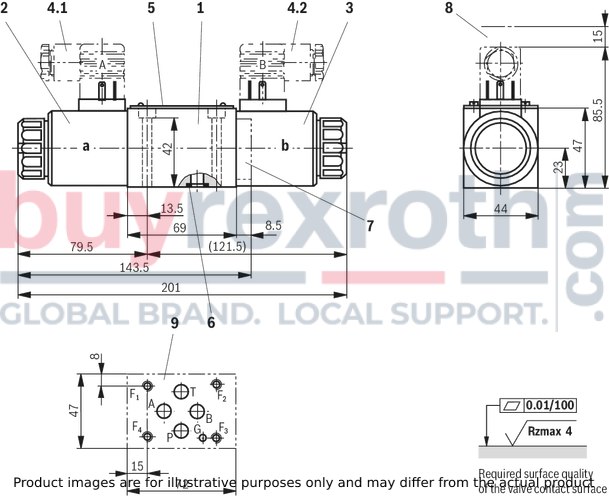

The 4/2 and 4/3 proportional directional valves are designed as direct operated devices in plate design. Operation by means of proportional solenoids with central thread and detachable coil. The solenoids are controlled by external control electronics.

Set-up:

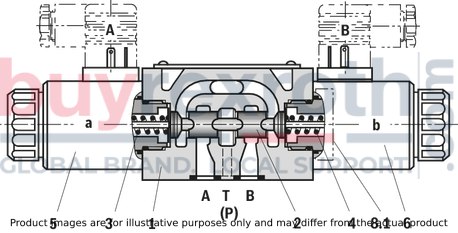

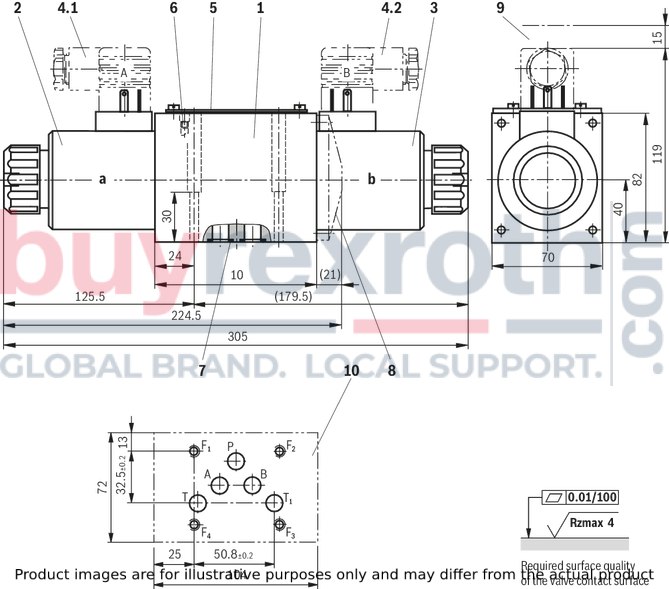

The valve basically consists of:

Housing (1) with connection surface Control spool (2) with compression springs (3 and 4) Solenoids (5 and 6) with central thread

Function:

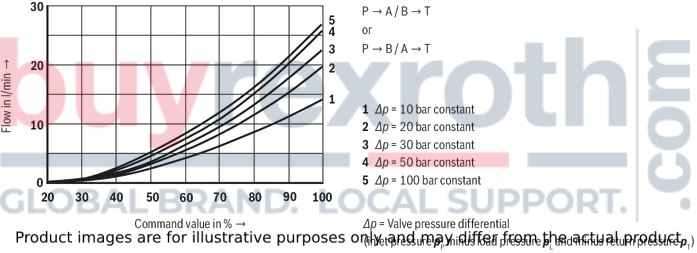

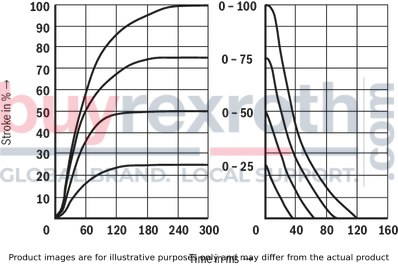

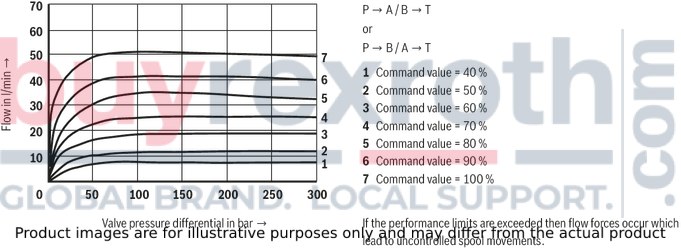

With de-energized solenoids (5 and 6), central position of the control spool (2) by compression springs (3 and 4) Direct operation of the control spool (2) by energization a proportional solenoid, e.g. control of solenoid "b" (6) Displacement of the control spool (2) to the left, proportionally to the electric input signal Connection from P to A and B to T via orifice-type cross-sections with progressive flow characteristics Switching off the solenoid (6) The compression spring (3) brings the control spool (2) back into the central position

Valve with two spool positions (type 4WRA...A...):

The function of this valve version basically corresponds to the valve with three spool positions. This 2 spool position valve is, however, only equipped with solenoid “a”. Instead of the 2nd proportional solenoid, there is a plug screw (8.1) with NG 6 or a cover (8.2) with NG10.

Notice:

The tank line must not be allowed to run empty. With corresponding installation conditions, a preload valve (preload pressure approx. 2 bar) must be installed.