POPPET DIRECTIONAL VALVE M-4SED6Y1X/350CG96N9K4/B15V

Manufacturer: Bosch Rexroth

Material #: R978918487

Model : M-4SED6Y1X/350CG96N9K4/B15V

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

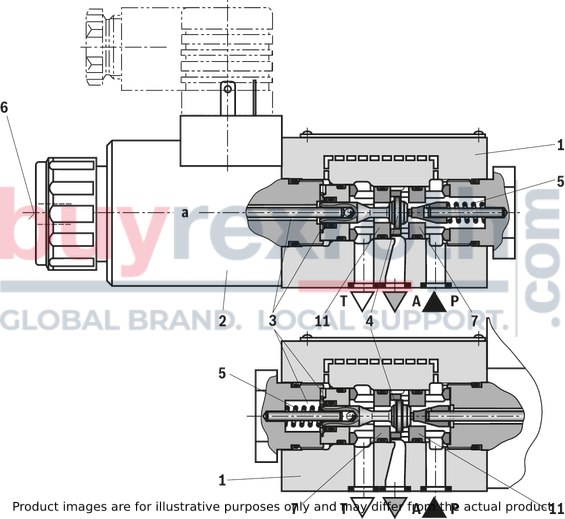

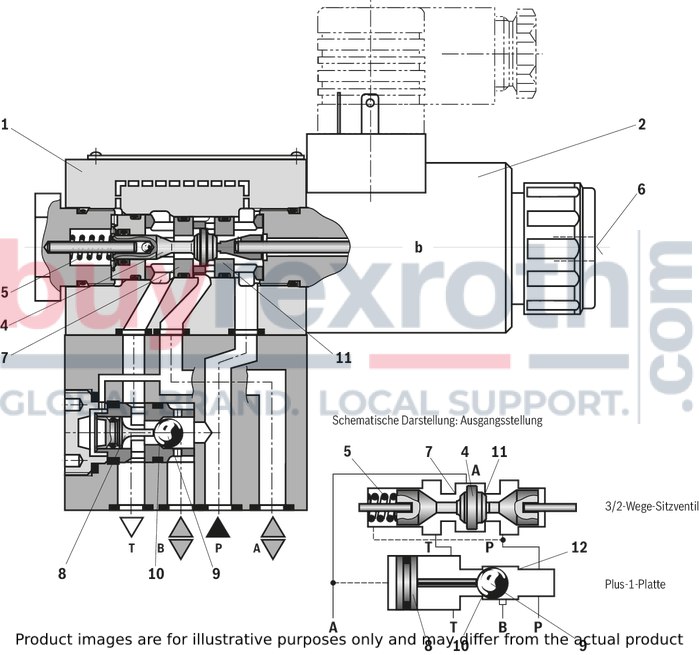

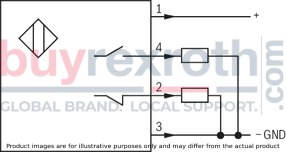

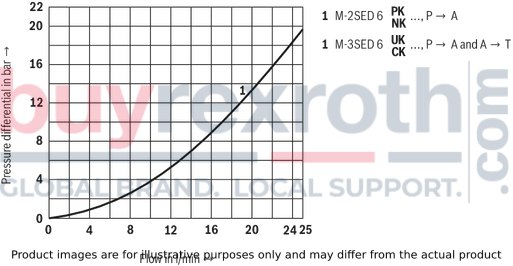

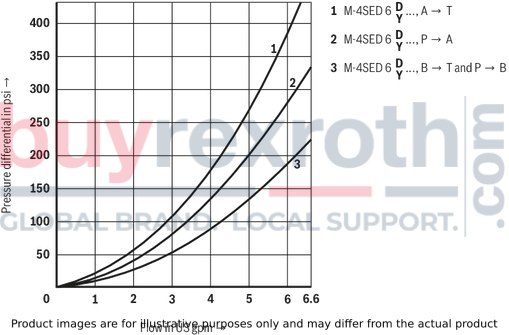

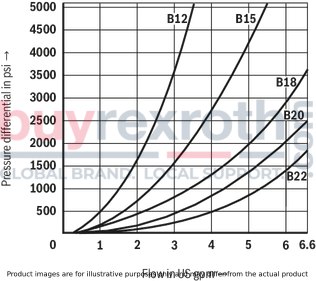

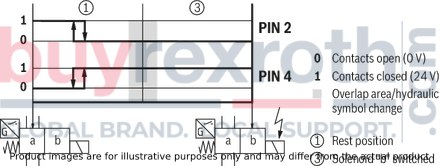

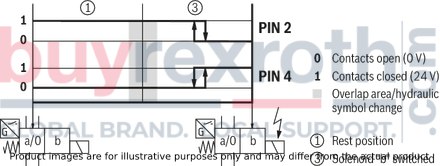

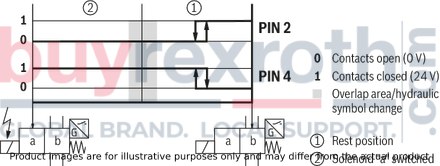

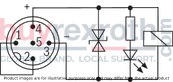

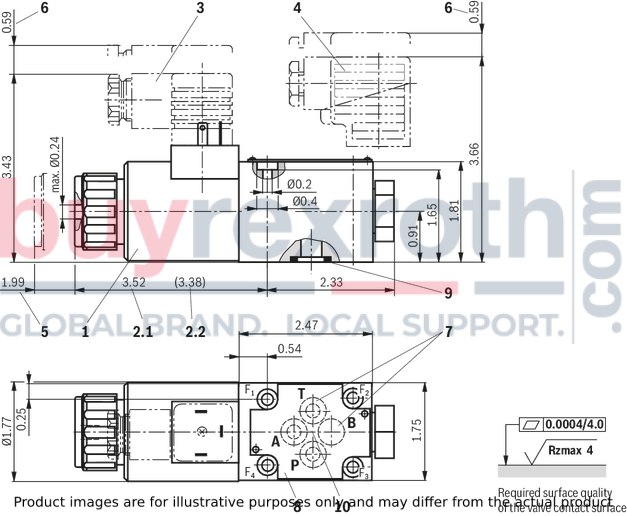

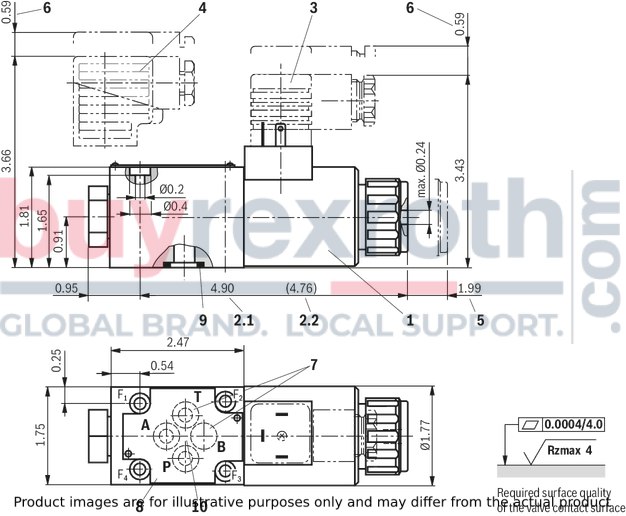

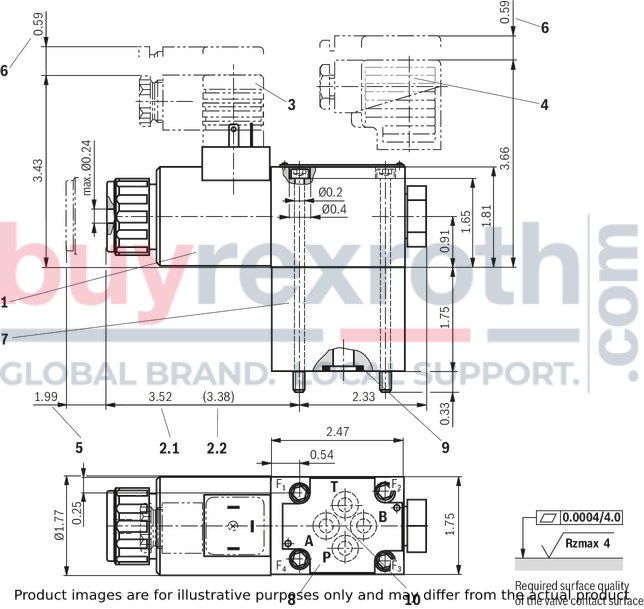

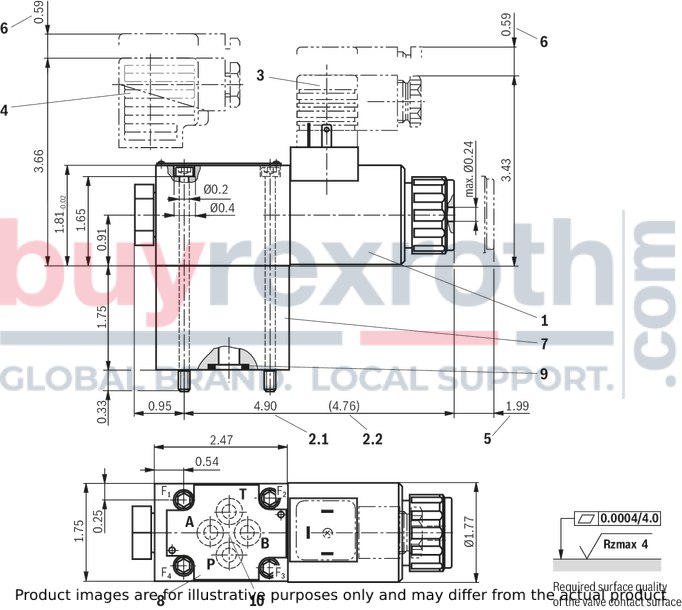

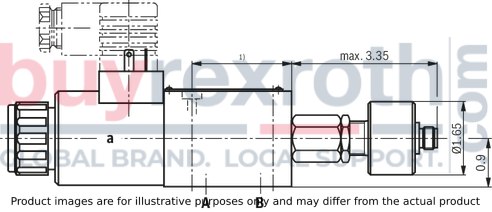

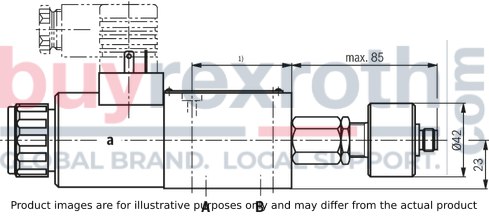

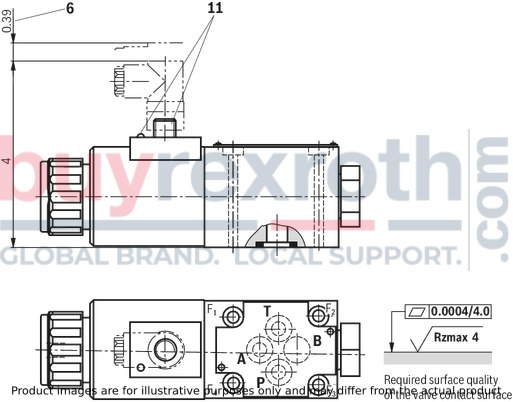

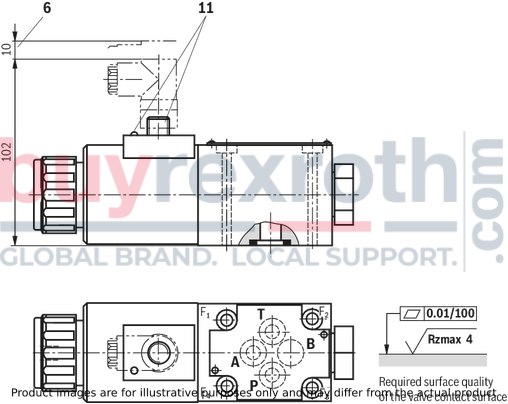

The Bosch Rexroth M-4SED6Y1X/350CG96N9K4/B15V (R978918487) is a high-performance industrial hydraulic valve designed for reliable switching of oil flow direction. This direct-actuated seat valve features a size 6 interface and employs solenoid actuation, with an electrical connection conforming to the EN 175301-803 standard, featuring a connector pole with PE grounding. It is capable of handling a maximum operating pressure of 350 bar and allows for a maximum flow of 60 liters per minute.

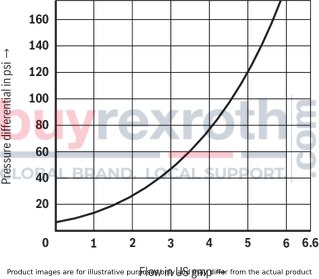

This model includes a throttle insert nozzle measuring 1.3 mm in channel P, ensuring precise control over fluid flow. The valve's spool symbol is designated as Symbol Y, indicating its specific flow path configuration. Additionally, the M-4SED6Y1X/350CG96N9K4/B15V valve comes equipped with both concealed manual override and auxiliary actuation options for enhanced operational flexibility.

The unit conforms to CE standards, including the Low Voltage Directive and has CSA approval according to CSA C22.2 No. 139. It supports various types of hydraulic fluids such as HL, HLP, HLPD, HVLP, HVLPD, HETG, HEES, HEPG, HFDU, and HFDR while utilizing FKM seals for durability and chemical resistance.

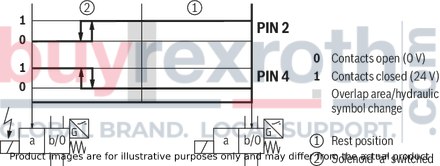

Designed for subplate mounting with connection diagrams adhering to NFPA T3.5.1 R2 D03 and ISO 4401 patterns, this Bosch Rexroth valve operates on a supply voltage of 24 VDC across four switching positions. Its robust construction ensures safe switching even after extended periods under pressure.

The M-4SED6Y1X/350CG96N9K4/B15V is particularly suited for applications requiring precise control over start-stop functions and directional flow in hydraulic systems while maintaining high levels of performance under varying operational conditions.

$2,083.00 USD

More are expected on August 10, 2026

Note: Sales tax, shipping, and applicable tariffs will be calculated at checkout.Status: This product is temporarily out of stock.

Qty: Delivered as early as August 10, 2026 when ordered in