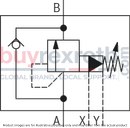

The valve type DZ is a pilot-operated pressure sequence valve.

It is applied for pressure-dependent connection of a second system.

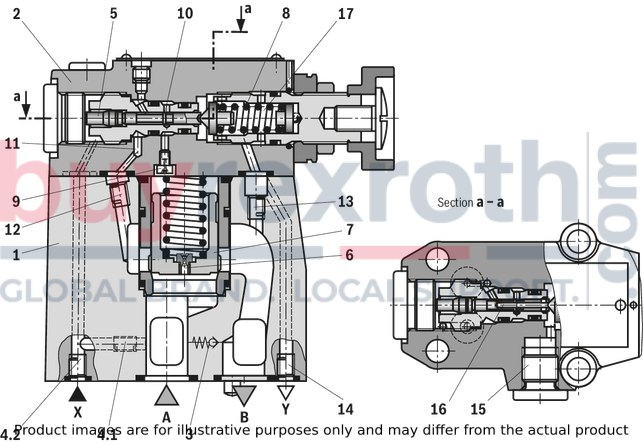

The pressure sequence valve basically consists of main valve (1) with main spool insert (7) and pilot control valve (2) with adjustment type and optional check valve (3).

According to the pilot oil supply and return and the respective function, the following differentiation is made:

Preload valve type DZ. . -.-5X/… (control lines 4.1, 12 and 13 open; control lines 4.2, 14 and 15 closed)

The pressure applied in channel A acts via the control line (4.1) on the pilot spool (5) in the pilot control valve (2). Simultaneously, the pressure in channel A acts via the nozzle (6) on the spring-loaded side of the main spool (7). If the pressure in channel P exceeds the value set at the spring (8), the pilot spool (5) is moved against the spring (8). The hydraulic fluid on the spring-loaded side of the main spool (7) now flows via the nozzle (9), the control edge (10) and control lines (11) and (12) into channel B. Due to this, a pressure drop occurs at the main spool (7). The main spool (7) is moved upwards and opens the connections from channel A to B. The pressure in channel A exceeds the value in channel B by the value set at the spring (8). The leakage occurring at the pilot spool (5) is directed internally via the spring chamber (17) of the pilot control valve and the control line (13) into channel B. If the pressure in the secondary circuit (channel B) exceeds the pressure in channel A, a check valve (3) may be optionally installed for free return flow.

Preload valve type DZ. . -.-5X/.X… (control lines 4.2, 12 and 13 open; control lines 4.1, 14 and 15 closed)

In principle, the function of this valve corresponds to the function of type DZ. . -.-5X/…. With version "X", however, the opening signal is received externally via control line X (4.2).

Sequence valve type DZ. . -.-5X/.Y… (control lines 4.1, 12 and 14 or 15 open; control lines 4.2 and 13 closed)

In principle, the function of this valve corresponds to the function of type DZ. . -.-5X/…. At version "Y", however, the leakage occurring at the pilot spool (5) has to be directed via line (14) or (15) to the tank by means of a depressurized connection. The pilot oil is directed via line (11) and (12) into channel B.

Circulation valve type DZ. . -.-5X/.XY… (control lines 4.2, 14 or 15 open; control lines 4.1, 12 and 13 closed)

In principle, the function of this valve corresponds to the function of type DZ. . -.-5X/…. With version "XY", however, the opening signal is received externally via control line X (4.2). The pilot oil at the pilot spool (16) bore and occurring leakage have to be directed via line (14) or (15) to the tank by means of a depressurized connection.