***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

The Bosch Rexroth 4WPH 10 J4X/6N/A (R978915599) is a high-precision, direct-operated directional spool valve designed for subplate mounting with pneumatic-hydraulic actuation. It is engineered to manage the initiation, cessation, and direction of fluid flow within hydraulic systems. The valve features a main valve housing, a control spool maintained in its initial position by return springs or pressurization, and a pilot control valve that regulates the spool's movement through pilot oil supplied via an internal or external source through port X.

The actuation process involves moving the pilot spool via the pilot control valve, which pressurizes one spring chamber while keeping the other depressurized. This action shifts the main control spool against its return spring force, allowing for the connection of specific ports in the main valve. When de-energized, the control spool returns to its central or initial position due to spring force.

This model includes an optional manual override feature that permits manual adjustment of the control spool without pneumatic pressure. It also offers various customization options such as spring centering, adjustable switching times, and optional auxiliary operating devices. The design follows ISO porting patterns and requires subplates compatible with data sheets 1 to 5 for proper installation.

The 4WPH series valves come in sizes 6 and 10 with component series ranging from X to X3. They can withstand a maximum operating pressure of up to bar and facilitate a maximum flow rate of l/min. Specific features like preload valves in channel P of the main valve or stroke settings at the main spool are available upon request. Additionally, this model can accommodate inductive position switches and proximity sensors for contactless detection.

It is essential that any modifications to this product's pilot oil supply be carried out only by authorized specialists or directly at the factory to ensure adherence to technical specifications and prevent operational issues.

$1,745.00 USD

More are expected on August 4, 2026

| Qty | Price | Savings |

|---|---|---|

| 5-24 | $1,701.37 USD | $43.63 USD |

| 25+ | $1,657.75 USD | $87.25 USD |

Status: This product is temporarily out of stock.

Qty: Delivered as early as August 4, 2026 when ordered in

This product is eligible for factory repair.

Type of actuation: pneumatic-hydraulic For subplate mounting Porting pattern according to ISO 4401 Subplates according to data sheets 45054 to 45060 (separate order) Spring centering, spring end position or hydraulic end position Optional auxiliary operating device Switching time adjustment, optional Preload valve in channel P of the main valve, optional Stroke setting at main spool, optional Stroke setting and/or end position control, optional Inductive position switch and proximity sensors (contactless)

Type 4WPH …

The WPH type valve is a direct-operated directional spool valve with pneumatic-hydraulic actuation. It controls the start, stop and direction of a flow.

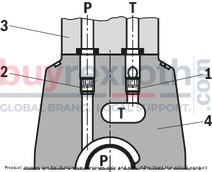

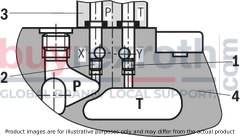

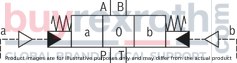

The directional valve basically consists of the main valve with housing (1), the main control spool (2), one or two return springs (3.1) and (3.2), as well as the pilot control valve (4).

The main control spool (2) in the main valve is held in the zero or initial position by the springs or by means of pressurization. In the initial position, the two spring chambers (5) and (7) are connected with the tank in a depressurized form via the pilot control valve (4). The pilot control valve (4) is supplied with pilot oil via the control line (6). Supply can be implemented internally or externally (externally via port X).

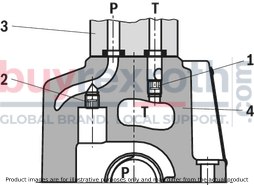

Upon actuation of the pilot control valve, e. g. side "a", the pilot spool (8) is moved to the left and thus, the spring chamber (7) is pressurized with pilot pressure. The spring chamber (5) remains depressurized.

The pilot pressure acts on the left side of the main control spool (2) and moves it against the spring (3.1). This connects port P with B and A with T in the main valve.

When de-energized, the control spool (8) is held in the central position or in the initial position by the return springs (9) (except impulse spool). The spring chamber (7) is unloaded to the tank.

The pilot oil from the spring chamber is displaced into channel Y via the pilot control valve (4).

The pilot oil supply and return are implemented internally or externally (externally via port Y).

An optional manual override (10) allows the control spool (8) to be moved without pneumatic pressure.

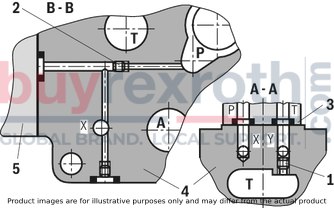

Pilot oil supply

NG10

Pilot oil supply

NG16

Pilot oil supply

NG25 (type 4W.H 22 .7X/…)

Pilot oil supply

NG25 (type 4W.H 25 .6X/…)

Pilot oil supply

Size 32

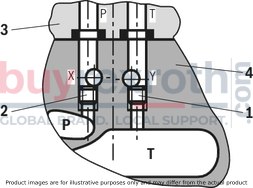

Attention!

The pilot oil supply may only be modified by authorized specialists or at the factory!

– External pilot oil supply X or return Y :

with NG10, version SO30 has to be used if sandwich plates are installed. The identification SO30 has to be used at the end of the type designation (sandwich plate). the maximum admissible operating parameters of the pilot control valve must be observed! maximum pilot pressure: please observe the Technical data!– Internal pilot oil supply (version “ET” and “E”):

minimum pilot pressure: please observe the Technical data! to prevent inadmissibly high pressure peaks, a “B10” throttle insert must be provided in port P of the pilot control valve.|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

||

|

WPH |

/ |

6 |

/ |

* |

|

01 |

up to 280 bar |

no code |

|

02 |

3-way version |

3 |

|

4-way version |

4 |

|

|

Types of actuation |

||

|

03 |

pneumatic-hydraulic |

WPH |

|

Size |

||

|

04 |

NG10 |

10 |

|

NG16 |

16 |

|

|

NG25 (type 4W.H 22 .7X/…) |

22 |

|

|

NG25 (type 4W.H 25 .6X/…) |

25 |

|

|

Size 32 |

32 |

|

|

Spool return in the main valve |

||

|

05 |

by means of springs |

no code |

|

hydraulic 3) |

H |

|

|

06 |

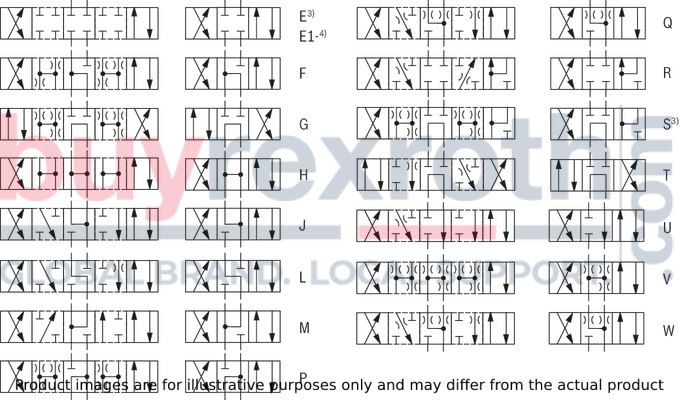

Symbols; for the possible version, see "Symbols/Circuit diagrams" |

|

|

Component series |

||

|

07 |

40 to 49 – NG10 (40 to 49: unchanged installation and connection dimensions) |

4X |

|

60 to 69 – NG25 (4W.H 25.) and NG32 (60 to 69: unchanged installation and connection dimensions) |

6X |

|

|

70 to 79 – NG16 (from series 72) and NG25 (4W.H 22.) (70 to 79: unchanged installation and connection dimensions) |

7X |

|

|

Spool return in the pilot control valve with 2 spool positions only possible with spools B, C, D and hydraulic control spool return in the main valve: |

||

|

08 |

With spring return |

no code |

|

Without spring return |

O |

|

|

Without spring return with detent |

OF |

|

|

Pilot control valve |

||

|

09 |

with fluidic actuation (standard valve) |

6 |

|

10 |

Without manual override |

no code |

|

With manual override |

N |

|

|

11 |

External pilot oil supply, external pilot oil return 1) |

no code |

|

Internal pilot oil supply, external pilot oil return 1; 2) |

E |

|

|

Pilot oil supply internal, pilot oil return internal 2) |

ET |

|

|

External pilot oil supply, internal pilot oil return 1) |

T |

|

|

12 |

without switching time adjustment |

no code |

|

Switching time adjustment as supply control |

S |

|

|

Switching time adjustment as discharge control |

S2 |

|

|

Spool position monitoring |

||

|

13 |

Without position switch |

no code |

|

Monitored spool position "a" |

QMAG24 |

|

|

Monitored spool position "b" |

QMBG24 |

|

|

Monitored spool position "a" and "b" |

QMABG24 |

|

|

Monitored rest position |

QM0G24 |

|

|

14 |

Stroke setting see stroke setting in type key table |

|

|

Throttle insert |

||

|

15 |

Without throttle insert |

no code |

|

Throttle Ø 0.8 mm |

B08 |

|

|

Throttle Ø 1.0 mm |

B10 |

|

|

Throttle Ø 1.2 mm |

B12 |

|

|

Throttle Ø 1.5 mm |

B15 |

|

|

Throttle Ø 2.0 mm |

B20 |

|

|

Throttle Ø 2.5 mm |

B25 |

|

|

preload valve (not for NG10) 4) |

||

|

16 |

without preload valve |

no code |

|

with preload valve (pö = 4.5 bar) |

P4,5 |

|

|

17 |

without pressure reducing valve |

no code |

|

with pressure reducing valve |

D3 4) |

|

|

Seal material |

||

|

18 |

NBR seals |

no code |

|

FKM seals (other seals upon request) |

V |

|

|

Observe compatibility of seals with hydraulic fluid used. |

||

|

19 |

Information in the plain text |

* |

| 1) External pilot oil supply X or return Y: | |

| – with NG10, version SO30 has to be used if sandwich plates are installed. The identification SO30 has to be used at the end of the type designation (sandwich plate). | |

| – the maximum admissible operating parameters of the pilot control valve must be observed! | |

| – observe the maximum pilot pressure! | |

| 2) Internal pilot oil supply (version “ET” and “E”): | |

| – minimum pilot pressure: please observe the Technical data! | |

| – to prevent inadmissibly high pressure peaks, a “B10” throttle insert must be provided in port P of the pilot control valve (see Pilot oil supply). | |

| 3) 2 spool positions (hydraulic end position): only piston C, D, Y, K ,Z | |

| 4) only in connection with throttle insert “B10” |

|

pSt |

Pilot pressure |

|

ppilot min |

Pilot pressure, minimum |

|

ptank |

Tank pressure |

|

pö |

Cracking pressure |

Preferred types and standard units are contained in the EPS (standard price list).

general

|

Size |

10 | 16 | 25 (4W.H22) | 25 (4W.H25) | 32 | ||

|

Weight (approx.) |

2 spool positions |

kg |

6.8 | 8.9 | 11.9 | 18 | |

|

3 spool positions |

kg |

7.6 | 9.7 | 12.7 | 19.8 | 41.8 | |

|

Switching time adjustment |

kg |

0.8 | |||||

|

Pressure reducing valve |

kg |

0.4 | |||||

|

Installation position |

any; horizontal with valves with hydraulic control spool return “H” and spool symbol B, C, D, K, Z, Y | ||||||

|

Ambient temperature range |

°C |

-30 … +50 | |||||

|

Storage temperature range |

°C |

-20 … +70 | |||||

|

Surface protection |

Valve body |

Coating, layer thickness max. 100 μm | |||||

hydraulic

|

Size |

10 | 16 | 25 (4W.H22) | 25 (4W.H25) | 32 | |||

|

Maximum operating pressure |

Port P |

bar |

280 | |||||

|

Anschluss A |

bar |

280 | ||||||

|

Port B |

bar |

280 | ||||||

|

Port T |

External pilot oil return Y |

bar |

280 | 250 | ||||

|

Internal pilot oil return Y 1) |

bar |

160 | ||||||

|

Port Y |

Pilot oil return, external |

bar |

160 | |||||

|

Hydraulic fluid 2) |

see table | |||||||

|

Hydraulic fluid temperature range |

NBR seals |

°C |

-30 … +80 | |||||

|

FKM seals |

°C |

-20 … +80 | ||||||

|

Viscosity range |

mm²/s |

2.8 … 500 | ||||||

|

Maximum admissible degree of contamination of the hydraulic fluid 3) |

Class 20/18/15 according to ISO 4406 (c) | |||||||

|

Maximum pilot pressure 4) |

bar |

250 | 210 | 250 | ||||

|

Minimum pilot pressure |

External or internal pilot oil supply X (with control spool D, K, E, J, L, M, Q, R, U, W) |

3-spool position valve, spring-centered |

bar |

10 | 14 | 10.5 | 13 | 8.5 |

|

3-spool position valve, pressure-centered |

bar |

- | 14 | - | 18 | 8.5 | ||

|

2-spool position valve with spring end position |

bar |

10 | 14 | 11 | 13 | 10 | ||

|

2-spool position valve with hydraulic end position |

bar |

7 | 14 | 8 | 5 | |||

|

Internal pilot oil supply X (with control spool C, F, G, H, P, T, V, Z, S) |

bar |

4.5 5) | 4.5 6) 7) | 4.5 7) | ||||

|

Pilot volume for switching process |

3-spool position valve, spring-centered |

cm³ |

2.04 | 5.72 | 7.64 | 14.2 | 29.4 | |

|

2-spool position valve |

from zero position in switching position “a” |

cm³ |

4.08 | 11.45 | 15.28 | 28.4 | 58.8 | |

|

from switching position “a” in zero position |

cm³ |

- | 2.9 | - | 7 | 15.1 | ||

|

from zero position in switching position “b” |

cm³ |

- | 5.72 | - | 14.15 | 29.4 | ||

|

from switching position “b” in zero position |

cm³ |

- | 2.83 | - | 5.73 | 14.4 | ||

|

Pilot flow for shortest switching time, approx. |

l/min |

35 | 45 | |||||

| 1) | As a 3-spool position valve, pressure-centered only possible if ppilot ≥ 2 x ptank + ppilot min |

| 2) | The ignition temperature of the process and operating medium used must be over the maximum solenoid surface temperature. |

| 3) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

| 4) | Internal pilot oil supply: With a higher pilot pressure, use of a “D3” pressure reducing valve is required. |

| 5) | For symbols C, F, G, H, P, T, V, Z, an internal pilot oil supply is only possible if the flow from P → T in the central position (for 3-spool position valve) or while crossing the central position (for 2-spool position valve) is so large that the pressure differential of P → T reaches a value of at least 6.5 bar. |

| 6) | Spool S only for NG16 |

| 7) | For spools C, F, G,J, H, P, T, V, Z, S – by means of preload valve (not NG10) or correspondingly high flow. (Determination of the required flow, see preload valve) |

|

Hydraulic fluid |

Classification |

Suitable sealing materials |

Standards |

|

|

Mineral oil |

HL, HLP |

FKM, NBR |

DIN 51524 |

|

|

Bio-degradable |

Insoluble in water |

HEES (synthetic esters) |

FKM |

VDMA 24568 |

|

HETG (rape seed oil) |

FKM, NBR |

|||

|

Soluble in water |

HEPG (polyglycols) |

FKM |

VDMA 24568 |

|

|

Other hydraulic fluids on request |

||||

Free flow cross-sections in zero position with spools Q, V and W

|

Size |

10 | 16 | 25 (4W.H22) | 25 (4W.H25) | 32 | ||

|

Spool Q |

A – T; B – T |

mm² |

13 | 32 | 78 | 83 | 78 |

|

Spool V |

P – A |

mm² |

13 | 32 | 73 | 83 | 73 |

|

A – T; B – T |

mm² |

13 | 32 | 84 | 83 | 84 | |

|

Spool W |

A – T; B – T |

mm² |

2.4 | 6 | 10 | 14 | 20 |

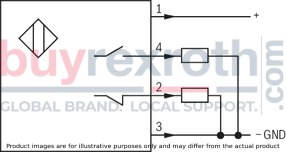

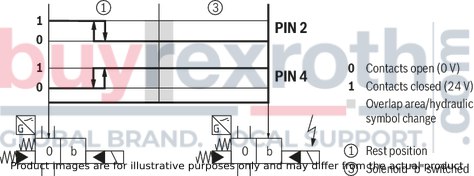

Inductive position switch type QM: electrical connection

The electric connection is realized via a 4-pole mating connector (separate order) with connection thread M12 x 1.

electrical

|

Connection voltage (DC voltage) |

V |

24 | ||

|

Voltage tolerance (connection voltage) |

+30 %/-15 % | |||

|

Admissible residual ripple |

% |

≤ 10 | ||

|

Max. load capacity |

mA |

400 | ||

|

Switching outputs

|

PNP transistor outputs, load between switching outputs and GND | |||

|

Pinout

|

1 |

V |

24 | |

|

2, 4 |

Switching output |

mA |

400 | |

|

3 |

Earthing (GND) |

V |

0 | |

For applications outside these parameters, please consult us!

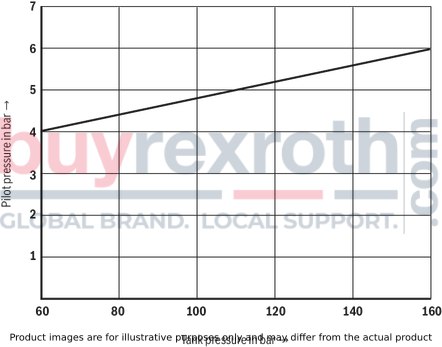

Minimum pilot pressure dependent on the tank pressure

At a higher tank pressure, the minimum pilot pressure has to be increased according to this diagram.

(measured with HLP46, ϑOil = 40 °C ± 5 °C)

Size 10

Δp-qV characteristic curves

|

Piston |

Spool position |

Piston |

Zero position |

|||||

|

P – A |

P – B |

A – T |

B – T |

A – T |

B – T |

P – T |

||

|

E, Y, D |

2 |

2 |

4 |

5 |

||||

|

F |

1 |

4 |

1 |

4 |

F |

3 |

– |

6 |

|

G, T |

4 |

2 |

2 |

6 |

G, T |

– |

– |

7 |

|

H, C |

4 |

4 |

1 |

4 |

H |

1 |

3 |

5 |

|

J, K |

1 |

2 |

1 |

3 |

||||

|

L |

2 |

3 |

1 |

4 |

L |

3 |

– |

– |

|

M |

4 |

4 |

3 |

4 |

||||

|

P |

4 |

1 |

3 |

4 |

P |

– |

7 |

5 |

|

Q, V, W, Z |

2 |

2 |

3 |

5 |

||||

|

R |

2 |

2 |

3 |

– |

||||

|

U |

3 |

3 |

3 |

4 |

U |

– |

4 |

– |

|

B |

2 |

2 |

– |

– |

||||

Performance limits: (measured with HLP46, ϑoil = 40 ±5 °C)

NG10

|

2-spool position valve – qV maxin l/min |

|||||

|

Symbol |

Operating pressure pmax in bar |

||||

|

70 |

140 |

210 |

280 |

350 |

|

|

X external – spring end position in the main valve1) (with ppilot min = 12 bar) |

|||||

|

C, D, K, Y, Z |

160 l/min |

160 l/min |

160 l/min |

160 l/min |

160 l/min |

|

X external – hydraulic end position in the main valve |

|||||

|

H |

160 l/min |

150 l/min |

|||

|

G, T |

160 l/min |

160 l/min |

|||

|

F, P |

160 l/min |

140 l/min |

|||

Size 16

Δp-qV characteristic curves

|

Symbol |

Spool position |

Zero position |

|||||

|

P – A |

P – B |

A – T |

B – T |

P – T |

A – T |

B – T |

|

|

D, E, Y |

1 |

1 |

3 |

3 |

|||

|

F |

1 |

2 |

5 |

5 |

4 |

3 |

– |

|

G |

4 |

1 |

5 |

5 |

7 |

– |

– |

|

C, H |

1 |

1 |

5 |

6 |

2 |

4 |

4 |

|

K, J |

2 |

2 |

6 |

6 |

– |

3 |

– |

|

L |

2 |

2 |

5 |

4 |

– |

3 |

– |

|

M |

1 |

1 |

3 |

4 |

|||

|

P |

2 |

1 |

3 |

6 |

5 |

– |

– |

|

Q |

1 |

1 |

6 |

6 |

|||

|

R |

2 |

4 |

7 |

– |

|||

|

S |

3 |

3 |

3 |

– |

9 |

– |

– |

|

T |

4 |

1 |

5 |

5 |

7 |

– |

– |

|

U |

2 |

2 |

3 |

4 |

6 |

||

|

V, Z |

1 |

1 |

6 |

6 |

10 |

8 |

8 |

|

W |

1 |

1 |

3 |

4 |

|||

Performance limits: (measured with HLP46, ϑoil = 40 ±5 °C)

NG16

|

2-spool position valve – qV max |

||||

|

Piston |

Operating pressure pmax in bar |

|||

|

70 bar |

140 bar |

210 bar |

280 bar |

|

|

X external, spring end position in the main valve (with ppilotmin = 12 bar) |

||||

|

C, D, K, Y, Z |

300 l/min |

300 l/min |

300 l/min |

300 l/min |

|

X external – spring end position in the main valve 1) |

||||

|

C |

300 l/min |

300 l/min |

300 l/min |

300 l/min |

|

D, Y |

300 l/min |

270 l/min |

260 l/min |

250 l/min |

|

K |

300 l/min |

250 l/min |

240 l/min |

230 l/min |

|

Z |

300 l/min |

260 l/min |

190 l/min |

180 l/min |

|

X external – hydraulic end position in the main valve |

||||

|

HC, HD, HK, HZ, HY |

300 l/min |

300 l/min |

300 l/min |

300 l/min |

| Attention! | |

| 1) If the specified flow values are exceeded, the function of the return spring is no longer guaranteed if the pilot pressure fails! |

|

3-spool position valve – qV max |

||||

|

Piston |

Operating pressure pmax in bar |

|||

|

70 bar |

140 bar |

210 bar |

280 bar |

|

|

X external – spring-centered |

||||

|

E, H, J, L, M, Q, U, W, R |

300 l/min |

300 l/min |

300 l/min |

300 l/min |

|

F, P |

300 l/min |

250 l/min |

180 l/min |

170 l/min |

|

G, T |

300 l/min |

300 l/min |

240 l/min |

210 l/min |

|

S |

300 l/min |

300 l/min |

300 l/min |

250 l/min |

|

V |

300 l/min |

250 l/min |

210 l/min |

200 l/min |

|

X external – pressure-centered (at minimum pilot pressure of 16 bar) |

||||

|

all spools 2) |

300 l/min |

300 l/min |

300 l/min |

300 l/min |

| 2) With spool V, the pilot control valve is not required for flows > 160 l/min. | |

(measured with HLP46, ϑOil = 40 °C ± 5 °C)

Size 25 (type W.H 22)

Δp-qV characteristic curves

|

Piston |

Spool position |

Piston |

Zero position |

||||||

|

P – A |

P – B |

A – T |

B – T |

B – A |

A – T |

B – T |

P – T |

||

|

C, E, M, P, Q, U, V, Z |

2 |

2 |

1 |

4 |

– |

F |

– |

– |

4 |

|

F |

1 |

2 |

1 |

2 |

– |

G, P |

– |

– |

6 |

|

G, T |

2 |

2 |

2 |

4 |

– |

H |

– |

– |

2 |

|

H, J, W, K, D |

2 |

2 |

1 |

3 |

– |

L |

4 |

– |

– |

|

L |

2 |

2 |

1 |

2 |

– |

T |

– |

– |

5 |

|

R |

1 |

2 |

1 |

– |

5 |

U |

– |

6 |

– |

|

B |

2 |

2 |

– |

– |

– |

||||

Performance limits: (measured with HLP46, ϑoil = 40 ±5 °C)

NG25 (type W.H 22)

|

2-spool position valve – qV max |

||||

|

Piston |

Operating pressure pmax in bar |

|||

|

70 bar |

140 bar |

210 bar |

280 bar |

|

|

X external – spring end position in the main valve (with ppilot min = 11 bar / 14 bar) |

||||

|

C, D, K, Y, Z |

450 l/min |

450 l/min |

450 l/min |

450 l/min |

|

X external – spring end position in the main valve 1) |

||||

|

C |

450 l/min |

450 l/min |

320 l/min |

250 l/min |

|

D, Y |

450 l/min |

450 l/min |

450 l/min |

400 l/min |

|

K |

450 l/min |

215 l/min |

150 l/min |

120 l/min |

|

Z |

350 l/min |

300 l/min |

290 l/min |

260 l/min |

|

X external – hydraulic end position in the main valve |

||||

|

HC, HD, HK, HZ, HY |

450 l/min |

450 l/min |

450 l/min |

450 l/min |

|

HC./O... HD./O... HK./O... HZ./O... |

450 l/min |

450 l/min |

450 l/min |

450 l/min |

|

HC./OF... HD./OF... HK./OF... HZ./OF... |

450 l/min |

450 l/min |

450 l/min |

450 l/min |

|

3-spool position valve – qV max |

||||

|

Piston |

Operating pressure pmax in bar |

|||

|

70 bar |

140 bar |

210 bar |

280 bar |

|

|

X external – spring-centered |

||||

|

E, J, L, M, Q, U, W, R |

450 l/min |

450 l/min |

450 l/min |

450 l/min |

|

H |

450 l/min |

450 l/min |

300 l/min |

260 l/min |

|

G |

400 l/min |

350 l/min |

250 l/min |

200 l/min |

|

F |

450 l/min |

270 l/min |

175 l/min |

130 l/min |

|

V |

450 l/min |

300 l/min |

240 l/min |

220 l/min |

|

T |

400 l/min |

300 l/min |

240 l/min |

200 l/min |

|

P |

450 l/min |

270 l/min |

180 l/min |

170 l/min |

(measured with HLP46, ϑOil = 40 °C ± 5 °C)

Size 25 (type W.H 25)

Δp-qV characteristic curves

|

Symbol |

Spool position |

Zero position |

|||||

|

P – A |

P – B |

A – T 1) |

B – T 1) |

A – T |

B – T |

P – T |

|

|

E, Y, D |

1 |

1 |

3 |

4 |

|||

|

F |

1 |

1 |

2 |

4 |

2 |

– |

5 |

|

G, T |

1 |

1 |

2 |

5 |

– |

– |

7 |

|

H |

1 |

1 |

2 |

5 |

2 |

2 |

4 |

|

C |

1 |

1 |

2 |

5 |

|||

|

J |

1 |

1 |

2 |

5 |

6 |

5 |

– |

|

K |

1 |

1 |

2 |

5 |

|||

|

L |

1 |

1 |

2 |

4 |

5 |

– |

– |

|

M |

1 |

1 |

3 |

4 |

|||

|

P |

1 |

1 |

3 |

5 |

– |

3 |

5 |

|

Q |

1 |

1 |

2 |

3 |

|||

|

R |

1 |

1 |

3 |

– |

|||

|

U |

1 |

1 |

2 |

5 |

– |

5 |

– |

|

V |

1 |

1 |

2 |

5 |

8 |

7 |

– |

|

Z |

1 |

1 |

2 |

5 |

|||

|

W |

1 |

1 |

3 |

4 |

|||

|

8 Symbol R, spool position B – A |

|||||||

| 1) | The pressure differential refers to the use of port T. If port T1 is additionally used, the pressure differential maybe lower. If only port T1 is used, the relations A – T and B – T may be reversed. |

|

7 |

Spool G central position P – T |

|

8 |

Spool T central position P – T |

Performance limits: (measured with HLP46, ϑoil = 40 ±5 °C)

NG25 (type W.H 25)

|

2-spool position valve – qV max |

||||

|

Piston |

Operating pressure pmax in bar |

|||

|

70 bar |

140 bar |

210 bar |

280 bar |

|

|

X external – spring end position in the main valve (with ppilotmin = 13 bar) |

||||

|

C, D, K, Y, Z |

700 l/min |

700 l/min |

700 l/min |

700 l/min |

|

X external – spring end position in the main valve 1) |

||||

|

C |

700 l/min |

700 l/min |

700 l/min |

700 l/min |

|

D, Y |

700 l/min |

650 l/min |

400 l/min |

350 l/min |

|

K |

700 l/min |

650 l/min |

420 l/min |

370 l/min |

|

Z |

700 l/min |

700 l/min |

650 l/min |

480 l/min |

|

X external – hydraulic end position in the main valve |

||||

|

HC, HD, HK, HZ, HY |

700 l/min |

700 l/min |

700 l/min |

700 l/min |

|

HC./O... HD./O... HK./O... HZ./O... |

700 l/min |

700 l/min |

700 l/min |

700 l/min |

|

HC./OF... HD./OF... HK./OF... HZ./OF... |

700 l/min |

700 l/min |

700 l/min |

700 l/min |

|

3-spool position valve – qV max |

||||

|

Piston |

Operating pressure pmax in bar |

|||

|

70 bar |

140 bar |

210 bar |

280 bar |

|

|

X external – spring-centered |

||||

|

E, L, M, Q, U, W |

700 l/min |

700 l/min |

700 l/min |

700 l/min |

|

G, T |

400 l/min |

400 l/min |

400 l/min |

400 l/min |

|

F |

650 l/min |

550 l/min |

430 l/min |

330 l/min |

|

H |

700 l/min |

650 l/min |

550 l/min |

400 l/min |

|

J |

700 l/min |

700 l/min |

650 l/min |

600 l/min |

|

p |

650 l/min |

550 l/min |

430 l/min |

330 l/min |

|

V |

650 l/min |

550 l/min |

400 l/min |

350 l/min |

|

R |

700 l/min |

700 l/min |

700 l/min |

650 l/min |

|

X external – pressure-centered (at minimum pilot pressure of 18 bar) |

||||

|

E, F, H, J, L, M, P, Q, R, U, V, W |

700 l/min |

700 l/min |

700 l/min |

700 l/min |

|

G, T |

400 l/min |

400 l/min |

400 l/min |

400 l/min |

|

X external – pressure-centered (with pilot pressure > 30 bar) |

||||

|

G, T |

700 l/min |

700 l/min |

700 l/min |

700 l/min |

| Attention! | |

| 1) If the specified flow values are exceeded, the function of the return spring is no longer guaranteed if the pilot pressure fails! |

(measured with HLP46, ϑOil = 40 °C ± 5 °C)

Size 32

∆p-qv-characteristic curves – Symbol E, R and W

|

Piston |

Spool position |

||||

|

P – A |

P – B |

A – T |

B – T |

B – A |

|

|

E |

4 |

4 |

3 |

2 |

– |

|

R |

4 |

4 |

3 |

– |

1 |

|

W |

4 |

4 |

3 |

2 |

– |

Size 32

∆p-qv- characteristic curves – Symbol G and T

|

Piston |

Spool position |

||||

|

P – A |

P – B |

A – T |

B – T |

P – T |

|

|

G |

7 |

8 |

7 |

5 |

6 |

|

T |

7 |

8 |

7 |

5 |

6 |

Performance limits: (measured with HLP46, ϑoil = 40 ±5 °C)

Size 32

|

2-spool position valve – qV max |

||||

|

Piston |

Operating pressure pmax in bar |

|||

|

70 bar |

140 bar |

210 bar |

280 bar |

|

|

X external – spring end position in the main valve (with ppilot min = 10 bar) |

||||

|

C, D, K, Y, Z |

1100 l/min |

1040 l/min |

860 l/min |

750 l/min |

|

X external – spring end position in the main valve 1) |

||||

|

C |

1100 l/min |

1040 l/min |

860 l/min |

800 l/min |

|

D, Y |

1100 l/min |

1040 l/min |

540 l/min |

480 l/min |

|

K |

1100 l/min |

1040 l/min |

860 l/min |

500 l/min |

|

Z |

1100 l/min |

1040 l/min |

860 l/min |

700 l/min |

|

X external – hydraulic end position in the main valve |

||||

|

HC, HD, HK, HZ, HY |

1100 l/min |

1040 l/min |

860 l/min |

750 l/min |

|

3-spool position valve – qV max |

||||

|

Piston |

Operating pressure pmax in bar |

|||

|

70 bar |

140 bar |

210 bar |

280 bar |

|

|

X external – spring-centered |

||||

|

E, J, L, M, Q, U, W |

1100 l/min |

1040 l/min |

860 l/min |

750 l/min |

|

G, T, H, F, P |

900 l/min |

900 l/min |

800 l/min |

650 l/min |

|

V |

1100 l/min |

1000 l/min |

680 l/min |

500 l/min |

|

X external – pressure-centered (at minimum pilot pressure of 8.5 bar) |

||||

|

all spools |

1100 l/min |

1040 l/min |

860 l/min |

750 l/min |

| 1) If the specified flow values are exceeded, the function of the return spring is no longer guaranteed if the pilot pressure fails! |

Performance limits: important information

Notice (applies to all sizes):

The specified switching power limits apply to the use with two directions of flow (e. g. from P to A and simultaneous return flow from B to T at a ratio of 1:1). Due to the flow forces acting within the valves, the admissible switching power limit may be considerably lower with only one direction of flow (e. g. from P to A while port B is blocked, with flow in the same or in different directions)! In such cases of application, please consult us!

The switching power limit was established while the solenoids were at operating temperature, at 10% undervoltage, and without tank preloading.

|

Attention! |

|

|

NG16 |

With pilot oil supply X internal, a preload valve has to be used for flows < 160 l/min due to the negative overlap of the symbols C, Z and HC, HZ. 4/3 directional valves with pressure centering of the control spool in the main valve can be used above the indicated performance limit. In this case, a higher pilot pressure is required (values see performance limits of the corresponding size). With pilot oil supply X internal, sufficient flow needs to be ensured due to the negative overlap of symbols F, G, H, P, S and T (for determination of the required flow, see "Preload valve" characteristic curves. If the required flow is not reached, a preload valve has to be used (see technical data). |

|

NG25 |

With pilot oil supply X internal a preload valve has to be used for flows < 180 l/min due to the negative overlap of spools Z, HZ and V. With pilot oil supply X internal sufficient flow needs to be ensured due to the negative overlap of symbols C, HC, F, G, H, P and T (for determination of the required flow, see “Preload valve” characteristic curves. If the required flow is not reached, a preload valve has to be used (see technical data). |

|

NG32 |

With pilot oil supply X internal, a preload valve has to be used for flows < 180 l/min due to the negative overlap of symbols Z, HZ and V. 4/3 directional valves with pressure centering of the control spool in the main valve can be used above the indicated performance limit. In this case, a higher pilot pressure is required (values see performance limits of the corresponding size). With pilot oil supply X internal, sufficient flow needs to be ensured due to the negative overlap of symbols C, HC, F, G, H, P and T (for determination of the required flow, see "Preload valve" characteristic curves. If the required flow is not reached, a preload valve has to be used (see technical data). |

(measured with HLP46, ϑOil = 40 ±5 °C)

| 1) | only for NG10 and 25 (4W.H 22.) if operating pressure > tank pressure, port T is to be used as a leakage port! |

| 2) | only type WMRH/WMUH and WMMH available. |

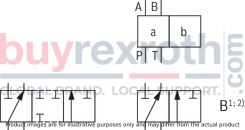

Attention!

Caution in conjunction with differential cylinders due to pressure intensification!

|

Order details |

Type of actuation |

|

|

Symbol |

Spool return |

pneumatic |

|

C, D, K, Z |

../.. |

|

|

..H../O |

|

|

|

..H../OF |

|

|

|

B, Y |

../.. |

|

|

Y |

..H../.. |

|

| 3) Example: | |

| – Spool E with actuating side “a” → ordering code ..EA.. | |

| – Spool E with actuating side “b” → ordering code ..EB.. | |

| 4) Spool symbol E1-: P → A/B pre-opening |

Attention!

Caution in conjunction with differential cylinders due to pressure intensification!

|

Order details |

Type of actuation |

|

|

Symbol |

Actuating side |

pneumatic |

|

E, F, G, H, J, L, M, Q, R, S, T, U, V, W |

.A |

|

|

.B |

|

|

|

||

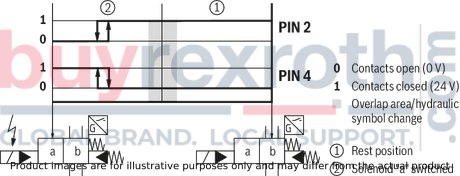

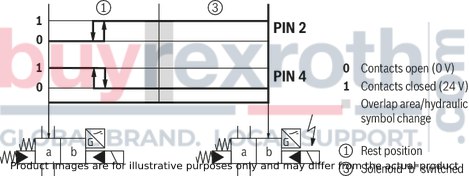

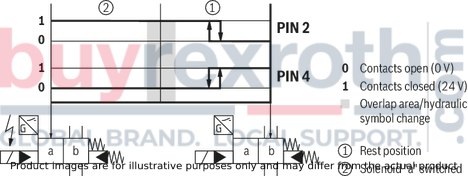

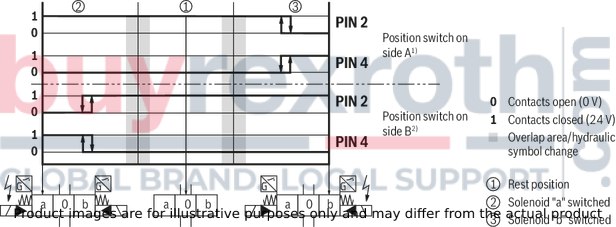

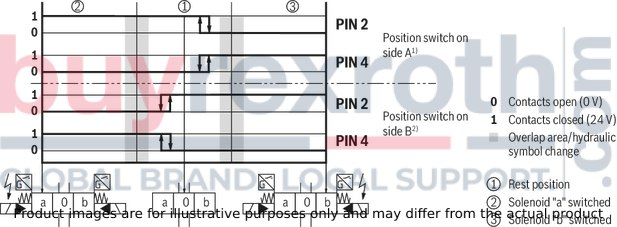

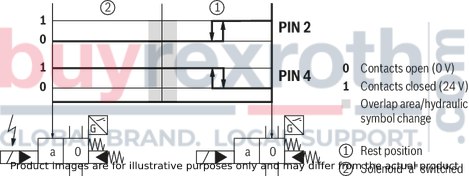

Inductive position switch type QM Switching logics

Version QMA

(Position switch on side B, monitored spool position of the main stage "a")

Version QMA

(Position switch on side B, monitored spool position of the main stage "a")

Version QMB

(Position switch on side A, monitored spool position of the main stage "b")

Version QMB

(Position switch on side A, monitored spool position of the main stage "b")

version QMAB

(Position switch on side A and B, monitored spool position "a" and "b")

Version QM0

(Position switch on side A and B, monitored spool position "0")

| 1) No signal change at the position switch on side B with spool position "a" | |

| 2) No signal change at the position switch on side A with spool position "b" |

Version QM0

(Position switch on side B, monitored spool position of the main stage "0")

Version QM0

(Position switch on side A, monitored spool position of the main stage "0")

2 spool positions

3 spool positions

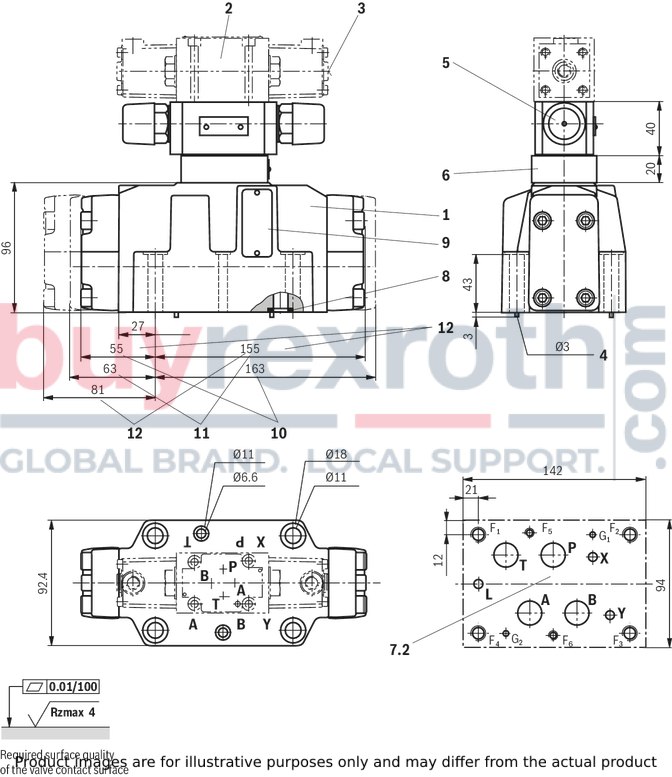

NG10

Dimensions in mm

|

1 |

Main valve |

|

2 |

Pilot control valve: For unit dimensions, see basic data sheets |

|

3 |

Manual override, “N”, optional Actuation of the manual override is only possible up to a tank pressure of approx. 50 bar. Avoid damage to the bore of the manual override! (Special tool for actuation, separate order, material no. R900024943). |

|

5 |

Switching time adjustment (wrench size 6), optional |

|

6 |

Pressure reducing valve, optional |

|

7.1 |

Machined valve contact surface; porting pattern according to ISO 4401-05-05-0-05 |

|

8 |

Seal rings |

|

9 |

Name plate complete valve |

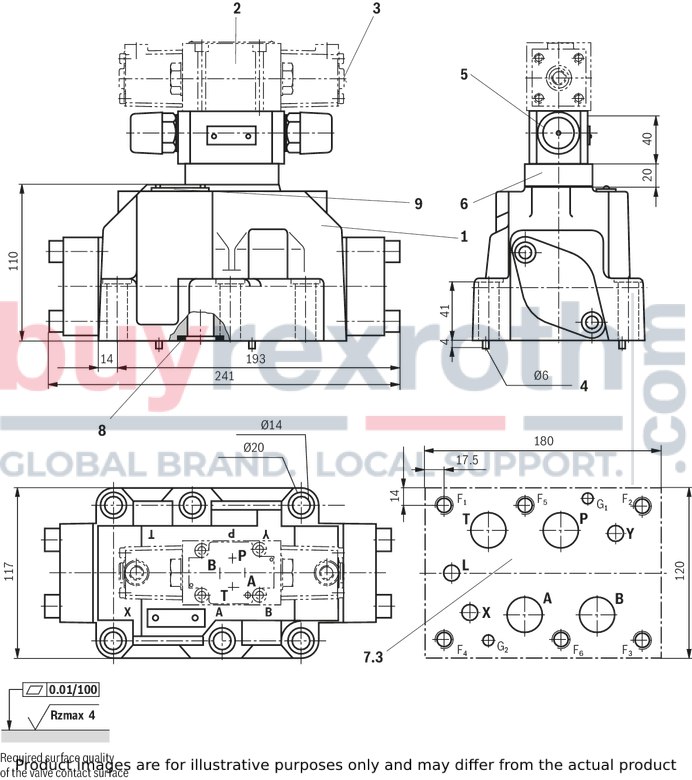

NG16

Dimensions in mm

|

1 |

Main valve |

|

2 |

Pilot control valve: For unit dimensions, see basic data sheets |

|

3 |

Manual override, “N”, optional Actuation of the manual override is only possible up to a tank pressure of approx. 50 bar. Avoid damage to the bore of the manual override! (Special tool for actuation, separate order, material no. R900024943). |

|

4 |

Locking pin |

|

5 |

Switching time adjustment (wrench size 6), optional |

|

6 |

Pressure reducing valve, optional |

|

7.2 |

machined valve contact surface; porting pattern according to ISO 4401-07-07-0-05 |

|

8 |

Seal rings |

|

9 |

Name plate complete valve |

|

10 |

2-spool position valves with spring end position in the main valve (spool symbols A, C, D) |

|

11 |

2-spool position valves with spring end position in the main valve (spool symbols B, Y) |

|

12 |

3-spool position valves, spring-centered; |

NG25 (type W.H 22)

Dimensions in mm

|

1 |

Main valve |

|

2 |

Pilot control valve: For unit dimensions, see basic data sheets |

|

3 |

Manual override, “N”, optional Actuation of the manual override is only possible up to a tank pressure of approx. 50 bar. Avoid damage to the bore of the manual override! (Special tool for actuation, separate order, material no. R900024943). |

|

4 |

Locking pin |

|

5 |

Switching time adjustment (wrench size 6), optional |

|

6 |

Pressure reducing valve, optional |

|

7.3 |

machined valve contact surface; porting pattern according to ISO 4401-08-08-0-05 |

|

8 |

Seal rings |

|

9 |

Name plate complete valve |

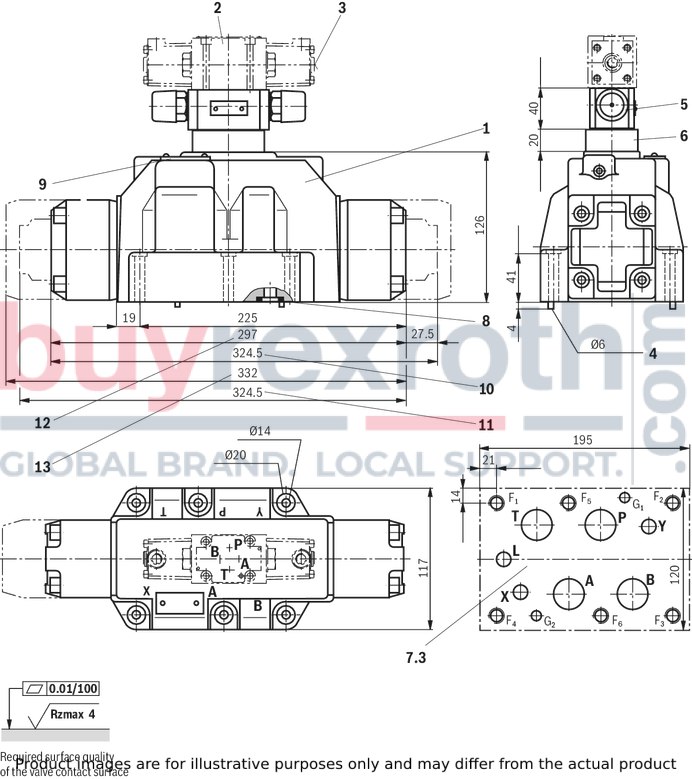

NG25 (type W.H 25)

Dimensions in mm

|

1 |

Main valve |

|

2 |

Pilot control valve: For unit dimensions, see basic data sheets |

|

3 |

Manual override, “N”, optional Actuation of the manual override is only possible up to a tank pressure of approx. 50 bar. Avoid damage to the bore of the manual override! (Special tool for actuation, separate order, material no. R900024943). |

|

4 |

Locking pin |

|

5 |

Switching time adjustment (wrench size 6), optional |

|

6 |

Pressure reducing valve, optional |

|

7.3 |

machined valve contact surface; porting pattern according to ISO 4401-08-08-0-05 |

|

8 |

Seal rings |

|

9 |

Name plate complete valve |

|

10 |

2-spool position valves with spring end position in the main valve (spool symbols A, C, D) |

|

11 |

2-spool position valves with spring end position in the main valve (spool symbols B, Y) |

|

12 |

3-spool position valves, spring-centered; |

|

13 |

3-spool position valves, pressure-centered |

Size 32

Dimensions in mm

|

1 |

Main valve |

|

2 |

Pilot control valve: For unit dimensions, see basic data sheets |

|

3 |

Manual override, “N”, optional Actuation of the manual override is only possible up to a tank pressure of approx. 50 bar. Avoid damage to the bore of the manual override! (Special tool for actuation, separate order, material no. R900024943). |

|

4 |

Locking pin |

|

5 |

Switching time adjustment (wrench size 6), optional |

|

6 |

Pressure reducing valve, optional |

|

7.4 |

machined valve contact surface; porting pattern according to ISO 4401-10-09-0-05 |

|

8 |

Seal rings |

|

9 |

Name plate complete valve |

|

10 |

2-spool position valves with spring end position in the main valve (spool symbols A, C, D) |

|

11 |

2-spool position valves with spring end position in the main valve (spool symbols B, Y) |

|

12 |

3-spool position valves, spring-centered; |

|

13 |

3-spool position valves, pressure-centered |

Subplates (separate order)

– NG10 (according to data sheet 45054)

without port X, Y:G 534/01 (G3/4)

G 534/12 (SAE-12; 1 1/16-12)1)

with port X, Y:G 535/01 (G3/4)

G 536/01 (G1)

G 535/12 (SAE-12; 1 1/16-12)1)

G 536/12 (SAE-16; 1 5/16-12)1)

– NG16 (according to data sheet 45056)

G 172/01 (G3/4)

G 172/02 (M27 x 2)

G 174/01 (G1)

G 174/02 (M33 x 2)

G 174/08 (flange)

G 172/12 (SAE-12; 1 1/16-12)1)

G 174/12 (SAE-16; 1 5/16-12)1)

– NG25 (type W.H 22 according to data sheet 45058)

G 151/01 (G1)

G 154/01 (G1 1/4)

G 156/01 (G1 1/2)

G 155/12 (SAE-16; 1 5/16-12)1)

G 154/12 (SAE-20; 1 5/8-20)1)

G 156/12 (SAE-24; 1 7/8-20)1)

– NG25 (type W.H 25 according to data sheet 45058)

G 151/01 (G1)

G 153/01 (G1), for valves with pressure-centered zero position

G 154/01 (G1 1/4)

G 154/08 (flange)

G 156/01 (G1 1/2)

G 153/12 (SAE-16; 1 5/16-12)1)

G 154/12 (SAE-20; 1 5/8-20)1)

G 156/12 (SAE-24; 1 7/8-20)1)

– NG32 (according to data sheet 45060)

G 157/01 (G1 1/2)

G 157/02 (M48 x 2)

G 158/10 (flange)

G 157/12 (SAE-24; 1 7/8-12)1)

1) on request

Valve mounting screws (separate order)

– NG10:

4 metric hexagon socket head cap screws

ISO 4762 - M6 x 45 - 10.9-flZn-240h-L

(friction coefficient μtotal = 0.09 to 0.14);

tightening torque MA = 12.5 Nm ± 10%,

material no. R913000258

4 hexagon socket head cap screws UNC

1/4-20 UNC x 1 3/4″ ASTM-A574

on request

– NG16:

4 metric hexagon socket head cap screws

ISO 4762 - M10 x 60 - 10.9-flZn-240h-L

(friction coefficientμtotal = 0.09 to 0.14);

tightening torqueMA = 75 Nm ± 10%,

material no. R913000116

2 metric hexagon socket head cap screws

ISO 4762 - M6 x 60 - 10.9-flZn-240h-L

(friction coefficientμtotal = 0.09 to 0.14);

tightening torque MA = 12.5 Nm ± 10%,

material no. R913000115

4 hexagon socket head cap screws UNC

3/8-16 UNC x 2 1/4″ ASTM-A574

on request

2 hexagon socket head cap screws UNC

1/4-20 UNC x 1/4″ ASTM-A574

on request

– NG25:

6 metric hexagon socket head cap screws

ISO 4762 - M12 x 60 - 10.9-flZn-240h-L

(friction coefficient μtotal = 0.09 to 0.14);

tightening torqueMA = 130 Nm ± 10%,

material no. R913000121

6 hexagon socket head cap screws UNC

1/2-13 UNC x 2 1/2″ ASTM-A574

on request

– NG32:

6 metric hexagon socket head cap screws

ISO 4762 - M20 x 80 - 10.9-flZn-240h-L

(friction coefficient μtotal = 0.09 to 0.14);

tightening torque MA = 430 Nm ± 10%,

material no. R901035246

6 hexagon socket head cap screws UNC

3/4-10 UNC x 3 1/4″ ASTM-A574

on request

Stroke setting, mounting options

The stroke of the control spool (1) is limited by the stroke setting.

The piston stroke is shortened by loosening the lock nut (2) and clockwise rotation of the adjustment spindle (3). The control chamber (4) must be depressurized for this.

|

NG |

L4 |

|

mm |

|

| 10 | 6.5 |

| 16 | 10 |

| 25 (4W.H22) | 9.5 |

| 25 (4W.H25) | 12.5 |

| 32 | 15 |

5 adjustment range

– NG10:

1 rotation = 1 mm adjustment travel

– NG16 to 32:

1 rotation = 1.5 mm adjustment travel

Stroke setting, mounting options

Stroke limitation on side A

Stroke setting, mounting options

Stroke limitation on side B

|

Mounting options |

NG |

3-spool position valve 1) |

|||||

|

Spring-centered |

Pressure-centered |

||||||

|

L1 (mm) |

L2 (mm) |

L3 (mm) |

L1 (mm) |

L2 (mm) |

L3 (mm) |

||

|

Stroke setting on valve side A and B |

10 |

90 |

144 |

234 |

|

|

|

|

16 |

100 |

200 |

300 |

|

|

|

|

|

25 2) |

96 |

241 |

337 |

|

|

|

|

|

25 3) |

123 |

276 |

399 |

|

|

|

|

|

32 |

133 |

344 |

477 |

|

|

|

|

|

Stroke setting on valve side A |

10 |

90 |

106 |

196 |

|

|

|

|

16 |

100 |

156 |

256 |

|

|

|

|

|

25 2) |

96 |

193 |

289 |

|

|

|

|

|

25 3) |

123 |

225 |

348 |

|

|

|

|

|

32 |

133 |

287 |

420 |

|

|

|

|

|

Stroke setting on valve side B |

10 |

52 |

144 |

196 |

– |

– |

– |

|

16 |

56 |

200 |

256 |

81 |

200 |

281 |

|

|

25 2) |

48 |

241 |

289 |

– |

– |

– |

|

|

25 3) |

72 |

276 |

348 |

107 |

276 |

283 |

|

|

32 |

76 |

344 |

420 |

120 |

344 |

464 |

|

| 1) | With symbol A only version "11", with symbol B only version "12" possible. |

| 2) | Version "W.H 22" |

| 3) | Version "W.H 25" |

| 1) With symbol A only version "11", with symbol B only version "12" possible. | |

| 2) Version "H-WEH 22" | |

| 3) Version "H-WEH 25" |

|

Mounting options |

NG |

2-spool position valve |

||||||||

|

Spring end position |

Hydraulic end position |

|||||||||

|

A, C, D, K, Z |

B, Y |

HC, HD, HK, HZ, HY |

||||||||

|

L1 (mm) |

L2 (mm) |

L3 (mm) |

L1 (mm) |

L2 (mm) |

L3 (mm) |

L1 (mm) |

L2 (mm) |

L3 (mm) |

||

|

Stroke setting on valve side A and B |

10 |

90 |

144 |

234 |

90 |

144 |

234 |

90 |

144 |

234 |

|

16 |

– |

– |

– |

– |

– |

– |

100 |

200 |

300 |

|

|

25 1) |

96 |

241 |

337 |

96 |

241 |

337 |

96 |

241 |

337 |

|

|

25 2) |

– |

– |

– |

– |

– |

– |

123 |

276 |

399 |

|

|

32 |

– |

– |

– |

– |

– |

– |

133 |

344 |

477 |

|

|

Stroke setting on valve side A |

10 |

90 |

106 |

196 |

– |

– |

– |

90 |

106 |

196 |

|

16 |

100 |

180 |

280 |

– |

– |

– |

100 |

156 |

256 |

|

|

25 1) |

96 |

193 |

289 |

96 |

193 |

289 |

96 |

193 |

289 |

|

|

25 2) |

123 |

253 |

376 |

– |

– |

– |

123 |

225 |

348 |

|

|

32 |

133 |

316 |

449 |

– |

– |

– |

133 |

287 |

420 |

|

|

Stroke setting on valve side B |

10 |

52 |

144 |

196 |

52 |

144 |

196 |

52 |

144 |

196 |

|

16 |

– |

– |

– |

80 |

200 |

280 |

56 |

200 |

256 |

|

|

25 1) |

48 |

241 |

289 |

48 |

241 |

289 |

48 |

241 |

289 |

|

|

25 2) |

– |

– |

– |

100 |

276 |

376 |

72 |

276 |

348 |

|

|

32 |

– |

– |

– |

105 |

344 |

449 |

76 |

344 |

420 |

|

| 1) | Version "W.H 22" |

| 2) | Version "W.H 25" |

| 1) Type 4W.H 22 | |

| 2) Type 4W.H 25 |

Spool position monitoring

Dimensions in mm

Inductive position switch type QM

Dimensions in mm

| 1) | Without mating connector |

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

|

Mounting options – 2-spool position valve |

||||||||||||||

|

Monitored spool position |

Ordering code |

NG |

Hydraulic end position HC, HD, HK, HZ |

Spring end position C, D, K, Z |

Spring end position Y |

|||||||||

|

L1 (mm) 1) |

L2 (mm) 1) |

L3 (mm) |

L4 (mm) |

L1 (mm) 1) |

L2 (mm) 1) |

L3 (mm) |

L4 (mm) |

L1 (mm) 1) |

L2 (mm) 1) |

L3 (mm) |

L4 (mm) |

|||

|

„a“ Position switch on side B |

QMAG24 |

10 |

211 |

57 |

211 |

57 |

211 |

57 |

||||||

|

16 |

259 |

55 |

259 |

55 |

||||||||||

|

25 2) |

294 |

47 |

294 |

47 |

294 |

47 |

||||||||

|

25 3) |

325 |

72 |

325 |

72 |

||||||||||

|

32 |

371 |

76 |

371 |

76 |

||||||||||

|

„b“ Position switch on side A |

QMBG24 |

10 |

157 |

111 |

157 |

111 |

157 |

111 |

||||||

|

16 |

159 |

155 |

159 |

155 |

||||||||||

|

25 2) |

149 |

192 |

149 |

192 |

149 |

192 |

||||||||

|

25 3) |

172 |

225 |

172 |

225 |

||||||||||

|

32 |

161 |

287 |

161 |

287 |

||||||||||

|

"a" and "b" Position switch on side A and B |

QMABG24 |

10 |

157 |

211 |

157 |

211 |

157 |

211 |

||||||

|

16 |

159 |

259 |

||||||||||||

|

25 2) |

149 |

294 |

149 |

294 |

149 |

294 |

||||||||

|

25 3) |

172 |

325 |

||||||||||||

|

32 |

161 |

371 |

||||||||||||

| 1) | Without mating connector |

| 2) | Version "W.H 22" |

| 3) | Version "W.H 25" |

| 1) Without mating connector | |

| 2) Type 4W.H 22.. | |

| 3) Type 4W.H 25.. |

|

Mounting options – 3-spool position valve |

||||||||||

|

Monitored spool position |

Ordering code |

NG |

Spring-centered |

Pressure-centered |

||||||

|

L1 (mm) 1) |

L2 (mm) 1) |

L3 (mm) |

L4 (mm) |

L1 (mm) 1) |

L2 (mm) 1) |

L3 (mm) |

L4 (mm) |

|||

|

„a“ Position switch on side B |

QMAG24 |

10 |

211 |

57 |

||||||

|

16 |

259 |

55 |

259 |

81 |

||||||

|

25 2) |

294 |

47 |

||||||||

|

25 3) |

325 |

72 |

325 |

107 |

||||||

|

32 |

371 |

76 |

371 |

120 |

||||||

|

„b“ Position switch on side A |

QMBG24 |

10 |

157 |

111 |

||||||

|

16 |

159 |

155 |

||||||||

|

25 2) |

149 |

192 |

||||||||

|

25 3) |

172 |

225 |

||||||||

|

32 |

161 |

287 |

||||||||

|

"a" and "b" Position switch on side A and B |

QMABG24 |

10 |

157 |

211 |

||||||

|

16 |

159 |

259 |

||||||||

|

25 2) |

149 |

294 |

||||||||

|

25 3) |

172 |

325 |

||||||||

|

32 |

161 |

371 |

||||||||

|

Zero position Position switch on side A and B 2 position switches |

QM0G24 4) |

10 |

157 |

211 |

||||||

|

16 |

159 |

259 |

||||||||

|

25 2) |

149 |

294 |

||||||||

|

25 3) |

172 |

325 |

||||||||

|

32 |

161 |

371 |

||||||||

| 1) | Without mating connector |

| 2) | Version "W.H 22" |

| 3) | Version "W.H 25" |

| 4) | 3-spool position valve |

| 1) Without mating connector | |

| 2) Type 4W.H 22 | |

| 3) Type 4W.H 25 | |

| 4) 3-spool position valve | |

|

Mounting options – 3-spool position valve with one solenoid |

||||||||||||||

|

Monitored spool position |

Ordering code |

NG |

Side A (EA, FA…) Spring-centered |

Solenoids on side B (EB, FB…) Spring-centered |

Side A (EA, FA…) Pressure-centered |

|||||||||

|

L1 (mm) 1) |

L2 (mm) 1) |

L3 (mm) |

L4 (mm) |

L1 (mm) 1) |

L2 (mm) 1) |

L3 (mm) |

L4 (mm) |

L1 (mm) 1) |

L2 (mm) 1) |

L3 (mm) |

L4 (mm) |

|||

|

„a“ Position switch on side B |

QMAG24 |

10 |

211 |

57 |

||||||||||

|

16 |

259 |

55 |

259 |

81 |

||||||||||

|

25 2) |

294 |

47 |

||||||||||||

|

25 3) |

325 |

72 |

325 |

107 |

||||||||||

|

32 |

371 |

371 |

120 |

|||||||||||

|

„b“ Position switch on side A |

QMBG24 |

10 |

157 |

111 |

||||||||||

|

16 |

159 |

155 |

||||||||||||

|

25 2) |

149 |

192 |

||||||||||||

|

25 3) |

172 |

225 |

||||||||||||

|

32 |

161 |

287 |

||||||||||||

|

Zero position Position switch on side A or B 1 position switches |

QM0G24 4) |

10 |

211 |

57 |

157 |

111 |

||||||||

|

16 |

259 |

55 |

159 |

155 |

259 |

81 |

||||||||

|

25 2) |

294 |

47 |

149 |

192 |

||||||||||

|

25 3) |

325 |

72 |

172 |

225 |

325 |

107 |

||||||||

|

32 |

371 |

76 |

161 |

287 |

371 |

120 |

||||||||

| 1) Without mating connector | |

| 2) Type 4W.H 22.. | |

| 3) Type 4W.H 25.. | |

| 4) 2-spool position valve | |

Switching time adjustment

Type 4W.H 10 ..4X/…S, type 4W.H 10 ..4X/…S2

The switching time of the main valve (1) is influenced by using a twin throttle check valve (2) (type Z2FS 6; data sheet 27506).

Modification of supply (3) to discharge control (4):

Remove the pilot control valve (5) – The plate (6) to accept the seal rings stays in place – Turn the switching time adjustment (2) around its longitudinal axis and put it back, install the pilot control valve (5).

Notice:

The modification may only be performed by authorized specialists or at the factory!

"D3” pressure reducing valve

Type 4W.H 10 ..4X/…/..D3

The pressure reducing valve (8) has to be used at a pilot pressure above 250 bar (with type 4W.H 22 …: 210 bar) and with version “H”.

The secondary pressure is kept at a constant level of 45 bar.

Notice:

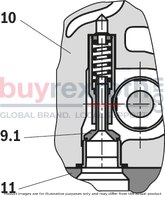

If a pressure reducing valve "D3" (8) is used, a "B10" throttle insert has to be installed in channel P of the pilot control valve. The modification may only be performed by authorized specialists or at the factory!Preload valve (not for NG10)

In case of valves with depressurized circulation and internal pilot oil supply, the installation of the preload valve (9) in channel P of the main valve is required in order to build up the minimum pilot pressure.

The pressure differential of the preload valve is to be added to the pressure differential of the main valve (see characteristic curves) to result in one total value.

The cracking pressure is approx. 4.5 bar.

|

9.1 |

Preload valve NG16 |

|

9.2 |

Preload valve NG25 and NG32 |

|

10 |

Main valve |

|

11 |

Subplate |

|

Type |

Material number P4,5 |

|

4W.H 16 … |

R901002365 |

|

4W.H 22 … |

R900315596 |

|

4W.H 25 … |

R900303717 |

|

4W.H 32 … |

R900317066 |

Δp–qVcharacteristic curve (measured with HLP46, ϑOil = 40 °C ± 5 °C)

The secondary pressure is kept at a constant level of 45 bar.

|

1 |

NG16 |

|

2 |

NG25 (type 4W.H 25 …) |

|

3 |

NG25 (type 4W.H 22 …) |

|

4 |

Size 32 |

Related Products

R978914290

$1,759.00 USD

R978901711

$819.00 USD

R978912001

$1,982.00 USD

R901406415

$1,671.00 USD

R978032138

$1,073.00 USD