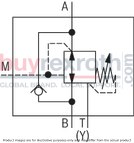

The valve type DR 10 DP is a direct operated pressure reducing valve in 3-way version, i. e. with pressure limitation of the secondary circuit.

It is used to limit a system pressure.

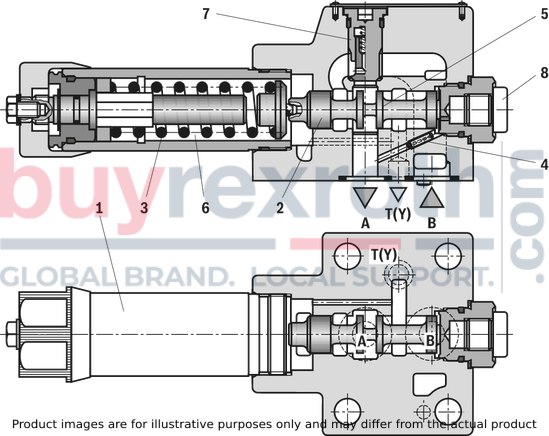

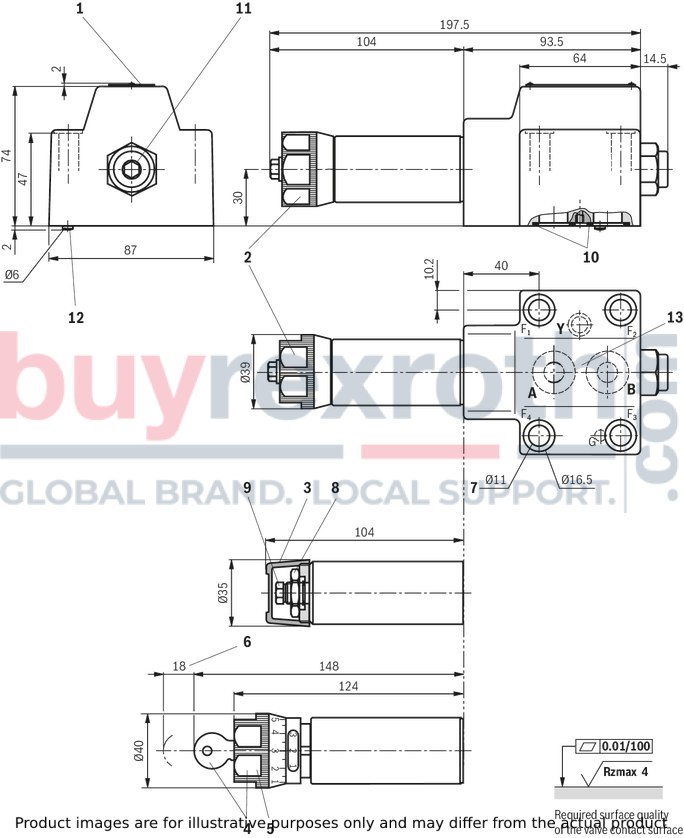

The secondary pressure is set via the adjustment type (1).

The valve is open in initial position. Hydraulic fluid can flow from channel B to channel A without restrictions. The pressure in channel A is simultaneously applied via the control line (4) at the piston area opposite the compression spring (3). If the pressure in channel A exceeds the value set at the compression spring (3), the control spool (2) moves to control position and keeps the set pressure in channel A at a constant level.

Signal and pilot oil are supplied internally via the control line (4) from channel A.

If the pressure in channel A increases further due to an external force effect at the actuator, it pushes the control spool (2) even further against the compression spring (3).

In this way, channel A is connected to channel T(Y) via the control edge (5) at the control spool (2). So much hydraulic fluid is discharged into the tank that the pressure can only increase slightly.

The leakage oil discharge from the spring chamber (6) is always effected externally via channel T(Y).

For the free flow back from channel A to channel B, a check valve (7) can optionally be installed.

A pressure gauge connection (8) allows for the control of the secondary pressure.

Type DR 10 DP1-4X/.Y…