The valve type ZDR is a direct operated pressure reducing valve in sandwich plate design with pressure limitation of the secondary circuit. It is used to reduce the system pressure.

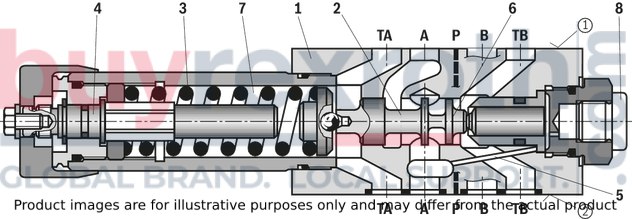

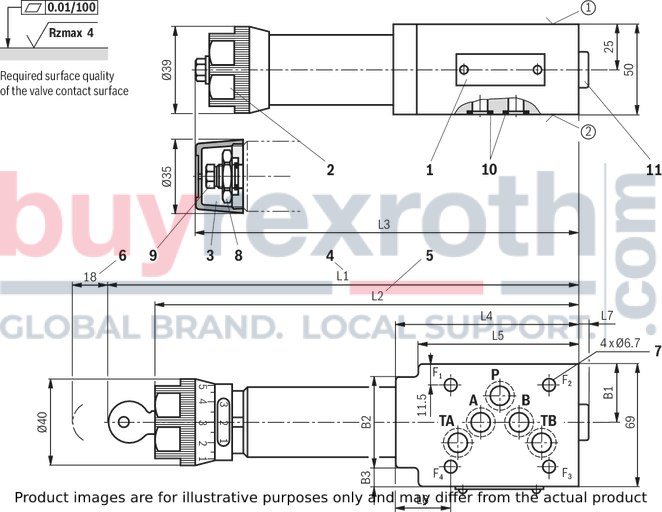

The pressure reducing valve basically comprises housing (1), control spool (2), compression spring (3), adjustment type (4) and an optional check valve.

The secondary pressure is set via the adjustment type (4).

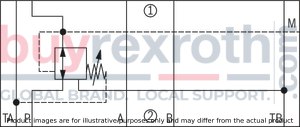

Version “A”

The valve is open in initial position. Hydraulic fluid can flow from channel A➀ to channel A➀ without restrictions. The pressure in channel A➀ is simultaneously applied via the control line (5) at the piston area opposite the compression spring (3). If the pressure in channel A➀ exceeds the value set at the compression spring (3), the control spool (2) is pushed against the compression spring (3) to control position and keeps the set pressure in channel A➀ at a constant level.

Control signal and pilot oil are supplied internally via the control line (5) from channel A➀.

If the pressure in channel A➀ increases further due to an external force effect at the actuator, it pushes the control spool (2) even further against the compression spring (3).

In this way, channel A➀ is connected to the tank (channel TB) via the control edge (6) at the control spool (2) and the housing (1). So much hydraulic fluid is discharged into the tank, that the pressure does not increase any further.

The leakage oil drain from the spring chamber (7) is always effected externally via channel TA.

A pressure gauge connection (8) allows for the control of the secondary pressure at the valve.

A check valve can be used for free flow back from channel A➀ to A➀ with version “A”.

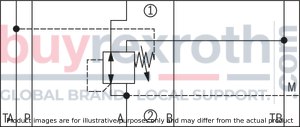

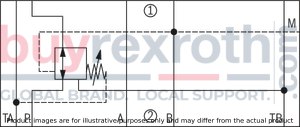

Versions “P” and “B”

For version “P”, the pressure reduction is effected in channel P➀. Control signal and pilot oil are supplied internally from channel P➀.

For version “B”, the pressure is reduced in channel P➀; but the pilot oil is extracted from channel B. If the directional valve is in spool position P to A, the pressure in channel B may not exceed the set secondary pressure. Otherwise, there is pressure reduction in channel A.

Attention!

If used without directional valve, channels TA and TB are connected to each other (e. g. in the cover plate). During set-up of a directional seat valve NG 10, a sandwich plate type HSZ10A078-3X/M00 (material no. R900537264) has to be used.

Type ZDR 10 DA …

|

➀

|

component side

|

|

➁

|

plate side

|