Subplate mounting

Size 10

Dimensions in mm

|

|

Required surface quality of the valve contact surface

|

|

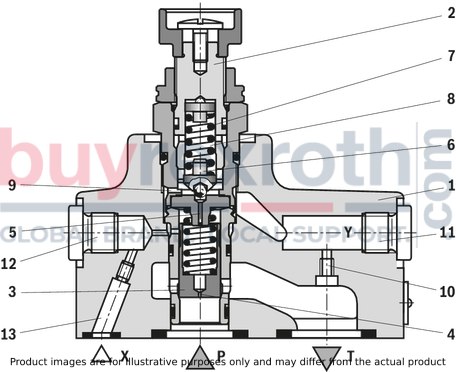

1

|

Name plate

|

|

2

|

Port X for remote control, optional

|

|

3

|

Y port for pilot oil return, external

|

|

4

|

Adjustment type "1"

|

|

5

|

Adjustment type "2"

|

|

6

|

Adjustment type "3"

|

|

7

|

Adjustment type "7"

|

|

8

|

Lock nut SW22, tightening torque MA = 10±5 Nm

|

|

9

|

Hexagon SW10

|

|

10

|

Hexagon SW30, tightening torque MA = 50 Nm

|

|

11

|

Space required to remove the key

|

|

12

|

Locating pin

|

|

13

|

Valve mounting bores

|

|

14

|

Pressure gauge connection

|

|

15

|

Identical seal rings for ports P and T

|

|

16

|

Seal ring for port X

|

|

28

|

Porting pattern according to ISO 6264-06-09-*-97

|

Valve mounting screws (separate order)

For reasons of stability, exclusively the following valve mounting screws may be used:

4 x ISO 4762 - M12 x 50 - 10.9-flZn-240h-L

with friction coefficient μtotal = 0.09 … 0.14,

tightening torque MA = 75 Nm ± 10 %,

material no. R913000283

Notice:

The tightening torques are guidelines when using screws with the specified friction coefficients and when using a manual torque wrench (tolerance ± 10 %).

Subplates (separate order) with porting pattern according to ISO 6264-06-09-*-97 see data sheet 45100.

NG25

Dimensions in mm

|

|

Required surface quality of the valve contact surface

|

|

1

|

Name plate

|

|

2

|

Port X for remote control, optional

|

|

3

|

Y port for pilot oil return, external

|

|

4

|

Adjustment type "1"

|

|

5

|

Adjustment type "2"

|

|

6

|

Adjustment type "3"

|

|

7

|

Adjustment type "7"

|

|

8

|

Lock nut SW22, tightening torque MA = 10±5 Nm

|

|

9

|

Hexagon SW10

|

|

10

|

Hexagon SW30, tightening torque for screw-in MA = 50 Nm

|

|

11

|

Space required to remove the key

|

|

12

|

Locating pin

|

|

13

|

Valve mounting bores

|

|

14

|

Pressure gauge connection

|

|

15

|

Identical seal rings for ports P and T

|

|

16

|

Seal ring for port X

|

|

29

|

Porting pattern according to ISO 6264-08-13-*-97

|

Valve mounting screws (separate order)

For reasons of stability, exclusively the following valve mounting screws may be used:

4 x ISO 4762 - M16 x 50 - 10.9-flZn-240h-L

with friction coefficient μtotal = 0.09 … 0.14,

tightening torque MA = 185 Nm ± 10 %,

material no. R913000378

Notice:

The tightening torques are guidelines when using screws with the specified friction coefficients and when using a manual torque wrench (tolerance ± 10 %).

Subplates (separate order) with porting pattern according to ISO 6264-08-13-*-97, see data sheet 45100.

Threaded connection

Dimensions in mm

|

1

|

Name plate

|

|

2

|

Port X for remote control, optional

|

|

3

|

Y port for pilot oil return, external

|

|

4

|

Adjustment type "1"

|

|

5

|

Adjustment type "2"

|

|

6

|

Adjustment type "3"

|

|

7

|

Adjustment type "7"

|

|

8

|

Lock nut SW22, tightening torque MA = 10±5 Nm

|

|

9

|

Hexagon SW10

|

|

10

|

Hexagon SW30, tightening torque MA = 50 Nm

|

|

11

|

Space required to remove the key

|

|

17

|

Grub screw is omitted with internal pilot oil return

|

|

18

|

Directional spool valve NG6 (data sheet 23178)

|

|

19

|

Mating connector without circuitry (separate order)

|

|

20

|

Mating connector with circuitry (separate order)

|

|

21

|

Dimension for valve without manual override

|

|

22

|

Dimension for valve with manual override "N"

|

|

23

|

Dimension for valve with concealed manual override "N9"

|

|

24

|

Housing for version "W“

|

|

25

|

Space required to remove the mating connector

|

|

26

|

Valve contact surface; port A is not bored

|

|

27

|

Space required to remove the solenoid coil

|

|

Version

|

D1

|

ØD2

|

|

mm

|

|

DB.10.G

|

G1/2

|

34

|

|

DB.15.G

|

G3/4

|

42

|

|

DB.20.G

|

G1

|

47

|

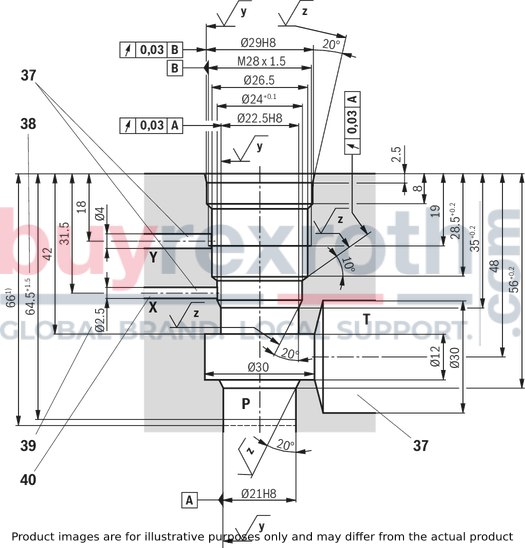

Mounting cavity

Version "XY" and type-examination tested safety valves version "Y…E"

Dimensions in mm

|

|

Required surface quality of the valve contact surface

|

|

37

|

Bore X, Y and T optionally at the circumference for version "XY"

Bore T optionally at the circumference for version "Y" (no separate bore Y required; pilot oil return via bore T)

|

|

38

|

Depth of fit

|

|

39

|

Bore Ø2.5 mm is only to be bored if required

|

|

40

|

Port X does not have to be bored for type-examination tested safety valves version "Y…E" as it does not have any function!

|

Version “Y”

Dimensions in mm

|

|

Required surface quality of the valve contact surface

|

|

37

|

Bore X, Y and T optionally at the circumference for version "XY"

Bore T optionally at the circumference for version "Y" (no separate bore Y required; pilot oil return via bore T)

|

|

38

|

Depth of fit

|