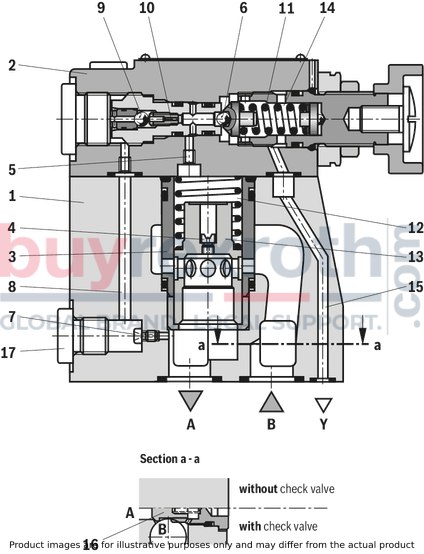

Type DRC…; cartridge valve

Dimensions in mm

|

1

|

Name plate

|

|

2.1

|

Y port for pilot oil return, external

|

|

2.2

|

Port Y optionally for external pilot oil return

|

|

3

|

Adjustment type "4"

|

|

4

|

Adjustment type "5"

|

|

5

|

Adjustment type "6"

|

|

6

|

Adjustment type "7"

|

|

7

|

Hexagon SW10

|

|

8

|

Space required to remove the key

|

|

9

|

Valve mounting bores

|

|

10

|

Seal rings

|

|

11

|

Main spool insert

|

|

12

|

Seal ring

|

|

13

|

Seal ring

|

|

14

|

Seal ring

|

|

15

|

Support ring

|

|

16

|

Support ring

|

Valve mounting screws (separate order)

4 hexagon socket head cap screws, metric

ISO 4762 - M8 x 40 - 10.9-flZn-240h-L

at friction coefficient μtotal = 0.09 to 0.14,

Tightening torque MA = 31 Nm ± 10 %,

material no. R913000205

Type DR…; threaded connection

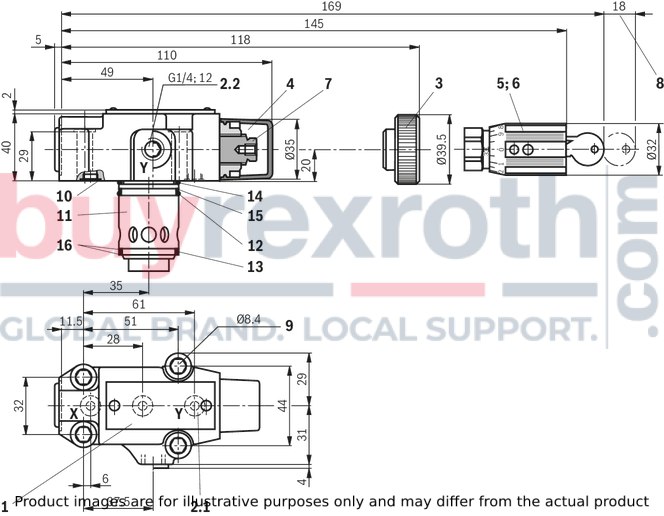

Dimensions in mm

|

1

|

Name plate

|

|

2.1

|

Y port for pilot oil return, external

|

|

3

|

Adjustment type "4"

|

|

4

|

Adjustment type "5"

|

|

5

|

Adjustment type "6"

|

|

6

|

Adjustment type "7"

|

|

7

|

Hexagon SW10

|

|

8

|

Space required to remove the key

|

|

9

|

Valve mounting bores

|

|

17

|

Pressure gauge connection

|

|

NG

|

D1

|

ØD2

|

T1

|

|

mm

|

mm

|

|

10

|

G1/2

|

34

|

14

|

|

16 (Typ DR...15)

|

G3/4

|

42

|

16

|

|

25 (Typ DR..20)

|

G1

|

47

|

18

|

|

25 (Typ DR...25)

|

G1 1/4

|

58

|

20

|

|

32 (Typ DR...30)

|

G1 1/2

|

65

|

22

|

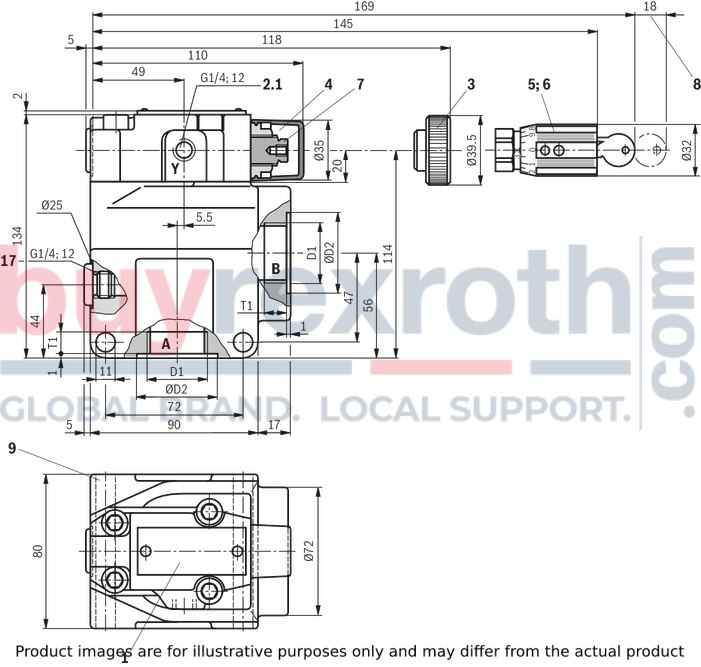

Type DR…; subplate mounting

Dimensions in mm

|

1

|

Name plate

|

|

2.1

|

Y port for pilot oil return, external

|

|

2.2

|

Port Y optionally for external pilot oil return

|

|

3

|

Adjustment type "4"

|

|

4

|

Adjustment type "5"

|

|

5

|

Adjustment type "6"

|

|

6

|

Adjustment type "7"

|

|

7

|

Hexagon SW10

|

|

8

|

Space required to remove the key

|

|

9

|

Valve mounting bores

|

|

17

|

Pressure gauge connection

|

|

18

|

Identical seal rings for ports A and B

|

|

Identical seal rings for ports X and Y

|

|

19

|

Port X without function (blind bore)

|

|

20

|

Locking pin

|

Subplate mounting:

Subplates (separate order)

Size 10

G 460/01 (G3/8)

G 461/01 (G1/2)

Size 20

G 412/01 (G3/4)

G 413/01 (G1)

Size 30

G 414/01 (G1 1/4)

G 415/01 (G1 1/2)

|

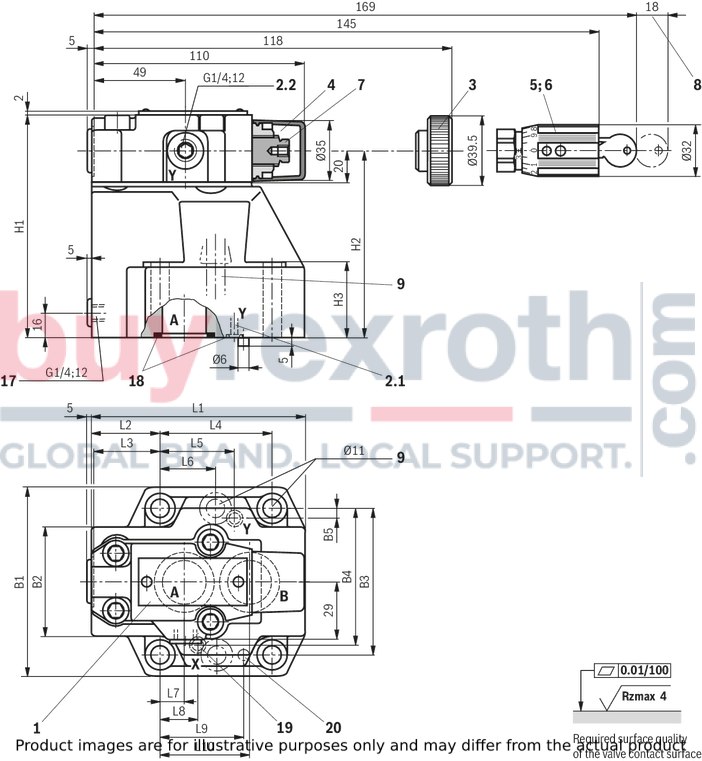

1

|

Notice!

Bore Ø32 can cut into Ø45 at any position. However, it must be observed that the connection bores and valve mounting bore are not damaged!

|

|

2

|

Support ring and seal rings are to be inserted into this bore before assembly of the main spool!

|

|

3

|

Nozzle, separate order

|

Valve mounting screws (separate order)

Size 10

4 hexagon socket head cap screws, metric

ISO 4762 - M10 x 50 - 10.9-flZn-240h-L

at friction coefficient μtotal = 0.09 to 0.14,

Tightening torque MA = 60 Nm ± 10 %,

material no. R913000471

Size 20

4 x ISO 4762 - M10 x 60 - 10.9-flZn-240h-L

at friction coefficient μtotal = 0.09 to 0.14,

Tightening torque MA = 60 Nm ± 10 %,

material no. R913000116

Size 30

6 x ISO 4762 - M10 x 70 - 10.9-flZn-240h-L

at friction coefficient μtotal = 0.09 to 0.14,

Tightening torque MA = 60 Nm ± 10 %,

material no. R913000126

|

NG

|

L1

|

L2

|

L3

|

L4

|

L5

|

L6

|

L7

|

L8

|

L9

|

L10

|

B1

|

B2

|

B3

|

B4

|

B5

|

H1

|

H2

|

H3

|

|

mm

|

mm

|

mm

|

mm

|

mm

|

mm

|

mm

|

mm

|

mm

|

mm

|

mm

|

mm

|

mm

|

mm

|

mm

|

mm

|

mm

|

mm

|

|

10

|

96

|

35.5

|

33

|

42.9

|

21.5

|

-

|

7.2

|

21.5

|

31.8

|

35.8

|

85

|

50

|

66.7

|

58.8

|

7.9

|

112

|

92

|

28

|

|

16

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

|

25

|

116

|

37.5

|

35.4

|

60.3

|

39.7

|

-

|

11.1

|

20.6

|

44.5

|

49.2

|

102

|

59.5

|

79.4

|

73

|

6.4

|

122

|

102

|

38

|

|

25

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

|

32

|

145

|

33

|

29.8

|

84.2

|

59.5

|

42.1

|

16.7

|

24.6

|

62.7

|

67.5

|

120

|

76

|

96.8

|

92.8

|

3.8

|

130

|

110

|

46

|

Valve mounting screws (separate order)

4 hexagon socket head cap screws, metric

ISO 4762 - M8 x 40 - 10.9-flZn-240h-L

at friction coefficient μtotal = 0.09 to 0.14,

Tightening torque MA = 31 Nm ± 10 %,

material no. R913000205

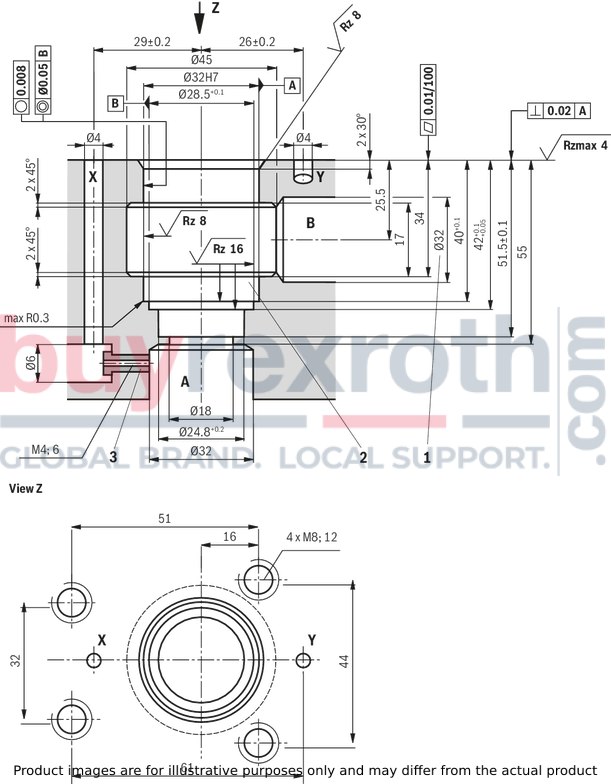

Installation bore

Dimensions in mm

Dimensions in mm

|

1

|

Notice!

Bore Ø32 can cut into Ø45 at any position. However, it must be observed that the connection bores and valve mounting bore are not damaged!

|

|

2

|

Support ring and seal rings are to be inserted into this bore before assembly of the main spool!

|

|

3

|

Nozzle, separate order

|

Valve mounting screws (separate order)

Size 10

4 hexagon socket head cap screws, metric

ISO 4762 - M10 x 50 - 10.9-flZn-240h-L

at friction coefficient μtotal = 0.09 to 0.14,

Tightening torque MA = 60 Nm ± 10 %,

material no. R913000471

Size 20

4 x ISO 4762 - M10 x 60 - 10.9-flZn-240h-L

at friction coefficient μtotal = 0.09 to 0.14,

Tightening torque MA = 60 Nm ± 10 %,

material no. R913000116

Size 30

6 x ISO 4762 - M10 x 70 - 10.9-flZn-240h-L

at friction coefficient μtotal = 0.09 to 0.14,

Tightening torque MA = 60 Nm ± 10 %,

material no. R913000126